Professional Documents

Culture Documents

Butterfly Valves - Figure 611 & 612: Features

Butterfly Valves - Figure 611 & 612: Features

Uploaded by

Ali KianersiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butterfly Valves - Figure 611 & 612: Features

Butterfly Valves - Figure 611 & 612: Features

Uploaded by

Ali KianersiCopyright:

Available Formats

Butterfly Valves - Figure 611 & 612

50mm - 300mm

• F611 Wafer style resilient seated bi-directional

butterfly valve in sizes 50 - 300mm to 1600 kPa.

• F612 Lugged style resilient seated bi-directional

butterfly valve in sizes 50 - 300mm to 1600 kPa.

Features

• Rounded polished disc edge gives

full concentric sealing, lower

torques, longer seat life and

bubble-tight shut-off.

• The seat is field replaceable and

fully isolates the body and stem

from the flow.

• Primary stem sealing exceeds the

pressure rating of the valve and

prevents leakage through shaft

area to atmosphere.

• A secondary shaft seal provides

back-up safety.

• Top and bottom inboard shaft

bearings for optimum support and

minimum friction to prolong valve

life.

• Top bushing absorbs actuator side

thrust loads.

• Top seal prevents moisture

penetrating into the shaft area.

• The thin disc provides minimum

obstruction to flow, resulting in

smooth flow characteristics.

• A molded-in O-ring in the seat for

flange sealing eliminates the need

for gaskets.

• Extended body neck allows pipe

insulation.

• Body locating holes ease

installation and centering between

the flanges.

• Available approvals: PED

(CE Mark), DNV, Lloyds.

General Applications: Technical Data:

These valves are ideally suited to Size Range:

many applications where tight shut-off F611 (wafer style) 50-300 mm

is required, such as: F612 (lugged style) 50-300 mm

Industrial processing Pressure: 1200 kPa

Water & wastewater End of line: up to 1600 kPa

Dry bulk conveying Temperature: minus 40 to 150°C

Paper mills End Connections:

Light slurry handling AS 2129 C, D, E & F

Food & beverage. ANSI 150

PN 6/10/16

JIS, 10K

A.B.N. 83 000 922 690

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

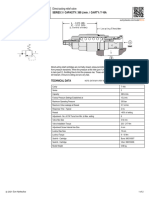

Pressure Ratings:

6

End of Line Service

7

Standard Seat = 1000 kPa

Super Seat = 1200 kPa

4

Temperature Rating:

Minus 400C to 1200C with EPDM &

9

XEPDM

Minus 150C to 1000C with Buna N &

XBuna N

Minus 300C to 1500C with HT EPDM

1

Note:

5 PED approved valves have a temperature

3 limitation of minus 280C due to body

material.

8 Consult factory for available trims.

Note: F611 valve illustrated

Parts List

No. Description Standard Material Material Specification

1 Upper Body Ductile Iron ASTM A536 Gr 65-45-12

2 Lower Body Ductile Iron ASTM A536 Gr 65-45-12

3 Disc 316 Stainless Steel ASTM A351 Gr CF8M

Aluminium Bronze ASTM B148 C95200

Ductile Iron (ENP Coated) ASTM A536 Gr 65-45-12

4 Shaft 316 Stainless Steel EN10088-3 X5Cr NiMo 17-12-2

5 Seat EPDM# EM-D1-48

Buna N# EM-D1-49

HT EPDM EM-D1-50

XEPDM -

XBuna N -

6 Shaft Bush Polyester -

7 Shaft Seal Buna N -

8 Body Screws Carbon Steel (Plated) BS EN ISO898-1 Class 8.8

9 Bearings Steel Backed PTFE -

Note:

# Food grade seat.

X = Super Seat version.

ENP = Electroless Nickel Plated (for corrosion resistance).

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

F

ØE

ØB ØYY

ØB1 ØA D

B2

Note: F611 valve illustrated Note: F612 valve illustrated

Dimensions (mm)

Valve Stem Stem Conn. Top Plate Mass

Size Conn. ØA ØB ØB1 B2 C D ØE F K Q ØYY HxG Key PCD. Hole Dia. F611 F612

mm Code inches inches mm mm kg

50 - 50 94 80 180 135 43 102 25 71 27 66 0.472 x 0.315 83 11 2.1 3.7

65 BAB 62 109 93 200 150 46 102 30 78 43 78 9/16 x 3/8 83 11 3.2 5.0

80 BAB 78 126 112 240 160 46 102 30 101 64 97 9/16 x 3/8 83 11 3.6 5.9

100 BAC 99 156 144 268 180 52 102 30 115 87 129 5/8 x 7/16 83 11 5.2 8.3

125 BAD 124 189 175 300 195 56 102 30 119 113 160 3/4 x 1/2 83 11 7.6 11.5

150 BAD 151 214 196 335 210 56 102 30 142 141 181 3/4 x 1/2 83 11 8.5 13.0

200 CAE 195 267 248 397 240 60 152 32 179 188 233 7/8 x 5/8 127 14 16.0 22.2

250 CAF 245 321 305 480 275 68 152 50 219 237 290 1

Ø1 /8 1/4 x 1/4 127 14 23.5 33.5

300 CAF 292 375 355 544 310 78 152 50 244 283 340 Ø11/8 1/4 x 1/4 127 14 32.0 51.0

Notes:

“Q” dimension is the disc chordal dimension at face of valve for disc clearance into lined pipe or fittings.

“H” dimension is the stem connection.

“G” dimension is across the stem flats.

“ØB1” dimension is to the outside of the seat.

“ØYY” dimension is to the O-ring seal.

Mass may vary depending on trim materials used.

Dimensions are nominal to ±1mm.

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

Anticipated Seating & Unseating Torque Values - Nm (Standard Seats) Note:

Shut Off Pressure kPa/(bar) 1. The charted seating and unseating

Valve Normal Service torques are the sum of all friction and

Size 0 350 700 1000 1400 1600 for opening and closing of the disc

against the indicated pressure

mm (0) (3.5) (7) (10) (12) (16)

differential for normal service.

50 13 13 13 14 15 15 2. Normal Service: Clean liquid service at

temperatures between minus 4.5°C to

65 18 19 20 21 23 25

93°C with no internal deposition or

80 25 26 27 30 33 36 chemical attack.

100 34 37 40 44 49 51 Operated a minimum of once per day.

125 53 58 63 70 80 85 3. The relationship between values are

linear, therefore you can interpolate

150 74 81 88 99 113 120

between nominated values.

200 132 148 164 188 219 235 4. The effect of dynamic torque is not

250 211 241 271 315 374 403 considered in tabulation.

300 303 345 387 451 536 578 5. In sizing operators it is not necessary to

include safety factors.

For conditions that vary from those noted, then apply the following Application Factor

Multipliers:

Operated less than once per day x 1.2

Dry Service with gas or air x 1.5

Dry Service with abrasives, cement x 1.7

Lubrication oils x 0.5

Temperature - lower than minus 4.5°C x 1.2

- higher than 93°C x 1.2

Chemical attack: Consult factory

Note:

To apply the as noted Application Factor Multipliers:

1. Find the base torque value by selecting the required valve size from the left hand column

and read across to the intended line pressure column. Note the torque value. (You can

interpolate between line pressure values.)

2. Find the zero pressure torque for the same valve on the same row and subtract this zero

pressure torque from the value in step 1.

3. Multiply the zero pressure torque value by the expected Application Factors.

4. Add the difference between the zero pressure torque and the line pressure torque (value of

step 2 plus value of step 3) to give the new torque value specific to the actual service

conditions.

Example:

A 100mm Figure 611 DEE2 AS 2129 E valve is to be used in a clean water application. The

line pressure is 1600 kPa (16 bar) @ 100ºC. The valve may only cycle twice per month.

1. Using the Normal Service Torque Values table Base Torque value for 150mm @ 1600 kPa

(16 bar) = 120Nm

2. Find torque value at zero kPa = 74 Nm

Subtract 120 - 74 = 46Nm

3. Multiply zero pressure torque value by Application Factors

Application Factors:

Operated less than once per day = x 1.2

Temperature higher than 93°C = x 1.2

Multiply Application Factors 1.2 x 1.2 = 1.44 ( round off to 1.4 )

74 x 1.4 = 104 Nm

4. Add the difference between zero pressure and line pressure, as per step 2 to the value

determined in step 3.

46 + 104 = 150Nm

The new torque value for this valve, specific to the actual service conditions is 150 Nm.

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

Notes: Anticipated Seating & Unseating Torque Values - Nm (Super Seat*)

As the Super Seat is intended for high Shut Off Pressure kPa/(bar)

pressure applications the base torque Valve Normal Service

commences at 1000 kPa/10 bar. Size 1000 1400 1600

Superseats are suitable for: mm (10) (12) (16)

• Severe vacuum applications.

• High line velocities up to 9 m/s for 50 18 19 19

liquids. 65 28 30 31

• Slip-on flanges. 80 40 43 44

• Full rated end-of-line service.

100 59 64 67

• Pressure testing during erection and

commissioning. 125 95 104 109

150 134 148 155

200 250 281 297

250 412 471 501

300 591 676 719

For conditions that vary from those noted, then apply the following Application Factor Multipliers:

Operated less than once per day x 1.2

Dry Service with gas or air x 1.5

Dry Service with abrasives, cement x 1.7

Lubrication oils x 0.5

Temperature - lower than minus 4.5°C x 1.2

- higher than 93°C x 1.2

Chemical attack: Consult factory

Note:

To apply the as noted Application Factor Multipliers:

1. Find the base torque value by selecting the required valve size from the left hand column and read across to the intended line pressure

column. Note the torque value. (You can interpolate between line pressure values.)

2. Find the 1000 kPa/(10 bar) pressure torque for the same valve on the same row and subtract this zero pressure torque from the value in

step 1.

3. Multiply the 1000 kPa/(10 bar) pressure torque value by the expected Application Factors.

4. Add the difference between the 1000 kPa/(10 bar) pressure torque and the line pressure torque (value of step 2 plus value of step 3) to give

the new torque value specific to the actual service conditions.

Notes: Anticipated Seating & Unseating Torque Values - Nm (Undercut Valves)

1.The charted seating and unseating Shut Off Pressure kPa/(bar)

torques are the sum of all friction and Normal Service

resistance for opening and closing of Size 350 700 1000

the disc against the indicated pressure

mm (3.5) (7) (10)

differential for normal service.

2. Normal Service: Clean liquid service at 50 10 11 11

temperatures between minus 4.5°C to

65 15 16 17

93°C with no internal deposition or

chemical attack. Operated a minimum of 80 21 22 24

once per day. 100 30 32 35

3. The relationship between values are 125 46 50 56

linear, therefore you can interpolate

150 65 71 79

between nominated values.

4. The effect of dynamic torque is not 200 119 131 150

considered in tabulation. 250 193 216 252

5. In sizing operators it is not necessary to 300 276 310 361

include safety factors.

For conditions that vary from those noted, then apply the following Application Factor Multipliers:

Operated less than once per day x 1.2

Dry Service with gas or air x 1.5

Dry Service with abrasives, cement x 1.7

Lubrication oils x 0.5

Temperature - lower than minus 4.5°C x 1.2

- higher than 93°C x 1.2

Chemical attack: Consult factory

Note:

To apply the as noted Application Factor Multipliers:

1. Find the base torque value by selecting the required valve size from the left hand column and read across to the intended line pressure

column. Note the torque value. (You can interpolate between line pressure values.)

2. Multiply the noted value by the expected Application Factors.

3. The result provides the new torque value specific to the actual service conditions.

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

Maximum Allowable Shaft Torques (Nm)

Valve size 50 65 80 100 125 150 200 250 300

316 S/S 65 110 110 160 260 260 480 970 970

Notes:

The values listed represent the maximum torques which can be transmitted through the actu-

ator flange. These values are based upon specific criteria and can be lower than the maxi-

mum allowable shaft torques. In this case the criteria can be changed in order to reach the

maximum allowable shaft torques.

Flowrate Co-efficients - Kv Values (Nm)

Size Disc Opening (Degrees)

(mm) 10° 20° 30° 40° 50° 60° 70° 80° 90°

50 0 0.9 4.8 14 30 47 72 99 108

65 0 2.4 11 27 50 78 123 172 217

80 0 6.0 28 55 91 141 215 304 409

100 0 14 57 109 177 265 407 600 807

125 0 28 85 158 250 389 630 964 1251

150 7 52 130 226 367 578 987 1551 1946

200 22 115 231 405 646 1029 1773 2910 3516

250 34 173 339 641 980 1546 2677 4449 5806

300 49 253 495 935 1430 2255 3905 6710 8910

Note:

Kv = The volume of water in m3/hr that will pass through a valve with a pressure drop of 1 bar (100 kPa) @ 20°C.

Simplified Sizing Formulas

LIQUID GAS HEAD LOSS

S.G. Q S.G. 10.194 ∆P

Kv = Q Kv = 28.5 HL =

∆P P2 ∆P S.G.

WHERE WHERE WHERE

3

Q = Flow through valve (m /hr) Q = Flow through valve (Nm /hr)

3

HL = Head Loss (m)

S.G. = Specific gravity (water = 1) S.G. = Specific gravity (air = 1) ∆P = Pressure drop across valve (bar)

∆P = Pressure drop across valve (bar) ∆P = Pressure drop across valve (bar) S.G. = Specific gravity (water = 1)

[Less than 1/2 inlet pressure

(bar)]

P2 = Outlet pressure (bar)

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

Butterfly Valves - Figure 611 & 612

50mm - 300mm

Typical Specifying Sequence

Example: 100 F611 DEE2 AE

Valve Size Figure No. Trim Code End Connections

Valve Trims

Figure No. Trim Code Body Disc Shaft Seat Bush Packing

F611/F612 DEE2 Ductile Iron 316 S/S 316 S/S EPDM Polyester Buna N

F611/F612 DEE3 Ductile Iron 316 S/S 316 S/S Buna N Polyester Buna N

F611/F612 DEEQ Ductile Iron 316 S/S 316 S/S XEPDM Polyester Buna N

F611/F612 DEER Ductile Iron 316 S/S 316 S/S XBuna N Polyester Buna N

F611/F612 DEET Ductile Iron 316 S/S 316 S/S HT EPDM Polyester Buna N

F611/F612 DLE2 Ductile Iron Al Bronze 316 S/S EPDM Polyester Buna N

F611/F612 DLE3 Ductile Iron Al Bronze 316 S/S Buna N Polyester Buna N

F611/F612 DLEQ Ductile Iron Al Bronze 316 S/S XEPDM Polyester Buna N

F611/F612 DLER Ductile Iron Al Bronze 316 S/S XBuna N Polyester Buna N

F611/F612 DLET Ductile Iron Al. Bronze 316 S/S HT EPDM Polyester Buna N

F611/F612 DYE2 Ductile Iron Ductile Iron 316 S/S EPDM Polyester Buna N

F611/F612 DYE3 Ductile Iron Ductile Iron 316 S/S Buna N Polyester Buna N

F611/F612 DYEQ Ductile Iron Ductile Iron 316 S/S XEPDM Polyester Buna N

F611/F612 DYER Ductile Iron Ductile Iron 316 S/S XBuna N Polyester Buna N

F611/F612 DYET Ductile Iron Ductile Iron 316 S/S HT EPDM Polyester Buna N

End Connections

• AE = AS 2129 table E

• AN = ANSI B16.5 Class 150

• Others available on request.

Note:

XEPDM & XBuna N denotes Super Seat option.

HT EPDM denotes high temperature EPDM.

Ductile iron discs are Electroless Nickel Plated (ENP).

Consult factory for available PED trims.

Available Actuators & Accessories

Figure

No. Description

F79U/E Aluminium Pneumatic actuators, double acting or spring return.

F79B Ductile Iron Pneumatic actuators, double acting or spring return.

F79S Stainless Steel Pneumatic actuators, double acting or spring return.

F777 Electric actuators.

F77Q Heavy Duty Electric actuators.

F791 Solenoid valves.

F792 Limit switches.

F793 Positioners.

F401 Manual Handle

F427 Gear operators.

© Copyright by Tyco International Ltd. F611/612/7/03

Tyco Flow Control reserves the right to change product designs and specifications without notice.

You might also like

- Dunham-Bush ACHDX-55 - 245TR-50Hz-ScrewDocument16 pagesDunham-Bush ACHDX-55 - 245TR-50Hz-ScrewEdgar José Silva Rincón0% (1)

- Ziehm Solo FD Service ManualDocument442 pagesZiehm Solo FD Service Manualdrakon100% (1)

- Excelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSERDocument2 pagesExcelam-: Q1400COLD/RS Q1400COLD/RSER Q1600COLD/RS Q1600COLD/RSER Q1600COMBI/RSEROdien SalehNo ratings yet

- Strahlenfolter Stalking - TI - V2K - RNM Remote Neural Monitoring Satellite Terrorism - October 2010 - Satelliteterrorism3.Blogspot - deDocument5 pagesStrahlenfolter Stalking - TI - V2K - RNM Remote Neural Monitoring Satellite Terrorism - October 2010 - Satelliteterrorism3.Blogspot - deKurt-Schneider50% (2)

- F611 Wafer Style Resilient Seated Butterfly Valves. - F612 Lugged Style Resilient Seated Butterfly ValvesDocument8 pagesF611 Wafer Style Resilient Seated Butterfly Valves. - F612 Lugged Style Resilient Seated Butterfly ValvesAli KianersiNo ratings yet

- 1377 Duragauge Pressure Gauge: Data SheetDocument4 pages1377 Duragauge Pressure Gauge: Data SheetkarthikNo ratings yet

- Bomba - Dab KLP 50 - 1200Document3 pagesBomba - Dab KLP 50 - 1200floro cortes. tNo ratings yet

- NC 559 Asm TF PDFDocument2 pagesNC 559 Asm TF PDFroto44No ratings yet

- Eccentric Screw PumpsDocument3 pagesEccentric Screw PumpserbiliNo ratings yet

- Brosur Yuema Gear PumpDocument16 pagesBrosur Yuema Gear PumpHafidz FerdianNo ratings yet

- Danuhm Bush Air Cooled Split PACUDocument16 pagesDanuhm Bush Air Cooled Split PACUFalak KhanNo ratings yet

- Burkert Valve CatalogueDocument13 pagesBurkert Valve CatalogueRoopa MahtoNo ratings yet

- BSK1 Bellows Sealed Globe ValvesDocument4 pagesBSK1 Bellows Sealed Globe ValvesAhmed RamadanNo ratings yet

- DS2000 Threaded EU enDocument13 pagesDS2000 Threaded EU enSamuel MarquezNo ratings yet

- KNF N 1200Document5 pagesKNF N 1200LAB PTBNo ratings yet

- Jamesbury 7000 Series Ball ValveDocument34 pagesJamesbury 7000 Series Ball ValveHamed FarajpourNo ratings yet

- 130P ITT Pressure SwitchsDocument2 pages130P ITT Pressure Switchsjcdavid24No ratings yet

- 2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-65Document13 pages2/2-Way Angle-Seat Valve For Medium Up To +180°C, Threaded Port Connection, DN 15-6588jdccNo ratings yet

- Features Material Specifications: ApplicationDocument1 pageFeatures Material Specifications: ApplicationJose CANo ratings yet

- ABB Level SwitchPDF - Js ViewerDocument4 pagesABB Level SwitchPDF - Js ViewerbambangNo ratings yet

- Vav Single DuctDocument18 pagesVav Single DuctArmudin SukantaNo ratings yet

- Bergquist Sil Pad TSP 1600s-EnDocument2 pagesBergquist Sil Pad TSP 1600s-EnKim WayneNo ratings yet

- Summary Battery SpecificationsDocument12 pagesSummary Battery Specificationssewot00No ratings yet

- RPH - 1316.024 - 05 - EN - Two Page LeafletDocument2 pagesRPH - 1316.024 - 05 - EN - Two Page LeafletRuddy Fabrizio Galvez JustinianoNo ratings yet

- Model Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162ADocument1 pageModel Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162AmhasansharifiNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- KLM KLP DKLM DKLP TS Eng PDFDocument13 pagesKLM KLP DKLM DKLP TS Eng PDFLuis Leiva SanchezNo ratings yet

- Danais 150TDocument16 pagesDanais 150TmariodalNo ratings yet

- Primeroyal Series: API 675 Metering PumpDocument6 pagesPrimeroyal Series: API 675 Metering PumpDavid GarciaNo ratings yet

- Diaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use FeaturesDocument5 pagesDiaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use Featuresnotaden1849No ratings yet

- Modelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10ADocument1 pageModelo Acción-Directa Alivio Válvula: Series 1 / Capacidad: 25 GPM / Cavidad: T-10AErasmo LimaNo ratings yet

- Valvula Crosby Series 800 PDFDocument196 pagesValvula Crosby Series 800 PDFYuri PalomarNo ratings yet

- Jamesbury Balll Valve Series-3000Document4 pagesJamesbury Balll Valve Series-3000Ponco Setiyo PamungkasNo ratings yet

- HPK03Document4 pagesHPK03Tan CkNo ratings yet

- Danais 150Document16 pagesDanais 150Eric AvilaNo ratings yet

- 2PE Salami PDFDocument35 pages2PE Salami PDFMartin MiaNo ratings yet

- RDHA Full en Metric LetterasdDocument2 pagesRDHA Full en Metric LetterasdessamNo ratings yet

- Interruptor de Presion KoboldDocument2 pagesInterruptor de Presion KoboldMagin Idelfonso TorreblancaNo ratings yet

- KAT-A 1310-EW EKN Edition16 07-10-2014 ENDocument6 pagesKAT-A 1310-EW EKN Edition16 07-10-2014 ENwinston11No ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- 101P PS FloreñaDocument2 pages101P PS Floreñamelannynaohmybayonaguio1104No ratings yet

- Catalogue WcsDocument12 pagesCatalogue WcsFaisal SamosirNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- Data Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Document8 pagesData Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Abdeldjalil AchourNo ratings yet

- 4 29a e Ae50s Automatic Air and Gas Vents For Liquids DN 15 25Document4 pages4 29a e Ae50s Automatic Air and Gas Vents For Liquids DN 15 25auxiliar.termicaNo ratings yet

- CP CP-G DCP DCP-G TS EngDocument36 pagesCP CP-G DCP DCP-G TS EngMarco Antonio Camacho Tezanos PintoNo ratings yet

- 620.9100 Huba ControlDocument4 pages620.9100 Huba Controlroni kurniawanNo ratings yet

- Eclipse F: Thermostatic Radiator ValvesDocument8 pagesEclipse F: Thermostatic Radiator Valvessandra1833No ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Brochure Isolation Valves Product Overview en en 5253576Document36 pagesBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNo ratings yet

- K Single-Impeller: Technical DataDocument4 pagesK Single-Impeller: Technical DataoiboriowoNo ratings yet

- 28-ACPS-P ChillerDocument16 pages28-ACPS-P Chillershahzad32552372No ratings yet

- Katalog MS0208DDocument16 pagesKatalog MS0208DzmatdaudNo ratings yet

- Eclipse en LQDocument12 pagesEclipse en LQSergioNo ratings yet

- 1279 Data SheetDocument2 pages1279 Data SheetJuan SNo ratings yet

- 160 PXDocument2 pages160 PXRonald EscaleraNo ratings yet

- RDDALDN Full en Us A4Document3 pagesRDDALDN Full en Us A4clark jonesNo ratings yet

- Circulators For Heating and Air Conditioning Systems: ApplicationsDocument18 pagesCirculators For Heating and Air Conditioning Systems: Applicationsresistance-bandsNo ratings yet

- Description: - Butterfly Valve DN 25 - 600Document2 pagesDescription: - Butterfly Valve DN 25 - 600JeromeNo ratings yet

- Sma 3 SMDocument14 pagesSma 3 SMAli KianersiNo ratings yet

- Suction Valve Cover Assembly (1St Stage)Document2 pagesSuction Valve Cover Assembly (1St Stage)Ali KianersiNo ratings yet

- Acf UcfDocument4 pagesAcf UcfAli KianersiNo ratings yet

- Ic FormatDocument1 pageIc FormatAli KianersiNo ratings yet

- NippleDocument1 pageNippleAli KianersiNo ratings yet

- 15/40/80CN Series: Coreless Medium Pressure FiltersDocument4 pages15/40/80CN Series: Coreless Medium Pressure FiltersAli KianersiNo ratings yet

- 0116425-010 DsDocument4 pages0116425-010 DsAli KianersiNo ratings yet

- Tuboscope Mexico - ISO 90012015 - Expires 022023Document6 pagesTuboscope Mexico - ISO 90012015 - Expires 022023Ali KianersiNo ratings yet

- Catalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Document4 pagesCatalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Ali KianersiNo ratings yet

- 3DZM0930061Document13 pages3DZM0930061Ali KianersiNo ratings yet

- Emerson Asco 3 2 Series 8300 8315 General Service Solenoid Valves PG 47 50 CatalogDocument4 pagesEmerson Asco 3 2 Series 8300 8315 General Service Solenoid Valves PG 47 50 CatalogAli KianersiNo ratings yet

- 0449P20150824 3DZM0930061Document2 pages0449P20150824 3DZM0930061Ali KianersiNo ratings yet

- 1054-Tube Fittings 2011 WebDocument34 pages1054-Tube Fittings 2011 WebAli KianersiNo ratings yet

- Fisher 4660 High Low Pressure Pilot: Instruction ManualDocument24 pagesFisher 4660 High Low Pressure Pilot: Instruction ManualAli KianersiNo ratings yet

- Fisher 4660 High-Low Pressure Pilot: FeaturesDocument12 pagesFisher 4660 High-Low Pressure Pilot: FeaturesAli KianersiNo ratings yet

- Hoordastan Co.: Owner: by DateDocument2 pagesHoordastan Co.: Owner: by DateAli KianersiNo ratings yet

- Bimetal Thermometer: ApplicationDocument3 pagesBimetal Thermometer: ApplicationAli KianersiNo ratings yet

- The Leading Manufacturer of Hand Wound Mechanical Starter Motors For Diesel EnginesDocument15 pagesThe Leading Manufacturer of Hand Wound Mechanical Starter Motors For Diesel EnginesAli KianersiNo ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- BS Soil and Rock Explanatory NotesDocument15 pagesBS Soil and Rock Explanatory NotesvictorNo ratings yet

- Build - Grow Grammar Space Beginner 3 SB KEYDocument53 pagesBuild - Grow Grammar Space Beginner 3 SB KEYSelin KozağaçNo ratings yet

- LV SwitchboardDocument11 pagesLV SwitchboardleungyautatNo ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Asus T12C (X51C) Motherboard Schematic DiagramDocument94 pagesAsus T12C (X51C) Motherboard Schematic DiagramYblis100% (1)

- Optoma DS325 DLP ProjectorDocument6 pagesOptoma DS325 DLP ProjectorWebAntics.com Online Shopping StoreNo ratings yet

- Module 2 (People and The Earth's Ecosystem)Document11 pagesModule 2 (People and The Earth's Ecosystem)chris ian0% (2)

- Parts Catalog ARDFDocument30 pagesParts Catalog ARDFUlmanu ValentinNo ratings yet

- DIAGRAMA - 2007 - NEW YarisDocument1 pageDIAGRAMA - 2007 - NEW YarisLuis M. Valenzuela Arias50% (2)

- Eurocode Conference 2023 Pluijm Van Der Eurocode 6Document14 pagesEurocode Conference 2023 Pluijm Van Der Eurocode 6Rodolfo BlanchiettiNo ratings yet

- Chemistry Folio Chapter 9 Form 4Document27 pagesChemistry Folio Chapter 9 Form 4Suhaila MohamedNo ratings yet

- An Essay To Introduction of Differential Geometry and ApplicationsDocument17 pagesAn Essay To Introduction of Differential Geometry and ApplicationsAmir Mosavi0% (1)

- ControlDocument58 pagesControlRobinson CardenasNo ratings yet

- Motion Information and MediaDocument39 pagesMotion Information and Mediajadeshades12No ratings yet

- P&Z Electronic (Dongguan) Co.,LtdDocument3 pagesP&Z Electronic (Dongguan) Co.,LtdTRMNo ratings yet

- Applications of DEsDocument37 pagesApplications of DEsjomgir09No ratings yet

- Feasibility Study of New Zealand Radiata Pine Cross-Laminated TimberDocument5 pagesFeasibility Study of New Zealand Radiata Pine Cross-Laminated TimberClaudio VillegasNo ratings yet

- Repro enDocument20 pagesRepro enWai Mei TeeNo ratings yet

- 510-15 CodigoDocument6 pages510-15 CodigoUriel MFNo ratings yet

- Agile ManufacturingDocument17 pagesAgile Manufacturingkaushalsingh20No ratings yet

- Wise Sayings of Holy Prophet SAWWSDocument5 pagesWise Sayings of Holy Prophet SAWWSShireen Zahra Khan100% (2)

- Remedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Document9 pagesRemedial Uas B.ing LM (Intani Julien Putri Xii Ipa 6)Intani JulienNo ratings yet

- Maersk IntrepidDocument8 pagesMaersk Intrepidrickyngs100% (1)

- Kezelesi Utmutato Q3 RF 2010 AngolDocument12 pagesKezelesi Utmutato Q3 RF 2010 AngolClaudiu AdamNo ratings yet

- Sub Pekerjaan: D.Pekerjaan Mekanikal & Elektrikal: A Pekerjaan Panel, Trafo, Dan GensetDocument15 pagesSub Pekerjaan: D.Pekerjaan Mekanikal & Elektrikal: A Pekerjaan Panel, Trafo, Dan Gensetberkah shokaNo ratings yet

- CoEpower SVG AHF Price ListDocument2 pagesCoEpower SVG AHF Price ListChristian Huanca OscoNo ratings yet

- Class 9 - ScienceDocument228 pagesClass 9 - ScienceYashwanth KasturiNo ratings yet

- The Talmud of Jerusalem - Schwab Moise 1839-1918 TRDocument201 pagesThe Talmud of Jerusalem - Schwab Moise 1839-1918 TRJanice O'BrianNo ratings yet