Professional Documents

Culture Documents

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

Uploaded by

PEMBINAAN MNM SDN BHDCopyright:

Available Formats

You might also like

- Design With Weldox and HardoxDocument146 pagesDesign With Weldox and Hardoxgkhn100% (5)

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- ASTM F 1306-16 Puncture ResistanceDocument5 pagesASTM F 1306-16 Puncture Resistancejai soni100% (2)

- Material Science Assignment Solution Class Activity Crystal Structure 1Document4 pagesMaterial Science Assignment Solution Class Activity Crystal Structure 1yudhispokemon100% (1)

- Challenges in Qualifying Additive Manufacturing For Turbine - Components - A ReviewDocument22 pagesChallenges in Qualifying Additive Manufacturing For Turbine - Components - A Reviewbryan zhuoNo ratings yet

- CUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-ADocument7 pagesCUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-APEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CDocument7 pagesCUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BDocument7 pagesCUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BPEMBINAAN MNM SDN BHDNo ratings yet

- ZTT Anti-Rodent Cable Cfs02752+cad0171Document8 pagesZTT Anti-Rodent Cable Cfs02752+cad0171Marcelo VenegasNo ratings yet

- ZTT Duct Cable 17-70971 - KAI - 210420 - 195939Document12 pagesZTT Duct Cable 17-70971 - KAI - 210420 - 195939Soebangkit TvNo ratings yet

- ZTT ADSS 96-8T Span100 Icon+Document8 pagesZTT ADSS 96-8T Span100 Icon+Frank GonrongNo ratings yet

- ZTT Ficha Tecnica FFOODocument12 pagesZTT Ficha Tecnica FFOOJosé Luis Franco Calderón BartraNo ratings yet

- ZTT AdssDocument9 pagesZTT AdssJose GonzalesNo ratings yet

- ZTT Adss 20-113931 - BDocument11 pagesZTT Adss 20-113931 - BervanNo ratings yet

- ZTT Duct Cable 20-109788-2-ADocument8 pagesZTT Duct Cable 20-109788-2-AVictor DoyoganNo ratings yet

- Multicom Armored Specs - MDocument8 pagesMulticom Armored Specs - Mnaseem AhamdNo ratings yet

- OFC 24G.652D SSF S1 Fig.8 HDPE DatasheetDocument8 pagesOFC 24G.652D SSF S1 Fig.8 HDPE Datasheetmahadi_prasetyawanNo ratings yet

- Cust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CDocument7 pagesCust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CPEMBINAAN MNM SDN BHDNo ratings yet

- Adss Urbano Stock Spec - Adss12 - 2fo - FTDocument10 pagesAdss Urbano Stock Spec - Adss12 - 2fo - FTRoy BNo ratings yet

- MLT Nma DJ (Gy27) (D) A Dq2y (ZN) 2yDocument2 pagesMLT Nma DJ (Gy27) (D) A Dq2y (ZN) 2yMohsin SiddiqiNo ratings yet

- 2022061310-GYFZY73 - Dielctric Armored Fo 12FDocument6 pages2022061310-GYFZY73 - Dielctric Armored Fo 12FGuillermo Romero UriarteNo ratings yet

- Fisa Tehnica FO Armata Corrugated Steel TapeDocument2 pagesFisa Tehnica FO Armata Corrugated Steel TapeAdrian PodinaNo ratings yet

- Cable F.O. Armada S.M. 12F 9-125um Yofc-KhomaxDocument2 pagesCable F.O. Armada S.M. 12F 9-125um Yofc-KhomaxventasNo ratings yet

- 2YOFC-KHOMAX 2019_SM G,652D_48 CORE_ADSS_DOUBLE JACKET SPAM 200Document7 pages2YOFC-KHOMAX 2019_SM G,652D_48 CORE_ADSS_DOUBLE JACKET SPAM 200Mario Diaz GonzalesNo ratings yet

- YOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Document7 pagesYOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Diana Cristina Vargas RuizNo ratings yet

- Nextractc1 6KNSMDocument6 pagesNextractc1 6KNSMgeorgeta.dumitrache50No ratings yet

- miniSLT-NMA-SJ - (GY12) - A-DQ (ZN) 2YDocument2 pagesminiSLT-NMA-SJ - (GY12) - A-DQ (ZN) 2YMohsin SiddiqiNo ratings yet

- Fibra OpticaDocument5 pagesFibra Opticacarlosantunez111No ratings yet

- 2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Document12 pages2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Felipe Martínez CalderónNo ratings yet

- Ficha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGDocument6 pagesFicha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGNestor RondonNo ratings yet

- HTGD - GYFY - Dielectric Armored CableDocument2 pagesHTGD - GYFY - Dielectric Armored CableGuillermo Romero UriarteNo ratings yet

- YOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mDocument7 pagesYOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mfermac telecomunicacionesNo ratings yet

- OFC 1G.652D Drop Cable LSZH 400N DatasheetDocument8 pagesOFC 1G.652D Drop Cable LSZH 400N DatasheetAnanggadhipa Sedyanto PutroNo ratings yet

- Lpfig8a22c 2KMDocument5 pagesLpfig8a22c 2KMrgear18No ratings yet

- Nextractc1 6KNDocument5 pagesNextractc1 6KNgeorgeta.dumitrache50No ratings yet

- Duplex Zipcord - J-V (ZN) HDocument2 pagesDuplex Zipcord - J-V (ZN) HMohsin SiddiqiNo ratings yet

- Cable de Fibra Optica Monomodo Adss Span 200 de 12-24-48-96 HilosDocument7 pagesCable de Fibra Optica Monomodo Adss Span 200 de 12-24-48-96 Hilosrichard gomez zapataNo ratings yet

- Fiber Optic-Supreme PDFDocument17 pagesFiber Optic-Supreme PDFdHanE anasNo ratings yet

- Fiber Optic & Accessories - BeldenDocument14 pagesFiber Optic & Accessories - Beldensulungbanyu24No ratings yet

- Ficha Tecnica Fibra Figura 8 SM 12 24 48F - MAINTRONICSDocument7 pagesFicha Tecnica Fibra Figura 8 SM 12 24 48F - MAINTRONICSNestor RondonNo ratings yet

- Tech. Gyfty53Document6 pagesTech. Gyfty53Guss SarangoNo ratings yet

- SpecificationofCFOA-SM-DD-S XX FIBRASDocument10 pagesSpecificationofCFOA-SM-DD-S XX FIBRASWDCNET WORKSNo ratings yet

- ZTT Riser CableDocument8 pagesZTT Riser CableJuan DonosoNo ratings yet

- ZTT Opgw 23-XJ25012Document8 pagesZTT Opgw 23-XJ25012miperNo ratings yet

- Spe For Opgw 48F IndiaDocument9 pagesSpe For Opgw 48F IndiaMahesh GKNo ratings yet

- Fo Adss 48 Spam 200 HengtongDocument3 pagesFo Adss 48 Spam 200 Hengtongwilliams eduardo gonzales niñoNo ratings yet

- Nextramicro 24 48 72 96 144 192 216 288 432 576G652DDocument8 pagesNextramicro 24 48 72 96 144 192 216 288 432 576G652Dgeorgeta.dumitrache50No ratings yet

- Ficha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGDocument5 pagesFicha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGluis carreñoNo ratings yet

- Nextractclszh1 6KNSMG652DDocument6 pagesNextractclszh1 6KNSMG652DDRAGOTA ALEXIANo ratings yet

- Line Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWDocument3 pagesLine Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWSadiqNo ratings yet

- Fibra Optica KeezeteckDocument6 pagesFibra Optica KeezeteckAndres Alberto ParraNo ratings yet

- DASA Fiber Optic Cable Specification - KSDDocument8 pagesDASA Fiber Optic Cable Specification - KSDHASSAN MRADNo ratings yet

- Specification ADSS 196FODocument7 pagesSpecification ADSS 196FOJuan Jose PerezNo ratings yet

- HojaDocument3 pagesHojaVincent Conco VegaNo ratings yet

- CCSI Buried DoubleJacket 12 G 652 D DGK Rev0Document2 pagesCCSI Buried DoubleJacket 12 G 652 D DGK Rev0Bilal AlifNo ratings yet

- Double Jacket GYFHTH68 Fiber Optic Cable Specificaiton - GLDocument9 pagesDouble Jacket GYFHTH68 Fiber Optic Cable Specificaiton - GLalonso villaNo ratings yet

- OPGWDocument74 pagesOPGWAnonymous 3y4Z5cUNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Standard Direct Buried CableDocument6 pagesStandard Direct Buried CableZeckrey JikurunNo ratings yet

- LifeFiber ADSS 8-Span 80mDocument8 pagesLifeFiber ADSS 8-Span 80mDiego FigueroaNo ratings yet

- GYTA53-4F Fiber Optic Cable Specification - GLDocument4 pagesGYTA53-4F Fiber Optic Cable Specification - GLAyeshan LahiruNo ratings yet

- DB27600104ENDocument3 pagesDB27600104ENaniba hamzaNo ratings yet

- 【GL】ADSS-24 coreDocument7 pages【GL】ADSS-24 coreAlex GonzalesNo ratings yet

- Leader Cable-Company ProfileDocument12 pagesLeader Cable-Company ProfilePEMBINAAN MNM SDN BHDNo ratings yet

- Cust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CDocument7 pagesCust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BDocument7 pagesCUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CDocument7 pagesCUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-ADocument7 pagesCUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-APEMBINAAN MNM SDN BHDNo ratings yet

- H +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: QuestionsDocument98 pagesH +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: Questionsakky81No ratings yet

- Astm A 645 .99 PDFDocument3 pagesAstm A 645 .99 PDFFrengki100% (1)

- Estofill PDFDocument2 pagesEstofill PDFKaren MiradNo ratings yet

- Lecture 22 PDFDocument6 pagesLecture 22 PDFBhavesh Dilip ChanchlaniNo ratings yet

- Epoxy Grout E33Document2 pagesEpoxy Grout E33AtulNo ratings yet

- Laxminiya-Sohal Jahada 4.Document23 pagesLaxminiya-Sohal Jahada 4.nitish JhaNo ratings yet

- Evolution PDFDocument16 pagesEvolution PDFPasquale CutriNo ratings yet

- MRS1184Document10 pagesMRS1184Samoon IbrahimNo ratings yet

- Copper-AlloysDocument9 pagesCopper-AlloysRm OtNo ratings yet

- Temperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGDocument104 pagesTemperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGUzair BukhariNo ratings yet

- Particle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForDocument5 pagesParticle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForMichele PreghenellaNo ratings yet

- (DIY) Masonry - Brick Barbecue ConstructionDocument4 pages(DIY) Masonry - Brick Barbecue ConstructionLuizGasparNo ratings yet

- 2023 PYD Life Catalog Sublimation Drink-Wares Heat PddwressesDocument18 pages2023 PYD Life Catalog Sublimation Drink-Wares Heat Pddwressesjnmjzy5kpmNo ratings yet

- Strength of Materials: Prepared By: Engr. Jeric P. SarteDocument30 pagesStrength of Materials: Prepared By: Engr. Jeric P. SarteGiacomo EllieNo ratings yet

- Northparkes TFPM CP 07122020Document20 pagesNorthparkes TFPM CP 07122020EDUARDO ROBLES VENEGASNo ratings yet

- HazmatDocument9 pagesHazmategarciachNo ratings yet

- FM-200 DesignDocument48 pagesFM-200 DesignMimi MimiNo ratings yet

- Properties of GPCDocument4 pagesProperties of GPCAngel NazNo ratings yet

- CRGODocument15 pagesCRGOipraoNo ratings yet

- BT101 Engg. Chem Pr. JournalDocument70 pagesBT101 Engg. Chem Pr. JournallavinaNo ratings yet

- Ascometal Grades en PDFDocument8 pagesAscometal Grades en PDFJuan LeonNo ratings yet

- Chapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasDocument27 pagesChapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasMohamad Shahrizal AliasNo ratings yet

- Chapter I Composition of Matter Marilou ELBODocument5 pagesChapter I Composition of Matter Marilou ELBOTn F'dzNo ratings yet

- Modification of Food Characteristics With CMCDocument10 pagesModification of Food Characteristics With CMCJR NilNo ratings yet

- Epoxy SLV MapeiDocument4 pagesEpoxy SLV MapeiAvinash PrajapatiNo ratings yet

- ANATEL Clean-In-Place (CIP) Application NoteDocument8 pagesANATEL Clean-In-Place (CIP) Application NoteMaritza Catalina Melo MartinezNo ratings yet

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

Uploaded by

PEMBINAAN MNM SDN BHDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

CUST TP-ADSS-24C-LongSpan-1-12535 - 32-004 - 202002-3-A

Uploaded by

PEMBINAAN MNM SDN BHDCopyright:

Available Formats

Design No.

: 1000012535 (3200000004)

24-CORE LONG SPAN

ALL-DIELECTRIC

SELF-SUPPORTING FIBER

OPTIC (ADSS) CABLE

1. GENERAL

1.1 SCOPE

This listed specification covers the design requirements and performance standard for the supply of

optical fiber cable in the industry. It also includes LEADER premium designed cable with optical,

mechanical and geometrical characteristics.

Cable type Application

OFC-24G.652D-FASA-S2 Self-supporting aerial installation cable

1.2 CABLE DESCRIPTION

LEADER cable possesses high tensile strength and flexibility in compact cable sizes. At the same

time, it provides excellent optical transmission and physical performance.

1.3 QUALITY

Excellent quality control is achieved through intense in-house quality check and stringent audit

acceptance by ISO 9001.

1.4 RELIABILITY

Initial and periodic product qualification tests for performance and durability are performed rigorously

to ensure product reliability.

1.5 REFERENCE

The cable which LEADER offered are designed, manufactured and tested according to international

standards as follows:

IEC 60793-1 Optical fiber Part 1: Generic specifications

IEC 60793-2 Optical fiber Part 2: Product specifications

Optical fiber cables –Part 4-20: Aerial optical cables along electrical power lines

IEC 60794-4-20

– Family specification for ADSS (All Dielectric Self Supported) optical cables

IEEE 1222 All dielectric self-supporting optical fiber cable

ITU-T G.650 Definition and test methods for the relevant parameters of single-mode fibers

ITU-T G.652 Characteristics of a single-mode optical fiber and cable

EIA/TIA 598 Color code of fiber optic cables

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 2 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

2. OPTICAL FIBER

The optical fiber is made of high pure silica and germanium doped silica. UV curable acrylate material

is applied over fiber cladding as optical fiber primary protective coating. The detail data of optical fiber

performance are shown in the following table.

G.652D Fiber

Specifications

Category Description

Max Average

Attenuation @1310 nm ≤0.40 dB/km ≤0.35 dB/km

Attenuation @1550 nm ≤0.25 dB/km ≤0.23 dB/km

Zero Dispersion Wavelength 1300~1320 nm

Zero Dispersion0 Slope ≤0.092 ps/nm2∙km

Optical

Specifications PMD (Polarization Mode Dispersion) ≤0.2 ps/√km

Cable Cutoff Wavelength (λcc) ≤1260 nm

Macro bending Loss

(100 turns; Ф60 mm) @1625 nm ≤ 0.10 dB

Mode Field Diameter @1310 nm (8.6 mm-9.5 mm) ±0.6 μm

Cladding Diameter 125 ±1μm

Dimensional Core/clad Concentricity Error ≤0.6μm

Specifications Cladding Non-Circularity ≤1.0%

Coating diameter 245 ± 10 μm

Proof stress ≥0.69Gpa

Mechanical

Specifications Proof test (whole length) is 1.0% strain during ≥1.0 sec

Stress corrosion factor (n) is >18

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 3 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

3. CABLE STRUCTURE

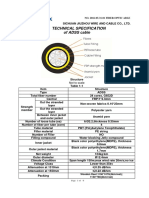

3.1 CABLE TYPE: OFC-24G.652D-FASA-S2

1

2

3

4

5

6

7

8

Picture is only for reference Construction :

Technical Characteristics 1. Outer sheath (AT, black, UV resistant)

The unique extruding technology provides the 2. Strength member (Aramid yarns)

fibers in the tube with good flexibility and 3. Loose tube, fiber and jelly

bending endurance 4. Cable jelly

The unique fiber excess length control 5. Central strength member (FRP)

method provides the cable with excellent 6. Inner sheath (PE black)

mechanical and environmental properties 7. Binder yarn

Multiple water blocking material filling 8. Ripcord*2 (Red)

provides dual water blocking function

Provide good tension performance

Dimension and Properties

Fiber count (G.652D) 24

No of loose tube / filler 2/4

Fiber No. per tube 12

Cable OD 13.3mm± 5%

Physical

Cable weight 156kg/km±10%

Operation temperature range -20 deg C to + 70 deg C

Installation temperature range -10 deg C to + 60 deg C

Transport and storage temperature range -20 deg C to + 70 deg C

MRCL(MAT) ≥12000N

MIT ≥5000N

MOT(MWT) ≥7500N

UTS ≥30000N

Mechanical

Short term crush load 2200N/100mm

Long term crush load 1100N/100mm

Minimal installation bending radius 20 x OD

Minimal operation bending radius 10 x OD

Color code scheme:

Fiber color blue orange green brown grey white red black yellow violet pink aqua

Tube color blue orange / / / / / / / / / /

Note: sheath thickness not consider ripcord portion; Max Span Length:600m

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 4 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

4. TEST REQUIREMENTS

Approved by various professional optical and communication product institution, LEADER also

conduct various in-house testing in its own Laboratory and Test Center. LEADER possess the

technology to keep its fiber attenuation loss within Industry Standards.

The cable is in accordance with applicable standard of cable and requirement of customer. The

following test items are carried out according to corresponding reference.

Routine tests of optical fiber

Mode field diameter IEC 60793-1-45

Mode field Core/clad concentricity IEC 60793-1-20

Cladding diameter IEC 60793-1-20

Cladding non-circularity IEC 60793-1-20

Attenuation coefficient IEC 60793-1-40

Chromatic dispersion IEC 60793-1-42

Cable cut-off wavelength IEC 60793-1-44

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 5 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

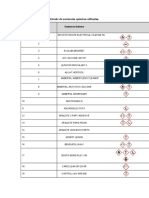

TEST LIST

All the following items are tested in accordance with the TNB specifications, IEC 60793-1 (Optical

fiber), IEC 60794-4-20 (Optical fiber cables), IEEE 1222 and IEC 60794-1-21/22 standard. If

necessary, some test items can replace the test standard after negotiation.

Item Test Method Acceptance test criteria

1) The cable element shall be free from

imperfection.

1 Visual Inspection /

2) The cable surface shall be free from

imperfection.

2

Dimensional Checks

(diameter): Complete cable

/ 13.3mm ±5%

3 Torsion IEC 60794-1-21 IEC 60794-4-20

Cable tensile and cyclic

4.1 IEEE 1222 IEEE 1222 6.5.1.2

stress strain tests

Strength element stress

4.2 IEEE 1222 IEEE 1222 6.5.1.3

strain fatigue test

The ultimate tensile strength of the cable

5 Ultimate Tensile Strength /

shall meet or exceed 100%RTS of the cable.

6 Crush IEC 60794-1-21 IEC 60794-4-20

7 Impact IEC 60794-1-21 IEC 60794-4-20

8 Temperature cycling IEC 60794-1-22 IEC 60794-4-20

9 Aeolian vibration IEC 60794-1-21 IEC 60794-4-20

10 Compound flow IEC 60794-1-22 IEC 60794-1-22

11 Galloping test IEEE 1222 IEEE 1222 (6.5.3.2)

12 Water penetration IEC 60794-1-22 IEC 60794-4-20

1) There shall be no change in optical

attenuation greater than 0.05dB at 1550 nm.

2) Under visual examination without

13 Bend IEC 60794-1-21 magnification, there shall be no damage to

the sheath or cable elements. There shall be

no change in attenuation at 1550nm after the

completion of the test.

14 Repeated Bending IEC 60794-1-21 IEC 60794-4-20

Tracking and erosion

15 IEC 60794-4-20 IEC 60794-4-20

resistance

16 Weight per Unit Length / 156 kg/km ±10%

Polarization Mode

IEC 60793-1-48

17 Dispersion (PMD) ≤0.2 ps/√km

/ G.650.2 (5.1)

Coefficient

1) Maximum Attenuation Coefficient:

0.40 dB/km at 1310 nm

Fiber Optic Cable IEC 60793-1-40 0.25 dB/km at 1550 nm

18

Attenuation / G.650.1 (5.4) 2) Average Attenuation Coefficient:

≤0.35 dB/km at 1310 nm

≤0.23 dB/km at 1550 nm

19 Cable Cut-off Wavelength IEC 60793-1-44 ≤1260 nm

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 6 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

5. PACKING AND DRUM

5.1 LEADER cables are coiled on bakelite, wooden or ironwood drum. During transportation, right

tools should be used to avoid damaging the package and to handle with ease. Cables should be

protected from moisture; kept away from high temperature and fire sparks; protected from over

bending and crushing; protected from mechanical stress and damage.

Wooden Drum

LEADER Cable

(

D*d*B ±5cm weights kg )

D: including seal plate thickness

Length

2Km/reel

Type

OFC-24G.652D-FASA-S2 125*60*75

Note: The drum size & cable weight as above is estimated and final size & weight shall be confirmed

before shipment.

5.2 The color of cable marking is white. (The printing shall be carried out at interval of 1 meter on the

outer sheath of cable) The inner end of cable is then sealed with heat shrinkable end cap to prevent

ingress of water and is made available for testing. The outer end of cable is equipped with heat

shrinkable end cap. Outer sheath marking legend can be changed according to user’s requests.

5.3 Outdoor cable packing

Bakelite, wooden or ironwood drum

Strong wooden batten protection

DATE: 06-06-2023 ALL Rights Reserved Copyright © 2020 page 7 of 7

CB No.: 15013915 (Leader 202002-3-A (24C))

You might also like

- Design With Weldox and HardoxDocument146 pagesDesign With Weldox and Hardoxgkhn100% (5)

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- ASTM F 1306-16 Puncture ResistanceDocument5 pagesASTM F 1306-16 Puncture Resistancejai soni100% (2)

- Material Science Assignment Solution Class Activity Crystal Structure 1Document4 pagesMaterial Science Assignment Solution Class Activity Crystal Structure 1yudhispokemon100% (1)

- Challenges in Qualifying Additive Manufacturing For Turbine - Components - A ReviewDocument22 pagesChallenges in Qualifying Additive Manufacturing For Turbine - Components - A Reviewbryan zhuoNo ratings yet

- CUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-ADocument7 pagesCUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-APEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CDocument7 pagesCUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BDocument7 pagesCUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BPEMBINAAN MNM SDN BHDNo ratings yet

- ZTT Anti-Rodent Cable Cfs02752+cad0171Document8 pagesZTT Anti-Rodent Cable Cfs02752+cad0171Marcelo VenegasNo ratings yet

- ZTT Duct Cable 17-70971 - KAI - 210420 - 195939Document12 pagesZTT Duct Cable 17-70971 - KAI - 210420 - 195939Soebangkit TvNo ratings yet

- ZTT ADSS 96-8T Span100 Icon+Document8 pagesZTT ADSS 96-8T Span100 Icon+Frank GonrongNo ratings yet

- ZTT Ficha Tecnica FFOODocument12 pagesZTT Ficha Tecnica FFOOJosé Luis Franco Calderón BartraNo ratings yet

- ZTT AdssDocument9 pagesZTT AdssJose GonzalesNo ratings yet

- ZTT Adss 20-113931 - BDocument11 pagesZTT Adss 20-113931 - BervanNo ratings yet

- ZTT Duct Cable 20-109788-2-ADocument8 pagesZTT Duct Cable 20-109788-2-AVictor DoyoganNo ratings yet

- Multicom Armored Specs - MDocument8 pagesMulticom Armored Specs - Mnaseem AhamdNo ratings yet

- OFC 24G.652D SSF S1 Fig.8 HDPE DatasheetDocument8 pagesOFC 24G.652D SSF S1 Fig.8 HDPE Datasheetmahadi_prasetyawanNo ratings yet

- Cust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CDocument7 pagesCust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CPEMBINAAN MNM SDN BHDNo ratings yet

- Adss Urbano Stock Spec - Adss12 - 2fo - FTDocument10 pagesAdss Urbano Stock Spec - Adss12 - 2fo - FTRoy BNo ratings yet

- MLT Nma DJ (Gy27) (D) A Dq2y (ZN) 2yDocument2 pagesMLT Nma DJ (Gy27) (D) A Dq2y (ZN) 2yMohsin SiddiqiNo ratings yet

- 2022061310-GYFZY73 - Dielctric Armored Fo 12FDocument6 pages2022061310-GYFZY73 - Dielctric Armored Fo 12FGuillermo Romero UriarteNo ratings yet

- Fisa Tehnica FO Armata Corrugated Steel TapeDocument2 pagesFisa Tehnica FO Armata Corrugated Steel TapeAdrian PodinaNo ratings yet

- Cable F.O. Armada S.M. 12F 9-125um Yofc-KhomaxDocument2 pagesCable F.O. Armada S.M. 12F 9-125um Yofc-KhomaxventasNo ratings yet

- 2YOFC-KHOMAX 2019_SM G,652D_48 CORE_ADSS_DOUBLE JACKET SPAM 200Document7 pages2YOFC-KHOMAX 2019_SM G,652D_48 CORE_ADSS_DOUBLE JACKET SPAM 200Mario Diaz GonzalesNo ratings yet

- YOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Document7 pagesYOFC Technical Specification Aerial Cable ADSS SS 100m, 200m nB1.3Diana Cristina Vargas RuizNo ratings yet

- Nextractc1 6KNSMDocument6 pagesNextractc1 6KNSMgeorgeta.dumitrache50No ratings yet

- miniSLT-NMA-SJ - (GY12) - A-DQ (ZN) 2YDocument2 pagesminiSLT-NMA-SJ - (GY12) - A-DQ (ZN) 2YMohsin SiddiqiNo ratings yet

- Fibra OpticaDocument5 pagesFibra Opticacarlosantunez111No ratings yet

- 2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Document12 pages2.4.3 Especificaciones tecnicas-AerialCable-ADSS-PEAT-Xm-48B1.3Felipe Martínez CalderónNo ratings yet

- Ficha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGDocument6 pagesFicha Tecnica Fibra Ducto SM 96F LSZH Antirroedor CHAQ SIMPLE Maintronics GGNestor RondonNo ratings yet

- HTGD - GYFY - Dielectric Armored CableDocument2 pagesHTGD - GYFY - Dielectric Armored CableGuillermo Romero UriarteNo ratings yet

- YOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mDocument7 pagesYOFC Technical Specification - GYFY (3U) - nB1.3-Span 80mfermac telecomunicacionesNo ratings yet

- OFC 1G.652D Drop Cable LSZH 400N DatasheetDocument8 pagesOFC 1G.652D Drop Cable LSZH 400N DatasheetAnanggadhipa Sedyanto PutroNo ratings yet

- Lpfig8a22c 2KMDocument5 pagesLpfig8a22c 2KMrgear18No ratings yet

- Nextractc1 6KNDocument5 pagesNextractc1 6KNgeorgeta.dumitrache50No ratings yet

- Duplex Zipcord - J-V (ZN) HDocument2 pagesDuplex Zipcord - J-V (ZN) HMohsin SiddiqiNo ratings yet

- Cable de Fibra Optica Monomodo Adss Span 200 de 12-24-48-96 HilosDocument7 pagesCable de Fibra Optica Monomodo Adss Span 200 de 12-24-48-96 Hilosrichard gomez zapataNo ratings yet

- Fiber Optic-Supreme PDFDocument17 pagesFiber Optic-Supreme PDFdHanE anasNo ratings yet

- Fiber Optic & Accessories - BeldenDocument14 pagesFiber Optic & Accessories - Beldensulungbanyu24No ratings yet

- Ficha Tecnica Fibra Figura 8 SM 12 24 48F - MAINTRONICSDocument7 pagesFicha Tecnica Fibra Figura 8 SM 12 24 48F - MAINTRONICSNestor RondonNo ratings yet

- Tech. Gyfty53Document6 pagesTech. Gyfty53Guss SarangoNo ratings yet

- SpecificationofCFOA-SM-DD-S XX FIBRASDocument10 pagesSpecificationofCFOA-SM-DD-S XX FIBRASWDCNET WORKSNo ratings yet

- ZTT Riser CableDocument8 pagesZTT Riser CableJuan DonosoNo ratings yet

- ZTT Opgw 23-XJ25012Document8 pagesZTT Opgw 23-XJ25012miperNo ratings yet

- Spe For Opgw 48F IndiaDocument9 pagesSpe For Opgw 48F IndiaMahesh GKNo ratings yet

- Fo Adss 48 Spam 200 HengtongDocument3 pagesFo Adss 48 Spam 200 Hengtongwilliams eduardo gonzales niñoNo ratings yet

- Nextramicro 24 48 72 96 144 192 216 288 432 576G652DDocument8 pagesNextramicro 24 48 72 96 144 192 216 288 432 576G652Dgeorgeta.dumitrache50No ratings yet

- Ficha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGDocument5 pagesFicha Tecnica Fibra Ducto SM 12-24F LSZH Antirroedor Maintronics GGluis carreñoNo ratings yet

- Nextractclszh1 6KNSMG652DDocument6 pagesNextractclszh1 6KNSMG652DDRAGOTA ALEXIANo ratings yet

- Line Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWDocument3 pagesLine Item 25 To 28 # Datasheet - 4F, 6F, 8F, 12F D UTA 2SW SS PE BK 7.5MM - GYXTWSadiqNo ratings yet

- Fibra Optica KeezeteckDocument6 pagesFibra Optica KeezeteckAndres Alberto ParraNo ratings yet

- DASA Fiber Optic Cable Specification - KSDDocument8 pagesDASA Fiber Optic Cable Specification - KSDHASSAN MRADNo ratings yet

- Specification ADSS 196FODocument7 pagesSpecification ADSS 196FOJuan Jose PerezNo ratings yet

- HojaDocument3 pagesHojaVincent Conco VegaNo ratings yet

- CCSI Buried DoubleJacket 12 G 652 D DGK Rev0Document2 pagesCCSI Buried DoubleJacket 12 G 652 D DGK Rev0Bilal AlifNo ratings yet

- Double Jacket GYFHTH68 Fiber Optic Cable Specificaiton - GLDocument9 pagesDouble Jacket GYFHTH68 Fiber Optic Cable Specificaiton - GLalonso villaNo ratings yet

- OPGWDocument74 pagesOPGWAnonymous 3y4Z5cUNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Standard Direct Buried CableDocument6 pagesStandard Direct Buried CableZeckrey JikurunNo ratings yet

- LifeFiber ADSS 8-Span 80mDocument8 pagesLifeFiber ADSS 8-Span 80mDiego FigueroaNo ratings yet

- GYTA53-4F Fiber Optic Cable Specification - GLDocument4 pagesGYTA53-4F Fiber Optic Cable Specification - GLAyeshan LahiruNo ratings yet

- DB27600104ENDocument3 pagesDB27600104ENaniba hamzaNo ratings yet

- 【GL】ADSS-24 coreDocument7 pages【GL】ADSS-24 coreAlex GonzalesNo ratings yet

- Leader Cable-Company ProfileDocument12 pagesLeader Cable-Company ProfilePEMBINAAN MNM SDN BHDNo ratings yet

- Cust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CDocument7 pagesCust Tp-Duct-48c-1-11762 - 32-006 - 202002-2-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BDocument7 pagesCUST TP-ADSS-24C-Short Span-1-11980 - 32-001 - 202002-1-BPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CDocument7 pagesCUST TP-ADSS-48-Short Span-1-11761-32-002 - 202002-1-CPEMBINAAN MNM SDN BHDNo ratings yet

- CUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-ADocument7 pagesCUST TP-ADSS-48C-LongSpan-1-12426-32-003 - 202002-3-APEMBINAAN MNM SDN BHDNo ratings yet

- H +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: QuestionsDocument98 pagesH +CL 2Hcl 3bacl +al (So) 2alcl +3baso 2Na+2H O 2Naoh+H: Questionsakky81No ratings yet

- Astm A 645 .99 PDFDocument3 pagesAstm A 645 .99 PDFFrengki100% (1)

- Estofill PDFDocument2 pagesEstofill PDFKaren MiradNo ratings yet

- Lecture 22 PDFDocument6 pagesLecture 22 PDFBhavesh Dilip ChanchlaniNo ratings yet

- Epoxy Grout E33Document2 pagesEpoxy Grout E33AtulNo ratings yet

- Laxminiya-Sohal Jahada 4.Document23 pagesLaxminiya-Sohal Jahada 4.nitish JhaNo ratings yet

- Evolution PDFDocument16 pagesEvolution PDFPasquale CutriNo ratings yet

- MRS1184Document10 pagesMRS1184Samoon IbrahimNo ratings yet

- Copper-AlloysDocument9 pagesCopper-AlloysRm OtNo ratings yet

- Temperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGDocument104 pagesTemperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGUzair BukhariNo ratings yet

- Particle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForDocument5 pagesParticle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForMichele PreghenellaNo ratings yet

- (DIY) Masonry - Brick Barbecue ConstructionDocument4 pages(DIY) Masonry - Brick Barbecue ConstructionLuizGasparNo ratings yet

- 2023 PYD Life Catalog Sublimation Drink-Wares Heat PddwressesDocument18 pages2023 PYD Life Catalog Sublimation Drink-Wares Heat Pddwressesjnmjzy5kpmNo ratings yet

- Strength of Materials: Prepared By: Engr. Jeric P. SarteDocument30 pagesStrength of Materials: Prepared By: Engr. Jeric P. SarteGiacomo EllieNo ratings yet

- Northparkes TFPM CP 07122020Document20 pagesNorthparkes TFPM CP 07122020EDUARDO ROBLES VENEGASNo ratings yet

- HazmatDocument9 pagesHazmategarciachNo ratings yet

- FM-200 DesignDocument48 pagesFM-200 DesignMimi MimiNo ratings yet

- Properties of GPCDocument4 pagesProperties of GPCAngel NazNo ratings yet

- CRGODocument15 pagesCRGOipraoNo ratings yet

- BT101 Engg. Chem Pr. JournalDocument70 pagesBT101 Engg. Chem Pr. JournallavinaNo ratings yet

- Ascometal Grades en PDFDocument8 pagesAscometal Grades en PDFJuan LeonNo ratings yet

- Chapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasDocument27 pagesChapter 3 Part 1 Pavement Materials: BY: Mohamad Shahrizal Bin AliasMohamad Shahrizal AliasNo ratings yet

- Chapter I Composition of Matter Marilou ELBODocument5 pagesChapter I Composition of Matter Marilou ELBOTn F'dzNo ratings yet

- Modification of Food Characteristics With CMCDocument10 pagesModification of Food Characteristics With CMCJR NilNo ratings yet

- Epoxy SLV MapeiDocument4 pagesEpoxy SLV MapeiAvinash PrajapatiNo ratings yet

- ANATEL Clean-In-Place (CIP) Application NoteDocument8 pagesANATEL Clean-In-Place (CIP) Application NoteMaritza Catalina Melo MartinezNo ratings yet