Professional Documents

Culture Documents

Basics of Continuous Casting of Steel - Copy-1

Basics of Continuous Casting of Steel - Copy-1

Uploaded by

Ghulam FareedCopyright:

Available Formats

You might also like

- Rolling FundamentalsDocument20 pagesRolling FundamentalsJo100% (7)

- Continuous Casting MachineDocument10 pagesContinuous Casting MachineHeet Patel0% (1)

- AAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsDocument4 pagesAAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsMarian Joyce MacadineNo ratings yet

- 226 PDFDocument16 pages226 PDFDwijendra60% (10)

- Steel - Continuous CastingDocument11 pagesSteel - Continuous CastingAli AzharNo ratings yet

- CCMDocument10 pagesCCMHeet PatelNo ratings yet

- Countinous CastingDocument7 pagesCountinous Castingandreasgorga100% (1)

- Thermal Analysis of Continuous Casting Process (Maryeling)Document10 pagesThermal Analysis of Continuous Casting Process (Maryeling)Marko's Brazon'No ratings yet

- Casting1 PDFDocument76 pagesCasting1 PDFahmedNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level Controlsalvador2meNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level ControlmehdihaNo ratings yet

- Project On "Caster Slab Dimensional Accuracy Technique"Document16 pagesProject On "Caster Slab Dimensional Accuracy Technique"Mayur ParvaniNo ratings yet

- University of The East College of Engineering: Plate No. 2 Rolling MillDocument17 pagesUniversity of The East College of Engineering: Plate No. 2 Rolling MillJOHNEDERSON PABLONo ratings yet

- EAT227-Lecture 2.3 - Continuous CastingDocument25 pagesEAT227-Lecture 2.3 - Continuous CastingSurya Da Rasta100% (1)

- Metallurgy of Continiuous Casting Technology PDFDocument20 pagesMetallurgy of Continiuous Casting Technology PDFRadi GoharNo ratings yet

- Continuous Casting PracticesDocument5 pagesContinuous Casting Practicesbhauvik0% (1)

- Cs Project ReportDocument24 pagesCs Project Reportharika mandadapuNo ratings yet

- Continuous Casting: Equipment and ProcessDocument8 pagesContinuous Casting: Equipment and ProcessErickman Simorangkir100% (1)

- Billet Casting DefectsDocument18 pagesBillet Casting DefectsMuhammad HassanNo ratings yet

- Metallurgy of Continuous Casting TechnologyDocument20 pagesMetallurgy of Continuous Casting Technologyahmed ebraheemNo ratings yet

- Metal Mould-Casting Processes: Unit Iv Moulding ProcessesDocument26 pagesMetal Mould-Casting Processes: Unit Iv Moulding ProcessesMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- Forging DefectDocument4 pagesForging DefectRashmi Bhatt NautiyalNo ratings yet

- Contoh Model Matematika Dalam Heat TransferDocument39 pagesContoh Model Matematika Dalam Heat TransferADITYA RAHMANNo ratings yet

- Metal CastingDocument28 pagesMetal CastingAngel ChanteyNo ratings yet

- 20 Steel Plants: Technology For UnderwritersDocument16 pages20 Steel Plants: Technology For Underwriterssatnam1979No ratings yet

- Mechanical Working of Metals MaterialDocument40 pagesMechanical Working of Metals MaterialRoyalmechNo ratings yet

- CCM LiteraturaDocument33 pagesCCM LiteraturaJose Marval RodriguezNo ratings yet

- Metal Casting Technology: Digital Assignment 2Document11 pagesMetal Casting Technology: Digital Assignment 2Sanket GandhiNo ratings yet

- ALUMINIUMTECHNOLOGIES Week10Document110 pagesALUMINIUMTECHNOLOGIES Week10NhocSkyzNo ratings yet

- Advances in Continuous Casting PDFDocument4 pagesAdvances in Continuous Casting PDFPrakash SarangiNo ratings yet

- M 451 ContentDocument66 pagesM 451 Contentsekson100% (1)

- Manufacturing Process 1 2Document70 pagesManufacturing Process 1 2MD Al-Amin100% (1)

- MANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)Document18 pagesMANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)TsihatesfaNo ratings yet

- NUCOR Paper-Round CasterDocument4 pagesNUCOR Paper-Round CasterJackthejackNo ratings yet

- 2.14. Multiple-Use-Mould Casting ProcessesDocument3 pages2.14. Multiple-Use-Mould Casting Processesaman chaudharyNo ratings yet

- Chapter 5Document14 pagesChapter 5Phuc Truong DucNo ratings yet

- Annexure 4 - Study 2Document5 pagesAnnexure 4 - Study 2Ujjwal BagmarNo ratings yet

- Study of Forging Process Equipemnts-Practical-3Document12 pagesStudy of Forging Process Equipemnts-Practical-3prashantNo ratings yet

- CVS 415 Notes 2021Document20 pagesCVS 415 Notes 2021Imani LughoNo ratings yet

- Solidification Analysis in Continuous Casting Process - Barman TambunanDocument11 pagesSolidification Analysis in Continuous Casting Process - Barman TambunanBarman TambunanNo ratings yet

- Lecture # 4 Investment CastingDocument53 pagesLecture # 4 Investment CastingAbdulRehman Ahmed SoomroNo ratings yet

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Fabrication of Automatic Spring Rolling MachineDocument45 pagesFabrication of Automatic Spring Rolling MachineANAND KRISHNANNo ratings yet

- Fabrication of MetalDocument22 pagesFabrication of MetalaurangzaibNo ratings yet

- ExcerptDocument10 pagesExcerptRAJANo ratings yet

- 2002 Mitsuo Hashimoto V 2002Document8 pages2002 Mitsuo Hashimoto V 2002ralish12No ratings yet

- Unit-3 - Special Moulding Processes PART-2Document25 pagesUnit-3 - Special Moulding Processes PART-2mahammad kamaluddeenNo ratings yet

- AbstractDocument4 pagesAbstractneptunaNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- CCM Equipment Detail For ClearanceDocument5 pagesCCM Equipment Detail For ClearancesmithNo ratings yet

- Module 2 Activity No. 1Document6 pagesModule 2 Activity No. 1Benz DyNo ratings yet

- Metal Fabrication TechniquesDocument29 pagesMetal Fabrication TechniquesAnn NavarroNo ratings yet

- Assignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Document12 pagesAssignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Uzair KhanNo ratings yet

- The Use of Water Cooling During The Continuous Casting of Steel and Aluminum AlloysDocument18 pagesThe Use of Water Cooling During The Continuous Casting of Steel and Aluminum AlloysRamesh RamNo ratings yet

- Rolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentDocument6 pagesRolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentahmadalsayehNo ratings yet

- Extrusion: Extrusion Is A Process Used To CreateDocument62 pagesExtrusion: Extrusion Is A Process Used To CreateSwapnesh PatelNo ratings yet

- Casting Its TypesDocument84 pagesCasting Its Typesanmanjunath086No ratings yet

- Manufacturing ProcessesDocument29 pagesManufacturing Processesemieel reegisNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Class Programme: Approval of ManufacturersDocument13 pagesClass Programme: Approval of ManufacturersYasser Hammad MohamedNo ratings yet

- ZCAST Brochure WebDocument8 pagesZCAST Brochure WebSrashmiNo ratings yet

- Galvanizedsteel PDFDocument23 pagesGalvanizedsteel PDFKok Wai100% (1)

- Steel Colour Code PDFDocument1 pageSteel Colour Code PDFJuan ZamoraNo ratings yet

- Blast FurnaceDocument32 pagesBlast FurnaceShailesh SharmaNo ratings yet

- Usage of Zinc-Silicate Coatings in Friction ConnectionsDocument13 pagesUsage of Zinc-Silicate Coatings in Friction ConnectionsDEWINo ratings yet

- Industeel - Stainless Steel Alloy PDFDocument2 pagesIndusteel - Stainless Steel Alloy PDFClaudio SampaioNo ratings yet

- TubeDocument126 pagesTubeONESTAR111100% (1)

- T-1046.02 (Qqz-325 Type II Class II)Document2 pagesT-1046.02 (Qqz-325 Type II Class II)jazz reyNo ratings yet

- Day 14 Heat Treatments of SteelDocument20 pagesDay 14 Heat Treatments of Steelعزت عبد المنعمNo ratings yet

- Review Article: Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical DataDocument34 pagesReview Article: Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical DataEric Manuel Mercedes AbreuNo ratings yet

- Astm A487 A487m 21Document7 pagesAstm A487 A487m 21Milady OyuelaNo ratings yet

- PLATINUMDocument12 pagesPLATINUMAli RiazNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- MIL-DTL-5541 Rev F - Part1Document1 pageMIL-DTL-5541 Rev F - Part1David WongNo ratings yet

- KATBAK - Ceramic Weld BackingDocument4 pagesKATBAK - Ceramic Weld BackingAnonymous 9zykaX6TNo ratings yet

- Types of Sheet Metal Press OperationsDocument4 pagesTypes of Sheet Metal Press OperationsRajat AhujaNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel Gradeanu swamiNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Aws A 5.10Document38 pagesAws A 5.10বিপ্লব পালNo ratings yet

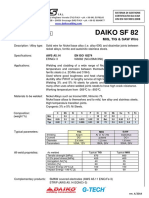

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- MP II - Lecture 5 - Tool Failure and Tool LifeDocument45 pagesMP II - Lecture 5 - Tool Failure and Tool LifeArif Hossain100% (1)

- Tantalum Niobium EtchantsDocument2 pagesTantalum Niobium EtchantsmitgraNo ratings yet

- Design Guide For Hot Dip Galvanizing Best Practice Venting and Draining PDFDocument15 pagesDesign Guide For Hot Dip Galvanizing Best Practice Venting and Draining PDFArshath FleminNo ratings yet

- Maintenance Manual-Counterweight PropellersDocument284 pagesMaintenance Manual-Counterweight PropellersMaria Helena Gonzalez Garcia100% (1)

- SLG-0001-1b Flange Designation Chart PDFDocument2 pagesSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimNo ratings yet

- CHPT 11-13Document42 pagesCHPT 11-13Charles Borromeo LiNo ratings yet

- OutoKumpu SS Pipe-2010Document124 pagesOutoKumpu SS Pipe-2010ahmedalishNo ratings yet

Basics of Continuous Casting of Steel - Copy-1

Basics of Continuous Casting of Steel - Copy-1

Uploaded by

Ghulam FareedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basics of Continuous Casting of Steel - Copy-1

Basics of Continuous Casting of Steel - Copy-1

Uploaded by

Ghulam FareedCopyright:

Available Formats

Basics of Continuous Casting of Steel

Continuous casting is the process whereby liquid steel is solidified into a semi finished product for

subsequent rolling in the finish rolling mills. Continuous casting of steel was conceived and patented in

1865 by Sir Henry Bessemer, but it could not be commercialized because of problems related to

engineering and equipment. After solving these problems, continuous casting of steel was introduced

commercially in 1950s and around 1475 million tons of continuous cast steel was produced globally in

2012.

Continuous casting has replaced several steps during steel making process such as ingot casting, mould

stripping, heating in soaking pits, and primary rolling with one operation. Continuous casting of steel has

helped to achieve improved yield, quality, productivity and cost efficiency. The principle of continuous

casting is shown in Fig. 1.

Fig 1 Principle of continuous casting

Referring to Fig 1, Liquid steel in the steel teeming ladle (1) from the secondary steel making unit is taken

to the continuous casting machine. The ladle is raised onto a turret that rotates the ladle into the casting

position above the tundish (3). Liquid steel flows out of the ladle into the tundish, and then into a

water-cooled copper mould (5). Solidification begins in the mould, and continues through the roll support

(6) and the turning zone (7). The continuous cast strand is then straightened, torch-cut, and then

discharged for intermediate storage or hot charged for finished rolling.

Depending on the product end use, various shapes are cast. In conventional continuous casting

machines these are slabs, blooms or billets. In recent years, the melting, casting, and rolling processes

have been linked while casting a shape that substantially conforms to the finished product. These near

net shape cast sections are usually applied to beams and flat rolled products, and results in a highly

efficient operation. In the case of near net shape casting, the complete process chain from liquid steel to

finished rolling can be achieved within two hours.

Billets have cross section with sizes up to about 150 mm square. Blooms have cross section either

square or rectangular with size of each side ranging from greater than 150 mm to less than 500 mm.

Round castings include diameters of 125mm to 500 mm. Beam blanks are shaped like dog bones, and

are subsequently rolled into I- beams. Slabs are cast with size range of thickness from 150 mm to 400

mm, and width from greater than 500 mm to 2500 mm. The width to thickness ratio, referred to as the

‘aspect ratio’, is used to determine the dividing line between blooms and slabs. An aspect ratio of 2.5:1 or

greater constitutes an as-cast product referred to as a slab. Thin slab has thickness in the range of 50

mm to 90 mm.

In the design of continuous casting machines the following are the important considerations.

● End use product influences the quality, grade and shape of the cast product (bloom, billet, round, slab,

thin slab, or beam blank)

● Annual tonnage to be cast

● Availability of liquid steel and heat size

● Planned operating hours

The above factors dictate the continuous machine design parameters such as the number of cast strands

and casting speed which must match the liquid steel supply to the continuous casting machine. Quality

and grade of the steel to be cast are utilized in determining various design parameters of the casting

machine such as its length, vertical height, curved or straight mould, water versus air mist cooling,

electromagnetic stirring etc.

There are two steps which are involved for the transfer of liquid steel from the steel teeming ladle to the

mould of continuous casting machine. These are (i) transferring or teeming of liquid steel from the

teeming ladle to the tundish and (ii) transfer of liquid steel from the tundish to the moulds. Regulation of

liquid steel flow from tundish to mould occurs through orifice devices of various designs such as slide

gates, stopper rods, or metering nozzles, the latter controlled by tundish steel level adjustment.

Sections and components of a continuous casting machine

The continuous casting machine consists of the following main sections

● A tundish, located above the mould to feed liquid steel to the mould at a regulated rate.

● A water cooled copper mould which is also the primary cooling zone, through which the liquid steel is

fed from the tundish. It generates a solidified outer shell sufficiently strong enough to maintain the

strand shape as it passes into the secondary cooling zone.

● A secondary cooling zone in association with a containment section positioned below the mould,

through which the strand, the major portion of which is still in liquid state, passes and is sprayed with

water or air mist for further solidification of the strand.

● An unbending and straightening section except in case of straight vertical casting machines.

● A severing unit (cutting torch or mechanical shears) to cut the solidified strand into pieces for removal

and further processing.

The main components of continuous casting machine are as follows.

● Tundish – The shape of the tundish is typically rectangular, but delta and ‘T’ shapes are also

sometimes used. Nozzles are located along its bottom for the distribution of liquid steel to the moulds.

The tundish also serves several other key functions which include (i) enhances oxide inclusion

separation, (ii) provides a continuous flow of liquid steel to the mould during the exchange of ladles,

(iii) maintains a steady liquid steel height above the nozzles to the moulds, thereby keeping steel flow

constant and hence casting speed constant as well (for an open-pouring metering system), and (iv)

provides more stable stream patterns to the moulds.

● Mould – The main function of the mould is to establish a solid shell sufficient in strength to contain its

liquid core upon entry into the secondary spray cooling zone. Key product elements are shape, shell

thickness, uniform shell temperature distribution, defect free internal and surface quality with minimal

porosity, and few non metallic inclusions. The mould is basically an open ended box structure,

containing a water cooled inner lining fabricated from a high purity copper alloy. Mould water transfers

heat from the solidifying shell. The working surface of the copper face is often plated with chromium or

nickel to provide a harder working surface, and to avoid copper pickup on the surface of the cast

strand, which can facilitate surface cracks on the product. Mould heat transfer is both critical and

complex. Mathematical and computer modeling are typically utilized in developing a greater

understanding of mould thermal conditions, and to aid in proper design and operating practices. Heat

transfer is generally considered as a series of thermal resistances namely (i) heat transfer through the

solidifying shell, (ii) heat transfer from the steel shell surface to the copper mould outer surface, (iii)

heat transfer through the copper mould, and (iv) heat transfer from the copper mould inner surface to

the mould cooling water.

● Mould oscillation – Mould oscillation is necessary to minimize friction and sticking of the solidifying

shell, avoidance of shell tearing, and liquid steel breakouts. Breakouts can cause major damage to

equipment and a large machine downtime is needed due to clean up and repairs. Friction between the

shell and mould is reduced through the use of mould lubricants such as oils or powdered fluxes.

Oscillation is achieved either hydraulically or via motor driven cams or levers which support and

reciprocate (or oscillate) the mould. Mould oscillating cycles vary in frequency, stroke and pattern.

However, a common approach is to employ what is called ‘negative strip’, a stroke pattern in which the

downward stroke of the cycle enables the mould to move down faster than the section withdrawal

speed. This enables compressive stresses to develop in the shell that increase its strength by sealing

surface fissures and porosity.

● Secondary cooling system – The secondary cooling system consists of several zones, each zone is

meant for a segment of controlled cooling of the solidifying strand as it progresses through the

machine. The sprayed medium is either water or a combination of air and water. The heat transfer

occurs in this region through all the three ways namely radiation, conduction and convection. The

predominant form of heat transfer in the upper regions of the secondary cooling area is by radiation.

As the product passes through the rolls, heat is transferred through the shell as conduction and also

through the thickness of the rolls, as a result of the associated contact. This form of heat transfer

follows the Fourier law. The third form of heat transfer mechanism occurs by fast moving sprayed

water droplets or mist from the spray nozzles, penetrating the steam layer next to the steel surface,

which then evaporates. This convective mechanism is as per the Newton’s law of cooling. The heat

transfer in the secondary zones serves the functions of (i) enhancing and controlling the rate of

solidification (ii) strand temperature regulation via spray water intensity adjustment (iii) machine

containment cooling.

● Shell growth – It is reliably predicted by the Fick’s law. This equation is also used to calculate the

casting distance where the product is fully solidified (i.e. no liquid core remaining).

● Strand containment – The containment region is an integral part of the secondary cooling area. A

series of retaining rolls contain the strand, extending across opposite strand faces. Edge roll

containment may also be needed. The focus here is to provide strand guidance and containment until

the solidifying shell is self supporting. In order to avoid compromises in product quality, careful

consideration is required to be made to minimize stresses associated with the roller arrangement and

strand unbending. Thus, roll layout, including spacing and roll diameters are carefully selected to

minimize between roll bulging and liquid/solid interface strains. Strand support requires maintaining

strand shape, as the strand itself is a solidifying shell containing a liquid core that possesses bulging

ferro-static forces from head pressure related to machine height. The area of greatest concern is high

up in the machine. Here, the bulging force is relatively small, but the shell is thinner and at its weakest.

To compensate for this inherent weakness and avoid shell rupturing and resulting liquid steel

breakouts, the roll diameter is small with tight spacing. Just below the mold all four faces are typically

supported, with only the broad faces supported at regions lower in the machine.

● Unbending and straightening – The unbending and straightening forces are as important as strand

containment and guidance from the vertical to horizontal plane are important. As unbending occurs,

the solid shell outer radius is under tension, while the inner radius is under compression. The resulting

strain is dictated by the arc radius along with the mechanical properties of the cast steel grade. If the

strain along the outer radius is excessive, cracks can occur. This will affect seriously the cast steel

quality. These strains are typically minimized by incorporating a multi point unbending process, in

which the radii become progressively larger in order to gradually straighten the product into the

horizontal plane.

The process of casting

For starting the casting of a fresh heat, the bottom of the mould is sealed by a steel dummy bar, which is

held in place hydraulically by the straightening withdrawing unit. This dummy bar prevents liquid steel

from flowing out of the mould. The liquid steel poured into the mould is partially solidified, producing a

steel strand with a solid outer shell and a liquid core. In this primary cooling area, once the steel shell has

a sufficient thickness, about 10 to 20 mm, the straightening withdrawal unit is started and proceeded to

withdraw the partially solidified strand out of the mould along with the dummy bar. Liquid steel continues

to pour into the mould to replenish the withdrawn steel at an equal rate. The withdrawal rate depends on

the cross-section, grade and quality of steel being produced, and may vary between 300 mm and 7,500

mm per minute. Casting time is typically 45 minutes to 90 minutes per heat to avoid excessive ladle heat

losses. After leaving the mould, the cast steel strand enters a roller containment section and secondary

cooling chamber in which the solidifying strand is sprayed with water, or a combination of water and air

(air mist) to promote solidification. This area preserves cast shape integrity and product quality. Larger

cross section requires extended roller containment. Once the strand is fully solidified and has passed

through the straightening-withdrawal units, the dummy bar is disconnected, removed and stored.

Following the straightening, the strand is cut into individual pieces of the as cast products (slabs, blooms,

billets, rounds, or beam blanks depending on machine design).

You might also like

- Rolling FundamentalsDocument20 pagesRolling FundamentalsJo100% (7)

- Continuous Casting MachineDocument10 pagesContinuous Casting MachineHeet Patel0% (1)

- AAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsDocument4 pagesAAMA 907-05: Voluntary Specification For Corrosion Resistant Coatings On Carbon Steel ComponentsMarian Joyce MacadineNo ratings yet

- 226 PDFDocument16 pages226 PDFDwijendra60% (10)

- Steel - Continuous CastingDocument11 pagesSteel - Continuous CastingAli AzharNo ratings yet

- CCMDocument10 pagesCCMHeet PatelNo ratings yet

- Countinous CastingDocument7 pagesCountinous Castingandreasgorga100% (1)

- Thermal Analysis of Continuous Casting Process (Maryeling)Document10 pagesThermal Analysis of Continuous Casting Process (Maryeling)Marko's Brazon'No ratings yet

- Casting1 PDFDocument76 pagesCasting1 PDFahmedNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level Controlsalvador2meNo ratings yet

- Continuous Casting and Mould Level ControlDocument15 pagesContinuous Casting and Mould Level ControlmehdihaNo ratings yet

- Project On "Caster Slab Dimensional Accuracy Technique"Document16 pagesProject On "Caster Slab Dimensional Accuracy Technique"Mayur ParvaniNo ratings yet

- University of The East College of Engineering: Plate No. 2 Rolling MillDocument17 pagesUniversity of The East College of Engineering: Plate No. 2 Rolling MillJOHNEDERSON PABLONo ratings yet

- EAT227-Lecture 2.3 - Continuous CastingDocument25 pagesEAT227-Lecture 2.3 - Continuous CastingSurya Da Rasta100% (1)

- Metallurgy of Continiuous Casting Technology PDFDocument20 pagesMetallurgy of Continiuous Casting Technology PDFRadi GoharNo ratings yet

- Continuous Casting PracticesDocument5 pagesContinuous Casting Practicesbhauvik0% (1)

- Cs Project ReportDocument24 pagesCs Project Reportharika mandadapuNo ratings yet

- Continuous Casting: Equipment and ProcessDocument8 pagesContinuous Casting: Equipment and ProcessErickman Simorangkir100% (1)

- Billet Casting DefectsDocument18 pagesBillet Casting DefectsMuhammad HassanNo ratings yet

- Metallurgy of Continuous Casting TechnologyDocument20 pagesMetallurgy of Continuous Casting Technologyahmed ebraheemNo ratings yet

- Metal Mould-Casting Processes: Unit Iv Moulding ProcessesDocument26 pagesMetal Mould-Casting Processes: Unit Iv Moulding ProcessesMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- Forging DefectDocument4 pagesForging DefectRashmi Bhatt NautiyalNo ratings yet

- Contoh Model Matematika Dalam Heat TransferDocument39 pagesContoh Model Matematika Dalam Heat TransferADITYA RAHMANNo ratings yet

- Metal CastingDocument28 pagesMetal CastingAngel ChanteyNo ratings yet

- 20 Steel Plants: Technology For UnderwritersDocument16 pages20 Steel Plants: Technology For Underwriterssatnam1979No ratings yet

- Mechanical Working of Metals MaterialDocument40 pagesMechanical Working of Metals MaterialRoyalmechNo ratings yet

- CCM LiteraturaDocument33 pagesCCM LiteraturaJose Marval RodriguezNo ratings yet

- Metal Casting Technology: Digital Assignment 2Document11 pagesMetal Casting Technology: Digital Assignment 2Sanket GandhiNo ratings yet

- ALUMINIUMTECHNOLOGIES Week10Document110 pagesALUMINIUMTECHNOLOGIES Week10NhocSkyzNo ratings yet

- Advances in Continuous Casting PDFDocument4 pagesAdvances in Continuous Casting PDFPrakash SarangiNo ratings yet

- M 451 ContentDocument66 pagesM 451 Contentsekson100% (1)

- Manufacturing Process 1 2Document70 pagesManufacturing Process 1 2MD Al-Amin100% (1)

- MANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)Document18 pagesMANUFACTURING TECHNOLOGY ASSIGNMENT (Bahirdar University)TsihatesfaNo ratings yet

- NUCOR Paper-Round CasterDocument4 pagesNUCOR Paper-Round CasterJackthejackNo ratings yet

- 2.14. Multiple-Use-Mould Casting ProcessesDocument3 pages2.14. Multiple-Use-Mould Casting Processesaman chaudharyNo ratings yet

- Chapter 5Document14 pagesChapter 5Phuc Truong DucNo ratings yet

- Annexure 4 - Study 2Document5 pagesAnnexure 4 - Study 2Ujjwal BagmarNo ratings yet

- Study of Forging Process Equipemnts-Practical-3Document12 pagesStudy of Forging Process Equipemnts-Practical-3prashantNo ratings yet

- CVS 415 Notes 2021Document20 pagesCVS 415 Notes 2021Imani LughoNo ratings yet

- Solidification Analysis in Continuous Casting Process - Barman TambunanDocument11 pagesSolidification Analysis in Continuous Casting Process - Barman TambunanBarman TambunanNo ratings yet

- Lecture # 4 Investment CastingDocument53 pagesLecture # 4 Investment CastingAbdulRehman Ahmed SoomroNo ratings yet

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Fabrication of Automatic Spring Rolling MachineDocument45 pagesFabrication of Automatic Spring Rolling MachineANAND KRISHNANNo ratings yet

- Fabrication of MetalDocument22 pagesFabrication of MetalaurangzaibNo ratings yet

- ExcerptDocument10 pagesExcerptRAJANo ratings yet

- 2002 Mitsuo Hashimoto V 2002Document8 pages2002 Mitsuo Hashimoto V 2002ralish12No ratings yet

- Unit-3 - Special Moulding Processes PART-2Document25 pagesUnit-3 - Special Moulding Processes PART-2mahammad kamaluddeenNo ratings yet

- AbstractDocument4 pagesAbstractneptunaNo ratings yet

- AMT-Forming (Compatibility Mode)Document15 pagesAMT-Forming (Compatibility Mode)Abdulhmeed MutalatNo ratings yet

- CCM Equipment Detail For ClearanceDocument5 pagesCCM Equipment Detail For ClearancesmithNo ratings yet

- Module 2 Activity No. 1Document6 pagesModule 2 Activity No. 1Benz DyNo ratings yet

- Metal Fabrication TechniquesDocument29 pagesMetal Fabrication TechniquesAnn NavarroNo ratings yet

- Assignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Document12 pagesAssignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Uzair KhanNo ratings yet

- The Use of Water Cooling During The Continuous Casting of Steel and Aluminum AlloysDocument18 pagesThe Use of Water Cooling During The Continuous Casting of Steel and Aluminum AlloysRamesh RamNo ratings yet

- Rolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentDocument6 pagesRolling Process Exp.: The Hashemite University Faculty of Engineering Industrial Engineering DepartmentahmadalsayehNo ratings yet

- Extrusion: Extrusion Is A Process Used To CreateDocument62 pagesExtrusion: Extrusion Is A Process Used To CreateSwapnesh PatelNo ratings yet

- Casting Its TypesDocument84 pagesCasting Its Typesanmanjunath086No ratings yet

- Manufacturing ProcessesDocument29 pagesManufacturing Processesemieel reegisNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Class Programme: Approval of ManufacturersDocument13 pagesClass Programme: Approval of ManufacturersYasser Hammad MohamedNo ratings yet

- ZCAST Brochure WebDocument8 pagesZCAST Brochure WebSrashmiNo ratings yet

- Galvanizedsteel PDFDocument23 pagesGalvanizedsteel PDFKok Wai100% (1)

- Steel Colour Code PDFDocument1 pageSteel Colour Code PDFJuan ZamoraNo ratings yet

- Blast FurnaceDocument32 pagesBlast FurnaceShailesh SharmaNo ratings yet

- Usage of Zinc-Silicate Coatings in Friction ConnectionsDocument13 pagesUsage of Zinc-Silicate Coatings in Friction ConnectionsDEWINo ratings yet

- Industeel - Stainless Steel Alloy PDFDocument2 pagesIndusteel - Stainless Steel Alloy PDFClaudio SampaioNo ratings yet

- TubeDocument126 pagesTubeONESTAR111100% (1)

- T-1046.02 (Qqz-325 Type II Class II)Document2 pagesT-1046.02 (Qqz-325 Type II Class II)jazz reyNo ratings yet

- Day 14 Heat Treatments of SteelDocument20 pagesDay 14 Heat Treatments of Steelعزت عبد المنعمNo ratings yet

- Review Article: Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical DataDocument34 pagesReview Article: Essential Magnesium Alloys Binary Phase Diagrams and Their Thermochemical DataEric Manuel Mercedes AbreuNo ratings yet

- Astm A487 A487m 21Document7 pagesAstm A487 A487m 21Milady OyuelaNo ratings yet

- PLATINUMDocument12 pagesPLATINUMAli RiazNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- MIL-DTL-5541 Rev F - Part1Document1 pageMIL-DTL-5541 Rev F - Part1David WongNo ratings yet

- KATBAK - Ceramic Weld BackingDocument4 pagesKATBAK - Ceramic Weld BackingAnonymous 9zykaX6TNo ratings yet

- Types of Sheet Metal Press OperationsDocument4 pagesTypes of Sheet Metal Press OperationsRajat AhujaNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel Gradeanu swamiNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Aws A 5.10Document38 pagesAws A 5.10বিপ্লব পালNo ratings yet

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- MP II - Lecture 5 - Tool Failure and Tool LifeDocument45 pagesMP II - Lecture 5 - Tool Failure and Tool LifeArif Hossain100% (1)

- Tantalum Niobium EtchantsDocument2 pagesTantalum Niobium EtchantsmitgraNo ratings yet

- Design Guide For Hot Dip Galvanizing Best Practice Venting and Draining PDFDocument15 pagesDesign Guide For Hot Dip Galvanizing Best Practice Venting and Draining PDFArshath FleminNo ratings yet

- Maintenance Manual-Counterweight PropellersDocument284 pagesMaintenance Manual-Counterweight PropellersMaria Helena Gonzalez Garcia100% (1)

- SLG-0001-1b Flange Designation Chart PDFDocument2 pagesSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimNo ratings yet

- CHPT 11-13Document42 pagesCHPT 11-13Charles Borromeo LiNo ratings yet

- OutoKumpu SS Pipe-2010Document124 pagesOutoKumpu SS Pipe-2010ahmedalishNo ratings yet