Professional Documents

Culture Documents

Extending PCI Lance Tube Performance

Extending PCI Lance Tube Performance

Uploaded by

pateta50Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extending PCI Lance Tube Performance

Extending PCI Lance Tube Performance

Uploaded by

pateta50Copyright:

Available Formats

STAINLESS STEELS 51

Extending PCI lance tube performance

Poor structural stability and creep strength properties found in standard stainless steel tube for blast

furnaces have lead to the development of an innovative material which could take the place of higher

alloyed materials such as 25Cr/20Ni steels, Alloy 800H, and even Alloy 600. David Zhou* explains why.

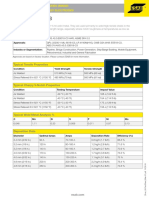

THE method of injecting pulverised Grades C Si Mn Cr Ni Ti Mo N Ce

coal into blast furnaces is shown to

bring remarkable economic benefits to 253 MA 0.08 1.60 ≤0.8 21.0 11.0 - - 0.17 0.05

demanding manufacturing processes, AISI 310 0.06 ≤0.75 1.5 24.5 21.0 - - - -

such as iron-making. For these purposes,

pulverised coal injection (PCI) lance tube Table 1: Chemical composition of 253 MA and AISI 310 (nominal composition, wt.%)

is one of the most critical parts of a blast

would identify a new and improved Chemical compositions

furnace and can significantly influence

material with excellent high temperature Typical domestic PCI lance tube materials

energy efficiency, production consistency

oxidation and carburisation corrosion include 310S, TP321H and 316L. Tests by

and safety.

resistance and high temperature strength. Sandvik focused on its own 253 MA grade

The new grade would prove capable of and AISI 310S, mainly examining the

Conventional materials

increasing the service life of PCI lance tube oxidation resistance and high temperature

The types of steel selected for these

by more than three times. creep rupture of each and comparing and

components can affect the advantages

testing the service life of the two materials.

achieved by operators. However, it has

Causes of PCI lance tube failure The chemical composition of the

become increasingly apparent in recent

Fig 1 is a schematic diagram of PCI lance materials are shown in Table 1.

times that standard materials are not

tube equipment. The PCI lance itself is one Sandvik’s 253 MA is an austenitic

capable of meeting growing demand for

seamless stainless steel tube, the outside chromium-nickel steel alloyed with

better performance and longer service.

surface of which is subjected to high hot nitrogen and rare earth metals and

Conventional materials are prone to wear

air temperatures in the range of 1,100 characterised by high creep strength,

and bending, which can shorten lifecycles,

to 1,300°C (2,010 to 2,370°F). The inner good resistance to isothermal and cyclic

sometimes to one month. These failures

surface is in prolonged contact with fine oxidation, good structural stability at

can result in the shutdown of blast

pulverised coal particles with a granularity high temperature and good weldability.

furnaces, creating huge economic losses.

range of 0-1000 μm, and the flow rate of The material is designed with a maximum

Standard grades that have exhibited

these can reach 15-30 metres per second operating temperature of approximately

insufficient performance properties

(m/s). 1,150°C (2,100°F).

include austenite steel, 304, otherwise

It is against these operational factors

known as 18/8 for its composition of 18%

and high temperatures that some steel Effects on the oxide scale structure

chromium and 8% nickel. It lacks resistance

grades are susceptible to high temperature The oxidation and corrosion resistance

to abrasion, oxidation and carburisation,

oxidation and carburisation corrosion. properties of common seamless stainless

prompting Sandvik to conduct extensive

As a consequence, PCI lance tubing steels come from the chromium (III)

research into high temperature corrosion

manufactured from standard grades can oxide (Cr2O3) protective films formed on

resistance and creep rupture strength of

be easily bent and worn-out during service substrates (or molecules upon which an

materials selected for PCI lance tubing.

at high temperatures, causing tube failure, enzyme acts). Cr2O3 protective films can

Through these assessments, the company

examples of which are shown in Fig 2. hinder oxygen (O), carbon (C), nitrogen

PCI rate 150kg/fHM

Coal & nitrogen Raceway

Lance tube

Blast (air-oxygen)

15-30m/s

200m/s 1250°C B

Blowpipe

Water cooled tuyere

Coal: ~ 150a/m3 of blast

BF walls

Fig 1: PCI lance tube equipment schematic diagram Fig 2: Examples of apparent failure of PCI lance tube; a) shows bending failure while b)

depicts wear out failure

* Technical marketing specialist, Sandvik Materials Technology

www.steeltimesint.com September 2015

STAINLESS STEELS T sandvik.indd 1 8/28/15 9:30 AM

You might also like

- A.K. Automatic LTD, RohtakDocument39 pagesA.K. Automatic LTD, RohtakTinku Budhwar0% (1)

- Deep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsDocument8 pagesDeep Nitrided 32crmov13 Steel For Aerospace Bearings ApplicationsmvanzijpNo ratings yet

- CPHFD 011Document7 pagesCPHFD 011Napoleon DasNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Metalurgia Física ModernaDocument20 pagesMetalurgia Física ModernaMariliaFrancoNo ratings yet

- ASME Secc II D Appendix 6 Metallurgical PhenomenaDocument6 pagesASME Secc II D Appendix 6 Metallurgical PhenomenaCARLOS MARIONo ratings yet

- Effects of Age Hardening On The Mechanical Properties of High Silicon Stainless SteelDocument6 pagesEffects of Age Hardening On The Mechanical Properties of High Silicon Stainless SteelMoin ANo ratings yet

- Jin 2017Document14 pagesJin 2017abdul basitNo ratings yet

- Influenceofheattreatmentonmechanicalproperitiesof 51 CR V4Document7 pagesInfluenceofheattreatmentonmechanicalproperitiesof 51 CR V4Chiheb BaNo ratings yet

- John Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialsDocument8 pagesJohn Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialssadhuNo ratings yet

- Wear Resistance of High Chromium White Cast Iron For Coal Grinding RollsDocument9 pagesWear Resistance of High Chromium White Cast Iron For Coal Grinding RollsJoseph CureNo ratings yet

- Surface & Coatings Technology: Yucel Birol, Behiye YukselDocument6 pagesSurface & Coatings Technology: Yucel Birol, Behiye YukselChitranjan KumarNo ratings yet

- Materials and Design: Emel Taban, Erdinc Kaluc, Alfred DhoogeDocument7 pagesMaterials and Design: Emel Taban, Erdinc Kaluc, Alfred DhoogeZahra MaylaNo ratings yet

- Artigo Questão 1Document7 pagesArtigo Questão 1eduardoNo ratings yet

- Maisuradze-Björk2021 Article MicrostructureAndMechanicalProDocument10 pagesMaisuradze-Björk2021 Article MicrostructureAndMechanicalProsaifbenNo ratings yet

- CH-24-Stainless Steel Notes PDFDocument7 pagesCH-24-Stainless Steel Notes PDFArvind RaguNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Water Side Corrosion in BoilersDocument10 pagesWater Side Corrosion in BoilerselgawadhaNo ratings yet

- Review of Corrosion Resistant Co-Extruded Tube Development For Power BoilersDocument14 pagesReview of Corrosion Resistant Co-Extruded Tube Development For Power BoilersthiagoturraNo ratings yet

- High-Strength Corrosion-Resistant Steels of The Austenitic-Martensitic ClassDocument1 pageHigh-Strength Corrosion-Resistant Steels of The Austenitic-Martensitic ClassakhileshNo ratings yet

- Welding of Steel 02Document53 pagesWelding of Steel 02Sir KoeNo ratings yet

- A Study of Mechanical Properties of MIGDocument10 pagesA Study of Mechanical Properties of MIGFred BosmanNo ratings yet

- HSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesDocument11 pagesHSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesEdgar HornusNo ratings yet

- Microstructure and Mechanical Properties of Two API Steels For Iron Ore PipelinesDocument7 pagesMicrostructure and Mechanical Properties of Two API Steels For Iron Ore PipelinesNilesh MistryNo ratings yet

- Stainless Steel Applications in Electrical EngineeringDocument9 pagesStainless Steel Applications in Electrical EngineeringUmang SoniNo ratings yet

- Austenitic Stainless SteelsDocument10 pagesAustenitic Stainless SteelsbramNo ratings yet

- Metals 11 01121Document18 pagesMetals 11 01121Izod GetterNo ratings yet

- Facts at Your Fingertips-200708-Materials of ConstructionDocument1 pageFacts at Your Fingertips-200708-Materials of Constructiononizuka-t2263No ratings yet

- cn7ms MC Caul 1991Document6 pagescn7ms MC Caul 1991Eliel OrtizNo ratings yet

- Corrosion Guide - Stainless Internation NickelDocument20 pagesCorrosion Guide - Stainless Internation NickelJohn BurkeNo ratings yet

- Stainless Steel 6Document10 pagesStainless Steel 6YKAGARWALNo ratings yet

- Metals 12 01765 v3Document8 pagesMetals 12 01765 v3Črtomir DonikNo ratings yet

- Cronidur Equivalent J.matchar.2019.110049Document15 pagesCronidur Equivalent J.matchar.2019.110049IltefatNo ratings yet

- Mechanical and Wear PropertiesDocument5 pagesMechanical and Wear PropertiesSyehifful FadlinNo ratings yet

- Corrosion Resistance of Co-Containing Maraging Stainless SteelDocument13 pagesCorrosion Resistance of Co-Containing Maraging Stainless SteelJinsoo KimNo ratings yet

- RR3000和CMSX 4单晶高温合金的高温氧化行为 PDFDocument9 pagesRR3000和CMSX 4单晶高温合金的高温氧化行为 PDFhk esatonNo ratings yet

- Alloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureDocument2 pagesAlloy Steels: Table 4.2 Typical Mechanical Properties of Some Commercial Steels at Room TemperatureBharathi SrinivasanNo ratings yet

- Materials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraDocument19 pagesMaterials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraCésar CastañedaNo ratings yet

- MN Steel WeldingDocument4 pagesMN Steel WeldingRam KadamNo ratings yet

- Duplex Stainless SteelsDocument19 pagesDuplex Stainless SteelsdinaksNo ratings yet

- INCO-WELD 686CPT With Super Duplex PDFDocument10 pagesINCO-WELD 686CPT With Super Duplex PDFewillia13No ratings yet

- Investigation and Application of High Strength Low Alloy Wear Resistant Cast SteelDocument4 pagesInvestigation and Application of High Strength Low Alloy Wear Resistant Cast Steelz2aliNo ratings yet

- Safety & Reliability in Ammonia Synthesis ConvertersDocument12 pagesSafety & Reliability in Ammonia Synthesis ConvertersGaurav GuptaNo ratings yet

- Duplex & Super Duplex InformationDocument7 pagesDuplex & Super Duplex InformationrajeshNo ratings yet

- Studies On Influence of WC On Scratch and Hot CorrDocument11 pagesStudies On Influence of WC On Scratch and Hot CorrMUHAMMED FAISALNo ratings yet

- Thep Khong GiDocument9 pagesThep Khong GiQuân BùiNo ratings yet

- Super Austenetic Steels P45 PDFDocument3 pagesSuper Austenetic Steels P45 PDFSyed Mahmud Habibur RahmanNo ratings yet

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringDocument6 pagesCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringSaif UllahNo ratings yet

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringDocument6 pagesCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringAgil SetyawanNo ratings yet

- Carbon Steel Pipe - An Overview - ScienceDirect Topics PDFDocument21 pagesCarbon Steel Pipe - An Overview - ScienceDirect Topics PDFsaif asqalanyNo ratings yet

- Aerospace MaterialsDocument28 pagesAerospace MaterialsSebastian M. PajaroNo ratings yet

- SSC DWDocument4 pagesSSC DWsanketpavi21No ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- Pages From MCSP Pt. 19Document15 pagesPages From MCSP Pt. 19cellNo ratings yet

- Thermal-Spray (Metallized) Coatings For Steel: Robert A. SulitDocument15 pagesThermal-Spray (Metallized) Coatings For Steel: Robert A. SulitvvpvarunNo ratings yet

- Wear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueDocument12 pagesWear Analysis of Chromium Carbide Coating On A516 WCB Steel by Plasma Spraying TechniqueIJRASETPublicationsNo ratings yet

- Weld Cladding Overlay - Topics by ScienceDocument73 pagesWeld Cladding Overlay - Topics by ScienceMichael TayactacNo ratings yet

- Materials Corrosion - 2024 - Ooi - A New Index To Estimate The Corrosion Resistance of Aluminium Containing SteelDocument12 pagesMaterials Corrosion - 2024 - Ooi - A New Index To Estimate The Corrosion Resistance of Aluminium Containing SteelSteve OoiNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Iso 3506 2 1997Document11 pagesIso 3506 2 1997Arun SharmaNo ratings yet

- Crevice Corrosion: How To Reduce The Risk of Crevice CorrosionDocument2 pagesCrevice Corrosion: How To Reduce The Risk of Crevice CorrosionMohamedNo ratings yet

- Astm A217-A217m-07Document4 pagesAstm A217-A217m-07NadhiraNo ratings yet

- The Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642Document2 pagesThe Al-Si Phase Diagram: Microsc Microanal 15 (Suppl 2), 2009 60 Doi: 10.1017/S1431927609092642divyanshNo ratings yet

- Princess Xyra T. Mallari 11-HUMSS, ST - Anthony de Padua Ms - Krizia Mae Enriquez September 01,2021Document6 pagesPrincess Xyra T. Mallari 11-HUMSS, ST - Anthony de Padua Ms - Krizia Mae Enriquez September 01,2021Xyy MallariNo ratings yet

- OUZENDocument80 pagesOUZENPLATIN DESIGNNo ratings yet

- Rare Earths A. Commodity SummaryDocument17 pagesRare Earths A. Commodity SummaryyeyintlayNo ratings yet

- Metals and Non-MetalsDocument10 pagesMetals and Non-MetalsPavandakoreNo ratings yet

- Daftar Isi Bukui GenesaDocument2 pagesDaftar Isi Bukui GenesaIrfanMarwanzaNo ratings yet

- Ferrous & Non-FerrousDocument1 pageFerrous & Non-Ferrousriain2008100% (3)

- SXXa XSDocument5 pagesSXXa XSraviteja tankalaNo ratings yet

- Cément Manufacturing ProcessDocument16 pagesCément Manufacturing ProcessM.IDREES KhanNo ratings yet

- Steel Casting, Austenitic Alloy, Estimating Ferrite Content ThereofDocument6 pagesSteel Casting, Austenitic Alloy, Estimating Ferrite Content ThereofcommandoNo ratings yet

- Wall Rock AlterationDocument25 pagesWall Rock AlterationKamalNo ratings yet

- Phase DiagramDocument21 pagesPhase DiagramEdison LimbagaNo ratings yet

- Groupe Automobile Jeandot - Wrangler-448Document1 pageGroupe Automobile Jeandot - Wrangler-448DarkedgeNo ratings yet

- Highlight WeldCanada CSA AWS Guides Preheat PWHTDocument5 pagesHighlight WeldCanada CSA AWS Guides Preheat PWHTAnonymous rYZyQQot55No ratings yet

- Bloxide®: An Aluminum-Base Weldable PrimerDocument1 pageBloxide®: An Aluminum-Base Weldable PrimerBHARANINo ratings yet

- Mechanisms of CorrosionDocument8 pagesMechanisms of CorrosionAli OtmanNo ratings yet

- Qw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationDocument7 pagesQw/Qb-422 Ferrous/Nonferrous P-Numbers (Cont'D) Grouping of Base Metals For QualificationHgagselim SelimNo ratings yet

- Best Periodic TableDocument1 pageBest Periodic Tablemuxi rongNo ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- Bohler Fox S EV 50-1Document1 pageBohler Fox S EV 50-1kamals55No ratings yet

- Sculpture MediumDocument13 pagesSculpture MediumMarieZanoriaNo ratings yet

- DDWJ 3921 Jominy End-Quench TestDocument2 pagesDDWJ 3921 Jominy End-Quench TestHaziq HanifahNo ratings yet

- Periodic Table PDFDocument1 pagePeriodic Table PDFsandystaysNo ratings yet

- Astm A312Document3 pagesAstm A312Zeeshan HasanNo ratings yet

- BHMA Finish ChartDocument5 pagesBHMA Finish ChartRey Eduard Q. UmelNo ratings yet