Professional Documents

Culture Documents

MD Assignment 6

MD Assignment 6

Uploaded by

Nava tejaCopyright:

Available Formats

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Reading Drwing PFD's and P & ID'S - OctoberDocument72 pagesReading Drwing PFD's and P & ID'S - OctoberAhmed ElShora100% (5)

- Ural Motorcycle Service Repair ManualDocument193 pagesUral Motorcycle Service Repair Manualesseltine100% (5)

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- INSEM Exam Question Bank For DTSDocument4 pagesINSEM Exam Question Bank For DTSMangesh SNo ratings yet

- MM N S MM N SDocument4 pagesMM N S MM N SAnchita Singh RajawatNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- Design of Machine Members-2Document2 pagesDesign of Machine Members-2Vibin KrishnaNo ratings yet

- MD-II Question BankDocument2 pagesMD-II Question BankmaheshNo ratings yet

- Subject: Machine Design Be Sem VII Mechanical Tutorial:01 (Spur Gear)Document2 pagesSubject: Machine Design Be Sem VII Mechanical Tutorial:01 (Spur Gear)rip111176No ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- Assignment No4Document2 pagesAssignment No4Jai SharmaNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- Faculty of EngineeringDocument2 pagesFaculty of EngineeringSamNihalNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsniteshNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Machine Design II t2 2015 NopassDocument2 pagesMachine Design II t2 2015 NopassAshish VajirNo ratings yet

- Machine_Design_Important_QuestionsDocument17 pagesMachine_Design_Important_Questionssharmaparivaar07No ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Machine Design II Question PaperDocument8 pagesMachine Design II Question PaperProf. Avinash MahaleNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- MD-II Question PapersDocument7 pagesMD-II Question PapersDinesh PatilNo ratings yet

- About I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018Document8 pagesAbout I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018npatil_10No ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- Integrated Mechanical DesignJAN - 11Document4 pagesIntegrated Mechanical DesignJAN - 11SasiKumar PetchiappanNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Dme KtuDocument9 pagesDme Ktuhyy5u6No ratings yet

- Assignment MD IIDocument6 pagesAssignment MD IIRupali PatilNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME)Document3 pagesWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNo ratings yet

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Assignment On Shaft DesignDocument2 pagesAssignment On Shaft DesignRitesh SinghNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Design of machine elements question paper sampleDocument5 pagesDesign of machine elements question paper sampleK V SATHEESHKUMAR MECHNo ratings yet

- UNit-2 Numerical ProblemsDocument16 pagesUNit-2 Numerical ProblemsMarthandeNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- Me 2303 - Design of Machine Elements December 2010Document3 pagesMe 2303 - Design of Machine Elements December 2010Ilaya Perumal K0% (1)

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Tutorial Sheet No 1 On Spur GearDocument3 pagesTutorial Sheet No 1 On Spur GearChirayuNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- DTSDocument7 pagesDTSmithundme659No ratings yet

- Design of Machine Elements question paper sampleDocument5 pagesDesign of Machine Elements question paper sampleK V SATHEESHKUMAR MECHNo ratings yet

- Design of Spur Gear Tutorial No: - DateDocument18 pagesDesign of Spur Gear Tutorial No: - DateAkhilesh NavikNo ratings yet

- Be Summer 2022Document3 pagesBe Summer 2022Karan SheladiyaNo ratings yet

- Machine Design Assignment 3Document2 pagesMachine Design Assignment 3sushantsingh8914No ratings yet

- CME 389 DTS IAT 1 2024Document3 pagesCME 389 DTS IAT 1 2024meganathanNo ratings yet

- Machine DesignDocument3 pagesMachine DesignSantosh Kumar SinghNo ratings yet

- Assignment 1 - Machine DesignDocument1 pageAssignment 1 - Machine DesignmrinalsinghrawatNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Mechanical Engineering s7 & s8Document330 pagesMechanical Engineering s7 & s8The OpenstudioNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Tom I MT QB - 2022-23Document2 pagesTom I MT QB - 2022-23KirtanNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- CNC UNIT-4Document23 pagesCNC UNIT-4Nava tejaNo ratings yet

- MD Assignment 5Document1 pageMD Assignment 5Nava tejaNo ratings yet

- CNC UNIT-5Document10 pagesCNC UNIT-5Nava tejaNo ratings yet

- CNC UNIT-6Document16 pagesCNC UNIT-6Nava tejaNo ratings yet

- CNC Assignment 1 PDFDocument1 pageCNC Assignment 1 PDFNava tejaNo ratings yet

- PV Work TermDocument4 pagesPV Work TermvaraduNo ratings yet

- A Comparison of Approaches To Involute Spur Gear DesignDocument196 pagesA Comparison of Approaches To Involute Spur Gear DesignNursena SEVİNÇNo ratings yet

- Deaerator TransientDocument8 pagesDeaerator TransientAshwini Kumar VermaNo ratings yet

- Sebu8075-11 MDocument70 pagesSebu8075-11 MManuel Alejandro BarocioNo ratings yet

- Informacion Tecnica Bomba de Vacio DekkerDocument1 pageInformacion Tecnica Bomba de Vacio DekkerMiguelon AngelNo ratings yet

- Catalogo de Pecas GeolineDocument456 pagesCatalogo de Pecas GeolineMZ Assistência TécnicaNo ratings yet

- Service Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1Document20 pagesService Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1xxsh100% (1)

- Padeye - SkidDocument16 pagesPadeye - SkidNaresh Kumar100% (1)

- Group 5 Compression AssignmentDocument11 pagesGroup 5 Compression AssignmentAvenash BabooramNo ratings yet

- Online QuizDocument16 pagesOnline QuizPhyo Marn Hone LinNo ratings yet

- Hydrostatic Pressure Test & Leakage Test Report External PipelineDocument2 pagesHydrostatic Pressure Test & Leakage Test Report External PipelineHK Khoo100% (2)

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Gear Pump PDFDocument50 pagesGear Pump PDFAnonymous CMS3dL1T100% (1)

- Truck and Trailer Final Checklist: Date Item ItemDocument2 pagesTruck and Trailer Final Checklist: Date Item ItemCamNo ratings yet

- TPDocument8 pagesTPSteel BeingNo ratings yet

- Pulling Running Sucker RodsDocument10 pagesPulling Running Sucker RodsAmmar KhuderNo ratings yet

- 1.2.1 B Tech All Branch Syllabus 2015 25082015 PDFDocument297 pages1.2.1 B Tech All Branch Syllabus 2015 25082015 PDFBch CharanNo ratings yet

- Parker AdaptersDocument62 pagesParker Adapterstoxicity23No ratings yet

- Stress Calculation in Spherical TankDocument4 pagesStress Calculation in Spherical TankStoragetankdesigntrNo ratings yet

- Solutions: Oil and Natural Gas Corporation Ltd. IndiaDocument41 pagesSolutions: Oil and Natural Gas Corporation Ltd. IndiaShubham WadavkarNo ratings yet

- Tesis ExergiaDocument71 pagesTesis ExergiaYanick SuárezNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- Geotechnical Journal October 2014 SLGS Part 3Document25 pagesGeotechnical Journal October 2014 SLGS Part 3simone stanoNo ratings yet

- A2 Mybmrchuc: VDP-1507-G0011-D01-01Document1 pageA2 Mybmrchuc: VDP-1507-G0011-D01-01tênchỉđểgọiNo ratings yet

- 3.Fmhm Lab ManualDocument56 pages3.Fmhm Lab ManualSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- RBC Heavy Duty Needle Roller BearingsDocument32 pagesRBC Heavy Duty Needle Roller BearingsMitul PatelNo ratings yet

- Dr. Tauseef Ahmad Ansari: Fluid DynamicsDocument37 pagesDr. Tauseef Ahmad Ansari: Fluid DynamicsTauseefNo ratings yet

- Technical Specifications SanNarciso WDDocument15 pagesTechnical Specifications SanNarciso WDFritz NatividadNo ratings yet

MD Assignment 6

MD Assignment 6

Uploaded by

Nava tejaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD Assignment 6

MD Assignment 6

Uploaded by

Nava tejaCopyright:

Available Formats

Manav Rachna International Institute of Research and Studies

School of Engineering & Technology

Mechanical Engineering

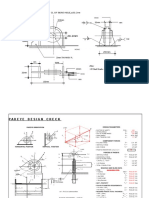

Subject Name: Machine Design Tutorial number: 06

Subject Code: BME-DS-604 Class / Semester: 6ME

Max. Marks : 10 Time Allowed: One Week

Unit-6 Gears

Q.1 It is required to design a pair of spur gears with 20° full-depth involute [CO-4 ,L-5]

teeth consisting of a 20-teeth pinion meshing with a 50 teeth gear. The

pinion shaft is connected to a 22.5 kW, 1450 rpm electric motor. The

starting torque of the motor can be taken as 150% of the rated torque.

The material for the pinion is plain carbon steel Fe 410 (Sut = 410

N/mm2), while the gear is made of grey cast iron FG 200 (Sut =200

N/mm2). The factor of safety is 1.5. Design the gears based on the Lewis

equation and using velocity factor to account for the dynamic load.

Q.2 A pair of spur gears with 20° full-depth involute teeth consists of a 20 teeth [CO-4 ,L-4]

pinion meshing with a 41 teeth gear. The module is 3 mm while the face

width is 40 mm. The material for pinion as well as gear is steel with an

ultimate tensile strength of 600 N/mm2. The gears are heat treated to a

surface hardness of 400 BHN. The pinion rotates at 1450 rpm and the

service factor for the application is 1.75. Assume that velocity factor

accounts for the dynamic load and the factor of safety is 1.5.

Determine the rated power that the gears can transmit.

Q.3 It is required to design a spur gear speed reducer for a compressor running [CO-4 ,L-5]

at 250 rpm driven by a 7.5 kW, 1000 rpm electric motor. The entre

distance between the axes of the gear shafts should be exactly 250 mm.

The starting torque of the motor can be assumed to be 150% of the rated

torque. The gears are made of carbon steel 50C4 (Sut = 700 N/mm2). The

pressure angle is 20°. The factor of safety is 2 for preliminary design based

on the use of velocity factor.

(i) Design the gears and specify their dimensions.

(ii) Assume that the gears are manufactured to meet the requirements of

Grade 6 and calculate the dynamic load by using Buckingham’s equation.

(iii) Calculate the effective load.

(iv) What is the actual factor of safety against bending failure?

(v) Using the same factor of safety against pitting failure, specify suitable

surface hardness for the gears.

Prepared By: Approved By:

Dr. Nitin Kumar Waghmare Dr. Manoj Nayak

Course Coordinator (HOD, ME)

You might also like

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Reading Drwing PFD's and P & ID'S - OctoberDocument72 pagesReading Drwing PFD's and P & ID'S - OctoberAhmed ElShora100% (5)

- Ural Motorcycle Service Repair ManualDocument193 pagesUral Motorcycle Service Repair Manualesseltine100% (5)

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- INSEM Exam Question Bank For DTSDocument4 pagesINSEM Exam Question Bank For DTSMangesh SNo ratings yet

- MM N S MM N SDocument4 pagesMM N S MM N SAnchita Singh RajawatNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityrajushamla9927No ratings yet

- Design of Machine Members-2Document2 pagesDesign of Machine Members-2Vibin KrishnaNo ratings yet

- MD-II Question BankDocument2 pagesMD-II Question BankmaheshNo ratings yet

- Subject: Machine Design Be Sem VII Mechanical Tutorial:01 (Spur Gear)Document2 pagesSubject: Machine Design Be Sem VII Mechanical Tutorial:01 (Spur Gear)rip111176No ratings yet

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 pagesWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakNo ratings yet

- Assignment No4Document2 pagesAssignment No4Jai SharmaNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model Paperlalamramesh78No ratings yet

- Faculty of EngineeringDocument2 pagesFaculty of EngineeringSamNihalNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsniteshNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- 05-04 Machine Design & Cad-II (Me)Document2 pages05-04 Machine Design & Cad-II (Me)Abdul AhadNo ratings yet

- Machine Design II t2 2015 NopassDocument2 pagesMachine Design II t2 2015 NopassAshish VajirNo ratings yet

- Machine_Design_Important_QuestionsDocument17 pagesMachine_Design_Important_Questionssharmaparivaar07No ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Machine Design II Question PaperDocument8 pagesMachine Design II Question PaperProf. Avinash MahaleNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- r05312401 Design of Machine ElementsDocument8 pagesr05312401 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- MD-II Question PapersDocument7 pagesMD-II Question PapersDinesh PatilNo ratings yet

- About I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018Document8 pagesAbout I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018npatil_10No ratings yet

- Machine Design IIDocument3 pagesMachine Design IIRushabh PatelNo ratings yet

- Integrated Mechanical DesignJAN - 11Document4 pagesIntegrated Mechanical DesignJAN - 11SasiKumar PetchiappanNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Dme KtuDocument9 pagesDme Ktuhyy5u6No ratings yet

- Assignment MD IIDocument6 pagesAssignment MD IIRupali PatilNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME)Document3 pagesWWW - Manaresults.Co - In: (Common To ME, AME)Your ChoiceNo ratings yet

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Assignment On Shaft DesignDocument2 pagesAssignment On Shaft DesignRitesh SinghNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- Design of machine elements question paper sampleDocument5 pagesDesign of machine elements question paper sampleK V SATHEESHKUMAR MECHNo ratings yet

- UNit-2 Numerical ProblemsDocument16 pagesUNit-2 Numerical ProblemsMarthandeNo ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- Me 2303 - Design of Machine Elements December 2010Document3 pagesMe 2303 - Design of Machine Elements December 2010Ilaya Perumal K0% (1)

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Tutorial Sheet No 1 On Spur GearDocument3 pagesTutorial Sheet No 1 On Spur GearChirayuNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- DTSDocument7 pagesDTSmithundme659No ratings yet

- Design of Machine Elements question paper sampleDocument5 pagesDesign of Machine Elements question paper sampleK V SATHEESHKUMAR MECHNo ratings yet

- Design of Spur Gear Tutorial No: - DateDocument18 pagesDesign of Spur Gear Tutorial No: - DateAkhilesh NavikNo ratings yet

- Be Summer 2022Document3 pagesBe Summer 2022Karan SheladiyaNo ratings yet

- Machine Design Assignment 3Document2 pagesMachine Design Assignment 3sushantsingh8914No ratings yet

- CME 389 DTS IAT 1 2024Document3 pagesCME 389 DTS IAT 1 2024meganathanNo ratings yet

- Machine DesignDocument3 pagesMachine DesignSantosh Kumar SinghNo ratings yet

- Assignment 1 - Machine DesignDocument1 pageAssignment 1 - Machine DesignmrinalsinghrawatNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Mechanical Engineering s7 & s8Document330 pagesMechanical Engineering s7 & s8The OpenstudioNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Tom I MT QB - 2022-23Document2 pagesTom I MT QB - 2022-23KirtanNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- CNC UNIT-4Document23 pagesCNC UNIT-4Nava tejaNo ratings yet

- MD Assignment 5Document1 pageMD Assignment 5Nava tejaNo ratings yet

- CNC UNIT-5Document10 pagesCNC UNIT-5Nava tejaNo ratings yet

- CNC UNIT-6Document16 pagesCNC UNIT-6Nava tejaNo ratings yet

- CNC Assignment 1 PDFDocument1 pageCNC Assignment 1 PDFNava tejaNo ratings yet

- PV Work TermDocument4 pagesPV Work TermvaraduNo ratings yet

- A Comparison of Approaches To Involute Spur Gear DesignDocument196 pagesA Comparison of Approaches To Involute Spur Gear DesignNursena SEVİNÇNo ratings yet

- Deaerator TransientDocument8 pagesDeaerator TransientAshwini Kumar VermaNo ratings yet

- Sebu8075-11 MDocument70 pagesSebu8075-11 MManuel Alejandro BarocioNo ratings yet

- Informacion Tecnica Bomba de Vacio DekkerDocument1 pageInformacion Tecnica Bomba de Vacio DekkerMiguelon AngelNo ratings yet

- Catalogo de Pecas GeolineDocument456 pagesCatalogo de Pecas GeolineMZ Assistência TécnicaNo ratings yet

- Service Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1Document20 pagesService Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1xxsh100% (1)

- Padeye - SkidDocument16 pagesPadeye - SkidNaresh Kumar100% (1)

- Group 5 Compression AssignmentDocument11 pagesGroup 5 Compression AssignmentAvenash BabooramNo ratings yet

- Online QuizDocument16 pagesOnline QuizPhyo Marn Hone LinNo ratings yet

- Hydrostatic Pressure Test & Leakage Test Report External PipelineDocument2 pagesHydrostatic Pressure Test & Leakage Test Report External PipelineHK Khoo100% (2)

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Gear Pump PDFDocument50 pagesGear Pump PDFAnonymous CMS3dL1T100% (1)

- Truck and Trailer Final Checklist: Date Item ItemDocument2 pagesTruck and Trailer Final Checklist: Date Item ItemCamNo ratings yet

- TPDocument8 pagesTPSteel BeingNo ratings yet

- Pulling Running Sucker RodsDocument10 pagesPulling Running Sucker RodsAmmar KhuderNo ratings yet

- 1.2.1 B Tech All Branch Syllabus 2015 25082015 PDFDocument297 pages1.2.1 B Tech All Branch Syllabus 2015 25082015 PDFBch CharanNo ratings yet

- Parker AdaptersDocument62 pagesParker Adapterstoxicity23No ratings yet

- Stress Calculation in Spherical TankDocument4 pagesStress Calculation in Spherical TankStoragetankdesigntrNo ratings yet

- Solutions: Oil and Natural Gas Corporation Ltd. IndiaDocument41 pagesSolutions: Oil and Natural Gas Corporation Ltd. IndiaShubham WadavkarNo ratings yet

- Tesis ExergiaDocument71 pagesTesis ExergiaYanick SuárezNo ratings yet

- Level Switches-CatalougeDocument4 pagesLevel Switches-CatalougeharishupretiNo ratings yet

- Geotechnical Journal October 2014 SLGS Part 3Document25 pagesGeotechnical Journal October 2014 SLGS Part 3simone stanoNo ratings yet

- A2 Mybmrchuc: VDP-1507-G0011-D01-01Document1 pageA2 Mybmrchuc: VDP-1507-G0011-D01-01tênchỉđểgọiNo ratings yet

- 3.Fmhm Lab ManualDocument56 pages3.Fmhm Lab ManualSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- RBC Heavy Duty Needle Roller BearingsDocument32 pagesRBC Heavy Duty Needle Roller BearingsMitul PatelNo ratings yet

- Dr. Tauseef Ahmad Ansari: Fluid DynamicsDocument37 pagesDr. Tauseef Ahmad Ansari: Fluid DynamicsTauseefNo ratings yet

- Technical Specifications SanNarciso WDDocument15 pagesTechnical Specifications SanNarciso WDFritz NatividadNo ratings yet