Professional Documents

Culture Documents

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Uploaded by

sinitt921Copyright:

Available Formats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- The Approach: The Living Building ChallengeDocument8 pagesThe Approach: The Living Building ChallengenethNo ratings yet

- Hoi - Thao T11-03 LuuDocument22 pagesHoi - Thao T11-03 LuuvuhachauNo ratings yet

- Final Group Work PDFDocument8 pagesFinal Group Work PDFTeddy MatiekaNo ratings yet

- Modern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALDocument86 pagesModern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALAe R ONNo ratings yet

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Precast Concrete Combined)Document13 pagesPrecast Concrete Combined)Ssu NguNo ratings yet

- Saint Louis College: BT3 (AR A315D)Document9 pagesSaint Louis College: BT3 (AR A315D)Dennis Roel T. DulayNo ratings yet

- Brick Making MachineDocument18 pagesBrick Making MachineSyed Nasir AhmedNo ratings yet

- Financial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabDocument6 pagesFinancial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabtienaicvnNo ratings yet

- Precast Concrete and Prestressed Concrete: Report Submitted By: Group IiDocument6 pagesPrecast Concrete and Prestressed Concrete: Report Submitted By: Group IiVaishnavi SikchiNo ratings yet

- Precast Concrete SlabDocument55 pagesPrecast Concrete SlabKimberly LoNo ratings yet

- Precast Concrete Slab: Here Starts The Lesson!Document55 pagesPrecast Concrete Slab: Here Starts The Lesson!Kimberly LoNo ratings yet

- 2 - RC Design I Introduction SDocument32 pages2 - RC Design I Introduction SMohamad DuhokiNo ratings yet

- Research Architectural: Tech VDocument6 pagesResearch Architectural: Tech VMark DanielNo ratings yet

- Building: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyDocument4 pagesBuilding: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyGlenn Mendoza100% (1)

- Pre Engineered BuildingDocument21 pagesPre Engineered BuildingJamaica Mae AndayaNo ratings yet

- .Precast Concrete ConnectionsDocument3 pages.Precast Concrete Connectionsparamarthasom1974No ratings yet

- Code Tiltup PrecastDocument47 pagesCode Tiltup Precastkorosh75No ratings yet

- Mivan TechnologyDocument24 pagesMivan TechnologyArjun MNo ratings yet

- Concrete MaterialsDocument2 pagesConcrete MaterialsVirgilio BiagtanNo ratings yet

- A Proposal For The Classification of Structural SyDocument10 pagesA Proposal For The Classification of Structural SyJesús Román CamachoNo ratings yet

- HKCV BT5 Alternative Building Construction System Notes 01Document34 pagesHKCV BT5 Alternative Building Construction System Notes 01Jessa ObraNo ratings yet

- Paper On Design Voded SlabDocument9 pagesPaper On Design Voded SlabAnonymous b9fkTYfEoRNo ratings yet

- Quindao Liza Marie PDocument5 pagesQuindao Liza Marie PLIZA MARIE QUINDAONo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteMariz Ellaine BaltazarNo ratings yet

- Pre Engineered BuildingDocument21 pagesPre Engineered BuildingJamaica Mae AndayaNo ratings yet

- Advanced Construction and Materials: Pre-Stressed ConcreteDocument19 pagesAdvanced Construction and Materials: Pre-Stressed ConcreteswethaadusumilliNo ratings yet

- Types of Structural SytemDocument10 pagesTypes of Structural SytemOlga KosuoweiNo ratings yet

- CE18B037 Assignment2Document9 pagesCE18B037 Assignment2Kota Thapaswini ce18b037No ratings yet

- Prestrest ConcreteDocument6 pagesPrestrest ConcreteWan ImranNo ratings yet

- Basic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewDocument10 pagesBasic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewJoe Bryan SamsonNo ratings yet

- Fama Homework01Document2 pagesFama Homework01Bojo FamaNo ratings yet

- ARCH402 Nora Ahmd 21902492Document16 pagesARCH402 Nora Ahmd 2190249221902492No ratings yet

- A Proposal For The Classification of Structural SyDocument10 pagesA Proposal For The Classification of Structural SyAngelica U SiraitNo ratings yet

- BUILDING TECHNOLOGY 5 HardDocument80 pagesBUILDING TECHNOLOGY 5 HardMargie Ocampo100% (1)

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- LP3 in CE 7Document17 pagesLP3 in CE 7Jhon Rhico DabuetNo ratings yet

- 1.1 Background of StudyDocument7 pages1.1 Background of StudyMuhamad Arief AmienNo ratings yet

- NL5 Notes - Weak BLDG Elements - WengYWDocument6 pagesNL5 Notes - Weak BLDG Elements - WengYWjeffyeung2015No ratings yet

- Universiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentDocument14 pagesUniversiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentEzanie IzyanNo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteSheryll de GuzmanNo ratings yet

- 11737-Article Text PDF-38368-1-10-20180601Document9 pages11737-Article Text PDF-38368-1-10-20180601maruns004No ratings yet

- Concrete Slab TypesDocument6 pagesConcrete Slab TypesMukovhe MuvhaliNo ratings yet

- Brosur 1 Lorem - SampleDocument44 pagesBrosur 1 Lorem - SampleChristopher DarrenNo ratings yet

- Contour Crafting: Construction Technologies .Document12 pagesContour Crafting: Construction Technologies .Jaimar AlcantaraNo ratings yet

- Building Report Hollow Core SlabDocument13 pagesBuilding Report Hollow Core SlabAhmad OmarNo ratings yet

- Basic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewDocument10 pagesBasic Types of Sheet Pile Walls and Their Application in The Construction Industry-A Reviewomed muhammadNo ratings yet

- Reinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisDocument23 pagesReinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisNI KH ILNo ratings yet

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- Open Prefabrication SystemsDocument17 pagesOpen Prefabrication SystemsRemya R. Kumar100% (2)

- TB 08 Building Envelope - CompressedDocument63 pagesTB 08 Building Envelope - CompressedNraisyahaldaf100% (1)

- Brosur Wika Beton Edisi 2022Document44 pagesBrosur Wika Beton Edisi 2022Dinda Hani SyarifahNo ratings yet

- Lecture 3 Tensile StructureDocument32 pagesLecture 3 Tensile StructureRuthNo ratings yet

- Engineer TermsDocument8 pagesEngineer TermsBintang RamadhanNo ratings yet

- Emag Lounge January 2020Document24 pagesEmag Lounge January 2020Constro FacilitatorNo ratings yet

- Seismic Behaviour of Buildings Having Flat Slabs With DropsDocument6 pagesSeismic Behaviour of Buildings Having Flat Slabs With DropsHani AdelNo ratings yet

- 1 Prefabricated StructuresDocument42 pages1 Prefabricated Structurespooja apteNo ratings yet

- Research I Reinforcement Concrete II Prestressed Reinforced ConcreteDocument6 pagesResearch I Reinforcement Concrete II Prestressed Reinforced ConcreteHamez HabibiNo ratings yet

- Seismic Design of Cold Formed Steel Structures in Residential ApplicationsDocument3 pagesSeismic Design of Cold Formed Steel Structures in Residential ApplicationsKristijanRunevskiNo ratings yet

- WelcomeDocument3 pagesWelcomeadam ArthurNo ratings yet

- RECO 2040-CPM1-2-ElementalEstimate - S2Document10 pagesRECO 2040-CPM1-2-ElementalEstimate - S2King Heng Shum100% (1)

- For Construction: Beachfront Beachfront Softscape-Shrub-Enlarged 08Document1 pageFor Construction: Beachfront Beachfront Softscape-Shrub-Enlarged 08Nhan Phan ThanhNo ratings yet

- Metaroll Pamphlet 01Document4 pagesMetaroll Pamphlet 01rohit6varma-4No ratings yet

- List CecDocument51 pagesList Cecajeez86No ratings yet

- Shift Report - November 24, 2023-2nd ShiftDocument4 pagesShift Report - November 24, 2023-2nd Shiftbobowapthree19No ratings yet

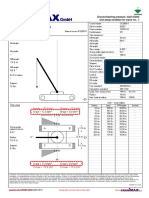

- Co-Extrusion Dies Based On Spiral Mandrel TechnologyDocument10 pagesCo-Extrusion Dies Based On Spiral Mandrel TechnologygermanpoloramosNo ratings yet

- Saic-Q-1066 Rev 1 (Final)Document3 pagesSaic-Q-1066 Rev 1 (Final)ryann mananquilNo ratings yet

- Instructions On Illegal Constructions dt.08.08.2020Document2 pagesInstructions On Illegal Constructions dt.08.08.2020Nagarkurnool MunicipalityNo ratings yet

- 2506 980-6000CLXIFT 8000CLXIFT-installDocument79 pages2506 980-6000CLXIFT 8000CLXIFT-installalbertgoukasianNo ratings yet

- Mep Technical & Financial Proposal - Larus Convenience CentreDocument78 pagesMep Technical & Financial Proposal - Larus Convenience CentreGabriel OdebodeNo ratings yet

- Complete PlanDocument1 pageComplete PlanNiluka EkanayakaNo ratings yet

- Rheobuild 850 - 09-06 - Basf PDFDocument2 pagesRheobuild 850 - 09-06 - Basf PDFnasser elbahyNo ratings yet

- Bill of Quantity For Wires, Cables, and TraysDocument2 pagesBill of Quantity For Wires, Cables, and TraysMosa Elnaid ElnaidNo ratings yet

- Texfilm404-2 ExpJnt DSDocument1 pageTexfilm404-2 ExpJnt DSdanny buiNo ratings yet

- ST - 13.01.05 Technical Specification For PipingDocument16 pagesST - 13.01.05 Technical Specification For PipingMaksim.em001No ratings yet

- Crawler CraneDocument11 pagesCrawler CraneidonotspammeNo ratings yet

- 07 - CIC 2016 Detailed Design PDFDocument8 pages07 - CIC 2016 Detailed Design PDFLívia A. SouzaNo ratings yet

- 4JMTXS ParkerDocument1 page4JMTXS ParkerantonyNo ratings yet

- Aastho 2011 2a TestsDocument947 pagesAastho 2011 2a Testselmer portilloNo ratings yet

- Types of RaftersDocument34 pagesTypes of RaftersJeriza AquinoNo ratings yet

- TCPM - Ikue Consulting Co - , LTD - Specification DispatchDocument30 pagesTCPM - Ikue Consulting Co - , LTD - Specification DispatchSPACELINK AERO SERVICESNo ratings yet

- Method Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonDocument16 pagesMethod Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonAhmad Rafly ZulfikarNo ratings yet

- Dubai Workshop RegistrationDocument2 pagesDubai Workshop RegistrationmfkmughalNo ratings yet

- Lifting StandardsDocument17 pagesLifting Standardsanantharamakrishnan kNo ratings yet

- FCP PRE-QualificationDocument80 pagesFCP PRE-Qualificationeromax1No ratings yet

- Quickie Load Form BlankDocument1 pageQuickie Load Form BlankAkshay KadiaNo ratings yet

- CvmniDocument6 pagesCvmniPalani Vel RajanNo ratings yet

- Mycelium Fungi As A Building Material: Maria Saxton Rise Writer Feb 14, 2020Document10 pagesMycelium Fungi As A Building Material: Maria Saxton Rise Writer Feb 14, 2020Prerana CholakheNo ratings yet

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Uploaded by

sinitt921Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Strengthening of Reinforced Concrete Hollow Core Slabs: July 2021

Uploaded by

sinitt921Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/353326643

strengthening of reinforced concrete hollow core slabs

Article · July 2021

DOI: 10.4001/182

CITATIONS READS

0 446

3 authors, including:

Ahmed Sharaf Ahmed Elmihi

Menoufia University Menoufia University

2 PUBLICATIONS 0 CITATIONS 3 PUBLICATIONS 0 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Ahmed Sharaf on 18 July 2021.

The user has requested enhancement of the downloaded file.

Research Paper on Concrete Structures, 2021 1

strengthening of reinforced concrete hollow core slabs

A.Rafat* , A.Sharaf** , A.Elmihi***

*

Civil Engineering Department, Faculty of Engineering of Shebin Elkom

**

Civil Engineering Department, Faculty of Engineering of Shebin Elkom

***

Civil Engineering Department, Faculty of Engineering of Shebin Elkom

Abstract: Hollow core slabs are highly walls, brick built walls, steel structures, on-

developed structural elements and are used all site concrete cast structures.

over the world due to their many advantages For infrastructure: hollow core slabs are

and diverse application. used extensively to protect roads from natural

Despite this, it has disadvantages that must be dangers. They are used to construct anti-

taken care of and taken in precautions so that landslide and avalanche guards as well as the

this does not lead to serious damage. road decking itself, all elements requiring high

Strengthening of reinforced concrete structural loading specifications Moreover hollow core

elements using advanced composite materials slabs possess certifiable fire resistances and

has become a very important issue. offer an economic solution to construct fire

Because of its significant role in the stop walls for warehouses, industrial buildings

construction and development process. and car park.

**This research is a summary of previous The content of the search

researchers work done in this area.

what is the definition of hollow core slab?

INTRODUCTION A hollow core slab, also known as a voided

Hollow core slabs are prestressed concrete

slab, hollow core plank or simply a concrete

elements that have a constant cross section.

They are manufactured using high tensile plank is a precast slab of prestressed concrete

strength prestressed strands or single wire

typically used in the construction of floors in

which are embedded within the element.

The production of these elements is achieved multi-story apartment buildings. The slab has

using our Extruder and Slip former machines

been especially popular in countries where the

that cast in one phase along a production bed

without the need of any formworks. emphasis of home construction has been on

In addition to they are one of the most well

precast concrete, including Northern Europe

known prefabricated elements because of their

technical and economic characteristics. and former socialist countries of Eastern

Hollow core slabs are widely used for flooring

Europe. Precast concrete popularity is linked

and wall panels in industrial commercial,

residential , infrastructure construction. with low-seismic zones and more economical

hollow core slabs can be used with different

constructions because of fast building

supporting structures concrete constructed

assembly, lower self weight (less material),

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 2

etc. Precast hollow-core elements is also One is a dry cast or extrusion system where

known as the most sustainable floor/roof a very low slump concrete is forced

through the machine. The cores are formed

system.

with augers or tubes with the concrete

what is the importance of voids in hollow being compacted around the cores.

core slab The second system uses a higher slump

hollow core slab has longitudinal voids concrete. Sides are formed either with

extending the full slab length which makes the

stationary, fixed forms or with forms

slab lighter than a considerable solid slab of

equal depth or strength The lower weight is attached to the machine with the sides

very important issue because it reduced the being slip formed. The cores in the normal

costs of transportation and construction costs. slump, or wet cast, systems are formed

with either lightweight aggregate fed

What are The most common thicknesses through tubes attached to the casting

with corresponding spans?

machine, pneumatic tubes anchored in a

Hollow core slab thickness 150 mm fixed form or long tubes attached to the

(Maximum span 7.0 m) casting machine which slip form the cores.

Hollow core slab thickness 200 mm For the low slump concretes, water content

(Maximum span 11.0 m) is limited to slightly more than that

Hollow core slab thickness 265 mm

required for cement hydration.

(Maximum span 13.5 m)

Hollow core slab thickness 320 mm Water-cement ratios are typically about

(Maximum span 16.0 m) 0.3. Mixing is critical because the limited

Hollow core slab thickness 370 mm water available must be well dispersed in

(Maximum span 14.0 m) the mix. Water reducing admixtures can be

Hollow core slab thickness 400 mm used to optimize a mix by reducing cement

(Maximum span 18.5 m) and water requirements while still retaining

Hollow core slab thickness 500 mm

adequate workability for proper

(Maximum span 20.0 m)

370-mm hollow core slabs have been compaction of the concrete by the machine.

specially developed for residential Air entrainment admixtures are not

buildings to fulfill sound insulation effective in the dry mix concrete. With the

requirements without additional topping low water-cement ratios and compaction

concrete. placing method, air is difficult to disperse

Methods of Manufacturing hollow core well and maintain.

slab: [18] Advantages of Hollow Core Slabs

Two basic manufacturing methods are

currently in use for the production of

hollow core slabs.

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 3

Speed of Erection Sustainable

Hollow core slabs can be installed quickly and Hollow core is an extremely durable

safely on-site in variable weather conditions, construction product, offering an exceptional

unlike in-situ concrete. lifespan through resistance to corrosion and

cracking.

They reduce the number of workers needed

on-site and provide an immediate un propped As it is produced in a controlled factory

working platform. environment, it also enables the reduction of

waste, noise and emissions during the entire

These benefits allow much faster completion construction process

of flooring and quicker erection of buildings,

increasing profits for the contractor. Quality

Lower Material Usage Prestressed hollow core requires the use of

high quality raw materials, such as high

Hollow core slabs are prestressed. strength concrete, and low relaxation steel

Pretensioned concrete allows for shallower wire/strand.

elements, reducing the amount of steel and

concrete needed. Strict quality assurance procedures and

controls can be applied throughout the

As they can achieve long spans unsupported, production process, ensuring that the product

this can also reduce the need for other meets the required national and international

supporting frame elements, such as columns standards.

and beams.

Lightweight

Cores that run longitudinally through hollow

core slabs mean that up to around 50% of the Depending on the profile of the slab, hollow

floor is void. core can be up to 50% or more in terms of

void/solid ratio.

Structural Efficiency

This means that corresponding supports and

Hollow core offers a versatile solution in steel, elements within the structure can also be

masonry and concrete structures. lighter in weight.

High span/depth ratios when compared to Diaphragm Action

other flooring methods make them suitable for

a wide range of applications, from housing, to In certain conditions, such as seismic activity

commercial and industrial buildings, car parks or high winds, lateral forces are transmitted

and sports stadia. through the floor of a building.

Wide, column-free interiors give more

flexibility in building design and usage

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 4

Hollow core slabs can be used to provide a It also fills all the spaces between the Hollow

rigid single unit, and therefore a diaphragm core tiles and the surface becomes finishabl.

action under such conditions. The Influence of Cross Section Shape on

Strengthening of Hollow Core Slabs

Sound Insulation Increasing pressure in separate areas when

reconstructing and improving industrial

When compared to solid units, prestressed buildings, may necessarily mean strengthening

hollow core can provide superior sound structural surfaces of buildings. In

insulation, an important consideration when experimental and analytical assessment

used in residential buildings. hollow cores slabs are represented as T-beams

and I-beams. The width of the beam edge

Services decreases according to the dimensions of the

voids inside the slab. In this paper the authors

The cores/voids found in hollow core slabs

test bearing strength and deformability of

provide natural ducts for services such as

hollow core slabs in different conditions of

electrical cables and plumbing

strengthening. Furthermore, the scholars

Thermal Efficiency perform their calculations in a non-linear

system, with a progressive loading, until the

Hollow core slabs offer excellent thermal samples are destroyed, with a plastic hinge

characteristics, helping to reduce energy formed in the area extended in a slab cross

consumption used in the heating and cooling section. Simulation and figure analyses were

of structures. designed in ANSYS program. The

researchers’ resulting of the stress-strain state

disadvantage of hollow core slab system of hollow core slabs is observed

are: experimentally at various stages of loading.

● Relative flexibility in the walls and not The researchers compared calculations of

entirely because of the block. slabs with the full-scale cross section shape

● Weak in moisture resistance. and calculations of the same I-beam slabs.

● It cannot bear high live loads such as Though, the investigators dwell on the impact

flats. of the cross-section on the results of the

● Difficulty in maintenance and repair. maximum slab deflections.

● Cracks occur when the hollow slabs The paper is also dedicated to a variety of

come into contact with the thinner slab. strengthening modes and it explains that the

What is the benefit of the saccharide layer cracking point for full-scale slabs comes after.

that is placed over the Hollow core slab and

what are its specifications?

The screed layer is a reinforced concrete layer

with a thickness of 5 to 7 cm. It is poured over

the Hollow core slab after their installation.

The aim is to make the structure deal as a

single unit, as there are beams of beams that

are overlapped with the screed iron.

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 5

compared to a cross section matching with the

drawings. This was a shock to them. When

casting four beds a day, they wasted 8 cubic

meters of concrete – money – every day. This

means 48 cubic meters a week, 192 cubic

meters a month, and almost 2,500 cubic

meters every year. I think this clearly

highlights the importance of suitable and

properly fitting spares and wears.

Also at the same factory, the extruder settings

What is the approximate percentage of

weren’t the most efficient. Their 200 mm slab

lowering the costs when using precast

height was 206 mm. When we went through

hollow core slab method instead of

this together, we could see that the 6mm

monolithic RC slab?

oversized slab meant an extra cubic meter pf

Save costs by saving concrete The truth is that

concrete consumption per bed

you can make the biggest savings in money

So, the factory used almost 3 cubic meters

with savings in concrete as concrete is by far

more concrete per bed than needed. It meant

the most expensive part in hollow core slab

that it was actually expensive to save in spare

production.

and wear part purchases.

Roughly speaking, concrete / strands account

for about 55% of the slab price and wear parts Behavior of Prestressed Hollow-Core

for only 3%. Hence, it is really a no-brainer to

see how to make savings if you want to save

Slabs Strengthened in Flexure with

on production costs. Near-Surface Mounted Carbon Fiber-

Reinforced Polymer Reinforcement

[14]

Flexural strengthening of reinforced concrete

using near-surface mounted (NSM) fiber-

reinforced polymer (FRP) composites is a

widely studied topic, and a promising

technology. However, overlooked applications

such as prestressed concrete and one-way

slabs require further experimental

Here are a few examples of what kind of investigation and theoretical refinement in

numbers we are talking about order to develop comprehensive design

It hasn’t been long since I visited a factory guidelines. This paper investigates the

using copy screws and sleeves. Their six-hole behavior of prestressed hollow-core slabs

and 200 mm slab cores were 15 mm smaller strengthened in flexure with NSM carbon FRP

than the cross section in the drawings. strip reinforcement. Seven full-scale simply

Furthermore, they were happy with the slab. supported slab specimens were tested to

Together, we calculated that they used about 2 failure under two-point monotonic load

cu. m. more concrete on each cast bed configuration.

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 6

Experimental variables included two different through the concrete. These longitudinal

internal prestressing reinforcement ratios, and cracks, extending with a vertical crack, trigger

three different NSM strengthening local debonding between the CFRP strips and

reinforcement ratios. This paper examines the concrete during the explosion. Maximum

cracking behavior and modes of failure, load- deflections and crack distribution predicted by

strain relationships, deflections, and the numerical analysis are in a good

strengthened capacities. Also, a comparison agreement with the experimental results.

between experimental results and theoretical

predictions by relevant Canadian and

American Standards or guidelines is present.

Blast response of retrofitted

reinforced concrete hollow core slabs

under a close distance explosion:

This article discusses the blast response of

reinforced concrete hollow core slabs

(RCHCS) with a topping layer subjected to a

close distance explosion and investigates the

efficiency of carbon fiber reinforced polymer

(CFRP) as externally bonded reinforcement

(EBR) in order to improve the blast resistance

of the slabs. Three simply supported RCHCS

with a topping layer are subjected to an

explosion of 1.5 kg of C4 suspended at mid-

span, underneath the slabs at a standoff

distance of 0.5 m. One of the slabs is used as a

reference specimen and the two remaining Conclusion

ones are retrofitted with different amounts of There have been many developments in

CFRP. A numerical analysis is also carried out concrete technologies that have had a major

using the finite element (FE) software LS- impact on structural systems.

DYNA to complement the experimental Hollow core slab contributed to this Great

results of the blast campaign. The results development.

indicate that bonding CFRP strips on the millimetres are so important in hollow core

surface opposite to the explosion is an slab production – is cost savings. Also, when

effective way to reduce the mid-span you use original spare parts, it is easy to make

deflections and to limit the damage levels in the best settings for your extruder.

the slabs. A reduction of 16% and 30% in the Feasibility to use HC one-way slab as a

maximum deflection is recorded for the roofing member for buildings. It was proved

RCHCS retrofitted with 2 strips and 4 strips, also that these slabs efficient after

respectively. Longitudinal cracks between the rehabilitation using carbon fiber

voids are observed on the lateral sides of the (CFRP) srips.

slabs due to the propagation of the blast wave The NSM-CFRP strengthening method

majorly supports the bending and shear load

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 7

capacity of prestressed HCS. The increase in Bonded GFRP Lateral Confinement and

failure flexural capacity was minimized in Near Surface Mounting Technique

slabs that failed by shear before reaching their (6) Nabil, Ahmed & Heiza, Khalid &

full bending capacity. Meleka, Nageh & Tayel, Magdy. (2014).

Unlike nonprestressed concrete, the addition Structural Performance of Concrete

of NSM laminates maximized both the energy Columns Strengthened with Externally

and absorption of the HCS. Bonded GFRP and Near Surface Mounted

.Steel

REFERENCES (7) Heiza, Khaled & Nabil, Ahmed &

Meleka, Nageh & Tayel, Magdy. (2014).

(1) Nabil, Ahmed & Othman, Islam & State-of-the Art Review: Strengthening of

Meleka, N.N. & Heiza, Khaled. (2021). Reinforced Concrete Structures – Different

Behavior of Reinforced Concrete Beams Strengthening Techniques

Strengthened by GFRP Composites In the last decades many researchers

Subjected to Combined Bending and studied the behavior of concrete structures

Torsion -Experimental study. 44. 295-302. strengthened with different strengthening

10.21608/ERJM.2021.78234.1098 techniques [7].

(2) Nabil hmed Mele a N N research works include works on reinforced

Fahmy hmad State-Of-The- rt concrete slabs weather conventional

Review On Strengthening Of Reinforced concrete slab or precast prestressed slab

Concrete Slabs ith Openings . Journal of units [2], [3], [4].

Al-Azhar University Engineering Sector. Other researches were focusing on the

42. 127-141 behavior of reinforced concrete beams

(3) Heiza, Khaled & Nabil, Ahmed. strengthened with innovative techniques

(2018). Ain Shams University Faculty Of like FRP systems [1].

Engineering Structural Engineering Also, extensive work was done on

Department Fifteenth International investigating the behavior of concrete

Conference On Structural And columns strengthened with FRP systems

Geotechnical Engineering Advances In and near surface mounted techniques [5],

Construction Techniques PPHC Slabs [6]. This research work provides quick

Strengthened With Different Types Of overview on the previous work in the field

Concrete Toppings of strengthening of reinforced concrete

(4) Nabil, Ahmed & Meleka, N. hollow core slabs.

(2017). Effects of Different Types of (8) Anderson, Arthur R., and Anderson,

Concrete Toppings on the Behavior of Richard G “ n ssurance Criterion for

PPHC Slabs. Journal of Engineering Flexural Bond in Pretensioned Hollow Core

Research. 40. 333-339. Units” CI Journal ugust 1976.

.10.21608/erjm.2017.66359 (9) Discussion and Closure “Development

(5) Nabil, Ahmed & Heiza, Khaled & of Prestressing Strand in Pretensioned

Meleka, N.N. & Tayel, Magdy. (2014). Members” CI Journal March 1977.

Strengthening of Axially Loaded Circular

Concrete Columns Using Externally

Menoufia University- Reinforced Concrete Research Group

Research Paper on Concrete Structures, 2021 8

(10) Discussion and Closure “Development Study on the Flexural Behavior of Hollow

Length of Prestressing Strands” PCI Core Concrete Slabs. Applied Mechanics

JOURNAL, July-August, 1978. and Materials. 857: 107-112.

(11) PCI Fire Committee “Design for Fire (18) Stephen C. Hollow core manufacture

Resistance of Precast Prestressed Concreter and factory design the Indian concrete

Second Edition” Precast/Prestressed journal 2013 pp 20-25

Concrete Institute, Chicago, IL, 1989.

(12) Martin, Leslie D. and Scott, Norman

L “Development of Prestressing Strand in

Pretensioned Members” CI Journal

August 1976.

(13)PCI Design Handbook - Precast and

Pre stressed Concrete, Fifth Edition,

Prestressed /Precast 1997.

(14) Foubert S., Mahmoud K. and El-

Salakawy E. 2016. Behavior of Prestressed

Hollow-Core Slabs Strengthened in Flexure

with Near-Surface Mounted Carbon Fiber-

Reinforced Polymer Reinforcement ASCE,

Journal of Composites for Construction.

(15) Mahdi A.S. 2011. Nonlinear Finite

Element Analysis of Reinforced Concrete

Hollow-core Slabs. MSc. Thesis, Al-

Nahrain University/Civil Engineering

Department.

(16) Prof. Batyr Yazyev, Stepan V.

Litvinov, Anton S. Chepurnenko, Anastasia

Lapina and Akay Oksana pages:24-29.

(17) PrakashanL.V., George, J., Edayadiyil,

J. B., George, J. M. 2017. Experimental

Menoufia University- Reinforced Concrete Research Group

View publication stats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- The Approach: The Living Building ChallengeDocument8 pagesThe Approach: The Living Building ChallengenethNo ratings yet

- Hoi - Thao T11-03 LuuDocument22 pagesHoi - Thao T11-03 LuuvuhachauNo ratings yet

- Final Group Work PDFDocument8 pagesFinal Group Work PDFTeddy MatiekaNo ratings yet

- Modern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALDocument86 pagesModern Construction Building Methods Techniques MST Connect With Design and Construciton of Pool MANUALAe R ONNo ratings yet

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Precast Concrete Combined)Document13 pagesPrecast Concrete Combined)Ssu NguNo ratings yet

- Saint Louis College: BT3 (AR A315D)Document9 pagesSaint Louis College: BT3 (AR A315D)Dennis Roel T. DulayNo ratings yet

- Brick Making MachineDocument18 pagesBrick Making MachineSyed Nasir AhmedNo ratings yet

- Financial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabDocument6 pagesFinancial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabtienaicvnNo ratings yet

- Precast Concrete and Prestressed Concrete: Report Submitted By: Group IiDocument6 pagesPrecast Concrete and Prestressed Concrete: Report Submitted By: Group IiVaishnavi SikchiNo ratings yet

- Precast Concrete SlabDocument55 pagesPrecast Concrete SlabKimberly LoNo ratings yet

- Precast Concrete Slab: Here Starts The Lesson!Document55 pagesPrecast Concrete Slab: Here Starts The Lesson!Kimberly LoNo ratings yet

- 2 - RC Design I Introduction SDocument32 pages2 - RC Design I Introduction SMohamad DuhokiNo ratings yet

- Research Architectural: Tech VDocument6 pagesResearch Architectural: Tech VMark DanielNo ratings yet

- Building: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyDocument4 pagesBuilding: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyGlenn Mendoza100% (1)

- Pre Engineered BuildingDocument21 pagesPre Engineered BuildingJamaica Mae AndayaNo ratings yet

- .Precast Concrete ConnectionsDocument3 pages.Precast Concrete Connectionsparamarthasom1974No ratings yet

- Code Tiltup PrecastDocument47 pagesCode Tiltup Precastkorosh75No ratings yet

- Mivan TechnologyDocument24 pagesMivan TechnologyArjun MNo ratings yet

- Concrete MaterialsDocument2 pagesConcrete MaterialsVirgilio BiagtanNo ratings yet

- A Proposal For The Classification of Structural SyDocument10 pagesA Proposal For The Classification of Structural SyJesús Román CamachoNo ratings yet

- HKCV BT5 Alternative Building Construction System Notes 01Document34 pagesHKCV BT5 Alternative Building Construction System Notes 01Jessa ObraNo ratings yet

- Paper On Design Voded SlabDocument9 pagesPaper On Design Voded SlabAnonymous b9fkTYfEoRNo ratings yet

- Quindao Liza Marie PDocument5 pagesQuindao Liza Marie PLIZA MARIE QUINDAONo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteMariz Ellaine BaltazarNo ratings yet

- Pre Engineered BuildingDocument21 pagesPre Engineered BuildingJamaica Mae AndayaNo ratings yet

- Advanced Construction and Materials: Pre-Stressed ConcreteDocument19 pagesAdvanced Construction and Materials: Pre-Stressed ConcreteswethaadusumilliNo ratings yet

- Types of Structural SytemDocument10 pagesTypes of Structural SytemOlga KosuoweiNo ratings yet

- CE18B037 Assignment2Document9 pagesCE18B037 Assignment2Kota Thapaswini ce18b037No ratings yet

- Prestrest ConcreteDocument6 pagesPrestrest ConcreteWan ImranNo ratings yet

- Basic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewDocument10 pagesBasic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewJoe Bryan SamsonNo ratings yet

- Fama Homework01Document2 pagesFama Homework01Bojo FamaNo ratings yet

- ARCH402 Nora Ahmd 21902492Document16 pagesARCH402 Nora Ahmd 2190249221902492No ratings yet

- A Proposal For The Classification of Structural SyDocument10 pagesA Proposal For The Classification of Structural SyAngelica U SiraitNo ratings yet

- BUILDING TECHNOLOGY 5 HardDocument80 pagesBUILDING TECHNOLOGY 5 HardMargie Ocampo100% (1)

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- LP3 in CE 7Document17 pagesLP3 in CE 7Jhon Rhico DabuetNo ratings yet

- 1.1 Background of StudyDocument7 pages1.1 Background of StudyMuhamad Arief AmienNo ratings yet

- NL5 Notes - Weak BLDG Elements - WengYWDocument6 pagesNL5 Notes - Weak BLDG Elements - WengYWjeffyeung2015No ratings yet

- Universiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentDocument14 pagesUniversiti Tun Hussein Onn Malaysia Faculty of Civil Engineering and Built EnvironmentEzanie IzyanNo ratings yet

- Prestressed ConcreteDocument15 pagesPrestressed ConcreteSheryll de GuzmanNo ratings yet

- 11737-Article Text PDF-38368-1-10-20180601Document9 pages11737-Article Text PDF-38368-1-10-20180601maruns004No ratings yet

- Concrete Slab TypesDocument6 pagesConcrete Slab TypesMukovhe MuvhaliNo ratings yet

- Brosur 1 Lorem - SampleDocument44 pagesBrosur 1 Lorem - SampleChristopher DarrenNo ratings yet

- Contour Crafting: Construction Technologies .Document12 pagesContour Crafting: Construction Technologies .Jaimar AlcantaraNo ratings yet

- Building Report Hollow Core SlabDocument13 pagesBuilding Report Hollow Core SlabAhmad OmarNo ratings yet

- Basic Types of Sheet Pile Walls and Their Application in The Construction Industry-A ReviewDocument10 pagesBasic Types of Sheet Pile Walls and Their Application in The Construction Industry-A Reviewomed muhammadNo ratings yet

- Reinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisDocument23 pagesReinforced Ultra-Lightweight Cement Composite Flat Slabs: Experiments and AnalysisNI KH ILNo ratings yet

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- Open Prefabrication SystemsDocument17 pagesOpen Prefabrication SystemsRemya R. Kumar100% (2)

- TB 08 Building Envelope - CompressedDocument63 pagesTB 08 Building Envelope - CompressedNraisyahaldaf100% (1)

- Brosur Wika Beton Edisi 2022Document44 pagesBrosur Wika Beton Edisi 2022Dinda Hani SyarifahNo ratings yet

- Lecture 3 Tensile StructureDocument32 pagesLecture 3 Tensile StructureRuthNo ratings yet

- Engineer TermsDocument8 pagesEngineer TermsBintang RamadhanNo ratings yet

- Emag Lounge January 2020Document24 pagesEmag Lounge January 2020Constro FacilitatorNo ratings yet

- Seismic Behaviour of Buildings Having Flat Slabs With DropsDocument6 pagesSeismic Behaviour of Buildings Having Flat Slabs With DropsHani AdelNo ratings yet

- 1 Prefabricated StructuresDocument42 pages1 Prefabricated Structurespooja apteNo ratings yet

- Research I Reinforcement Concrete II Prestressed Reinforced ConcreteDocument6 pagesResearch I Reinforcement Concrete II Prestressed Reinforced ConcreteHamez HabibiNo ratings yet

- Seismic Design of Cold Formed Steel Structures in Residential ApplicationsDocument3 pagesSeismic Design of Cold Formed Steel Structures in Residential ApplicationsKristijanRunevskiNo ratings yet

- WelcomeDocument3 pagesWelcomeadam ArthurNo ratings yet

- RECO 2040-CPM1-2-ElementalEstimate - S2Document10 pagesRECO 2040-CPM1-2-ElementalEstimate - S2King Heng Shum100% (1)

- For Construction: Beachfront Beachfront Softscape-Shrub-Enlarged 08Document1 pageFor Construction: Beachfront Beachfront Softscape-Shrub-Enlarged 08Nhan Phan ThanhNo ratings yet

- Metaroll Pamphlet 01Document4 pagesMetaroll Pamphlet 01rohit6varma-4No ratings yet

- List CecDocument51 pagesList Cecajeez86No ratings yet

- Shift Report - November 24, 2023-2nd ShiftDocument4 pagesShift Report - November 24, 2023-2nd Shiftbobowapthree19No ratings yet

- Co-Extrusion Dies Based On Spiral Mandrel TechnologyDocument10 pagesCo-Extrusion Dies Based On Spiral Mandrel TechnologygermanpoloramosNo ratings yet

- Saic-Q-1066 Rev 1 (Final)Document3 pagesSaic-Q-1066 Rev 1 (Final)ryann mananquilNo ratings yet

- Instructions On Illegal Constructions dt.08.08.2020Document2 pagesInstructions On Illegal Constructions dt.08.08.2020Nagarkurnool MunicipalityNo ratings yet

- 2506 980-6000CLXIFT 8000CLXIFT-installDocument79 pages2506 980-6000CLXIFT 8000CLXIFT-installalbertgoukasianNo ratings yet

- Mep Technical & Financial Proposal - Larus Convenience CentreDocument78 pagesMep Technical & Financial Proposal - Larus Convenience CentreGabriel OdebodeNo ratings yet

- Complete PlanDocument1 pageComplete PlanNiluka EkanayakaNo ratings yet

- Rheobuild 850 - 09-06 - Basf PDFDocument2 pagesRheobuild 850 - 09-06 - Basf PDFnasser elbahyNo ratings yet

- Bill of Quantity For Wires, Cables, and TraysDocument2 pagesBill of Quantity For Wires, Cables, and TraysMosa Elnaid ElnaidNo ratings yet

- Texfilm404-2 ExpJnt DSDocument1 pageTexfilm404-2 ExpJnt DSdanny buiNo ratings yet

- ST - 13.01.05 Technical Specification For PipingDocument16 pagesST - 13.01.05 Technical Specification For PipingMaksim.em001No ratings yet

- Crawler CraneDocument11 pagesCrawler CraneidonotspammeNo ratings yet

- 07 - CIC 2016 Detailed Design PDFDocument8 pages07 - CIC 2016 Detailed Design PDFLívia A. SouzaNo ratings yet

- 4JMTXS ParkerDocument1 page4JMTXS ParkerantonyNo ratings yet

- Aastho 2011 2a TestsDocument947 pagesAastho 2011 2a Testselmer portilloNo ratings yet

- Types of RaftersDocument34 pagesTypes of RaftersJeriza AquinoNo ratings yet

- TCPM - Ikue Consulting Co - , LTD - Specification DispatchDocument30 pagesTCPM - Ikue Consulting Co - , LTD - Specification DispatchSPACELINK AERO SERVICESNo ratings yet

- Method Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonDocument16 pagesMethod Statement and Job Safety Analysis FOR Upper Pile Site Repair Wika BetonAhmad Rafly ZulfikarNo ratings yet

- Dubai Workshop RegistrationDocument2 pagesDubai Workshop RegistrationmfkmughalNo ratings yet

- Lifting StandardsDocument17 pagesLifting Standardsanantharamakrishnan kNo ratings yet

- FCP PRE-QualificationDocument80 pagesFCP PRE-Qualificationeromax1No ratings yet

- Quickie Load Form BlankDocument1 pageQuickie Load Form BlankAkshay KadiaNo ratings yet

- CvmniDocument6 pagesCvmniPalani Vel RajanNo ratings yet

- Mycelium Fungi As A Building Material: Maria Saxton Rise Writer Feb 14, 2020Document10 pagesMycelium Fungi As A Building Material: Maria Saxton Rise Writer Feb 14, 2020Prerana CholakheNo ratings yet