Professional Documents

Culture Documents

ROLAND ZAT540 002e

ROLAND ZAT540 002e

Uploaded by

gesssmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ROLAND ZAT540 002e

ROLAND ZAT540 002e

Uploaded by

gesssmCopyright:

Available Formats

NO.

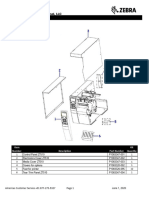

ZAT540-002 (1 / 2)

DATE 2008.12.10

SERVICE INFORMATION

Confidential ROLAND DG CORPORATION / SERVICE DEPT.

TO :

ENGINEERS

MODEL : SUBJECT :

ZAT-540 [No tool sensor connected] error

SYMPTOM:

1. [No tool sensor connected] error occurs.

2. Since Z-origin sensor is in a state of a tool detected, improper values or coordinates can be set

when performing the Tool-length offset or setting the Z-axis Origin.

CAUSE:

When conductive cutting dust is accumulated on the screws for fixing Z-origin sensor, it causes

the metal part of Z-origin sensor and the fixing screws to short out.

This situation is considered to be that Z-origin sensor is detecting the tool, because the electric

potential of Z-origin sensor becomes 0V (Ground).

SOLUTION:

The material of the screws for fixing Z-origin sensor has been changed to the non-conductive one.

< For the T-slot table > < For the standard table >

3000000106 3000000107

SCREW,PAN RENY M4*15 SCREW,PAN RENY M4*30

Revision No. Date Description of Changes Approval Issued by

0 08.3.28 First Edition Kato Mabuchi

1 08.12.10 Serial number has been revised. Kato Misako

Copyright 2008. Roland DG Corporation. All rights reserved. DQF-7511-02-1(Rev.0)

No sell, no rental, no distribution, no disclosure and no reproduction without permission.

-1-

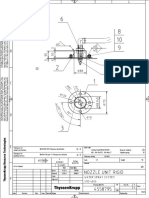

NO. ZAT540-002 (2 / 2)

DATE 2008.12.10

SERVICE PARTS:

Screws for fixing the T-slot table is attached.

3000000106 SCREW,PAN RENY M4*15

Screws for fixing the original standard table is attached.

3000000107 SCREW,PAN RENY M4*30

SERIAL NUMBER:

ZAT-540 : ZX00166 and above. Revised 1

-2-

You might also like

- Agile Electric - Quality Issues in Global Supply ChainDocument16 pagesAgile Electric - Quality Issues in Global Supply ChainAsher RamishNo ratings yet

- Service Bulletin: Information On The Replacement of The PartsDocument45 pagesService Bulletin: Information On The Replacement of The PartsDarekNo ratings yet

- Spare Parts Catalog: 12 AS 2301 IT (####### ####: 14.01.2013) Material Number: 1327.040.034Document100 pagesSpare Parts Catalog: 12 AS 2301 IT (####### ####: 14.01.2013) Material Number: 1327.040.034Dime JovanovNo ratings yet

- Spare Parts List SB 302 TunnelDocument32 pagesSpare Parts List SB 302 Tunnelslam9No ratings yet

- ServiceManualOKI C610 - ES6410 PDFDocument217 pagesServiceManualOKI C610 - ES6410 PDFLeofler Laureta AguinaldoNo ratings yet

- DOC1 Users GuideDocument453 pagesDOC1 Users GuideEzra Gutierrez0% (1)

- Complaint Management SystemDocument120 pagesComplaint Management SystemGemechis Shiferaw71% (7)

- EOS Quartz Date Back E Instruction ManualDocument17 pagesEOS Quartz Date Back E Instruction ManualBrett RogersNo ratings yet

- Relief Valve From HysysDocument8 pagesRelief Valve From Hysysarmin100% (1)

- ROLAND ZLC 540 001eDocument2 pagesROLAND ZLC 540 001egesssmNo ratings yet

- ROLAND ZAT540 001eDocument1 pageROLAND ZAT540 001egesssmNo ratings yet

- J S Auto Cast Foundry India PVT LTD.,: Tool LayoutDocument24 pagesJ S Auto Cast Foundry India PVT LTD.,: Tool Layoutkishore RavindranNo ratings yet

- Component Part List: Pos. Code Description Qty. NotesDocument1 pageComponent Part List: Pos. Code Description Qty. NotesLeandro Lima RamaldesNo ratings yet

- SB 0161Document3 pagesSB 0161Rabea EzzatNo ratings yet

- 01.17510.0003 - VDB027 - Rev 00 - ADocument504 pages01.17510.0003 - VDB027 - Rev 00 - AThiagoNo ratings yet

- RSB-0086 enDocument2 pagesRSB-0086 enSupremo HaloNo ratings yet

- Ups Train3Document157 pagesUps Train3Younes SaifiNo ratings yet

- Inspection ReportDocument1 pageInspection ReportvenkatNo ratings yet

- 20036855-IDX-0201, Rev. 01 - NOI Norway Supplied InstrumentDocument2 pages20036855-IDX-0201, Rev. 01 - NOI Norway Supplied InstrumentInstrument EngineerNo ratings yet

- Zebra ZT510 PCDocument10 pagesZebra ZT510 PCVinh AnhNo ratings yet

- ComplienceDocument2 pagesCompliencetamil saroNo ratings yet

- Rectificador Milwaukee Modelo 5192 Part ListDocument1 pageRectificador Milwaukee Modelo 5192 Part ListJesus RamirezNo ratings yet

- ZT230 (ZT200 Series) Parts CatalogDocument10 pagesZT230 (ZT200 Series) Parts CatalogNipuna RangikaNo ratings yet

- Zt200 Series Parts Catalog en UsDocument10 pagesZt200 Series Parts Catalog en UsJonel BuenaventuraNo ratings yet

- St12 Series: Microsd Memory Card ConnectorDocument5 pagesSt12 Series: Microsd Memory Card ConnectorMhb AliloNo ratings yet

- Vdb016 Ar4000 IronDocument297 pagesVdb016 Ar4000 IronBruno MapurungaNo ratings yet

- 5.0.4 Spare Part List Drive PumpDocument35 pages5.0.4 Spare Part List Drive PumpJose Antonio Escribano RoldanNo ratings yet

- Cat 4.4Document3 pagesCat 4.4Michael Maluenda CastilloNo ratings yet

- Job Separator IV N - NII - NIII Parts ManualDocument3 pagesJob Separator IV N - NII - NIII Parts Manualkbrown02No ratings yet

- Rfi No. Sis-W-Positive Material Identification-SummaryDocument17 pagesRfi No. Sis-W-Positive Material Identification-Summarynorman moralesNo ratings yet

- Service Parts List: Catalog NoDocument4 pagesService Parts List: Catalog NoJosé Daniel ArenasNo ratings yet

- Vibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Document3 pagesVibration Damper and Pulley - Install - Pulley With Split Lock Rings (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Binder1 ModificadoDocument116 pagesBinder1 Modificadohitch10No ratings yet

- S-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireDocument8 pagesS-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireEl rincón de RaulNo ratings yet

- Epl 1617 PDFDocument461 pagesEpl 1617 PDFetuk2100% (1)

- GG 3904 01 enDocument2 pagesGG 3904 01 enSamprit BasuNo ratings yet

- Nozzle Unit RigidDocument2 pagesNozzle Unit RigidR.Gaspar BaltaNo ratings yet

- Binder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1Document10 pagesBinder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1JHONATAN RODRIGUEZ VENTONo ratings yet

- Engine Complete 4Document41 pagesEngine Complete 4Garcia CruzNo ratings yet

- Accessories & Hardware: ShroudsDocument1 pageAccessories & Hardware: ShroudsDario Gabriel Coz RojasNo ratings yet

- Specifications: Customer Item Model Name Part No DateDocument11 pagesSpecifications: Customer Item Model Name Part No Datejoroma58No ratings yet

- Radiography Interpretation Report: TNK-LT-SAR-P-RT-0001Document4 pagesRadiography Interpretation Report: TNK-LT-SAR-P-RT-0001ZaidiNo ratings yet

- TMX800SDocument21 pagesTMX800ScuongNo ratings yet

- T-10, T20 Service Manual (EN) 201710 Rev.D (VR)Document35 pagesT-10, T20 Service Manual (EN) 201710 Rev.D (VR)Leandro PifferNo ratings yet

- Solid State Relay Bajo Consumo PDFDocument2 pagesSolid State Relay Bajo Consumo PDFMiguel Scq SclNo ratings yet

- Spare Parts Catalogue Feedback Unit 101 528 NG024 NG027 NG029 Edition 08Document1 pageSpare Parts Catalogue Feedback Unit 101 528 NG024 NG027 NG029 Edition 08Javier Fundora PaezNo ratings yet

- Tariff Metering PanelDocument12 pagesTariff Metering PanelNikhil JaiswalNo ratings yet

- SM GTP5210 PDFDocument55 pagesSM GTP5210 PDFKyrie AbayaNo ratings yet

- Gpd150-A N-Max Abs Crankshaft & PistonDocument1 pageGpd150-A N-Max Abs Crankshaft & PistonapingNo ratings yet

- GG 3903 01 enDocument1 pageGG 3903 01 enSamprit BasuNo ratings yet

- DD-7 Service Notes PDFDocument24 pagesDD-7 Service Notes PDFjamesNo ratings yet

- ZT600 Series Parts Catalog: Outer CasingDocument12 pagesZT600 Series Parts Catalog: Outer CasingNaeem AkhtarNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Visual DaniellDocument1 pageVisual DaniellNurlaila FitrianiNo ratings yet

- Gambro BCT Trima Apheresis System - Service ManualDocument27 pagesGambro BCT Trima Apheresis System - Service ManualMagdiNo ratings yet

- Atlas C. - Dynapac Weda S30NDocument67 pagesAtlas C. - Dynapac Weda S30NnunovazNo ratings yet

- Service Parts List: Catalog NoDocument4 pagesService Parts List: Catalog NoAbdelbagiNo ratings yet

- A11VLO260DRSDocument20 pagesA11VLO260DRSPercy TP100% (1)

- TMX600ADocument20 pagesTMX600AcuongNo ratings yet

- Key Switch Unit-A1 A2-PcDocument16 pagesKey Switch Unit-A1 A2-PcBranga CorneliuNo ratings yet

- 23902Document1 page23902Samprit BasuNo ratings yet

- Injector Specification: Nozzle Holder Assembly No. 38183Document2 pagesInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinNo ratings yet

- L0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023Document25 pagesL0062-Glatt System-BIN Developement-7-035-200130 - 11-05-2023quality assuranceNo ratings yet

- Transistores Mosfet de PotenciaDocument15 pagesTransistores Mosfet de PotenciaLuis SanchezNo ratings yet

- ROLAND ZLC 540 001eDocument2 pagesROLAND ZLC 540 001egesssmNo ratings yet

- Roland-Zcl-540 Use en R3Document80 pagesRoland-Zcl-540 Use en R3gesssmNo ratings yet

- ROLAND ZCL540eDocument22 pagesROLAND ZCL540egesssmNo ratings yet

- Roland Zat650Document20 pagesRoland Zat650gesssmNo ratings yet

- ROLAND Zat650Document29 pagesROLAND Zat650gesssmNo ratings yet

- ROLAND ZAT540 001eDocument1 pageROLAND ZAT540 001egesssmNo ratings yet

- Roland-Zat-540 Use en R4Document92 pagesRoland-Zat-540 Use en R4gesssmNo ratings yet

- Stylus Pro 5500Document21 pagesStylus Pro 5500gesssmNo ratings yet

- Roland-Zat540 10Document25 pagesRoland-Zat540 10gesssmNo ratings yet

- Exploded View Part List ML 3471Document25 pagesExploded View Part List ML 3471gesssmNo ratings yet

- ROLLAND ZAT540eDocument17 pagesROLLAND ZAT540egesssmNo ratings yet

- P330i-P430i Spare Parts List ROHS - v4.01Document125 pagesP330i-P430i Spare Parts List ROHS - v4.01gesssm100% (1)

- PED Application FormDocument2 pagesPED Application Formsamuk171No ratings yet

- Illustrated Parts Catalog: Figure 50B PAGE 50B-0 DEC.01/14Document3 pagesIllustrated Parts Catalog: Figure 50B PAGE 50B-0 DEC.01/14randoll jamesNo ratings yet

- Classified2019 2 3564799 PDFDocument9 pagesClassified2019 2 3564799 PDFaarianNo ratings yet

- Irc SP 112-2017Document113 pagesIrc SP 112-2017Sanjay67% (9)

- InterimStmt 20231215-1Document9 pagesInterimStmt 20231215-1mitchellallie393No ratings yet

- 2CD474 115pcf ASD 40ksiDocument2 pages2CD474 115pcf ASD 40ksiLitharienNo ratings yet

- Bottlenecks To Promote Merchant Acquiring Business and Strategies To Overcome ItDocument11 pagesBottlenecks To Promote Merchant Acquiring Business and Strategies To Overcome ItDeepak Singh NegiNo ratings yet

- Technical Terms: Bug: Bug Is An Error, Flaw, or A Problem With The Functionality of AnDocument15 pagesTechnical Terms: Bug: Bug Is An Error, Flaw, or A Problem With The Functionality of AnsridharkotteNo ratings yet

- Science Performance TaskDocument3 pagesScience Performance Taskapi-329472482No ratings yet

- TALRUT InspectionDocument1 pageTALRUT Inspectionenemesio_85No ratings yet

- Obtaining Technology - ImplementationDocument13 pagesObtaining Technology - ImplementationEric EugenioNo ratings yet

- Did You Know... ? Member Directory: Recruit A Member Member BenefitsDocument6 pagesDid You Know... ? Member Directory: Recruit A Member Member BenefitsAseem JunejaNo ratings yet

- 3PL 4PL DifferenceDocument2 pages3PL 4PL DifferenceAditya Gupta100% (1)

- Shop DrawingsDocument3 pagesShop DrawingsTommie FanNo ratings yet

- Astm A82Document5 pagesAstm A82Darwin DarmawanNo ratings yet

- Barden Cf6 Series Repair ProgramDocument2 pagesBarden Cf6 Series Repair ProgramNikooNo ratings yet

- General Superintendent or Project ManagerDocument2 pagesGeneral Superintendent or Project Managerapi-78460821No ratings yet

- Sap Basis Faq 1Document9 pagesSap Basis Faq 1Alim Ullah HashmiNo ratings yet

- TWMC Price BookDocument171 pagesTWMC Price BookEdisonNo ratings yet

- Customer Satisfaction StudyDocument2 pagesCustomer Satisfaction StudyranasherdilNo ratings yet

- India S 501 1000 CompaniesDocument38 pagesIndia S 501 1000 Companiespaul_costasNo ratings yet

- Chapter 8Document27 pagesChapter 8Cẩm MiiNo ratings yet

- International Secondary Price List 2021Document157 pagesInternational Secondary Price List 2021Wasif SaeedNo ratings yet

- Markov Decision ProcessDocument21 pagesMarkov Decision ProcessBalqis YafisNo ratings yet

- Smooth Body ConductorsDocument2 pagesSmooth Body Conductorssridhar_cltNo ratings yet