Professional Documents

Culture Documents

Saratoga MArketing

Saratoga MArketing

Uploaded by

San JivCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saratoga MArketing

Saratoga MArketing

Uploaded by

San JivCopyright:

Available Formats

PIPER FLYER ASSOC IATION

PO BOX 6203 PRSRTSTO

ALTADENA, CA 91003 US POSTAGE

PAID

PERMIT NO 5377

DENVER , CO

CHANGE SERVI CE REQUESTED

<>"/;bb~- .

"70.,..~

..

SARATOGA SCHOOL:

Buying and maintaining a Saratoga doesn't have

to be confusing, provided you have all the facts.

_.> 3&• MARCH 2015

As Jennifer Dellenbusch writes in her

model history "Saratoga Tale: PA-32

tangents" featured in the October 2013

issue of this magazine, the Saratoga has

a confusing history. It evolved from two

other Piper PA-32 models-the Lance and

the Cherokee Six-but the company later

adopted the Saratoga name for all PA-32s.

Today, prices ·for a Saratoga can range

anywhere from $100,000 for early 1980s

models to over $350,000 for a glass panel

Saratoga. When you have this kind of

price spectrum, it's probably a good idea

to find someone who knows the model

very well to ensure a rewarding acquisi-

tion experience.

Meet The Saratoga King

Bartelt Aviation in Sturgis, Mich. is wide-

ly known for specializing in the PA-32 line,

and is the world's leader for Piper Saratoga

sales. When we spoke in late .January,

Bartelt himself- who's known as "The

Saratoga King"-was preparing the deliv-

ery of the company's 4·28'" Saratoga.

Bartelt has fo und that 'havi ng aircraft

sales associated vvith his maintenance

busi ness makes each segment stronger-

a checks-and-balances approach, if you

will. He and his staff of three IAs have

surveyed a lot of Saratogas, and they

01

often find that maintenance practices

on the aircraft are not up to par. "The

single biggest issue [in the inspection of

a Saratoga] is t he quality of the mai nte-

nance," Bartelt said.

When an aircraft meets or exceeds

the maintenance stand ards, and t he

sales pri ce is fair to all parties involved,

Bartelt said, it can be a win-vvin.

"Ou r Aircraft Acq ui sition Consulting

Program ensures our clients get a solid

aircraft that's a irworthy at the correct

entry point," he exp lained. That strategy 01 A close'UJJ ofthe TI0-540-AHlA

has workecl - 4·28 times. engine ·i nstalled in a 2001 PA-32R-

30I T Saratoga II TC.

Pre-purchase and annual costs

The typical Saratoga buyer is a small 02 17w vanel qfthis 2002 PA-32R-

business owner or an executive buying fo r 301T Turbo Saratoga II TC has been

personal use. Bartelt advises not to buy this heavily updated w'ith several vrocl-

airplane on you r own. He encourages th e v.cts ji·om Garmin, including a G500

use of an acq uisit ion specialist that is sea- PFD with synthet·ic v·ision, a GMA-35

soned in dealing wit h pre-owned aircraft. audio panel with six-place intercom,

Bartelt also cautioned me that "just plus GPS, transponde1; XM weather

because a seller's as king price is attrac- and a coll-ision avo'iclance system..

tive, it might not be a good deal." Any

buye r needs to bear in mind that the 03 A view qf the club seating offered in

cost to buy and repair a particular the rear cabin qfa 2001 PA-32R-301T

airplan e may exceed the cost of a com- Saratoga fl TC.

pletely different ai rcraft with all of that

work already acco mplished.

And even if the logs show that a lot

of work is already done, it takes time to

evaluate an aircraft properly. "A pre-buy

PIPER FLYER » 40 « MARCH 2015

Cracked Oxygen Support Brackets

Bartelt Aviation is finding craclcs in

oxygen support brackets on 1980 to

1987 Turbo Saratoga SPs. To.fix the

issue, old braclcets need to be drilled

out and new ones riveted in place.

OJ The l<;fi-hand

·i nside support braclcet.

02 The right-hand

·i nside support bracket.

03 Th'is photo shows the

vert'ica.l craclc in the support

on the pilot's sidefi'01n the

forward encl.

0 4·A photo illustrating the

view.from the aft side.

isn't a six or eight-hour deal ; it's more ment. "We find these brackets cracked on

like two or three days;' Bartelt explained. many of the 1980 to 1987 Turbo Saratoga Plastics Custom Interior Installation Carpet Aircraft Insulation

"On average, we find $15,000 to $25,000 SPs," Bartelt informed me. If it's not fixed ,

wrong with a single-engine aircraft:' you risk cracki ng of the fuselage side skins.

Keep in mind, t he average annu al It takes about eight hours of labor to

inspection and mai ntenance on a drill out t he cracked brackets and rivet

Saratoga can cost $5,000 to $8,000-and new units in place. Each vertical bracket

that's if the aircraft is "already straight- costs about $70, and there are four brack-

ened out;' Bartelt said. Beware of any ets. Additional labor is needed to remove

mechanics who want to charge too-good-to- and replace the rear bulkhead and oxygen

be-true prices for an annual, he cautioned. bottle to gain access.

"I can teII yo u, that aircraft probably won't

pass the pre-buy inspection proce s:' Landing gear Ul

(/)

L...

c:

Bartelt and his crew often find that Q) ::s

Common service issues landing gear bush ings, bolts, and bearings >

0 <

If you're considering a Saratoga, it's a are out of tolerance. When this occms it

good idea to have an understanding of the should be add ressed, or you increase your

u (/)

0

..c: -,

(/)

common service issues so that the aircralt chances of a gear coll apse and/or retrac- (/)

is as safe and sound as possible. tion issues.

co

0

John Bartelt was very willing to pass The cost to rebuild the main landing

along his find ings about certain systems gear is around $2,500 per side; $1,500

in the Saratoga and share cost informa- for the nosegear. To avoid frequent Ul

Accessories m

tion with Piper Flyer readers. Some of replacement of parts, Bartelt recorn mends 3:

these areas are the subject of Service that the landing gear be serviced and -0

Bulletins, while some are not. Each of the lubricated every 100 hours. -,

0

issues along with general prices for repair 0..

are listed below. Nosegear trunnions

L...

c:

A nosegear trunnion with excessive

0

0 ,..,.

n

(/)

Cracked o.xygen support brackets play can sometimes be adequately greased

u..

Bartelt is finding cracks in 0>..-ygen sup- and/or shimmed in order to eliminate

ports, prompting t he need for replace- excessive forward and alt play, but not 3161 College Blvd. Alva, OK 73717

PIPER FLYER » 42 « MARCH 2015

Service Bulletin 1006 - Corrosion Inspection of Main Spar

R eports q/ sign:ificant corrosion

on the spar cap behind the.fuel tanks

·i nPA-28 and PA-32, eries aircrqft

prompted the 'issuance ofService

Bulletin .Z00 6 ·i n 1997.

0 1 '171.is bulletin requires around

2.'J hours q/labor to complete.

If corrns'ion is m ·issed, a loss q/

structural integrity ·i n th e :;7xtr

can result.

02 Thefitel tan/cs are removed

as part of this recu:1ring inspection.

03 7/w lfifl hand.fiwl tank removed

.fi'om a 1985 P.11 -32R -30J'l'.

i5 04 The right; hand.Ji.tel tanlc removed

.fi'om, a 1985 PA-32 R-301T'.

u

0

always, acco rding to Bartelt . If not, a set '1·9.25 may develop a crack, located ve rti- 0

.r:;

a..

of new inner and outer nose trunnions cally along the bend radius of the fl ange

can cost nearly $11·,000. common to t he main wing spar and the

side brace attach fi tting."

Service Bulletin 1006 Bartelt mys h e h as seen evidence

In 1997, Piper Ai rcraft issued a Service of these ribs cracking, and if it's not

Bull etin directing se rvice profess ionals addressed, the crack could exceed t he

to inspect fo r co rrosion of t he main spar effective ness of the repair kit. The kit

behind the fu el tanks. This recurring costs less than $350, but between 12 a.nd

inspection was prompted by "reports of 16 hours ufl abor per side are needed in

corros ion on the spar cap due to fu el leaks order to complete t he installation.

behind t he fuel tanks in PA-28 and PA-32 The price of not doing it? "If the crack

series aircraft," acco rding to t he bulletin . goes too fa.r, yo u're looking at wing spe-

Bartelt says he has never fo und signifi- cialist work;' says Bartelt. "The whole rib

cant issues with a spar when complying might require repl acement:'

with this bulletin, bu t did say SB 1006 is

wo rth doing because it allows t he owner Service Bullet·i n 1216B

to replace t he rubber fuel inte rconn ects, Piper considers this inspection f"o r a.ile-

replace fuel ve nt lines and protect the ro n rib cracks mandato ry. The document

spar with a rust protection product like states, "ove r ti me, cracks may develop in

Dinotrol. It also allows the service ·facility the aileron nose ri b common to the out-

to repair any leaking ri vets on the back board aileron hinge fitt ing. Left undetect-

offuel tanks t hat are imposs ible to see ed, t hese cracks may lead to separation of

unless the fu el tank is removed. Cost to t he hinge fi tting from the nose rib ... ". The

repair is about $500 in parts and about inspection (and, if needed, repl ace ment)

25 to 30 hours ofl abor. is fo r both the left and right sides.

Bartelt explains furt her. "There are

Nichole Hoppe, Service Bu lletin 1161 two ri vnuts-female receptacles fo r

Aviation Division Not everyo ne completes the work on bolts-these go in to th e rib fo r the aile-

Client Services this Service Bulletin that was issued on ron attach arm mounting. The majority

March 8, 2006, even though it covers the of the Saratoga aileron ribs we inspect

nhoppe@

maj ority of the retractable Piper aircraft, are cracked," h e said . To change the rib,

forestagency.com

Bartelt told me. the cost is abo ut $900 per side, plu s two

This document was prompted afte r the hours per aileron.

A FRIENDLY PLACE TO DO BUSINESS. finding that "the rib assembly on the aft "We've [even] fo und th em cracked

side of the main wing spar at wing station where the Service Bull etin does n't cover

PIPER FLYER » 44 « MARCH 2015

it -and the only way to see it is to remove Sources: "Saratoga Tale: PA-32 tangents," by

Service Bulletin 1161- Rib Assembly Inspection &Modification

~

bolts a nd paint at the focus area," Bartelt Jenn ifer Dellenbusch, Piper Flyer October 2013;

• ~

explained. The aileron rib can also be "Piper Saratoga: 1980-Present," Plane & Pilot

cracked at t he inside location, which is online. pub. 2001.

not visible. "If the ai lero n attach a rm were

Heather Skwnatz is managing editor.for Continental Lycoming

let loose;' he said, "the aileron wou ld most

Piper Flyer. Send questions O'I' comments

likely leave t he ai rcraft!"

Overhauled eng·ines

to editor@p·ipe1.flye1:org. Ca.tS'ttJIK £91/re o~e~~aa.f'

The quality of a n engine overhaul is

extremely important. Bartelt advises that RESOURCES >»>> "THE top-rated shop"

you make sure to get a two- or t hree-year - Aviation Consume1~ June 2013

Bartelt Aviation, Inc.

warranty and stresses the use of a new

8arteltAviation.com

camshaft, not a reg rin d. This practice, he Call Herman or L.J. 800-204-0735

says, can mean the engin e has better odds Website zephyrengines.com • E-mail zephyrengn@aol.com

Service Bulletins

of not making metal before the recom-

SB1006, "Corrosion Inspection of

mended TBO.

Main Spar Behind Fuel Tanks"

He finds that many engine overhaul

PiperFlyer.org/881006

issues are often due to t he us' of reworked

cylinders and can be avoided by spend-

SB1161, "Rib Assembly Inspection

ing a n extra $3,000 fo r the facto ry-new

and Modification, Aft Wing WS 49.25"

cylinder kits. Bartelt also finds issues with

PiperFlyer.org/881161

/fl TERfORS STYLE • COMFORT • SECURITY

engine mounts, including cracks in the welds.

Bartelt Avia tion sends engines out to

SB1216B, "Aileron Rib Inspection"

a specialty shop fo r overhaul, and the n

installs them in-house. "Larry Russell, PiperFlyer.org/8812168

According to Service Bu lletin JJ 6J, 'The ·1ib assembly on the aft side qfthe main wing our directo r of maintenance a nd Vi ·e

spa'!' at wing station 1·9.25 may develop a craelc, located ve'l'tically along the bend radius Pres ident of Aircraft Sales, does the best

oftheflange ...''. engine install I've ever seen. The engine

OJ This photo clearly 'illustmtes the rib crack on the right hand s·ide. 02 ~ftlie crack is compartment looks brand-new after he

,•• ,

small enough, it can be repa·ired with a bracket. 03 A craclc detected ·i n the ll!ft hand side is done!" A quali ty engine ove rh aul wit h

of this 1·ib assembly. 04 This lq_fl hand /cit requfre1; 12to16 hours to install. a detailed in:;tall ation by an experi enced

team can run $55,000 to $70,000.

After every overhau l, Bartelt's staff

Service Bulletin 1216B -Aileron Rib Inspection flie th air ' raft an add itional seven to

lO hours. This is part of t he compa ny's

QC Program and it ensure· their clients

are not t he test pilot after majo r work is

performed on t heir aircraft. A fli ght test

I I

QUALITY

CARPET-MANY

..

1111111

I I-

should be done as part ofreturning the

COLORS

ai rcraft to servi ce, acco rding to the FARs.

"Many maintenance facilitie:· do not PA-32R-301T VINYL

perform fli ght test afte r working on air-

craft," Bartelt said. The reasons fo r that

can vary. Perhaps the shop doesn' t carry

GENERAL CHARACTERISTICS I FLOORING

Engine: (1) Lycoming TI0-540-S1AD or FLOOR MATS

the necessary insurance, or maybe they

-AH1 A, 300 hp (1 ,800/2,000 TBO)

don't have a pilot that's current on their WING MATS

staff. Bartelt recommends yo u m ake sure No. of seats: 7

a ny shop you choose for service:; has a

pilot on staff t hat can perform the necessary

Wingspan: 36 feet, 2 inches

Length: 28 feet, 4 inches

-11• DOGGY MATS

flight tests. He also recommends that you SHEEPSKIN

confirm with the ·facility that its insurance

policy includes non-owned coverage.

T hough the Saratoga may have had a

Height: 9 feet, 6 inches

MTOW: 3,600 pounds 111:ll ENSOLITE

co nfusing chronology, it can be sorted PERFORMANCE .. .AND MORE!

out with a litt le patience, and a lot of

Cruise speed: 177 knots

resourcefulness. And good airp lanes

are defi nitely out the re. If you're in the Range: 730 nm

mar ket for a s ix-seat workhorse with a Takeoff run: 960 feet

A mandatory inspection.for aileron rib cracks is detailed in Service Bulletin 12I6B issued comfortab le rid e, I recommend you do Takeoff (over 50-foot obstacle): 1,420 feet

·i n 2012. OJ A closeup of an aileron rib crack 02 The craclc is more easily seen when you r research , ask qu estions, read all of

Landing roll: 1,700 feet

magn~/ied. 03 A shot qf the aircrqfi: with a cracked aileron 1ib. 01· ln this photo the t he docume ntation , a nd find an ex pert

a'ileron rib has been replaced. to guid e you . 111

II Source: Vref

PIPER FLYER » 46 « MARCH 201 5

PA-32 VARIANTS

PA-32-260 (1965-1978)

Piper's original PA-32 was a sign ificantly

modified version of the PA-28 Cherokee.

PA-32-300 (1966-1977)

CERTAIN BENCHMARKS OF Piper's new Cherokee Six sported a

INNOVATION HAVE TRULY 300 hp Lycoming I0-540-K1A5 engine.

CHANGED THE INDUSTRY.

Aerocet floats are among PA-32R-300 (1976- 1978)

those. Our floats are designed The Piper Cherokee Lance was the

better, made smarter and last

first of the retractable PA-32s and had

longer. With hybrid composite

mater ials you get "on the step "

faster, can carry more cargo

a conventional tail.

...that's what attendees of the Gathering

and they're FAA certified. When

you're ready to take off, we're

PA-32RT-300 (1978- 1979)

The Lance II had a T-tail design.

at Waupaca tell us, year aA:;er year. ..

here to elevate the ex per ience.

PA-32RT-300T (1978- 1979)

The Turbo Lance II was the first SIGN UP &ENJOY

turbocharged single in the PA-32 line.

• Afull slate of seminars

PA-32-301 (1980-1991)

and workshops

A fixed-gear version of the Saratoga

was manufactured for 11 years. • Sunday evening banquet

and many other opportu-

PA-32-301T (1980- 1984) nities for socializing

A turbocharged Saratoga with a fixed

gear was produced on ly in the early to • Raffle prizes

mid-1980s.

ANO

PA-32R-301T (1980- 1987) • Two days of luxury motor

Introduced as the Turbo Saratoga coach transportation to

SP, only 13 of the more than 400 air- EAA AirVenture

craft were made with de-ice boots.

Production stopped from 1988 to 1997.

PA-32R-301 (1980-1992)

The retractable Saratoga SP was in

production for 12 years, but none

were produced in 1991.

11TH ANNUAL GATHERING AT WAUPACA

PA-32R-301 (1994-2006)

JULY 18-19, 2015

The Saratoga II HP model debuted in

1994 and was in production for 12 years.

PA-32R-301T (1998- 2008)

The Saratoga II TC had the option

of a TKS system for de-icing.

PA-32-301XTC (2003-2006)

SPACE IS LIMITED...

Piper's 6XT, a turbocharged fixed-gear

aircraft, was produced for three years. SIGN UP TODAY!

PA-32-301 FT (2003-2008)

The Piper 6X is a non-turbocharged

fixed -gear aircraft. Like its predecessors,

the Saratoga HP, Saratoga TC and 6XT,

it has a 2,000 hour TBO.

800-493-7450 I PIPERFLYER.ORG

Source: Bartelt Aviation , Inc.

Make your hotel reservationsat Comfort Suites Foxfire, 199 Foxfire Drive, Waupaca, WI 54981. Call (715) 942-0500 to book.

You might also like

- Kasawari PL - SowDocument102 pagesKasawari PL - SowRaphael Owusu kyeremateng100% (2)

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- Grundfos Pump CRN2 CRN2G Parts D1101Document6 pagesGrundfos Pump CRN2 CRN2G Parts D1101KrrishNo ratings yet

- Parmac 122 D631468-XDocument31 pagesParmac 122 D631468-XEdisson Santiago Deaza Gómez100% (2)

- Forecasting Crude Oil Prices Using EviewsDocument5 pagesForecasting Crude Oil Prices Using EviewsNaba Kr MedhiNo ratings yet

- Instruction: Se RviceDocument3 pagesInstruction: Se RvicecarlNo ratings yet

- HarmoniumDocument9 pagesHarmoniumSardanapal ben EsarhaddonNo ratings yet

- Part Catalogue Satria HiuDocument56 pagesPart Catalogue Satria HiuAldi KusumawNo ratings yet

- Bottom End Bearing 'B & W'Document4 pagesBottom End Bearing 'B & W'aliakbar tavafiNo ratings yet

- 81745H Basic - Swivel, CS4 7 (963 1338)Document2 pages81745H Basic - Swivel, CS4 7 (963 1338)rwinmillNo ratings yet

- Img 20230501 0002 PDFDocument1 pageImg 20230501 0002 PDFKRISHNA ENGINEERING CO. BHOPALNo ratings yet

- Galv CertificateDocument2 pagesGalv CertificatejaseelNo ratings yet

- Fluorescrnt Capacitor: Value SISDocument28 pagesFluorescrnt Capacitor: Value SISGopalakrishnanNo ratings yet

- Fluorescrnt Capacitor: Value SISDocument28 pagesFluorescrnt Capacitor: Value SISGopalakrishnanNo ratings yet

- 04 ExDocument4 pages04 Exlone_anarchistNo ratings yet

- Assembly Drawing CY8CKIT-028-EPD E-INK: Primary SideDocument2 pagesAssembly Drawing CY8CKIT-028-EPD E-INK: Primary SideAshwin MahoneyNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: Model BDocument21 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: Model BSolofoniaina Ginô ChristianNo ratings yet

- Cameron HC 18 750 15K ConnectorDocument24 pagesCameron HC 18 750 15K ConnectorНикита Промиснкий100% (1)

- P RFCCDocument1 pageP RFCCMihai BancuNo ratings yet

- AWS A5.7-84 Specification For Copper and Copper Alloy Bare Welding Rods and Electrodes R (1991)Document17 pagesAWS A5.7-84 Specification For Copper and Copper Alloy Bare Welding Rods and Electrodes R (1991)HenryNo ratings yet

- TATA Valve ClassesDocument5 pagesTATA Valve ClassesIgnacio Moratinos CastañedaNo ratings yet

- Ward-Beck Systems - M466 Compressor - LimiterDocument54 pagesWard-Beck Systems - M466 Compressor - LimiterHuwJorgannNo ratings yet

- Certificado Guayas Escala Reales MT Ice VictoryDocument2 pagesCertificado Guayas Escala Reales MT Ice Victorycarlomonsalve1No ratings yet

- 31B SeareyLSA - Motor Assembly 914 2014-1-7 PDFDocument41 pages31B SeareyLSA - Motor Assembly 914 2014-1-7 PDFАлексей КрамарNo ratings yet

- 610-9050 Kit-Water Pump GasketDocument1 page610-9050 Kit-Water Pump Gasketma.powersourceNo ratings yet

- DTM04-2P-P007: DT04-3P,, DT06-3S,, A Drc16-70sam,, Drc12-70paDocument9 pagesDTM04-2P-P007: DT04-3P,, DT06-3S,, A Drc16-70sam,, Drc12-70paАндрейNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-0388-B1Document34 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-0388-B1armacaNo ratings yet

- PPRA TenderDocument4 pagesPPRA TenderAzeem YaseenNo ratings yet

- At-Dom24-58-At-Dom24 ManualDocument5 pagesAt-Dom24-58-At-Dom24 ManualJuanNo ratings yet

- GA of Fabric Expansion BellowDocument17 pagesGA of Fabric Expansion BellowEILA545 QAQCNo ratings yet

- Cascade Thinline4port Hydraulic Hose Reel PartsDocument6 pagesCascade Thinline4port Hydraulic Hose Reel PartssandmsolutionsNo ratings yet

- 4PortTHINLINEPartsDocument6 pages4PortTHINLINEPartsbenjaminNo ratings yet

- 4PortTHINLINEPartsDocument6 pages4PortTHINLINEPartsLKNo ratings yet

- Ammunition DataDocument201 pagesAmmunition Datahakan56915691100% (1)

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

- Fire Extinguisher InspectionDocument4 pagesFire Extinguisher InspectionR Sahadeo ReddyNo ratings yet

- Excess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesDocument1 pageExcess Flow Valves For Flange Mounting in Container Service A3500 Series and A4500 SeriesLPG Equipment Consulting and ServicesNo ratings yet

- EngSpecs 360 440 350 454Document1 pageEngSpecs 360 440 350 454api-3721459No ratings yet

- Current Flow Diagram - Basic Equipment From March 2015Document17 pagesCurrent Flow Diagram - Basic Equipment From March 2015Elena BujorNo ratings yet

- Sensores CMP y CKPDocument3 pagesSensores CMP y CKPGggNo ratings yet

- Diesel Kunden Information: Technical DepartmentiDocument3 pagesDiesel Kunden Information: Technical DepartmentimariodalNo ratings yet

- Service Newsletter: Technical SupportDocument2 pagesService Newsletter: Technical Supportdsgarcia26No ratings yet

- RTG Range.: Ready To Go StockDocument56 pagesRTG Range.: Ready To Go StockFercomil S.A.SNo ratings yet

- Parts PRO8000Document17 pagesParts PRO8000Marc BlanchetteNo ratings yet

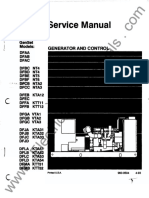

- Service Manual: Generator and ControlDocument92 pagesService Manual: Generator and ControlBrianHazeNo ratings yet

- Pulley 10-In-Gen03 Rev2011Document2 pagesPulley 10-In-Gen03 Rev2011densrxNo ratings yet

- Rev0-Drawing Panel 380V 300aDocument3 pagesRev0-Drawing Panel 380V 300amazdaNo ratings yet

- NO. Description Mat' Q'Ty Unit Total Remark Weight (KG) : P3FH-MS-2405-DTL-2190-008 430/92/DAT/2016Document1 pageNO. Description Mat' Q'Ty Unit Total Remark Weight (KG) : P3FH-MS-2405-DTL-2190-008 430/92/DAT/2016tiantaufikNo ratings yet

- MIL-B-81934 2C Bearings, Self LubricatingDocument5 pagesMIL-B-81934 2C Bearings, Self LubricatingthomasNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 021032-0010-E1Document13 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 021032-0010-E1Jose AltamiranoNo ratings yet

- Parts: ManualDocument12 pagesParts: ManualMike ErftmierNo ratings yet

- Solar SB 16-002Document3 pagesSolar SB 16-002jussmeeeNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09P702-0143-H1Document21 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 09P702-0143-H1claudiobauerNo ratings yet

- TNCMDocument17 pagesTNCMYona Brian OkotNo ratings yet

- VKP - Apartment Schedule 09.01.2024Document14 pagesVKP - Apartment Schedule 09.01.2024shaikh sarfarazNo ratings yet

- Continental PC125-RCD SHOP-IN-A-BOX Quick Start Guide 05142020Document4 pagesContinental PC125-RCD SHOP-IN-A-BOX Quick Start Guide 05142020miguel.angel.garcia.011295No ratings yet

- Drawing Liner 495x495Document1 pageDrawing Liner 495x495Abdul HarisNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-3402-B1Document31 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 219807-3402-B1Rémi GrangeNo ratings yet

- TA300U09Document2 pagesTA300U09Leo Emerson Coronel YurivilcaNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Continental Risque: An Isaac Biddlecomb NovelFrom EverandThe Continental Risque: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (11)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Electric DrivesDocument2 pagesElectric DrivesUmashankar SubramaniamNo ratings yet

- Formulating Specialised Legislation To Address The Growing Spectre of Cybercrime: A Comparative StudyDocument45 pagesFormulating Specialised Legislation To Address The Growing Spectre of Cybercrime: A Comparative Studytech hutNo ratings yet

- 5 23 1e PDFDocument16 pages5 23 1e PDFkats2404No ratings yet

- Ramsbottom Carbon Residue of Petroleum Products: Standard Test Method ForDocument9 pagesRamsbottom Carbon Residue of Petroleum Products: Standard Test Method ForMuhannad NasifNo ratings yet

- Case Study On The Accessibility of The Ninoy Aquino International AirportDocument17 pagesCase Study On The Accessibility of The Ninoy Aquino International AirportaltezNo ratings yet

- CabinetDocument4 pagesCabinetJoan Grace LaguitanNo ratings yet

- Sav-331 PDFDocument5 pagesSav-331 PDFAbolfazl Yousef ZamanianNo ratings yet

- Book 8Document17 pagesBook 8Bernanda Cenank ClaluNo ratings yet

- Women On Board: Evidence From A Masculine IndustryDocument18 pagesWomen On Board: Evidence From A Masculine IndustryAhmad Shah KakarNo ratings yet

- TT Lubricating Oils Greases Shelf Life RecommendationsDocument2 pagesTT Lubricating Oils Greases Shelf Life RecommendationsSanogo YayaNo ratings yet

- Noida Master Plan 2031 DetailDocument104 pagesNoida Master Plan 2031 DetailPuneet RainaNo ratings yet

- Sap Table RefDocument18 pagesSap Table RefArjun GhattamneniNo ratings yet

- TMP Nedjo Jarsao For PrintDocument20 pagesTMP Nedjo Jarsao For PrintGenetNo ratings yet

- All Research Methods - Reading Material (PGS) DR Gete2-2Document326 pagesAll Research Methods - Reading Material (PGS) DR Gete2-2Wassie Getahun50% (2)

- 9.igtr Aurangabad MCCM QualfileDocument23 pages9.igtr Aurangabad MCCM QualfilewarekarNo ratings yet

- Maharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Document58 pagesMaharshi Dayanand University, Rohtak: A Project Report On "E-Commerce"Shivraj CyberNo ratings yet

- GPOADmin Quick Start Guide 58Document25 pagesGPOADmin Quick Start Guide 58Harikrishnan DhanapalNo ratings yet

- Swift Tutorial PDFDocument23 pagesSwift Tutorial PDFShubham GuptaNo ratings yet

- TeamWork Intro Slides For IIT DelhiDocument15 pagesTeamWork Intro Slides For IIT DelhiVIVEK KUMARNo ratings yet

- Mihalis KAVARATZISDocument18 pagesMihalis KAVARATZISPaulo FerreiraNo ratings yet

- Camsco E Catalog PDFDocument384 pagesCamsco E Catalog PDFKelvyn Raqui100% (1)

- Digital Booklet - ArularDocument17 pagesDigital Booklet - ArularMax Coates BurlingameNo ratings yet

- 18MAT41 Question BankDocument17 pages18MAT41 Question BankIbrahim ShaikhNo ratings yet

- Cyber Bullying and The WorkplaceDocument3 pagesCyber Bullying and The WorkplaceIsabel MonicaNo ratings yet

- Courier: Council Pursuing ManufacturerDocument15 pagesCourier: Council Pursuing ManufacturerAnonymous 9eadjPSJNgNo ratings yet

- Claim Duit Thesis JpaDocument5 pagesClaim Duit Thesis Jpaafkofvidg100% (2)

- Newsletter Even 2021-22Document9 pagesNewsletter Even 2021-22Sachin K GowdaNo ratings yet