Professional Documents

Culture Documents

Heating Schedule For Castable Dry Out

Heating Schedule For Castable Dry Out

Uploaded by

ArvindCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heating Schedule For Castable Dry Out

Heating Schedule For Castable Dry Out

Uploaded by

ArvindCopyright:

Available Formats

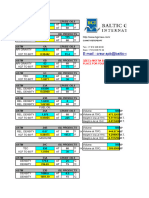

Bravo Sponge Heating Schedule

Sl no. Heating schedule(350 tpd ) Hrs Cummulative Time Temp in deg.c

After completion of castable lining keep DRI kiln as such for air drying for at least

1 24 hrs. After 24 hrs. kiln can be rotate for air tube fitting.Pls. don't hammer the kiln 0 0 0

shell during inserting of airtube inside kiln.

Wood firing to be done at cooler Inlet for 72 hrs. (At Cooler Inlet)

2 0 0 70

kiln rotation 1/4 th in every 2 hr.

3 Raise the temp from 70 0 C to 130 0 C @ 15 0 C/hr. 0 4 130

4 Soak at this temp. for 48 hrs. 48 52 130

0 0

5 Raise the temp. to 250 C @ 20 C/hr. 6 58 250

6 Soak at this temp. for 48 hrs. 48 106 250

7 Raise the temp. 350 0C @ 250C/hr 4 110 350

8 Soak at this temp for 36 hrs 36 146 350

9 Raise the temp 350 to 550 deg.c @ 40 deg.c 5 151 550

10 Soak at this temp for 36 hrs 36 187 550

Raise the temp from 550 to 750 deg. C by charging 300 to 350 kg coal fines &

11 HSD ( Kiln should be in rotation in auxilary drive after 550 deg. C ) HSD flow 8 195 750

rate to reduce slowly after coal fines catches fire.) Soak at this temp for 8 hrs.

Check Hot gas temp. of T -11, T-10, T-9 in every one hr. Avg. temp to be noted down. Hot gas

Total 195 hrs

temp at inletside should be 350 0 C & more during soaking at 550 deg.c.

Note:Depending upon F.C % in coal, Fines to be feed during raising from 550 deg.c to 750 deg.c & Soaking. If F.C is ( 35 -

40%) then feed 300-350 kg. approx in every 2 hrs. of interval.If F.C is (45-55 %) feed rate will be 200-250 kg in every 2 hrs.

of interval. After soaking at 750 to 800 deg. c feed rate of fine coal can be increased upto process temp.

Fuels recommendation

0

Raise temperature upto 550 C by firing HSD or LDO inside the kiln,after that coal

1 fines & HSD/LDO to be used. HSD/LDO flow rate to be reduce slowly after coal

fine catches fire.

2 Raise temperature upto operating temperature by coal fines after 750 deg.c.

Dry out schedule for 350 tpd DRI Kiln

a) From kiln temp 70 deg.c to 130 deg.C @ 15 deg.C/hr.------4 hrs.

b) Hold at 130 deg.C for 48 hrs-------- 48 hrs (Kiln rotation 1/4th in every 2 hr)

c) From 130 deg.C to 250 deg.C @ 20 deg.C/hr.-------6 hrs

d) Hold at 250 deg.C for 48 hrs-------48 hrs (Kiln rotation 1/4th in every 2 hr)

e) From 250 deg.C to 350 deg.C @ 25 deg.C/hr------4 hrs

f) Hold at 350 deg.C for 36 hrs-----36 hrs (Kiln rotation 1/4 th in every 2 hr)

g) From 350 deg.C to 550 deg.C @ 40 deg.C/hr.------5hrs

h) Hold at 550 deg.C for 36 hrs---36 hrs (Kiln rotation 1/4th in every 2 hr)

I) From 550 deg. C to 750 deg.c- 8 hrs.(Continue kiln rotation in main drive)

Dry-Out Schedule

800 750

700

600 550 550

500

TEMP. IN C

400 350 350

300 250 250

200 130 130

70

100

0

0

0 0 4 52 58 106 110 146 151 187 195

TIME IN HR

You might also like

- Kiln Start Up Procedures PDFDocument12 pagesKiln Start Up Procedures PDFfaheemqc100% (2)

- GMP Dolphin-G SeriesDocument1 pageGMP Dolphin-G SeriesNenad AndjelkovicNo ratings yet

- Alloy Process Data Sheet - 105-85Document3 pagesAlloy Process Data Sheet - 105-85Ugur KayaNo ratings yet

- PWHT of P91Document7 pagesPWHT of P91Howo4Die100% (4)

- Portland Cement - Composition, Production and PropertiesDocument234 pagesPortland Cement - Composition, Production and Propertiesanon_748334526100% (3)

- Partial Heating Schedule - 350TPD KilnDocument3 pagesPartial Heating Schedule - 350TPD KilnbijayaceNo ratings yet

- Microsoft Word - 50-3100RDocument2 pagesMicrosoft Word - 50-3100RTan SoNo ratings yet

- Heat-Up Schedule As Per RequirementDocument1 pageHeat-Up Schedule As Per RequirementVijay BhanNo ratings yet

- D&H-301 Rev 4 Golite XXX & XXX GMDocument1 pageD&H-301 Rev 4 Golite XXX & XXX GMخربوش سماعينNo ratings yet

- Fired Heater Decoking StepsDocument2 pagesFired Heater Decoking StepssaadNo ratings yet

- HOVAL Dati Tecnici Caldaie IngleseDocument57 pagesHOVAL Dati Tecnici Caldaie Ingleseosama alabsiNo ratings yet

- Kaolite Insulating CastablesDocument2 pagesKaolite Insulating CastablesChan Keng ChunNo ratings yet

- DHA World Heat TreatDocument4 pagesDHA World Heat TreatMichael KrummNo ratings yet

- Cement Mill BehaviourDocument3 pagesCement Mill Behaviourhmaza shakeelNo ratings yet

- Vac Arc PDFDocument2 pagesVac Arc PDFX800XLNo ratings yet

- Tratamientos Térmicos AluminioDocument1 pageTratamientos Térmicos AluminioOctvo Lzd FlNo ratings yet

- Production of Biochar From Sheep BonesDocument17 pagesProduction of Biochar From Sheep BonesNizar MousaNo ratings yet

- Instruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerDocument20 pagesInstruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerLuis Gomez JimenezNo ratings yet

- Oil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceDocument6 pagesOil-Hardening Cold Work Tool Steels (0 Series) : Recommended Heat Treating Practice Recommended Processing SequenceJonathan JuarezNo ratings yet

- HeatTreatments PDFDocument2 pagesHeatTreatments PDFleosac6No ratings yet

- Heat TreatmentsDocument2 pagesHeat TreatmentsRandy FajardoNo ratings yet

- DH31-EX Heat TreatDocument4 pagesDH31-EX Heat TreatMichael KrummNo ratings yet

- Manual de OperacionDocument34 pagesManual de OperacionEdgar Barrios JNo ratings yet

- Inva Tubular1Document2 pagesInva Tubular1venkat22eshNo ratings yet

- 1 2344 PDFDocument2 pages1 2344 PDFtayefehNo ratings yet

- WWW Matweb Com Search Datasheet Print Aspx Matguid E30d1d103Document3 pagesWWW Matweb Com Search Datasheet Print Aspx Matguid E30d1d103Vijay PalNo ratings yet

- A10Document3 pagesA10giulior89No ratings yet

- Glycol FAQDocument2 pagesGlycol FAQSakib ShaikhNo ratings yet

- Force Cure Schedule Thermaline 450 Novolac 04302014Document1 pageForce Cure Schedule Thermaline 450 Novolac 04302014huycongvuNo ratings yet

- S.Pathak & N.K Gupta: Heat TreatmentDocument2 pagesS.Pathak & N.K Gupta: Heat TreatmentdgpkidNo ratings yet

- BURNOUT (Lecture by DR - Muhammad Seddeek @AmCoFam)Document26 pagesBURNOUT (Lecture by DR - Muhammad Seddeek @AmCoFam)AmericanCornerFamilyNo ratings yet

- 9 BTU Heat Requirement TableDocument1 page9 BTU Heat Requirement TableJan LerNo ratings yet

- Furnace A Shut Down InstructionsDocument1 pageFurnace A Shut Down InstructionsHb MeoNo ratings yet

- Beijing BF SeminarDocument36 pagesBeijing BF SeminarAnaruzzaman Sheikh100% (2)

- Experiment 2 E H T M P: IcrostructureDocument1 pageExperiment 2 E H T M P: Icrostructureafnene1No ratings yet

- Ultra-Green 45: Product DataDocument1 pageUltra-Green 45: Product DataWatashi Wa Abilene RockanLoverNo ratings yet

- Milk Cooling CalculationsDocument10 pagesMilk Cooling CalculationsAshraf N HaniaNo ratings yet

- Heating Up Curve-Kiln BurnerDocument2 pagesHeating Up Curve-Kiln Burnerclau100% (1)

- Week 13Document27 pagesWeek 13josewilliam85No ratings yet

- Ruben Rega 0806331960Document9 pagesRuben Rega 0806331960rubenrega_1No ratings yet

- Boiler Refractory Dry Out PDFDocument2 pagesBoiler Refractory Dry Out PDFBoiler Scrubber100% (1)

- CPM Magnacut - Technical Data: Your in Specialty MetalsDocument2 pagesCPM Magnacut - Technical Data: Your in Specialty MetalscpNo ratings yet

- Therminol-55 Physical Properties-MergedDocument16 pagesTherminol-55 Physical Properties-MergedRahul S. ChandrawarNo ratings yet

- Morflor 160 165x 170 Low Cement-NewDocument3 pagesMorflor 160 165x 170 Low Cement-NewLucas de Brito NascimentoNo ratings yet

- Heatreatment Evaluation ReportDocument14 pagesHeatreatment Evaluation ReportFelizarta Ell JessieNo ratings yet

- Rolling Procedure For Turbine (CPP)Document8 pagesRolling Procedure For Turbine (CPP)Dhanesh DubeyNo ratings yet

- Boiler Refractory Dry-Out ProcedureDocument2 pagesBoiler Refractory Dry-Out ProcedurePark JunyoungNo ratings yet

- Kiln Heat-Up, Optimun Kiln OperationDocument42 pagesKiln Heat-Up, Optimun Kiln OperationJoko Dewoto100% (11)

- Refrigeration and Cold Storage: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerDocument27 pagesRefrigeration and Cold Storage: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerBilly AgustinNo ratings yet

- Bro Celtra Duo Firing en VfinDocument8 pagesBro Celtra Duo Firing en VfinEidy A HerasNo ratings yet

- Aisi A10Document2 pagesAisi A10123vigenNo ratings yet

- Standard Test Method For Major and Minor Elements in Combustion Residues From Coal Utilization ASTM D3682Document3 pagesStandard Test Method For Major and Minor Elements in Combustion Residues From Coal Utilization ASTM D3682ikhsanNo ratings yet

- BG42 Data SheetDocument0 pagesBG42 Data SheetTroy AshcraftNo ratings yet

- 94 PDFDocument8 pages94 PDFNancy Carolina Prieto MartinezNo ratings yet

- Api Astm TableDocument3 pagesApi Astm TableBlessing OjeaburuNo ratings yet

- Renolin ThermDocument1 pageRenolin ThermFarhan TamjidNo ratings yet

- Furnace TempDocument4 pagesFurnace TempjekiranNo ratings yet

- Upgradation of Unit I & Ii: Based On Recommendation by Mr. Larsen and Reviewed by BCLDocument7 pagesUpgradation of Unit I & Ii: Based On Recommendation by Mr. Larsen and Reviewed by BCLritesh shrivastavNo ratings yet

- PLANT UPGRADATION LarsenDocument7 pagesPLANT UPGRADATION Larsenritesh shrivastavNo ratings yet

- 4 Vertical Shaft Brick Kiln (VSBK) PDFDocument4 pages4 Vertical Shaft Brick Kiln (VSBK) PDFhoangpalestineNo ratings yet

- Bespoke Benchmarking PDFDocument2 pagesBespoke Benchmarking PDFDurga PrasadNo ratings yet

- Bze Report Rethinking Cement WebDocument98 pagesBze Report Rethinking Cement WebSoniaSegerMercedesNo ratings yet

- PG 1591-1634 Chap5-RawMealHomogenization TextDocument44 pagesPG 1591-1634 Chap5-RawMealHomogenization TextMKPashaPasha100% (3)

- Status of Sponge Iron Plant in OrissaDocument36 pagesStatus of Sponge Iron Plant in OrissachiranjibdcNo ratings yet

- 01.02 Doctrine Raw MixDocument2 pages01.02 Doctrine Raw Mixrupesh soniNo ratings yet

- Cementing Materials: Semi-Finished ProductDocument7 pagesCementing Materials: Semi-Finished ProductMD.MOSHIUR RAHMANNo ratings yet

- In Thailand: - WWW - Skf.co - TH - 44 - ! 18 - " # 2548Document24 pagesIn Thailand: - WWW - Skf.co - TH - 44 - ! 18 - " # 2548Tan JaiNo ratings yet

- Electrostatic PrecipitatorsDocument62 pagesElectrostatic Precipitatorsking1q100% (1)

- CEMENTDocument77 pagesCEMENTLeecel CalugayNo ratings yet

- Role of RDF in SDGsDocument16 pagesRole of RDF in SDGsANo ratings yet

- Media - Brochures - Brochures For Kilns and Firing - HRBMFloreslowresDocument4 pagesMedia - Brochures - Brochures For Kilns and Firing - HRBMFloreslowresOmar Jesus CocaNo ratings yet

- Corrosion and Protection of Reinforced Concrete 2021Document403 pagesCorrosion and Protection of Reinforced Concrete 2021lilopezNo ratings yet

- Cement ManufacturingDocument25 pagesCement ManufacturingHimanshu PalNo ratings yet

- Horsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersDocument4 pagesHorsepower To Drive Rotary Kilns, Cooler or Dryer by Allis ChalmersTsakalakis G. Konstantinos100% (2)

- US6767528Document6 pagesUS6767528Helwinda ApriliaNo ratings yet

- Ikn Brochure 2014 HighresDocument28 pagesIkn Brochure 2014 HighresJarrod ClarkNo ratings yet

- All Types of Waste IncineratorsDocument12 pagesAll Types of Waste IncineratorsNiyati Mihir PatelNo ratings yet

- Cement Chemistry Notation and Mineral NamesDocument2 pagesCement Chemistry Notation and Mineral NamesAfqan B-vNo ratings yet

- 2013 - Recycling Glass Fibre Reinforced Composites - History and ProgressDocument5 pages2013 - Recycling Glass Fibre Reinforced Composites - History and ProgressSubramani PichandiNo ratings yet

- Exposure Effect To Cement Dust Pollution: A Mini Review: Emmanuel Adeyanju Chukwueloka Austin OkekeDocument17 pagesExposure Effect To Cement Dust Pollution: A Mini Review: Emmanuel Adeyanju Chukwueloka Austin OkekeSamiNo ratings yet

- Diamond Electronics: Cameras & Monitoring SystemsDocument15 pagesDiamond Electronics: Cameras & Monitoring SystemsKR PANo ratings yet

- Final Project of Rayeen SteelsDocument56 pagesFinal Project of Rayeen SteelsShiva PrasannaNo ratings yet

- A Simplified Model To Calculate The Power Draw For Material Movement in Industrial Rotary KilnsDocument5 pagesA Simplified Model To Calculate The Power Draw For Material Movement in Industrial Rotary KilnsAnonymous NxpnI6jCNo ratings yet

- Tehcnical Economic ORCDocument23 pagesTehcnical Economic ORC123habib123fikriNo ratings yet

- Ultratech Cement: Unit: Birla WhiteDocument24 pagesUltratech Cement: Unit: Birla WhiteAbhishek LambaNo ratings yet

- Small Scale Cement Plants A Study in EconomicsDocument33 pagesSmall Scale Cement Plants A Study in EconomicsplutocowNo ratings yet

- ESP Lesson 7 (Industrial Applications For Fabric Filters)Document24 pagesESP Lesson 7 (Industrial Applications For Fabric Filters)jkaunoNo ratings yet

- Rotaflam PillardDocument34 pagesRotaflam PillardRogério CorreiaNo ratings yet