Professional Documents

Culture Documents

Wheel-Bearing-Adjustment 258046645

Wheel-Bearing-Adjustment 258046645

Uploaded by

Jean Ignatios Van Der MerweCopyright:

Available Formats

You might also like

- Turbofan SpecificationsDocument5 pagesTurbofan SpecificationsRasoul gholinia kiviNo ratings yet

- Parts Info 211-212-213-241-243 PDFDocument8 pagesParts Info 211-212-213-241-243 PDFmanutecnicoNo ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABmt11280% (1)

- Vesta 1000 01 PDFDocument53 pagesVesta 1000 01 PDFDuta NarendratamaNo ratings yet

- Bachelor Degree TimetableDocument20 pagesBachelor Degree Timetablebite meNo ratings yet

- Manual Wheel Bearing Adj Procedures Sell SheetDocument2 pagesManual Wheel Bearing Adj Procedures Sell SheetKhanh Pham DangNo ratings yet

- PID - Lube Oil SkidDocument1 pagePID - Lube Oil SkidTalha AamirNo ratings yet

- 318BL Renr2922Document2 pages318BL Renr2922rodineiNo ratings yet

- Inclined ConveyorDocument1 pageInclined ConveyorShaiju NarayananNo ratings yet

- Caterpillar Curso de HidraulicaDocument2 pagesCaterpillar Curso de Hidraulicamisaelandres1100% (1)

- BSG1018 - Rev 3Document1 pageBSG1018 - Rev 3Xu DuaNo ratings yet

- Armazones y Forma Contructiva Motores BALDOR Norrma IECDocument1 pageArmazones y Forma Contructiva Motores BALDOR Norrma IECCesareo Rafael Brochero MarenNo ratings yet

- Ken R 15920001Document2 pagesKen R 15920001Percy Ccalla sefrNo ratings yet

- Delta SC InstructionDocument2 pagesDelta SC Instructionamir65esfNo ratings yet

- CASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779Document6 pagesCASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779MilanNo ratings yet

- Fundação Com Parafusos: QTY Item Part No. DescriptionDocument1 pageFundação Com Parafusos: QTY Item Part No. DescriptiontiagoNo ratings yet

- Diagramas Caterpillar RENR1166 - 01Document2 pagesDiagramas Caterpillar RENR1166 - 01jorge antonio guillenNo ratings yet

- Silent Zero Piler - Scz-Eco600sDocument1 pageSilent Zero Piler - Scz-Eco600sPHÁT NGUYỄN THẾNo ratings yet

- ZF As Tronic Schematic - EDocument2 pagesZF As Tronic Schematic - EBienvenu Massouangui50% (2)

- Plunger Pumps: DescriptionDocument20 pagesPlunger Pumps: DescriptionDaveNo ratings yet

- Current Revision Approved: Crusher Control Panel, Plus1Document3 pagesCurrent Revision Approved: Crusher Control Panel, Plus1Gerencia TEAM S.A.S.No ratings yet

- 6.4.4.2 Load Flow ReportDocument147 pages6.4.4.2 Load Flow ReportMohamed FaroukNo ratings yet

- H3015-H6020.zh-CN.enDocument12 pagesH3015-H6020.zh-CN.enRenato KristicNo ratings yet

- 42/47RE Transmissions: Won't Shift Without The AlternatorDocument7 pages42/47RE Transmissions: Won't Shift Without The AlternatorRicardo Rangel PosadasNo ratings yet

- Isometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)Document1 pageIsometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)b_m_leeNo ratings yet

- Poster g4 Druck Englisch 0718Document1 pagePoster g4 Druck Englisch 0718Dardo GoyaNo ratings yet

- HD600 - ModelCode BreakdownDocument1 pageHD600 - ModelCode Breakdownenio10No ratings yet

- Ngebers 10/16/2019 TWR Post Base 4ear T2 Stg2 10Ft TOLERANCE: 1/32" & 1 Scale: 1:8Document1 pageNgebers 10/16/2019 TWR Post Base 4ear T2 Stg2 10Ft TOLERANCE: 1/32" & 1 Scale: 1:8Ephraim BarezNo ratings yet

- Cxa VVVF 220Document1 pageCxa VVVF 220Mohamed ArefNo ratings yet

- 30 Urban CruiserDocument1 page30 Urban CruiserHEMIL ROBERTO RODRIGUEZ HERRERANo ratings yet

- Arbonia Column RadiatorsDocument100 pagesArbonia Column RadiatorsMikhailNo ratings yet

- Disassembly and Assembly Procedures For Rollers With Inverted Duo-Cone SealsDocument1 pageDisassembly and Assembly Procedures For Rollers With Inverted Duo-Cone Seals----No ratings yet

- Emcoder Incremetal Das Serras Extrusoras E50-series-INSDocument1 pageEmcoder Incremetal Das Serras Extrusoras E50-series-INSEle isNo ratings yet

- Clevis Hangers Combined PDFDocument1 pageClevis Hangers Combined PDFSaleem BashaNo ratings yet

- 4283773-01-E Balde G2Document2 pages4283773-01-E Balde G2Robin carcamoNo ratings yet

- ND BRG GuideDocument32 pagesND BRG Guidemohammed barghothiNo ratings yet

- WPS 800 AL GA 800kVA AL Standard TX Arrangement 1Document1 pageWPS 800 AL GA 800kVA AL Standard TX Arrangement 1SathishNo ratings yet

- TP - wy51.PB751D Schematic DiagramDocument15 pagesTP - wy51.PB751D Schematic DiagramUdeni ReksikaNo ratings yet

- Gde01 03 029 BDocument1 pageGde01 03 029 Bluca.laniNo ratings yet

- Redcat Lightning EPX ManualDocument1 pageRedcat Lightning EPX ManualBobby HancockNo ratings yet

- Bomba Desplazamiento PositivoDocument14 pagesBomba Desplazamiento PositivoAlvaro Jose DíazNo ratings yet

- SB62-IG112 Surge Arrester Structure 3600mm - V1Document1 pageSB62-IG112 Surge Arrester Structure 3600mm - V1hung.nguyenmanhNo ratings yet

- 4 V158 TIhhDocument1 page4 V158 TIhhramizbd5No ratings yet

- E5.06 Oneline Exercise2344322Document1 pageE5.06 Oneline Exercise2344322WyattNo ratings yet

- Item No. 7 .Hino SpekDocument1 pageItem No. 7 .Hino SpekivomNo ratings yet

- WPS 800 AL A003 800kVA AL Standard TX Arrangement LV CAB 1Document1 pageWPS 800 AL A003 800kVA AL Standard TX Arrangement LV CAB 1SathishNo ratings yet

- SL T. Manual 583 PDFDocument1 pageSL T. Manual 583 PDFJuan PabloNo ratings yet

- 2022 ATV ROV Wiring DiagramsDocument9 pages2022 ATV ROV Wiring Diagrams张连杉No ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABhansenfarms.chNo ratings yet

- APT Catalog 0918 LowDocument20 pagesAPT Catalog 0918 LowZippi ToonsNo ratings yet

- Niigata Airport: ELEV 1.40m (4.6ft)Document23 pagesNiigata Airport: ELEV 1.40m (4.6ft)張允執No ratings yet

- Bản Vẽ Dao Cách Ly GE China 2019Document25 pagesBản Vẽ Dao Cách Ly GE China 2019Nguyễn Văn HiệnNo ratings yet

- Var Wal 01 - 02 Variax t8 System Back Table Layout - FinalDocument1 pageVar Wal 01 - 02 Variax t8 System Back Table Layout - FinalEric RothNo ratings yet

- 980F 3HK, 8CJ, 5XJ1-587Document2 pages980F 3HK, 8CJ, 5XJ1-587Rafa GarciaNo ratings yet

- Footpad Detail Section A-A: CL CLDocument2 pagesFootpad Detail Section A-A: CL CLjonathan pariguanaNo ratings yet

- Manual Encoder Rotatorio E50SDocument1 pageManual Encoder Rotatorio E50SFabian MezaNo ratings yet

- Front Shovel enDocument15 pagesFront Shovel enAlejandro RodriguezNo ratings yet

- Auto Adaptive SHUNT - SchematicDocument1 pageAuto Adaptive SHUNT - Schematicslobodan.jovanovic.jaNo ratings yet

- Repair Service: 1051 - Air Cleaner PartsDocument2 pagesRepair Service: 1051 - Air Cleaner PartshayaNo ratings yet

- Test Bank For Child Development A Thematic Approach 6th EditionDocument6 pagesTest Bank For Child Development A Thematic Approach 6th EditionCharles Pando100% (44)

- (Limpin, Shakti Dev) Mil Q4W1Document3 pages(Limpin, Shakti Dev) Mil Q4W1Shakti Dev LimpinNo ratings yet

- A Project Report-1 - 231020 - 204422Document59 pagesA Project Report-1 - 231020 - 204422Ankit Sharma 028No ratings yet

- EnSight UserManualDocument868 pagesEnSight UserManualAnonymous scnl9rHNo ratings yet

- English Work - Maria Isabel GrajalesDocument5 pagesEnglish Work - Maria Isabel GrajalesDavid RodriguezNo ratings yet

- TI Manual SJX Elevator-2Document11 pagesTI Manual SJX Elevator-2Alex MillerNo ratings yet

- Design Thinking: Secure Car ParkDocument12 pagesDesign Thinking: Secure Car ParkSiddhesh JadhavNo ratings yet

- Learning Skill For 21ST CenturyDocument16 pagesLearning Skill For 21ST CenturyKSSNo ratings yet

- Bago CityDocument8 pagesBago CityTricia Marvi P. NavarroNo ratings yet

- Difference Between Battle and WarDocument3 pagesDifference Between Battle and Warwaniarbaz28No ratings yet

- Prenatal EclipsesDocument10 pagesPrenatal EclipsesAnahiti Atena100% (3)

- Accounting May-June 2019 EngDocument18 pagesAccounting May-June 2019 Englindort00No ratings yet

- Hard TimesDocument3 pagesHard TimesPaola LamannaNo ratings yet

- Position Department Annual Salary LocationDocument2 pagesPosition Department Annual Salary LocationdasdasNo ratings yet

- Selection of A Premier in Nunavut and Related IssuesDocument93 pagesSelection of A Premier in Nunavut and Related IssuesNunatsiaqNewsNo ratings yet

- Work Plan in EnglishDocument2 pagesWork Plan in EnglishMADELEINE PADURA100% (4)

- ACOSTA, Josef De. Historia Natural y Moral de Las IndiasDocument1,022 pagesACOSTA, Josef De. Historia Natural y Moral de Las IndiasJosé Antonio M. Ameijeiras100% (1)

- PCR Qurbani 2018 TharparkarDocument3 pagesPCR Qurbani 2018 TharparkarKARWAN DEVELOPMENT FOUNDATIONNo ratings yet

- UNFCU Foundation Grant Application 2019Document4 pagesUNFCU Foundation Grant Application 2019Anonymous PbCsXeZNo ratings yet

- Management Unit 5 MCQDocument4 pagesManagement Unit 5 MCQPranav MhatreNo ratings yet

- Stop Using Pandas To Read - Write Data - This Alternative Is 7 Times Faster - by Dario Radečić - Oct, 2021 - Towards Data ScienceDocument10 pagesStop Using Pandas To Read - Write Data - This Alternative Is 7 Times Faster - by Dario Radečić - Oct, 2021 - Towards Data ScienceVítor Luís Pauda da SilvaNo ratings yet

- Police Log July 17, 2016Document13 pagesPolice Log July 17, 2016MansfieldMAPoliceNo ratings yet

- A. H. M. Jones - Studies in Roman Government and Law-Basil Blackwell (1960)Document260 pagesA. H. M. Jones - Studies in Roman Government and Law-Basil Blackwell (1960)L V100% (1)

- Lec 6 Technology of OperativeDocument8 pagesLec 6 Technology of OperativeHassan TantawyNo ratings yet

- Kerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaDocument3 pagesKerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaAyyoobNo ratings yet

- Engr. Frederick B. Garcia: Proposed 3-Storey ResidenceDocument1 pageEngr. Frederick B. Garcia: Proposed 3-Storey Residencesam nacionNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- Setting MikrotikDocument10 pagesSetting MikrotikLambace KecciNo ratings yet

Wheel-Bearing-Adjustment 258046645

Wheel-Bearing-Adjustment 258046645

Uploaded by

Jean Ignatios Van Der MerweCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wheel-Bearing-Adjustment 258046645

Wheel-Bearing-Adjustment 258046645

Uploaded by

Jean Ignatios Van Der MerweCopyright:

Available Formats

MANUAL Wheel Bearing Adjustment Procedures

The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm). This procedure applies to steer,

drive and trailer axle assemblies using conventional double nut or single nut systems on Class 6, 7 and 8 trucks. This refers only to torque specifications and bearing

adjustment. Please refer to the original equipment manufacturer’s recommended procedures for complete installation details.

NOTE: For single nut self-locking systems, consult manufacturers’ instructions. If you have a system that differs from what is indicated in this procedure, consult the

vehicle manufacturer’s recommended procedure.

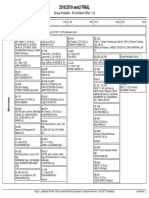

Tapered Roller Bearing Adjustment Procedure RP 618A

Step 1: Lubricate the tapered roller bearing with clean axle lubricant of the same type used in the axle sump or hub assembly. NOTE: Never use an impact wrench

when tightening or loosening lug nuts or bolts during the procedure.

Initial Adjusting Final Adjusting Torque Acceptable

Initial Back Off Axle Type Threads Per Inch Final Back Off Nut Size

Nut Torque Nut Torque Specifications End Play

Step 2 Step 3 Step 4 Step 5 Step 6 Step 7 Step 8

12 1/6 Turn*

Install Cotter Pin to Lock

1/4 Turn* Axle Nut in Position

18

Steer

(Front) 12 1/3 Turn*

Non-Drive Less Than 200-300 lbf•ft

14 0.001” - 0.005”

200 lbf•ft 50 lbf•ft 1/2 Turn* 2 5/8”(66.7 mm) (271-407 N•m)

(.025 - .127 mm)

(271N•m) (68 N•m) 18

One

While While

Full Turn 300-400 lbf•ft As Measured Per

Rotating Rotating 12 Dowel Type Washer

(407-542 N•m) Procedure With Dial

Wheel Wheels

Drive 1/4 Turn* Indicator

200-275 lbf•ft

16 Tang Type Washer**

(271-373 N•m)

12

Less Than 300-400 lbf•ft

Trailer 1/4 Turn*

2 5/8”(66.7 mm) (407-542 N•m)

16

* If dowel pin and washer (or washer tang and nut flat) are not aligned, remove the washer, turn it over and reinstall. If required, loosen the inner (adjusting) nut just enough for alignment.

** Bendable type washer lock only: Secure nuts by bending one wheel nut washer tang over the inner and outer nut. Bend the tangs over the closest flat perpendicular to the tang.

Verify end play with a dial indicator. Wheel end play is the free movement of the tire and wheel assembly along the spindle axis.

a) Make sure the brake drum-to-hub fasteners are tightened to the manufacturers’ specifications.

b) Attach the dial indicator with its magnetic base to the hub or brake drum.

c) Adjust the dial indicator so that its plunger or pointer is against the end of the spindle with its line of action approximately parallel to the axis of the spindle.

d) Grasp the wheel assembly at the 3 o’clock and 9 o’clock positions. Push the wheel assembly in and out while oscillating it to seat the bearings. Read the bearing end

play as the total indicator movement.

NOTE: If end play is not within specification, readjustment is required.

TMC RP 618A, Wheel Bearing Adjustment Procedure, appears in TMC’s 2010-2011 Recommended Practices Manual, and is published by the Technology & Maintenance Council (TMC) of American Trucking Associations;

950 N. Glebe Road, Arlington, VA 22203; (703) 838-1763; http://tmc.truckline.com. Reprinted with permission.

PRE-ADJUSTED Wheel Bearing Adjustment Procedures

NOTE: This refers only to torque specifications and bearing adjustment. Please refer to the original equipment manufacturer’s recommended procedures for complete

installation details.

1) Mount the hub assembly onto the axle spindle, while holding the outer cone in place. Make sure the bearing cones, spacer and spindle are aligned to avoid seal damage.

2) Install the inner spindle nut and torque to 300 ft-lbs. Do not back off the spindle nut.

3) Engage the locking device that is part of the spindle nut system. If the locking system cannot be engaged when the nut is at 300 ft-lbs, advance the nut until the

locking system can be engaged (reference note above). For a double nut or jam nut system, bend the lock tab or install the set screw after the outer nut is torqued to

200 ft-lbs.

4) For one-piece spindle nut systems, torque the nut to a minimum of 300 ft-lbs. Do not back off the spindle nut. Engage any locking device that is part of the spindle nut

system. If the locking device cannot be engaged when the nut is at 300 ft-lbs, advance the nut until engagement takes place and the nut is locked.

WARNING Failure to follow these warnings could create a risk of death or serious bodily injury.

Proper maintenance and handling practices are critical. Always follow installation instructions and maintain proper lubrication. Never spin a bearing with compressed air. The rolling elements may be forcefully expelled.

Always follow wheel torque recommendations. Excessive or inadequate wheel torque can lead to failure of the wheel mounting system and loss of a wheel.

Do not remove the outer bearing once it has been installed on the spindle. Removing it could cause the seal to become misaligned and lead to a seal failure or loss of a wheel.

Every reasonable effort has been made to ensure the accuracy of the information contained in this writing, but no liability is accepted for errors, omissions or for any other reason.

www.timken.com/aftermarket Visit timken.com/techseries to enroll in free technical training.

.5M 10-19 :29 Order No. 10420 | Timken® is a registered trademark of The Timken Company. | © 2019 The Timken Company | Printed in U.S.A. Get more TechTips online at www.timken.com/techtips.

You might also like

- Turbofan SpecificationsDocument5 pagesTurbofan SpecificationsRasoul gholinia kiviNo ratings yet

- Parts Info 211-212-213-241-243 PDFDocument8 pagesParts Info 211-212-213-241-243 PDFmanutecnicoNo ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABmt11280% (1)

- Vesta 1000 01 PDFDocument53 pagesVesta 1000 01 PDFDuta NarendratamaNo ratings yet

- Bachelor Degree TimetableDocument20 pagesBachelor Degree Timetablebite meNo ratings yet

- Manual Wheel Bearing Adj Procedures Sell SheetDocument2 pagesManual Wheel Bearing Adj Procedures Sell SheetKhanh Pham DangNo ratings yet

- PID - Lube Oil SkidDocument1 pagePID - Lube Oil SkidTalha AamirNo ratings yet

- 318BL Renr2922Document2 pages318BL Renr2922rodineiNo ratings yet

- Inclined ConveyorDocument1 pageInclined ConveyorShaiju NarayananNo ratings yet

- Caterpillar Curso de HidraulicaDocument2 pagesCaterpillar Curso de Hidraulicamisaelandres1100% (1)

- BSG1018 - Rev 3Document1 pageBSG1018 - Rev 3Xu DuaNo ratings yet

- Armazones y Forma Contructiva Motores BALDOR Norrma IECDocument1 pageArmazones y Forma Contructiva Motores BALDOR Norrma IECCesareo Rafael Brochero MarenNo ratings yet

- Ken R 15920001Document2 pagesKen R 15920001Percy Ccalla sefrNo ratings yet

- Delta SC InstructionDocument2 pagesDelta SC Instructionamir65esfNo ratings yet

- CASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779Document6 pagesCASE IH AXIAL-FLOW 7120 - 8120 - 9120 Combines Hydraulic Schematic - 47462779MilanNo ratings yet

- Fundação Com Parafusos: QTY Item Part No. DescriptionDocument1 pageFundação Com Parafusos: QTY Item Part No. DescriptiontiagoNo ratings yet

- Diagramas Caterpillar RENR1166 - 01Document2 pagesDiagramas Caterpillar RENR1166 - 01jorge antonio guillenNo ratings yet

- Silent Zero Piler - Scz-Eco600sDocument1 pageSilent Zero Piler - Scz-Eco600sPHÁT NGUYỄN THẾNo ratings yet

- ZF As Tronic Schematic - EDocument2 pagesZF As Tronic Schematic - EBienvenu Massouangui50% (2)

- Plunger Pumps: DescriptionDocument20 pagesPlunger Pumps: DescriptionDaveNo ratings yet

- Current Revision Approved: Crusher Control Panel, Plus1Document3 pagesCurrent Revision Approved: Crusher Control Panel, Plus1Gerencia TEAM S.A.S.No ratings yet

- 6.4.4.2 Load Flow ReportDocument147 pages6.4.4.2 Load Flow ReportMohamed FaroukNo ratings yet

- H3015-H6020.zh-CN.enDocument12 pagesH3015-H6020.zh-CN.enRenato KristicNo ratings yet

- 42/47RE Transmissions: Won't Shift Without The AlternatorDocument7 pages42/47RE Transmissions: Won't Shift Without The AlternatorRicardo Rangel PosadasNo ratings yet

- Isometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)Document1 pageIsometric: 52 I/ D PIP E 40 (I/ D) (LI NIN G)b_m_leeNo ratings yet

- Poster g4 Druck Englisch 0718Document1 pagePoster g4 Druck Englisch 0718Dardo GoyaNo ratings yet

- HD600 - ModelCode BreakdownDocument1 pageHD600 - ModelCode Breakdownenio10No ratings yet

- Ngebers 10/16/2019 TWR Post Base 4ear T2 Stg2 10Ft TOLERANCE: 1/32" & 1 Scale: 1:8Document1 pageNgebers 10/16/2019 TWR Post Base 4ear T2 Stg2 10Ft TOLERANCE: 1/32" & 1 Scale: 1:8Ephraim BarezNo ratings yet

- Cxa VVVF 220Document1 pageCxa VVVF 220Mohamed ArefNo ratings yet

- 30 Urban CruiserDocument1 page30 Urban CruiserHEMIL ROBERTO RODRIGUEZ HERRERANo ratings yet

- Arbonia Column RadiatorsDocument100 pagesArbonia Column RadiatorsMikhailNo ratings yet

- Disassembly and Assembly Procedures For Rollers With Inverted Duo-Cone SealsDocument1 pageDisassembly and Assembly Procedures For Rollers With Inverted Duo-Cone Seals----No ratings yet

- Emcoder Incremetal Das Serras Extrusoras E50-series-INSDocument1 pageEmcoder Incremetal Das Serras Extrusoras E50-series-INSEle isNo ratings yet

- Clevis Hangers Combined PDFDocument1 pageClevis Hangers Combined PDFSaleem BashaNo ratings yet

- 4283773-01-E Balde G2Document2 pages4283773-01-E Balde G2Robin carcamoNo ratings yet

- ND BRG GuideDocument32 pagesND BRG Guidemohammed barghothiNo ratings yet

- WPS 800 AL GA 800kVA AL Standard TX Arrangement 1Document1 pageWPS 800 AL GA 800kVA AL Standard TX Arrangement 1SathishNo ratings yet

- TP - wy51.PB751D Schematic DiagramDocument15 pagesTP - wy51.PB751D Schematic DiagramUdeni ReksikaNo ratings yet

- Gde01 03 029 BDocument1 pageGde01 03 029 Bluca.laniNo ratings yet

- Redcat Lightning EPX ManualDocument1 pageRedcat Lightning EPX ManualBobby HancockNo ratings yet

- Bomba Desplazamiento PositivoDocument14 pagesBomba Desplazamiento PositivoAlvaro Jose DíazNo ratings yet

- SB62-IG112 Surge Arrester Structure 3600mm - V1Document1 pageSB62-IG112 Surge Arrester Structure 3600mm - V1hung.nguyenmanhNo ratings yet

- 4 V158 TIhhDocument1 page4 V158 TIhhramizbd5No ratings yet

- E5.06 Oneline Exercise2344322Document1 pageE5.06 Oneline Exercise2344322WyattNo ratings yet

- Item No. 7 .Hino SpekDocument1 pageItem No. 7 .Hino SpekivomNo ratings yet

- WPS 800 AL A003 800kVA AL Standard TX Arrangement LV CAB 1Document1 pageWPS 800 AL A003 800kVA AL Standard TX Arrangement LV CAB 1SathishNo ratings yet

- SL T. Manual 583 PDFDocument1 pageSL T. Manual 583 PDFJuan PabloNo ratings yet

- 2022 ATV ROV Wiring DiagramsDocument9 pages2022 ATV ROV Wiring Diagrams张连杉No ratings yet

- 2015 Dodge Ram Cab Lights Installation 82211190ABDocument7 pages2015 Dodge Ram Cab Lights Installation 82211190ABhansenfarms.chNo ratings yet

- APT Catalog 0918 LowDocument20 pagesAPT Catalog 0918 LowZippi ToonsNo ratings yet

- Niigata Airport: ELEV 1.40m (4.6ft)Document23 pagesNiigata Airport: ELEV 1.40m (4.6ft)張允執No ratings yet

- Bản Vẽ Dao Cách Ly GE China 2019Document25 pagesBản Vẽ Dao Cách Ly GE China 2019Nguyễn Văn HiệnNo ratings yet

- Var Wal 01 - 02 Variax t8 System Back Table Layout - FinalDocument1 pageVar Wal 01 - 02 Variax t8 System Back Table Layout - FinalEric RothNo ratings yet

- 980F 3HK, 8CJ, 5XJ1-587Document2 pages980F 3HK, 8CJ, 5XJ1-587Rafa GarciaNo ratings yet

- Footpad Detail Section A-A: CL CLDocument2 pagesFootpad Detail Section A-A: CL CLjonathan pariguanaNo ratings yet

- Manual Encoder Rotatorio E50SDocument1 pageManual Encoder Rotatorio E50SFabian MezaNo ratings yet

- Front Shovel enDocument15 pagesFront Shovel enAlejandro RodriguezNo ratings yet

- Auto Adaptive SHUNT - SchematicDocument1 pageAuto Adaptive SHUNT - Schematicslobodan.jovanovic.jaNo ratings yet

- Repair Service: 1051 - Air Cleaner PartsDocument2 pagesRepair Service: 1051 - Air Cleaner PartshayaNo ratings yet

- Test Bank For Child Development A Thematic Approach 6th EditionDocument6 pagesTest Bank For Child Development A Thematic Approach 6th EditionCharles Pando100% (44)

- (Limpin, Shakti Dev) Mil Q4W1Document3 pages(Limpin, Shakti Dev) Mil Q4W1Shakti Dev LimpinNo ratings yet

- A Project Report-1 - 231020 - 204422Document59 pagesA Project Report-1 - 231020 - 204422Ankit Sharma 028No ratings yet

- EnSight UserManualDocument868 pagesEnSight UserManualAnonymous scnl9rHNo ratings yet

- English Work - Maria Isabel GrajalesDocument5 pagesEnglish Work - Maria Isabel GrajalesDavid RodriguezNo ratings yet

- TI Manual SJX Elevator-2Document11 pagesTI Manual SJX Elevator-2Alex MillerNo ratings yet

- Design Thinking: Secure Car ParkDocument12 pagesDesign Thinking: Secure Car ParkSiddhesh JadhavNo ratings yet

- Learning Skill For 21ST CenturyDocument16 pagesLearning Skill For 21ST CenturyKSSNo ratings yet

- Bago CityDocument8 pagesBago CityTricia Marvi P. NavarroNo ratings yet

- Difference Between Battle and WarDocument3 pagesDifference Between Battle and Warwaniarbaz28No ratings yet

- Prenatal EclipsesDocument10 pagesPrenatal EclipsesAnahiti Atena100% (3)

- Accounting May-June 2019 EngDocument18 pagesAccounting May-June 2019 Englindort00No ratings yet

- Hard TimesDocument3 pagesHard TimesPaola LamannaNo ratings yet

- Position Department Annual Salary LocationDocument2 pagesPosition Department Annual Salary LocationdasdasNo ratings yet

- Selection of A Premier in Nunavut and Related IssuesDocument93 pagesSelection of A Premier in Nunavut and Related IssuesNunatsiaqNewsNo ratings yet

- Work Plan in EnglishDocument2 pagesWork Plan in EnglishMADELEINE PADURA100% (4)

- ACOSTA, Josef De. Historia Natural y Moral de Las IndiasDocument1,022 pagesACOSTA, Josef De. Historia Natural y Moral de Las IndiasJosé Antonio M. Ameijeiras100% (1)

- PCR Qurbani 2018 TharparkarDocument3 pagesPCR Qurbani 2018 TharparkarKARWAN DEVELOPMENT FOUNDATIONNo ratings yet

- UNFCU Foundation Grant Application 2019Document4 pagesUNFCU Foundation Grant Application 2019Anonymous PbCsXeZNo ratings yet

- Management Unit 5 MCQDocument4 pagesManagement Unit 5 MCQPranav MhatreNo ratings yet

- Stop Using Pandas To Read - Write Data - This Alternative Is 7 Times Faster - by Dario Radečić - Oct, 2021 - Towards Data ScienceDocument10 pagesStop Using Pandas To Read - Write Data - This Alternative Is 7 Times Faster - by Dario Radečić - Oct, 2021 - Towards Data ScienceVítor Luís Pauda da SilvaNo ratings yet

- Police Log July 17, 2016Document13 pagesPolice Log July 17, 2016MansfieldMAPoliceNo ratings yet

- A. H. M. Jones - Studies in Roman Government and Law-Basil Blackwell (1960)Document260 pagesA. H. M. Jones - Studies in Roman Government and Law-Basil Blackwell (1960)L V100% (1)

- Lec 6 Technology of OperativeDocument8 pagesLec 6 Technology of OperativeHassan TantawyNo ratings yet

- Kerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaDocument3 pagesKerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaAyyoobNo ratings yet

- Engr. Frederick B. Garcia: Proposed 3-Storey ResidenceDocument1 pageEngr. Frederick B. Garcia: Proposed 3-Storey Residencesam nacionNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- Setting MikrotikDocument10 pagesSetting MikrotikLambace KecciNo ratings yet