Professional Documents

Culture Documents

IOM HE-10825C, X Motor O&M

IOM HE-10825C, X Motor O&M

Uploaded by

maryadiCopyright:

Available Formats

You might also like

- Serie 60 Informacion AdicionalDocument51 pagesSerie 60 Informacion AdicionalMauricio Campos Quiros100% (1)

- Prueba Resorte de EmbragueDocument2 pagesPrueba Resorte de Embraguejohan gomezNo ratings yet

- CH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsDocument46 pagesCH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsEnrrique LaraNo ratings yet

- 3500 ENGINE Specifications Pistons and RingsDocument5 pages3500 ENGINE Specifications Pistons and RingsVan Phuc ThaiNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Clearances Mentioned in Manual.Document3 pagesClearances Mentioned in Manual.AshishNo ratings yet

- Fuel Injection Equipment: EspecificacionesDocument29 pagesFuel Injection Equipment: EspecificacionesSergio Ricardo Ibañez100% (1)

- DisassemblyDocument8 pagesDisassemblyEdson CRNo ratings yet

- Roller Circle - Check and AdjustDocument3 pagesRoller Circle - Check and AdjustGilney FreitasNo ratings yet

- Point Sheave - 1Document2 pagesPoint Sheave - 1Gilney FreitasNo ratings yet

- Informacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297Document13 pagesInformacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297hector100% (3)

- RENR492704Document3 pagesRENR492704Victor NoschangNo ratings yet

- Connecting Rod - Steel Crankshaft PDFDocument6 pagesConnecting Rod - Steel Crankshaft PDFjoaobargasNo ratings yet

- Drive Shaft O&M April 2010Document4 pagesDrive Shaft O&M April 2010elperrote3No ratings yet

- Specifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)Document19 pagesSpecifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)ariel avalos100% (2)

- Connecting Rod: SMCS - 1218 Part Number - 319-7945 S/NDocument5 pagesConnecting Rod: SMCS - 1218 Part Number - 319-7945 S/NsuportethermoNo ratings yet

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- 690 06 Fenner Taper Lock InstallationDocument1 page690 06 Fenner Taper Lock InstallationManhar PanchalNo ratings yet

- Deethanizer Reflux Pump InfoDocument5 pagesDeethanizer Reflux Pump InfoarasNo ratings yet

- C4.4 Medida Cigüeñal PermitidasDocument3 pagesC4.4 Medida Cigüeñal PermitidasLuis GutiérrezNo ratings yet

- Assembly U241E TransmissionDocument29 pagesAssembly U241E TransmissionFirman SuryaNo ratings yet

- SRAM SPECTRO S7 Maintenance - en PDFDocument0 pagesSRAM SPECTRO S7 Maintenance - en PDFkuvalda2000No ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- Acoples TramecDocument26 pagesAcoples TramecAndres ValderramaNo ratings yet

- 140H DAKYFA Differential and Bevel Gear - TestDocument11 pages140H DAKYFA Differential and Bevel Gear - TestDaniel TekleNo ratings yet

- Main Bearing Journal: Shutdown SIS Previous ScreenDocument3 pagesMain Bearing Journal: Shutdown SIS Previous Screenariy yuli styawanNo ratings yet

- Clutch: Workshop ManualDocument38 pagesClutch: Workshop ManualMuslihnofalNo ratings yet

- 1 GRDocument11 pages1 GRGanbileg BatbilegNo ratings yet

- A33 Manual Acople WoochangDocument16 pagesA33 Manual Acople WoochangEduardoNo ratings yet

- Cylinder Head: C15 On Highway EngineDocument11 pagesCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANo ratings yet

- Cojinetes de Biela y Bancada STD SeleccionDocument5 pagesCojinetes de Biela y Bancada STD SeleccionAlejandro ValenzuelaNo ratings yet

- Datos de Reparacion de Motor Caterpillar c6.6Document21 pagesDatos de Reparacion de Motor Caterpillar c6.6Marcos Astete EgoavilNo ratings yet

- Bawn 004Document4 pagesBawn 004sike1977No ratings yet

- Panewki, Czopy Główne c4.2Document3 pagesPanewki, Czopy Główne c4.2Beniamin Kowoll100% (1)

- HINO US Chap05Document64 pagesHINO US Chap05Andres GomezNo ratings yet

- Calculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesDocument6 pagesCalculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesmkNo ratings yet

- 3500 ENGINE Specifications Water PumpDocument5 pages3500 ENGINE Specifications Water PumpVan Phuc ThaiNo ratings yet

- Maintenance Specifications: 6.1. Tightening TorqueDocument9 pagesMaintenance Specifications: 6.1. Tightening TorqueWshop2 AdminNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocument4 pagesGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковNo ratings yet

- Crankshaft: Shutdown SIS Previous ScreenDocument5 pagesCrankshaft: Shutdown SIS Previous Screenariy yuli styawan100% (1)

- Disc Pack Coupling STCDocument2 pagesDisc Pack Coupling STCYudo ArdianNo ratings yet

- Ser 200 IMDocument5 pagesSer 200 IMshadialameddinNo ratings yet

- Peugeot dw8 Checks and AdjustmentsDocument3 pagesPeugeot dw8 Checks and AdjustmentsAlvaro RochaNo ratings yet

- Calibracion de Valvulas 966H - 01Document5 pagesCalibracion de Valvulas 966H - 01Freddy QuispeNo ratings yet

- Especificação Da BielaDocument5 pagesEspecificação Da BielasuportethermoNo ratings yet

- Especificaciones de Biela CaterpillarDocument2 pagesEspecificaciones de Biela CaterpillarYubiangel Celeste Perugini Parababith100% (1)

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustHAmir Alberto Mojica MojicaNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument29 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceEdU RECTIFICANo ratings yet

- Ajuste Valvulas Motor 336DDocument5 pagesAjuste Valvulas Motor 336Djuan sebastianNo ratings yet

- Calculating Cylinder Liner Projection For G3500Document7 pagesCalculating Cylinder Liner Projection For G3500NimNo ratings yet

- 07epa04mbe40005 PDFDocument14 pages07epa04mbe40005 PDFEduardo TorresNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Bearing Fit ChartDocument6 pagesBearing Fit ChartAvinash MamillapalliNo ratings yet

- Torque-Hose ClampsDocument3 pagesTorque-Hose Clampsyoga_jpbmbmNo ratings yet

- MSA5TCD95L5569Document4 pagesMSA5TCD95L5569Ariel PrietoNo ratings yet

- Manual: 292 Engine Kt-150 SeriesDocument20 pagesManual: 292 Engine Kt-150 SeriesSuwan Noo ThomsonNo ratings yet

- Different Types of Combustion Chamber and TurbineDocument13 pagesDifferent Types of Combustion Chamber and TurbineRonoRoa ZoRen100% (1)

- Submersible Sump Pumps 83-TMSS-01, Rev 0Document12 pagesSubmersible Sump Pumps 83-TMSS-01, Rev 0Pageduesca RouelNo ratings yet

- CORRECTDocument60 pagesCORRECTLovely TarunNo ratings yet

- VDZ-Onlinecourse 4 5 enDocument30 pagesVDZ-Onlinecourse 4 5 enAnonymous iI88LtNo ratings yet

- Water Lifting Devices PDFDocument41 pagesWater Lifting Devices PDFSrinathRaghavan0% (1)

- An Investigation On The Performance Characteristics of A Centrifugal CompressorDocument7 pagesAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDNo ratings yet

- Wilo MONOBLOCKDocument10 pagesWilo MONOBLOCKwaseemybNo ratings yet

- Intership 1Document28 pagesIntership 1Abhishek KhandekarNo ratings yet

- Attachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 BoosterDocument1 pageAttachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 Boosterachmadj1405No ratings yet

- 160.73-Eg1 YorkDocument72 pages160.73-Eg1 Yorkmauricio.vidalyork6735No ratings yet

- Roots BlowerDocument2 pagesRoots Blowereko bagus sunaryoNo ratings yet

- Selecting Centrifugal Pumps DataDocument92 pagesSelecting Centrifugal Pumps DataarvindzdenNo ratings yet

- Review of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersDocument12 pagesReview of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersHosseinNo ratings yet

- Fan Installation GuideDocument50 pagesFan Installation GuideGohds100% (1)

- Axiblade: One System For All Applications?Document12 pagesAxiblade: One System For All Applications?wai_shengNo ratings yet

- Agitator DesignDocument9 pagesAgitator DesignDeepika100% (1)

- PMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetDocument2 pagesPMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetfarhaNo ratings yet

- Water WastewaterDocument20 pagesWater WastewaterterryjoseeNo ratings yet

- LRN-JRN ENG 50HzDocument16 pagesLRN-JRN ENG 50HzJoséTorres100% (1)

- Comparision of PDFDocument9 pagesComparision of PDFSmith Salazar AscueNo ratings yet

- Naffco Listed Fire Pumps 2900 RPM: 1-1/2" BS 336 MaleDocument12 pagesNaffco Listed Fire Pumps 2900 RPM: 1-1/2" BS 336 MaleGUNABALANNo ratings yet

- Subaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceDocument88 pagesSubaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceEdgardo M. Diolola100% (1)

- Costs of EqpmentsDocument7 pagesCosts of EqpmentsNishithNo ratings yet

- Hoja de Datos Bombas SumergiblesDocument7 pagesHoja de Datos Bombas SumergiblesRicardo BarrosNo ratings yet

- Ds Fluor BasfDocument4 pagesDs Fluor BasfAnil KumarNo ratings yet

- Kirloskar Domestic PumpsDocument26 pagesKirloskar Domestic PumpssandystaysNo ratings yet

- 001 PumpDocument20 pages001 PumpMohà MedNo ratings yet

- Preventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)Document25 pagesPreventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)mukesh ojhaNo ratings yet

- Centrifugal Pumps List of Possible Causes of Failure 1610329837Document1 pageCentrifugal Pumps List of Possible Causes of Failure 1610329837Marcos Marcandali de JesusNo ratings yet

- Uvents 2021 CatalogDocument92 pagesUvents 2021 CatalogTevfik KurtulusNo ratings yet

IOM HE-10825C, X Motor O&M

IOM HE-10825C, X Motor O&M

Uploaded by

maryadiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IOM HE-10825C, X Motor O&M

IOM HE-10825C, X Motor O&M

Uploaded by

maryadiCopyright:

Available Formats

HE-10825

5 5) Insulation resistance should be measured between each power terminal

U, V, W and the motor frame. The resistance should be 100 M ohms or more.

Never try to check insulation resistance between power terminals.

C) Reassembly

After cleaning parts, assembling can be made in the reverse manner of

disassembly. Assembly always requires adjustment. Pay attention to the

following:

1) In order to lock Shaft Sleeve (17) against rotating movement, Key (58B)

or Pin (60) is provided. (shown in the supplementary figure for Table 2)

2) After inserting Shaft Sleeve (17) (rear side), screw in Bolt (46E) and

lock the shaft sleeve with Lock Washer (57B).

3) When the stator and rotor are reassembled by using the same parts, the

gap in axial direction of Rotor Assembly (19) shall be within the range

indicated in the following table. If the bearing and the thrust collar wear

in the axial direction, playing gap becomes bigger. When the gap is less

than the limited value, they are reusable. For a new bearing, if the gap

is not within listed values, adjust gap using adjusting washers (55C) in

the rear bearing housing.

Table 3 PLAYING GAP OF ROTOR IN AXIAL DIRECTION

Motor Frame No. New Bearing Gap limit

210 1.9 - 2.1 mm / 0.075 - 0.083" 3.2 mm / 0.126"

310 1.9 - 2.1 mm / 0.075 - 0.083" 3.2 mm / 0.126"

410 2.3 - 2.5 mm / 0.091 - 0.098" 3.6 mm / 0.142"

510,420 2.7 - 2.9 mm / 0.106 - 0.114" 4.0 mm / 0.157"

610,520 2.8 - 3.0 mm / 0.110 - 0.118" 4.1 mm / 0.161"

620 3.2 - 3.4 mm / 0.126 - 0.134 4.5 mm / 0.177"

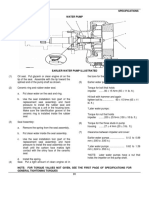

4) Adjustment of the Impeller Axial Gap

For standard type, adjust the gap "g" with pulling impeller forward as

shown in Fig. 3 with Adjusting Washer (56) to the following values. For

TBL type, adjust the gap "g" with pushing impeller backward to

0.5 ± 0.1 mm with Adjusting Washer (56).

Figure 3

(Standard Type) (TBL type)

g±0.1 (mm)

(5) Tighten Impeller (02) and bend Lock Washer (75A) to prevent loosening of impeller bolt.

(6) Clean gaskets.

(7) Teflon seal tape for nipples and plugs should be renewed.

You might also like

- Serie 60 Informacion AdicionalDocument51 pagesSerie 60 Informacion AdicionalMauricio Campos Quiros100% (1)

- Prueba Resorte de EmbragueDocument2 pagesPrueba Resorte de Embraguejohan gomezNo ratings yet

- CH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsDocument46 pagesCH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsEnrrique LaraNo ratings yet

- 3500 ENGINE Specifications Pistons and RingsDocument5 pages3500 ENGINE Specifications Pistons and RingsVan Phuc ThaiNo ratings yet

- AA02193C STRG Pin Wear Checks and SizesDocument8 pagesAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteNo ratings yet

- Clearances Mentioned in Manual.Document3 pagesClearances Mentioned in Manual.AshishNo ratings yet

- Fuel Injection Equipment: EspecificacionesDocument29 pagesFuel Injection Equipment: EspecificacionesSergio Ricardo Ibañez100% (1)

- DisassemblyDocument8 pagesDisassemblyEdson CRNo ratings yet

- Roller Circle - Check and AdjustDocument3 pagesRoller Circle - Check and AdjustGilney FreitasNo ratings yet

- Point Sheave - 1Document2 pagesPoint Sheave - 1Gilney FreitasNo ratings yet

- Informacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297Document13 pagesInformacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297hector100% (3)

- RENR492704Document3 pagesRENR492704Victor NoschangNo ratings yet

- Connecting Rod - Steel Crankshaft PDFDocument6 pagesConnecting Rod - Steel Crankshaft PDFjoaobargasNo ratings yet

- Drive Shaft O&M April 2010Document4 pagesDrive Shaft O&M April 2010elperrote3No ratings yet

- Specifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)Document19 pagesSpecifications For Connecting Rods in 3500 Family of Engines (0761, 0767, 1218)ariel avalos100% (2)

- Connecting Rod: SMCS - 1218 Part Number - 319-7945 S/NDocument5 pagesConnecting Rod: SMCS - 1218 Part Number - 319-7945 S/NsuportethermoNo ratings yet

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- 690 06 Fenner Taper Lock InstallationDocument1 page690 06 Fenner Taper Lock InstallationManhar PanchalNo ratings yet

- Deethanizer Reflux Pump InfoDocument5 pagesDeethanizer Reflux Pump InfoarasNo ratings yet

- C4.4 Medida Cigüeñal PermitidasDocument3 pagesC4.4 Medida Cigüeñal PermitidasLuis GutiérrezNo ratings yet

- Assembly U241E TransmissionDocument29 pagesAssembly U241E TransmissionFirman SuryaNo ratings yet

- SRAM SPECTRO S7 Maintenance - en PDFDocument0 pagesSRAM SPECTRO S7 Maintenance - en PDFkuvalda2000No ratings yet

- SMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesDocument5 pagesSMC-IMG-Specifications For Connecting Rods and Bearings Used in 3600 and C280 Family of EnginesVictor NoschangNo ratings yet

- Acoples TramecDocument26 pagesAcoples TramecAndres ValderramaNo ratings yet

- 140H DAKYFA Differential and Bevel Gear - TestDocument11 pages140H DAKYFA Differential and Bevel Gear - TestDaniel TekleNo ratings yet

- Main Bearing Journal: Shutdown SIS Previous ScreenDocument3 pagesMain Bearing Journal: Shutdown SIS Previous Screenariy yuli styawanNo ratings yet

- Clutch: Workshop ManualDocument38 pagesClutch: Workshop ManualMuslihnofalNo ratings yet

- 1 GRDocument11 pages1 GRGanbileg BatbilegNo ratings yet

- A33 Manual Acople WoochangDocument16 pagesA33 Manual Acople WoochangEduardoNo ratings yet

- Cylinder Head: C15 On Highway EngineDocument11 pagesCylinder Head: C15 On Highway EngineJohan Ricardo HUANCA ESPINOZANo ratings yet

- Cojinetes de Biela y Bancada STD SeleccionDocument5 pagesCojinetes de Biela y Bancada STD SeleccionAlejandro ValenzuelaNo ratings yet

- Datos de Reparacion de Motor Caterpillar c6.6Document21 pagesDatos de Reparacion de Motor Caterpillar c6.6Marcos Astete EgoavilNo ratings yet

- Bawn 004Document4 pagesBawn 004sike1977No ratings yet

- Panewki, Czopy Główne c4.2Document3 pagesPanewki, Czopy Główne c4.2Beniamin Kowoll100% (1)

- HINO US Chap05Document64 pagesHINO US Chap05Andres GomezNo ratings yet

- Calculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesDocument6 pagesCalculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesmkNo ratings yet

- 3500 ENGINE Specifications Water PumpDocument5 pages3500 ENGINE Specifications Water PumpVan Phuc ThaiNo ratings yet

- Maintenance Specifications: 6.1. Tightening TorqueDocument9 pagesMaintenance Specifications: 6.1. Tightening TorqueWshop2 AdminNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocument4 pagesGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковNo ratings yet

- Crankshaft: Shutdown SIS Previous ScreenDocument5 pagesCrankshaft: Shutdown SIS Previous Screenariy yuli styawan100% (1)

- Disc Pack Coupling STCDocument2 pagesDisc Pack Coupling STCYudo ArdianNo ratings yet

- Ser 200 IMDocument5 pagesSer 200 IMshadialameddinNo ratings yet

- Peugeot dw8 Checks and AdjustmentsDocument3 pagesPeugeot dw8 Checks and AdjustmentsAlvaro RochaNo ratings yet

- Calibracion de Valvulas 966H - 01Document5 pagesCalibracion de Valvulas 966H - 01Freddy QuispeNo ratings yet

- Especificação Da BielaDocument5 pagesEspecificação Da BielasuportethermoNo ratings yet

- Especificaciones de Biela CaterpillarDocument2 pagesEspecificaciones de Biela CaterpillarYubiangel Celeste Perugini Parababith100% (1)

- Engine Valve Lash - Inspect - AdjustDocument5 pagesEngine Valve Lash - Inspect - AdjustHAmir Alberto Mojica MojicaNo ratings yet

- Overhaul: 1. Inspect Connecting Rod Thrust ClearanceDocument29 pagesOverhaul: 1. Inspect Connecting Rod Thrust ClearanceEdU RECTIFICANo ratings yet

- Ajuste Valvulas Motor 336DDocument5 pagesAjuste Valvulas Motor 336Djuan sebastianNo ratings yet

- Calculating Cylinder Liner Projection For G3500Document7 pagesCalculating Cylinder Liner Projection For G3500NimNo ratings yet

- 07epa04mbe40005 PDFDocument14 pages07epa04mbe40005 PDFEduardo TorresNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Bearing Fit ChartDocument6 pagesBearing Fit ChartAvinash MamillapalliNo ratings yet

- Torque-Hose ClampsDocument3 pagesTorque-Hose Clampsyoga_jpbmbmNo ratings yet

- MSA5TCD95L5569Document4 pagesMSA5TCD95L5569Ariel PrietoNo ratings yet

- Manual: 292 Engine Kt-150 SeriesDocument20 pagesManual: 292 Engine Kt-150 SeriesSuwan Noo ThomsonNo ratings yet

- Different Types of Combustion Chamber and TurbineDocument13 pagesDifferent Types of Combustion Chamber and TurbineRonoRoa ZoRen100% (1)

- Submersible Sump Pumps 83-TMSS-01, Rev 0Document12 pagesSubmersible Sump Pumps 83-TMSS-01, Rev 0Pageduesca RouelNo ratings yet

- CORRECTDocument60 pagesCORRECTLovely TarunNo ratings yet

- VDZ-Onlinecourse 4 5 enDocument30 pagesVDZ-Onlinecourse 4 5 enAnonymous iI88LtNo ratings yet

- Water Lifting Devices PDFDocument41 pagesWater Lifting Devices PDFSrinathRaghavan0% (1)

- An Investigation On The Performance Characteristics of A Centrifugal CompressorDocument7 pagesAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDNo ratings yet

- Wilo MONOBLOCKDocument10 pagesWilo MONOBLOCKwaseemybNo ratings yet

- Intership 1Document28 pagesIntership 1Abhishek KhandekarNo ratings yet

- Attachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 BoosterDocument1 pageAttachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 Boosterachmadj1405No ratings yet

- 160.73-Eg1 YorkDocument72 pages160.73-Eg1 Yorkmauricio.vidalyork6735No ratings yet

- Roots BlowerDocument2 pagesRoots Blowereko bagus sunaryoNo ratings yet

- Selecting Centrifugal Pumps DataDocument92 pagesSelecting Centrifugal Pumps DataarvindzdenNo ratings yet

- Review of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersDocument12 pagesReview of Parameters Influencing Hydraulic Forces On Centrifugal ImpellersHosseinNo ratings yet

- Fan Installation GuideDocument50 pagesFan Installation GuideGohds100% (1)

- Axiblade: One System For All Applications?Document12 pagesAxiblade: One System For All Applications?wai_shengNo ratings yet

- Agitator DesignDocument9 pagesAgitator DesignDeepika100% (1)

- PMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetDocument2 pagesPMP-901 & 902 - 2. DSGN-SP-0005 Glycol Pump - MHN-12-02TN - DatasheetfarhaNo ratings yet

- Water WastewaterDocument20 pagesWater WastewaterterryjoseeNo ratings yet

- LRN-JRN ENG 50HzDocument16 pagesLRN-JRN ENG 50HzJoséTorres100% (1)

- Comparision of PDFDocument9 pagesComparision of PDFSmith Salazar AscueNo ratings yet

- Naffco Listed Fire Pumps 2900 RPM: 1-1/2" BS 336 MaleDocument12 pagesNaffco Listed Fire Pumps 2900 RPM: 1-1/2" BS 336 MaleGUNABALANNo ratings yet

- Subaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceDocument88 pagesSubaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceEdgardo M. Diolola100% (1)

- Costs of EqpmentsDocument7 pagesCosts of EqpmentsNishithNo ratings yet

- Hoja de Datos Bombas SumergiblesDocument7 pagesHoja de Datos Bombas SumergiblesRicardo BarrosNo ratings yet

- Ds Fluor BasfDocument4 pagesDs Fluor BasfAnil KumarNo ratings yet

- Kirloskar Domestic PumpsDocument26 pagesKirloskar Domestic PumpssandystaysNo ratings yet

- 001 PumpDocument20 pages001 PumpMohà MedNo ratings yet

- Preventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)Document25 pagesPreventive Maintenance of Hydraulic Pumps and Motors: Induction/Refresher Drilling Training Programme Foreman (Drilling)mukesh ojhaNo ratings yet

- Centrifugal Pumps List of Possible Causes of Failure 1610329837Document1 pageCentrifugal Pumps List of Possible Causes of Failure 1610329837Marcos Marcandali de JesusNo ratings yet

- Uvents 2021 CatalogDocument92 pagesUvents 2021 CatalogTevfik KurtulusNo ratings yet