Professional Documents

Culture Documents

Lifting Operation With Tower Crane

Lifting Operation With Tower Crane

Uploaded by

Lheo PaduaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Operation With Tower Crane

Lifting Operation With Tower Crane

Uploaded by

Lheo PaduaCopyright:

Available Formats

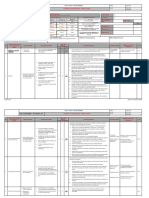

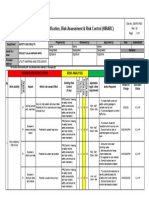

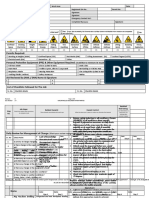

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Lifting Operations with Tower crane

Revision: 0

Overall Task Details Relevant Applicable MAS:

Additional Training required: NOC’s Required for task:

01412 – Lifting Operations; Project Name: xxx

Lifting operations using Tower crane within site boundary

00941 – Lifting equipment Riggers / Slingers As applicable

RA Ref No.: xxx

RISK SCORE CALCULATOR RA compilation

Use the Risk Score Calculator to Determine the Level of Risk of each Hazard Review date:

Date:

What is the LIKELIHOOD of an occurrence? Hierarchy of Controls

What would be the Date:

CONSEQUENCE Frequent/Almost certain (5) Rarely (1) Can the hazard be Eliminated or removed

Often (4) Likely (3) Possible (2)

of an occurrence be? Continuous or will happen Less than once every 5

frequently

6 to 12 times a year 1 to 5 times a year Once every 5 years

years

from the work place? Compiled by:

Catastrophic (5) Can the product or process be substituted for

High 25 High 20 High 15 Medium 10 Medium 5 Reviewed by:

Multiple Fatalities a less hazardous alternative?

Serious (4) Can the hazard be engineered away with

High 20 High 16 High 12 Medium 8 Low 4

Class 1 single fatality guards or barriers?

Approved by:

Moderate (3)

Can Administration Controls be adopted

Class2 (AWI or LTI) or Class 1 High 15 High 12 Medium 9 Medium 6 Low 3

Permanently disabling effects I.e. procedures, job rotation etc.

Minor (2)

Medical attention needed, no work Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment &

restrictions. MTI Clothing be worn to safe guard against

Insignificant (1) hazards?

Medium10 Medium 4 Low 3 Low 2 Low 1

FAI

Specific Task Step Initial Risk

Additional Control

No (In sequence of Hazard Details Consequence/Risk Rating Control Measures Residual Risks RR

Measures

works) P S RR

i. Worker pedestrian routes to be designed and implemented with clear

Collision with plant or vehicles and

signage to provide segregation;

live traffic;

Access of Tower crane Plant and workers in ii. Instruction to workers at induction on use of access routes around the Workers not

Workers struck by plant, very high 12

1 sections to work areas same working area 3 4 project; complying with Regular topic in TBT’s Low

risk of fatality; High

as delivery truck; flagmen

iii. Flagmen to be used to control crane movements;

Uncontrolled crane reversing;

iv. The Logistics plan shall clearly illustrate crane access and egress points;

Excavations; See Risk Assessment 010 –

i. Crane foundations to be designed by approved persons, to clear design

Use of plant – Excavations;

criteria;

Tower crane excavators etc.; 20

2 See Risk Assessment 014 – use of 4 5 Low

foundations High ii. Foundations given adequate curing time before crane erection;

Use of concrete; Mobile Concrete pump;

iii. Temporary Works Coordinator to control excavations and concrete pours;

Temporary Works; Failure due to incorrect design;

i. Ensure crane is erected to standards by trained competent erection

personnel;

ii. No crane erection in adverse weather or high wind speed;

Fall from height;

iii. Concise erection Method Statement compiled and available in work area

Falling materials from height; for review;

Use of untrained erectors; iv. Area below works cleared and barriers implemented;

v. Solid barriers should be situated, where practicable, to protect erected

Works at Height; Erection in adverse weather;

crane from traffic routes;

Siting, setting up and 12 Failure of crash Crane quarantined until

3 Working in proximity Collision with overhead services; 3 4 vi. Consideration given to overhead services and existing structures when Low

testing of Tower crane High detector repaired and tested

to existing structures siting tower crane;

and services; Blocking access routes;

Load striking moving and/or vii. All Tower cranes to be Third Party Certificated by a DM approved

stationary structures; inspector prior to use, documentation available on arrival to site;

Use of untested crane; viii.Load tests undertaken prior to use and available for review;

Use of unqualified operator; ix. Operators to have in-date Third Party certificate by approved body,

available for review;

x. Crane load indicator to be installed and functioning correctly;

xi. Crash detectors installed and functioning correctly;

Page 1 of 2 HSEQ -Rev-01(Aug-2018)

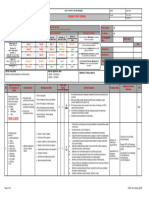

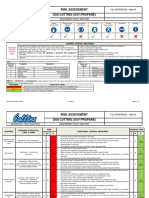

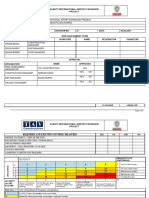

HEALTH SAFETY AND ENVIRONMENT Author: Approved:

Issued: Rev. Date:

RISK ASSESSMENT: ACT/HSE/RA 001 Lifting Operations with Tower crane

Revision: 0

Initial Risk

Rating

i. HLG Minimum Acceptable Standard HLG/OHS/MAS/00941 to be adhered

to at all times;

ii. Lift Plan to be completed prior to any lift taking place by crane supervisor

and engineer;

Incident due to use of defective Machine

lifting gear / equipment; iii. Ensure all lifting tackle and equipment have valid test certificate before breakdown

Specific Task Step Operator competency use (6 monthly 3rd party inspections); Machine isolated and

Lifting of equipmentof Additional Control

No (In sequence Hazard

and Details

health; Consequence/Risk

Crane collapse due to lifting loads Control Measures Residual Risks quarantined until repaired. RR

and material beyond SWL; 20 iv. Method statements and risk assessments to be submitted and adhered to Measures

4 works) 4 5 Low

Lift planning; HIGH for technical and/or non-routine lifts; Hydraulic fluid spill

No crane documentation in place; Spoil removed and treated as

(Tower crane Operator) v. Crane load indicator to be functioning correctly, and not to be overridden hazardous waste

Tower crane operator collapse whilst under any circumstances;

in cab; Operator deemed

vi. Operator to adhere to crane safe working load limits, weight of load and Removed from operation

unfit to operate

COG established before lifting; crane

vii. Tower crane operator subject to regular health checks;

i. Lift controlled by designated trained rigger/banks man using approved

hand signals only;

Persons underneath load struck by

ii. No personnel situated or walking under elevated loads, avoid over-

materials;

sailing of personnel if practicable;

Lifting operations Load swinging / spinning Work stopped, area cleared

iii. No over-sailing of loads over live traffic routes without road closure;

around workers; uncontrolled; and full investigation

iv. No lifts undertaken when wind speed exceeds 40kph; Incident – falling

Tower Crane Falling materials; 20 materials undertaken

5 Workers in crane 4 5 v. No blind lifts without visual and communication aids, radios etc.; Low

supervision Damage to lifting slings from sharp High

operating radius; vi. Tag lines shall be used to guide materials while lifting, 2 lines minimum

edges;

10m in length;

Over-sailing of material over live

vii. Slings protected from sharp edges with rubber etc.;

traffic routes;

viii. Riggers to undertake visual inspection of all lifting equipment daily;

High winds – adverse weather;

ix. Tower crane allowed to ‘weather vane’ in high winds;

i. Ensure crane is jumped or dismantled to standards by trained competent

Fall from height; erection personnel;

Falling materials from height; ii. No dismantling or jumping in adverse weather or high winds;

Jumping and Works at Height; Storage of Designated area established

20 iii. Concise Dismantling Method Statement compiled and available in work

6 dismantling of Tower Use of untrained personnel; 4 5 dismantled clear of access routes Low

High area for review;

Crane material

Dismantling in adverse weather;

iv. Area below works cleared and barriers implemented during jumping or

dismantling;

Page 2 of 2 HSEQ -Rev-01(Aug-2018)

You might also like

- Nutrition and Diet Therapy, 6th Ed (2015)Document697 pagesNutrition and Diet Therapy, 6th Ed (2015)Neomorpheous90100% (2)

- PalmTherapy Program Your Mind by Moshe ZwangDocument751 pagesPalmTherapy Program Your Mind by Moshe Zwangjules6294100% (7)

- Piling Works, Pile Head Cutting and Trimming at Pipe BridgeDocument28 pagesPiling Works, Pile Head Cutting and Trimming at Pipe BridgeAlif Shahril100% (1)

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizeNo ratings yet

- Emergency Case Review: Advanced Cardiac Life Support (ACLS) 2015Document51 pagesEmergency Case Review: Advanced Cardiac Life Support (ACLS) 2015Lely Yuniarti AhqafNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Lifting Operations With Mobile CraneKhalid KhalidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Laying Blockwork With Access ScaffoldingEdwin MofokengNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Sheet Piling Operations (Temporary Works)M ShahzadNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingLheo PaduaNo ratings yet

- 17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bDocument2 pages17trafficoperations Workingonliveroadsriskassessmenttemplates 230419084508 3275aa2bM ShahzadNo ratings yet

- Crane RaDocument6 pagesCrane Ramark jayson yabesNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardSaravanaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardAffin RoyNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument6 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPearl TeresaNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument2 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardPRASAD6219No ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Document2 pagesRisk Assessment: Act/Hse/Ra 001: Use of Suspended Access Cradles and Platforms (Temporary Works)Saravana0% (1)

- Risk Assessment: Act/Hse/Ra 001: Confined Space WorkingDocument1 pageRisk Assessment: Act/Hse/Ra 001: Confined Space WorkingbrandedwahidNo ratings yet

- Risk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each HazardDocument3 pagesRisk Assessment: Act/Hse/Ra 001: Use The Risk Score Calculator To Determine The Level of Risk of Each Hazardshaibaz chafekarNo ratings yet

- 13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558Document6 pages13initialprojectsiteofficeset Upriskassessmenttemplates 200616093558test fypNo ratings yet

- Jsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.Document67 pagesJsa For Installation, Testing and Commissioning of Sewer and Strom Water Drainage System at 14 Nos. of Alijarah Warehouse.jafar mohdNo ratings yet

- Utility Mapping and Site SurveyDocument1 pageUtility Mapping and Site Surveyasr.engineering2023No ratings yet

- Excavator Operation RADocument4 pagesExcavator Operation RAMujahid AyyubNo ratings yet

- Hira Gaurd HouseDocument14 pagesHira Gaurd HouseNagadevan GovindanNo ratings yet

- HIRARC IBS Components Installation Rev 0Document21 pagesHIRARC IBS Components Installation Rev 0Suraindran ManoharanNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Risk Assessment For Split AC UnitsDocument2 pagesRisk Assessment For Split AC UnitsAhmed mahlawy100% (1)

- 209 Using of Angle GrinderDocument9 pages209 Using of Angle GrindergrantNo ratings yet

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Risk Assessment And Analysis رطاخلما مييقت: substation 8902 in HAILDocument4 pagesRisk Assessment And Analysis رطاخلما مييقت: substation 8902 in HAILnavaniNo ratings yet

- Gas Cutting Risk AssessmentDocument3 pagesGas Cutting Risk AssessmentchemjesuNo ratings yet

- Risk AssessmentDocument2 pagesRisk AssessmentNia NovitaNo ratings yet

- DRAFT - HIRARC REGISTER (45637)Document6 pagesDRAFT - HIRARC REGISTER (45637)Leliance Ann BillNo ratings yet

- Fire Risk Assessment Form and GuidanceDocument16 pagesFire Risk Assessment Form and GuidanceTerence PuwakeNo ratings yet

- AML - Job Safety Analysis Form - PilingDocument8 pagesAML - Job Safety Analysis Form - PilingBhagat DeepakNo ratings yet

- Risk Assessment For Excavation and BackfillingDocument5 pagesRisk Assessment For Excavation and BackfillingBulent AkNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- Manual Handling Risk Assessment Form: Department / Service: Location: Date: Assessed By: Signature: Review DateDocument2 pagesManual Handling Risk Assessment Form: Department / Service: Location: Date: Assessed By: Signature: Review DateAbdul RafeequeNo ratings yet

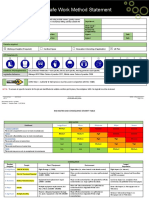

- CHRC SWMS Lifting OperationsDocument6 pagesCHRC SWMS Lifting OperationsvsfchanNo ratings yet

- Risk AssessmentDocument2 pagesRisk Assessmentapi-390974064No ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- RA For OwsDocument1 pageRA For OwsLogesh RajNo ratings yet

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- CRA For Beam Stregthening WorksDocument4 pagesCRA For Beam Stregthening WorksVikki P ReddiNo ratings yet

- Risk Assesment Generic Tender Despatch Electrical DepotDocument10 pagesRisk Assesment Generic Tender Despatch Electrical DepotanishavanloggerenbergNo ratings yet

- Welcome To TÜV Rheinland Vietnam: Risk AssessmentDocument50 pagesWelcome To TÜV Rheinland Vietnam: Risk AssessmentTruong Quang HuyNo ratings yet

- CHRC SWMS Excavation Activities PDFDocument6 pagesCHRC SWMS Excavation Activities PDFBorislav VulićNo ratings yet

- Examples of HIRARC 3Document3 pagesExamples of HIRARC 3fairus100% (1)

- Final Risk Assessment For R1114 ProjectDocument45 pagesFinal Risk Assessment For R1114 Projectvinothsekar6662No ratings yet

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (3)

- Risk Assessment - Breaking ConcreteDocument2 pagesRisk Assessment - Breaking Concretednmule83% (6)

- 4.oetc Hse o CRR F 000 FormatDocument2 pages4.oetc Hse o CRR F 000 FormatTATI HSENo ratings yet

- GEN-038 Balance Turbine Unit - All TypesDocument3 pagesGEN-038 Balance Turbine Unit - All Typesacanbasri1980No ratings yet

- PMF-017-HSE-121 - 02 Manual Handling Risk AssessmentDocument1 pagePMF-017-HSE-121 - 02 Manual Handling Risk Assessmentmuhammad.younisNo ratings yet

- Q209-04 - ENG Supplier Risk AssessmentDocument30 pagesQ209-04 - ENG Supplier Risk AssessmentDiego MatillaNo ratings yet

- Job Safety Analysis FormDocument9 pagesJob Safety Analysis FormBhagat DeepakNo ratings yet

- Hanford Risk Assessment For Glass PartitionDocument5 pagesHanford Risk Assessment For Glass PartitionAbiama FrankNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- KALBEDocument6 pagesKALBEAgness Noviita SariiNo ratings yet

- Lawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesDocument11 pagesLawsuit Against DHEC Seeks Names of Assisted Living Facilities With COVID-19 CasesABC News 4No ratings yet

- Admission Letter 2Document2 pagesAdmission Letter 2tajul50No ratings yet

- Mental Health Nursing.: Lesson 1Document177 pagesMental Health Nursing.: Lesson 1Eng Steve WairuaNo ratings yet

- The Facts On Tweens and Teens and Dating ViolenceDocument2 pagesThe Facts On Tweens and Teens and Dating ViolenceFilipaTorresCostaNo ratings yet

- Pone 0245511Document13 pagesPone 0245511Dr-Akram HadiNo ratings yet

- Different InjuriesDocument2 pagesDifferent InjuriesJailian NagpiingNo ratings yet

- Deliberative Systematic Phase of The Nursing Process That Involves Decision-Making and Problem-SolvingDocument10 pagesDeliberative Systematic Phase of The Nursing Process That Involves Decision-Making and Problem-SolvingLove Jovellanos ÜNo ratings yet

- CBSE Class 10 Term 2 How Do Organisms Reproduce MCQ With SolutionsDocument6 pagesCBSE Class 10 Term 2 How Do Organisms Reproduce MCQ With SolutionsShrideep BoseNo ratings yet

- Total Knee Replacement Oet ReadingDocument19 pagesTotal Knee Replacement Oet ReadingDenit JochanNo ratings yet

- CMS 3000 High Frequency Surgical Unit: FeatureDocument1 pageCMS 3000 High Frequency Surgical Unit: Feature-Nurman Hidayat-No ratings yet

- Safe Work Practices PDFDocument7 pagesSafe Work Practices PDFDheeraj MenonNo ratings yet

- DLL Mapeh Q 3 WK2 Health StraightDocument6 pagesDLL Mapeh Q 3 WK2 Health StraightEdelyn UnayNo ratings yet

- Concept of Environmental Sustainability Awareness Strategies in Pre-Construction StageDocument14 pagesConcept of Environmental Sustainability Awareness Strategies in Pre-Construction StageAnonymous 6FUcbaPNo ratings yet

- TeksolDocument5 pagesTeksolniki fitraNo ratings yet

- Mid Xii IpsDocument12 pagesMid Xii IpsEttyMarini Panggabean 11No ratings yet

- Ca4 - The Use of Enzyme Supplements in Shrimp DietsDocument20 pagesCa4 - The Use of Enzyme Supplements in Shrimp DietsSrivatsava RajagopalanNo ratings yet

- Reading Comprehension 20 March 1Document32 pagesReading Comprehension 20 March 1jpoonia19804No ratings yet

- Construction Safety ChecklistDocument3 pagesConstruction Safety ChecklistbangladragosNo ratings yet

- Bleaching With Without ReservoirsDocument8 pagesBleaching With Without ReservoirsBasil AlNo ratings yet

- MR in Neuro: Clinical Work and Research by Our UsersDocument48 pagesMR in Neuro: Clinical Work and Research by Our UsersJose luis EspinosaNo ratings yet

- 5W Vdec Dinkes 01sd10dec2018 10dec2018Document238 pages5W Vdec Dinkes 01sd10dec2018 10dec2018ihwan Ukhrawi AlyNo ratings yet

- Essay On SexualityDocument6 pagesEssay On Sexualitylud0b1jiwom3100% (2)

- Module 6-Key Attributes of Cost AnalysesDocument3 pagesModule 6-Key Attributes of Cost AnalysesLou CalderonNo ratings yet

- Behavior Intervention and Support Plan (BISP)Document5 pagesBehavior Intervention and Support Plan (BISP)api-379946201No ratings yet

- Identification, Assessment, and Intervention - IeDocument8 pagesIdentification, Assessment, and Intervention - Ieroshni tripatiNo ratings yet

- Biomaterials Syllabus Fall 2014 UpdatedDocument4 pagesBiomaterials Syllabus Fall 2014 UpdatedEileen LyNo ratings yet