Professional Documents

Culture Documents

Typical Support Arrangements and Details of

Typical Support Arrangements and Details of

Uploaded by

Sergio A. Espinosa0 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

Typical support arrangements and details of

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageTypical Support Arrangements and Details of

Typical Support Arrangements and Details of

Uploaded by

Sergio A. EspinosaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

300 Pressure Vessel Design Manual

fb ¼ Stress, bending, PSI

fC ¼ Stress, compressive, PSI Hold down or

balls

fT ¼ Stress, tension, PSI

F ¼ Total load of bed, Lbs

Fb ¼ Allowable bending stress, PSI

Filter media,

Fbr ¼ Allowable stress, bearing, PSI packing, catalyst,

etc.

FC ¼ Allowable stress, compression, PSI

FS ¼ Allowable stress, shear, PSI

Fy ¼ Minimum specified yield strength at design

temperature, PSI

Moment of inertia, in4

Beam

I ¼ Ring

K ¼ End connection coefficient per AISC

K1 ¼ Vertical distance from bottom of beam flange to Clip

Beam seat

top of fillet on web, in

LL ¼ Live load, Lbs r

M ¼ Moment, in-Lbs D

nb ¼ Number of bolts required

ng ¼ Number of bearing bars per foot

Nb ¼ Minimum bearing length, in Grating, support plate

vapor distributor,

N ¼ Number of beams etc.

P ¼ Concentrated load, Lbs

PL ¼ Product load, Lbs Slot clip

Pc ¼ Free area in packing/catalyst, %

p ¼ Uniform load over entire bed, PSI

r ¼ Radius of gyration, in

R ¼ End reactions, Lbs

Ra ¼ Root area of bolt, in2

S ¼ Allowable stress in shell, tension, PSI

SU ¼ Minimum specified tensile strength, PSI

t ¼ Thickness, in Screen

Tn ¼ Tension force in beam, Lbs

tw ¼ Thickness of web, in

WC ¼ Weight, contents, (catalyst, packing, etc) Lbs Some applications

We ¼ Weight of entrained liquid, Lbs require packing

in this area

Wg ¼ Weight, grating, Lbs

Wb ¼ Weight, beams, Lbs

wf ¼ Size of fillet weld, in

wn ¼ Uniform load on beam, Lbs/in

Volume, catalyst/packing, Ft3

Put slot in

Vc ¼ beam seat for

Z ¼ Section modulus, PSI thermal expansion

d ¼ Deflection, in

DP ¼ Differential pressure loading Figure 5-1. Typical support arrangements and details of

an internal bed.

This book belongs to Sergio Espinosa (s.espinosa.08n@gmail.com) Copyright Elsevier 2024

You might also like

- Memo For Hand Receipt HoldersDocument10 pagesMemo For Hand Receipt HoldersTerrence StaplesNo ratings yet

- Swi Rope SocketDocument54 pagesSwi Rope SocketJose Antonio Acosta100% (2)

- Connection TypesDocument4 pagesConnection TypesHaidar Abdul SyakurNo ratings yet

- Crumhorn Kelhorn FingeringDocument2 pagesCrumhorn Kelhorn FingeringAntonio100% (1)

- Aluminum in ShipbuildingDocument5 pagesAluminum in ShipbuildingAnonymous e3ceN15No ratings yet

- Shell Stresses Due To Loadings at Support Beam LocationsDocument1 pageShell Stresses Due To Loadings at Support Beam LocationsSergio A. EspinosaNo ratings yet

- Saddle v1-5: Fixed Saddle Sliding SaddleDocument9 pagesSaddle v1-5: Fixed Saddle Sliding Saddleduf fuNo ratings yet

- PETE 411 Well Drilling: Lesson 10 Drilling Hydraulics (Cont'd)Document39 pagesPETE 411 Well Drilling: Lesson 10 Drilling Hydraulics (Cont'd)mirzasdNo ratings yet

- Properties of Stiffening RingsDocument4 pagesProperties of Stiffening RingsSergio A. EspinosaNo ratings yet

- Thrust Block Design - Presentationhanson PDFDocument10 pagesThrust Block Design - Presentationhanson PDFSaravanan MuthuramanNo ratings yet

- Long Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesDocument24 pagesLong Side Failure: Ultimate Bearing Capacity, Q Net Bearing Capacity, Q Computed Factor of Safety, FS N Value N ValuesPervy SageNo ratings yet

- Shear Stress and Bearing StressDocument12 pagesShear Stress and Bearing StressJQNo ratings yet

- PETE 411 Well Drilling: Lesson 10 Drilling Hydraulics (Cont'd)Document39 pagesPETE 411 Well Drilling: Lesson 10 Drilling Hydraulics (Cont'd)HaziNo ratings yet

- StremaDocument20 pagesStremaLara Jane OpeñaNo ratings yet

- One Way Slab DesignDocument6 pagesOne Way Slab DesignLavender HoneyNo ratings yet

- Investigation of Wellbore Storage Effects On Analysis of Well Test DataDocument54 pagesInvestigation of Wellbore Storage Effects On Analysis of Well Test DataOmid Shahbazi100% (1)

- Clean Copy Metal Building Foundation Rev 2.1Document14 pagesClean Copy Metal Building Foundation Rev 2.1jurieskNo ratings yet

- Tubing PerformanceDocument14 pagesTubing PerformanceTeoh Chia YangNo ratings yet

- Proper Bedding For PVC Pressure PipeDocument6 pagesProper Bedding For PVC Pressure PipeUnibellNo ratings yet

- F1 Footing Size in M: Reaction Summary From Staad at The All Nodes ComparedDocument3 pagesF1 Footing Size in M: Reaction Summary From Staad at The All Nodes ComparedPrabhumk07No ratings yet

- Bolted Joints and Bolt Preload OverviewDocument14 pagesBolted Joints and Bolt Preload OverviewKishore MylavarapuNo ratings yet

- Drill String Notes and Calculations 157Document9 pagesDrill String Notes and Calculations 157Pilar AmayaNo ratings yet

- Introduction Drill String & Casing Design PDFDocument9 pagesIntroduction Drill String & Casing Design PDFSatyaNo ratings yet

- (Midasbridge - Com) 2D - Strut-and-Tie Model For 4piles CapDocument5 pages(Midasbridge - Com) 2D - Strut-and-Tie Model For 4piles Capsanusi69No ratings yet

- Prepared By: THAMARAIKANNAN Requested By: Tuesday, February 20, 2018Document16 pagesPrepared By: THAMARAIKANNAN Requested By: Tuesday, February 20, 2018thamaraikannanNo ratings yet

- Drillpipe 3.500 110KSI 225 ID NC38Document1 pageDrillpipe 3.500 110KSI 225 ID NC38Lucas Paul Perez HernandezNo ratings yet

- Bollard Design Rev 2Document5 pagesBollard Design Rev 2Sameera JayaratneNo ratings yet

- PDFDocument5 pagesPDFSameera JayaratneNo ratings yet

- Cellular CofferdamDocument14 pagesCellular Cofferdamsuhairi12No ratings yet

- Well Completions QuestionaireDocument27 pagesWell Completions QuestionaireashwaniNo ratings yet

- Shell and Tube Heat ExchangerDocument1 pageShell and Tube Heat ExchangerNurulHiNo ratings yet

- Threaded Fasteners and Nonpermanent JointsDocument25 pagesThreaded Fasteners and Nonpermanent JointsCesar Manuel Diaz QuinteroNo ratings yet

- YacimientoDocument70 pagesYacimientoJonathan SemperteguiNo ratings yet

- PETE 355 Offshore DrillingDocument39 pagesPETE 355 Offshore DrillingNural Muradli100% (1)

- Data Sheet: Hydrohammer B.VDocument1 pageData Sheet: Hydrohammer B.VViệt Đức ĐỗNo ratings yet

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (2)

- MODULE 6 - (Laterally Supported Beams)Document31 pagesMODULE 6 - (Laterally Supported Beams)Tobi100% (1)

- B.5.4 Warship Structure Details: Figure B.5.4: Typical Midship Section Nomenclature For War ShipsDocument28 pagesB.5.4 Warship Structure Details: Figure B.5.4: Typical Midship Section Nomenclature For War Shipsy_596688032No ratings yet

- Estrangulador Camisa Externa Mod. P4E BB 10KDocument2 pagesEstrangulador Camisa Externa Mod. P4E BB 10Kclaudio godinezNo ratings yet

- Cleat Angle ConnectionDocument13 pagesCleat Angle ConnectionMadhubalan AlagarNo ratings yet

- 2023-04-07 Ksi Rod N' Reel - Double Angle SsDocument6 pages2023-04-07 Ksi Rod N' Reel - Double Angle SsRavi LoharNo ratings yet

- Torsion Bar Rate ChartDocument1 pageTorsion Bar Rate Chartvinothp53No ratings yet

- INQUIRYDocument2 pagesINQUIRYArifin ZakyNo ratings yet

- Ask The Engineer Proper Bedding For PVC Pressure PipeDocument5 pagesAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellNo ratings yet

- Lysaght Bondek II Catalogue 2009Document35 pagesLysaght Bondek II Catalogue 2009waiNo ratings yet

- Paramax Options PDFDocument51 pagesParamax Options PDFConrad Hendrik De KockNo ratings yet

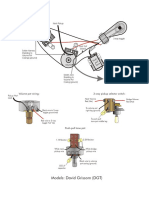

- Models: David Grissom (DGT) : Solder Black Ground Wire From Bridge To Volume Pot CasingDocument1 pageModels: David Grissom (DGT) : Solder Black Ground Wire From Bridge To Volume Pot CasingGreg JonskyNo ratings yet

- Bolt Stress RevBDocument50 pagesBolt Stress RevBMichael Walters100% (1)

- 5-1/2" Ht-55 HWDP Performance Data SheetDocument1 page5-1/2" Ht-55 HWDP Performance Data SheetJanderson Sanchez CastañedaNo ratings yet

- Service Manual Nakamichi MR-1Document44 pagesService Manual Nakamichi MR-1Luis De PazNo ratings yet

- Retaining Wall Design - Only Retaining With Water TableDocument34 pagesRetaining Wall Design - Only Retaining With Water Tableanthropolozist entertainNo ratings yet

- Prepared By: Matilde Castillo Requested By: Miércoles, 09 de Noviembre de 2016Document14 pagesPrepared By: Matilde Castillo Requested By: Miércoles, 09 de Noviembre de 2016Ivonne CastilloNo ratings yet

- BHA AnalysisDocument15 pagesBHA Analysismfazaeli40No ratings yet

- Verticalcm (4 983)Document6 pagesVerticalcm (4 983)Arunava SenguptaNo ratings yet

- LRFD Dimensions&Properties FuDocument8 pagesLRFD Dimensions&Properties FuEngDbtNo ratings yet

- Railroad Crossing Design Sample Problem (Revised Thickness)Document2 pagesRailroad Crossing Design Sample Problem (Revised Thickness)vijay pitchaiNo ratings yet

- SIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3Document1 pageSIGUIL-VETM-F-TEC-AWWA0-001-R1 11/19/2019 - 3:27 PM Page 1 of 1 Form: FRP-AWWA-M45-R3gojiNo ratings yet

- 2 Humbuckers 1 Tone 3 Way ToggleDocument1 page2 Humbuckers 1 Tone 3 Way ToggleCarlos M. Arzola50% (2)

- PT24 111 20 Load ChartDocument1 pagePT24 111 20 Load ChartAlexandri HermansyahNo ratings yet

- Assignment 2-Slab ScheduleDocument1 pageAssignment 2-Slab Schedulembugagao1008No ratings yet

- Determination of Applied Loads and Bearing Analysis: EngineeringDocument4 pagesDetermination of Applied Loads and Bearing Analysis: EngineeringasdNo ratings yet

- Heavy Weight DrillPipe PDFDocument10 pagesHeavy Weight DrillPipe PDFDanielStiglitzNo ratings yet

- Radial Beams Shown Are Example OnlyDocument1 pageRadial Beams Shown Are Example OnlySergio A. EspinosaNo ratings yet

- Analysis When Reinforcing Pads Are UsedDocument1 pageAnalysis When Reinforcing Pads Are UsedSergio A. EspinosaNo ratings yet

- Weight of (1) Hemispherical Head, Based On Inside Diameter, LBSDocument2 pagesWeight of (1) Hemispherical Head, Based On Inside Diameter, LBSSergio A. EspinosaNo ratings yet

- Basic Wind Speeds For Occupancy Category II Buildings and Other StructuresDocument1 pageBasic Wind Speeds For Occupancy Category II Buildings and Other StructuresSergio A. EspinosaNo ratings yet

- Study of Icf Bogie: K.Pavan Kumar Vignan Engg. College HyderabadDocument49 pagesStudy of Icf Bogie: K.Pavan Kumar Vignan Engg. College HyderabadBoby PatelNo ratings yet

- Akumulator Sa HidrogenomDocument6 pagesAkumulator Sa Hidrogenombhstudent_537083349No ratings yet

- Product Information Rockwell Hardness Tester ZHR4045/4150/8150Document4 pagesProduct Information Rockwell Hardness Tester ZHR4045/4150/8150Ricardo Morales MorenoNo ratings yet

- Kumpulan Soal Mekanika A Damped Oscillator Is Driven by An External Force of The FormDocument1 pageKumpulan Soal Mekanika A Damped Oscillator Is Driven by An External Force of The Formyayang1394No ratings yet

- Determination of Double-K Criterion For Crack Propagation in Quasi-Brittle Fracture, Part I: Experimental Investigation of Crack PropagationDocument39 pagesDetermination of Double-K Criterion For Crack Propagation in Quasi-Brittle Fracture, Part I: Experimental Investigation of Crack Propagationliufei3190No ratings yet

- Optimum Selection of Variable Punch-Die Clearance To Improve Tool Life in Blanking Non-Symmetric ShapesDocument10 pagesOptimum Selection of Variable Punch-Die Clearance To Improve Tool Life in Blanking Non-Symmetric ShapesMatheus William CesarNo ratings yet

- Al Ameen College Report GuidelinesDocument14 pagesAl Ameen College Report GuidelinesjinshadNo ratings yet

- Tool Steel Comparison ChartDocument1 pageTool Steel Comparison ChartSree Raj75% (4)

- NewsDocument606 pagesNewsM A Jaya DamanikNo ratings yet

- Visual C++Document3 pagesVisual C++Santosh Kumar MauryaNo ratings yet

- Qa-Qc InterviewDocument7 pagesQa-Qc InterviewEmil MemmedovNo ratings yet

- Secc ABB 230 KV (Organizado)Document5 pagesSecc ABB 230 KV (Organizado)Oscar Pulido SuarezNo ratings yet

- Vigirex CatalogueDocument29 pagesVigirex CatalogueGansar Kharismawan100% (1)

- SSM10 Administrator's GuideDocument62 pagesSSM10 Administrator's GuideNeil LirussoNo ratings yet

- Archimides' PrincipleDocument2 pagesArchimides' PrincipleAna Gabriel Lopez NevarezNo ratings yet

- Practical Experience Gained From Dissolved Gas Analysis at An Aluminium Smelter - Eurotehcon2011-PresentationDocument42 pagesPractical Experience Gained From Dissolved Gas Analysis at An Aluminium Smelter - Eurotehcon2011-PresentationK.RamachandranNo ratings yet

- DS Sheet#7AnsDocument3 pagesDS Sheet#7AnsCasey Scott0% (2)

- 4 - Oxygen Is Needed For CombustionDocument14 pages4 - Oxygen Is Needed For CombustionmizwhiteNo ratings yet

- Accropode IIDocument4 pagesAccropode IIAhmad Balah100% (1)

- Pump Selection and Troubleshooting Field Guide-American Water Works Association (AWWA) (2009)Document109 pagesPump Selection and Troubleshooting Field Guide-American Water Works Association (AWWA) (2009)msaqibraza93100% (5)

- Part2 Maxwell Ultracapacitors TechnologyAtGlanceDocument80 pagesPart2 Maxwell Ultracapacitors TechnologyAtGlanceruhulNo ratings yet

- 4 - Baseband or Systhesised Frequency HoppingDocument2 pages4 - Baseband or Systhesised Frequency HoppingNishant PrabhakarNo ratings yet

- CCK/W33: Spherical Roller BearingsDocument4 pagesCCK/W33: Spherical Roller BearingshamdaNo ratings yet

- Intze Water Tank Based On K. RajuDocument69 pagesIntze Water Tank Based On K. Rajurushicivil1No ratings yet

- Interactive Textile Structures - Lena T.H.Berglin PDFDocument200 pagesInteractive Textile Structures - Lena T.H.Berglin PDFJuan Pablo EspínolaNo ratings yet

- Integral Plant Maintenance: Maximum Performance From Your AssetsDocument12 pagesIntegral Plant Maintenance: Maximum Performance From Your AssetsWALDO MOLINA PINTONo ratings yet

- Chair DesignDocument8 pagesChair Designasimonovska50% (2)