Professional Documents

Culture Documents

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Uploaded by

Hamza AliCopyright:

Available Formats

You might also like

- Best 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTDocument32 pagesBest 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTRaju Maity100% (5)

- Marine Machinery CourseDocument452 pagesMarine Machinery CourseMerrel Ross100% (1)

- Boiler Preservation Methods Dry and WetDocument14 pagesBoiler Preservation Methods Dry and WetTin Aung KyiNo ratings yet

- Steam Condensers and Their Application in Sugar FactoriesDocument11 pagesSteam Condensers and Their Application in Sugar FactoriesRamon PeyegrinNo ratings yet

- Bubble Cap FucntionDocument4 pagesBubble Cap FucntionPujo PurwantoNo ratings yet

- 500mwboilermahagenco 140115124304 Phpapp02Document38 pages500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanNo ratings yet

- BoilersDocument26 pagesBoilersDeepak GawdeNo ratings yet

- Jigger Tube - IsSCT Technical PaperDocument10 pagesJigger Tube - IsSCT Technical PapermaithanhhaiNo ratings yet

- Better Understand BoilersDocument6 pagesBetter Understand BoilersdigecaNo ratings yet

- Don't Send Money Down The Drain: Steam ManagementDocument3 pagesDon't Send Money Down The Drain: Steam ManagementAnonymous lqsJIe6l5No ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Marine Machinary CourseDocument452 pagesMarine Machinary CourseMc Liviu100% (1)

- Smoke Tube Boilers: Tank (Scotch) BoilerDocument4 pagesSmoke Tube Boilers: Tank (Scotch) BoilerMeghanath AdkonkarNo ratings yet

- 1981 - Addison - Large Falling Film EvaporatorsDocument3 pages1981 - Addison - Large Falling Film EvaporatorsshondabagueNo ratings yet

- Distillation Column DesignDocument7 pagesDistillation Column DesignTouhidBinAnwarNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Steam 1Document5 pagesSteam 1NaNo ratings yet

- Intelligent Gas LiftDocument17 pagesIntelligent Gas Liftmemos2011No ratings yet

- Steam Boiler Feedwater Storage Technology White PaperDocument16 pagesSteam Boiler Feedwater Storage Technology White Paperchristiancandido100% (1)

- Ideal Steam DrumDocument6 pagesIdeal Steam DrumFahad RockingNo ratings yet

- pp57-65 MS06Document9 pagespp57-65 MS06vikaskatheriaNo ratings yet

- Tube Settlers CatalogueDocument10 pagesTube Settlers CatalogueIlu Singh100% (1)

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumar100% (1)

- Steam BoilerDocument9 pagesSteam BoilerzaidinNo ratings yet

- Boilers Basic Components (Att. VIII)Document28 pagesBoilers Basic Components (Att. VIII)Vijay RajNo ratings yet

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdNo ratings yet

- THERMAL-1 Experiment 1 Part ADocument7 pagesTHERMAL-1 Experiment 1 Part Anishith ranaNo ratings yet

- E101 3240 Industrial Water Tube Package Boilers Babcock WilcoxDocument12 pagesE101 3240 Industrial Water Tube Package Boilers Babcock Wilcoxa_parratNo ratings yet

- Improving Bagasse Boiler PerformanceDocument9 pagesImproving Bagasse Boiler PerformanceUsama MalikNo ratings yet

- Thermal Cracking - Delayed Coking 2Document8 pagesThermal Cracking - Delayed Coking 2Anonymous rUs4PjYo5No ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011Pradyot DeoliaNo ratings yet

- ConstructionDocument38 pagesConstructionChakravarthi NagaNo ratings yet

- Manual On Boiler Tube FailureDocument69 pagesManual On Boiler Tube Failureyogeshmangal1974100% (2)

- Tower Tray Oil and Gas IndustryDocument11 pagesTower Tray Oil and Gas IndustryHeet PatelNo ratings yet

- Replacing A Steam Boiler - ES MagazineDocument10 pagesReplacing A Steam Boiler - ES MagazineBorkoBGNo ratings yet

- Cochran and Babcock & Wilcox BoilersDocument3 pagesCochran and Babcock & Wilcox BoilersAshish VermaNo ratings yet

- Pages - Steam Mains and DrainageDocument10 pagesPages - Steam Mains and DrainageSPK 27No ratings yet

- BOILERfinal - Print Out PDFDocument25 pagesBOILERfinal - Print Out PDFRahulBhartiNo ratings yet

- Presentation TemplateDocument18 pagesPresentation Templatesaibabu sai100% (1)

- Section A.6 Steam and Water Cycle EquipmentDocument19 pagesSection A.6 Steam and Water Cycle EquipmentChava TejaNo ratings yet

- Quantity Unit Description Item: Brand New Acid Blending PlantDocument4 pagesQuantity Unit Description Item: Brand New Acid Blending Plantgplese0No ratings yet

- Optimizing The Design of Splitter TowersDocument6 pagesOptimizing The Design of Splitter TowersZangNo ratings yet

- FCSG For SAGDDocument7 pagesFCSG For SAGDaugur886No ratings yet

- Steam Mains and Drainage Spirax PDFDocument19 pagesSteam Mains and Drainage Spirax PDFsachin nagavkarNo ratings yet

- Water Tube Boiler What You Need To KnowDocument7 pagesWater Tube Boiler What You Need To KnowBrilliano Wahyu RamadhanNo ratings yet

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass Valvesadehriya100% (2)

- Chemtreat Challenges of Industrial Boiler Water TreatmentDocument17 pagesChemtreat Challenges of Industrial Boiler Water TreatmentKhondoker Nayeem ul haqueNo ratings yet

- Westco PumpDocument8 pagesWestco PumpWorapat PuttakasemNo ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011ankit trivediNo ratings yet

- Concentric-Coiled-Tubing Well Vacuuming For Complex Horizontal WellsDocument3 pagesConcentric-Coiled-Tubing Well Vacuuming For Complex Horizontal WellsAQUILES CARRERANo ratings yet

- TB1-019 Off-Line Boiler Protection OptionsDocument1 pageTB1-019 Off-Line Boiler Protection Optionsjesus_manrique2753No ratings yet

- Steam Distribution Economical PipingDocument4 pagesSteam Distribution Economical PipingmohdnazirNo ratings yet

- Bottom Ash Hopper CollectionsDocument11 pagesBottom Ash Hopper Collectionsatgsganesh0% (1)

- Surface Condenser HEIDocument7 pagesSurface Condenser HEIJesús Santiago QuijadaNo ratings yet

- Experiment One-To Study The Cochran and Babcock and Wilcox BoilersDocument8 pagesExperiment One-To Study The Cochran and Babcock and Wilcox BoilersHasib IslamNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901From EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Hints on cheese-making, for the dairyman, the factoryman, and the manufacturerFrom EverandHints on cheese-making, for the dairyman, the factoryman, and the manufacturerNo ratings yet

- Moon Landing (1) NewDocument2 pagesMoon Landing (1) NewHamza AliNo ratings yet

- Safety MeasuresDocument5 pagesSafety MeasuresHamza AliNo ratings yet

- 11 - Gas-Liquid MixingDocument56 pages11 - Gas-Liquid MixingHamza AliNo ratings yet

- 7 - PowerFlow CharacteristicsDocument63 pages7 - PowerFlow CharacteristicsHamza AliNo ratings yet

- 1.basic Concepts of Thermo - Spring 2020Document48 pages1.basic Concepts of Thermo - Spring 2020Hamza AliNo ratings yet

- MTExam-1 2021Document2 pagesMTExam-1 2021Hamza AliNo ratings yet

- 1st Law For Open Systems - Spring 2020Document63 pages1st Law For Open Systems - Spring 2020Hamza AliNo ratings yet

- Chapter 25Document10 pagesChapter 25Hamza AliNo ratings yet

- Chapter 13 - Sections 13.6-13.8Document34 pagesChapter 13 - Sections 13.6-13.8Hamza AliNo ratings yet

- Chapter 17Document37 pagesChapter 17Hamza AliNo ratings yet

- Feed:: PropyleneDocument7 pagesFeed:: PropyleneHamza AliNo ratings yet

- Simulation of Carbon Dioxide - Monoethanolamine - Water System Using Equilibrium ApproachDocument47 pagesSimulation of Carbon Dioxide - Monoethanolamine - Water System Using Equilibrium ApproachHamza AliNo ratings yet

- Unit Operations - FExam-2 - 2021Document1 pageUnit Operations - FExam-2 - 2021Hamza AliNo ratings yet

- Avogadro's Number LinkdinDocument2 pagesAvogadro's Number LinkdinHamza AliNo ratings yet

- Maxwell RelationsDocument1 pageMaxwell RelationsHamza AliNo ratings yet

- Topic 2 - 2021 - Updated 9-20-21Document15 pagesTopic 2 - 2021 - Updated 9-20-21Hamza AliNo ratings yet

- Some of The Graphical Transient Solutions in Higher ResolutionDocument2 pagesSome of The Graphical Transient Solutions in Higher ResolutionHamza AliNo ratings yet

- Acutal GraphDocument2 pagesAcutal GraphHamza AliNo ratings yet

- FORMULA SHEET - Final Exam - CHME312Document2 pagesFORMULA SHEET - Final Exam - CHME312Hamza AliNo ratings yet

- Cryogenic DistillationDocument5 pagesCryogenic DistillationHamza AliNo ratings yet

- Column Pressure SelectionDocument2 pagesColumn Pressure SelectionHamza AliNo ratings yet

- APPENDIX B2 Constants For The Antoine Equation For Vapor Pressures of Pure SpeciesDocument1 pageAPPENDIX B2 Constants For The Antoine Equation For Vapor Pressures of Pure SpeciesHamza AliNo ratings yet

- Saftey ConsiderationDocument2 pagesSaftey ConsiderationHamza AliNo ratings yet

- HYDRAcap MAXDocument2 pagesHYDRAcap MAXHamza AliNo ratings yet

- Flash CalculationsDocument10 pagesFlash CalculationsHamza AliNo ratings yet

- Ahmed Deyab: Senior Process Engineer Process Simulation ConsultantDocument154 pagesAhmed Deyab: Senior Process Engineer Process Simulation ConsultantHamza AliNo ratings yet

- Jarso DoyoDocument82 pagesJarso DoyoDawit NegussieNo ratings yet

- Ferguson's FormulaDocument5 pagesFerguson's FormulaShrey AgarwalNo ratings yet

- Detailed Lesson Plan For Senior HighDocument3 pagesDetailed Lesson Plan For Senior HighSora HazelbitzNo ratings yet

- Against Wind Farms: A Short EssayDocument7 pagesAgainst Wind Farms: A Short EssayJaci RaeNo ratings yet

- Mat Score and Its InterpretationDocument2 pagesMat Score and Its InterpretationSHASHANK SINGHNo ratings yet

- Improving Grammatical Range and Accuracy: Test Section - Speaking Part 2Document9 pagesImproving Grammatical Range and Accuracy: Test Section - Speaking Part 2Cengizhan AkdağNo ratings yet

- The Legend of Malin KundangDocument3 pagesThe Legend of Malin KundangSiti Evayanti100% (3)

- Psychological Assessment - Learning Guide 2024Document14 pagesPsychological Assessment - Learning Guide 2024murendeni.025No ratings yet

- JHS Detailed Lesson PlanDocument9 pagesJHS Detailed Lesson PlanJewelNo ratings yet

- Effects of Abm Subjects To The Content Knowledge in Abm StudentsDocument10 pagesEffects of Abm Subjects To The Content Knowledge in Abm StudentsJENNELLE LORILLANo ratings yet

- Thermal Recovery MethodDocument25 pagesThermal Recovery Methodmahmud masudNo ratings yet

- Recycled CarpetsDocument10 pagesRecycled Carpetsken riveraNo ratings yet

- Letting Go of Stress, Anxiety, and Fear During Study and Test TakingDocument3 pagesLetting Go of Stress, Anxiety, and Fear During Study and Test TakingRamonNo ratings yet

- IEQ Micro ProjectDocument22 pagesIEQ Micro ProjectMoiz SayyedNo ratings yet

- The World of Lapp: Innovations 2017 18Document48 pagesThe World of Lapp: Innovations 2017 18Andrew LowNo ratings yet

- Bren Davy LetterDocument2 pagesBren Davy LetterAbril Biente SincoNo ratings yet

- Physics: FlashbackDocument2 pagesPhysics: FlashbackWonderlapseNo ratings yet

- Activity PR ItoDocument4 pagesActivity PR ItoSamantha Nicolle QuierraNo ratings yet

- MaximumDocument3 pagesMaximumJowiNo ratings yet

- Payback BC MethodDocument1 pagePayback BC MethodJam LarsonNo ratings yet

- SeismoStruct User Manual PDFDocument325 pagesSeismoStruct User Manual PDFStr Engr Mohammad AliNo ratings yet

- Etp Progress Report - g70Document18 pagesEtp Progress Report - g70EeHuey ChooNo ratings yet

- Course Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesDocument1 pageCourse Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesNags DevaNo ratings yet

- DE THI TUYEN SINH CUA S 4 Năm NayDocument17 pagesDE THI TUYEN SINH CUA S 4 Năm Nay[][][][][][][][]No ratings yet

- Datamaster DMT Breath Test Operator Training Course ManualDocument147 pagesDatamaster DMT Breath Test Operator Training Course ManualMetalAnonNo ratings yet

- Ug Catalog 21-22 0Document243 pagesUg Catalog 21-22 0Faisal Abdul MalakNo ratings yet

- Bridge Ergonomic Design A ReviewDocument7 pagesBridge Ergonomic Design A ReviewLibrary Jasaan CampusNo ratings yet

- Lee Moi Wong Chief Research Officer Kuala LumpurDocument2 pagesLee Moi Wong Chief Research Officer Kuala LumpurTony MathewNo ratings yet

- Chapter 4 Thesis Sample FilipinoDocument7 pagesChapter 4 Thesis Sample Filipinojum1p0tonip3100% (2)

- Ciam T10Document3 pagesCiam T10Nino SilvaNo ratings yet

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Uploaded by

Hamza AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Design Testing of Vacuum Pan in Sugar Industry Ijariie12348

Uploaded by

Hamza AliCopyright:

Available Formats

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

Design &Testing of Vacuum Pan in Sugar

Industry

Prof. Dr. A.D. Desai, Prof. A.B. Verma, Prof. A.B. Bhane, G.H.Kulkarni.

Principal, Mechanical Engineering Dept., SRCOE, Maharashtra, India

HOD, Mechanical Engineering Dept., SRCOE, Maharashtra, India

P.G Coordinator, Mechanical Engineering Dept., SRCOE, Maharashtra, India

Student, Mechanical Engineering Dept., SRCOE, Maharashtra, India

ABSTRACT

In this paper we are going to study the most important equipment in the sugar industry which plays very vital role in

the boiling house. Steam is the important parameter in sugar industry which is used for heating the cane juice

coming from mill house. After juice heating and sulphitation its allowed to pass in the evaporator station and then it

is converted in to the muddy Syrup whose concentration is more than the syrup in the evaporator station. In sugar

Vacuum pan concentration of syrup is increased and then its converted in to mud called massecuite.Design of

Vacuum pan is the important task in the sugar industry in which design were carried on trial and error basis by

considering the more thickness of all the accessories in the sugar pan. But in this paper we are going to optimize the

various thickness, diameters of inlet and outlet pipes for juice and steam inlet.

Keyword : - Vaccum Pan, Shell thickness calculation ,Pan Model 3D, Types of pan.

1. INTRODUCTION

The pan station of a sugar factory is located on separate floor either in line with the evaporator station at a height

of 7-8 m. from ground floor or at a height of 15-16 m. from ground floor so as to facilitate gravity flow of

Massecuitte from pans up to centrifugal station. Pan station is equipped with 4 to 8 pans of capacities varying from

50 to 60 t. together with 15-20 syrup and molasses tanks and seed crystallizers for storing seed for high grade

boiling. Besides these, vacuum crystallizers are also installed now days for storing 'cutting' from pans. The entire

boiling is conducted under vacuum and therefore the pans are connected to condensers by large vapor pipes. The

various important pipe connections of a Pan include:-

(i) Steam or Vapour,

(ii) Syrup and Molasses,

(iii) Seed Intake or Cut over Pipe,

(iv) Condensate Outlet,

(v) Vapour Outlet,

(vi) Hot Water,

(vii) Gauges and Meters

1.1 Types of Pans in Sugar Industry

Pan boiling has so far been a batch operation but in the last two decades Continuous pans have been introduced. In

Indian industry gradually continuous pans will take the place of batch pans in the near future particularly for

intermediate grade boiling. The batch pans can be broadly classified into two types

(i) Coil pans,

12348 www.ijariie.com 1119

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

(ii) Calendria pans.

Whatever the design or type of pan it is necessarily fitted with following accessories

(a) a condenser connected to vapor pipe, either barometric type or a multi-jet one.

(b) Catchall at the top before the vapor pipe to prevent entrainment or carryover.

(c) A vacuum breaking valve to be used before dropping a strike.

(d) Sight glasses on the front as well as at the back.

(e) Manhole door.

(f) Large discharge valve.

(g) Pan washing arrangement.

Besides above the various pipe connections are provided with appropriate valves

i) Coil Pan

The sugar plants established in the thirties or even prior to 1930 were provided with coil pans. In the old design,

coils were of copper tubes bent into spirals with the upper end connected to the wall of the pan while the other one

i.e. the lower one is joined to the condensate-drain. The coil is wound in such a way as to facilitate easy drainage of

condensate. A set of coils is installed, each one being connected to steam line through valve and steam trap to enable

independent start or cutout of any one coil. The successive coils are so laid as to aid circulation of massecuite in the

pan. The pan body can be of MS. or cast iron. The coils are made of 10-15 cm. dia copper tubes with wall thickness

of about 2.5 - 4 mm. The ratio of length to diameter of coil is 200-250 for live steam, but for using exhaust steam it

has to be 75-100. The pan is equipped with usual fittings like sight glasses for observing levels of Massecuitte, catch

all etc. Pan with flattened coils—In a new design of coil pan introduced in Queensland the flattened coils form the

heating surface. The coil constructed of 12.5 cm. dia. copper tube is flattened so as to give nearly 1½ times or

double the height over the width. The coil consists of concentric flattened tubes with two ends connected to steam

manifold and condensate outlet respectively. The only advantage of the coil pans is that the heating surface is

gradually cut in or brought into operation as the strike level rises but the main

Disadvantages are-

(a) High maintenance costs,

(b) Use of vapors or low pressure exhaust is not possible as mostly live steam is required for boiling.

(c) Mechanical circulator cannot be installed.

In recent past for the above reasons coil pans have completely been replaced by Calendria pans.

ii) Calendria Pans

Like an evaporator body a Calendria pan has tubular Calendria with the difference that the tubes are of larger

diameter and shorter length as also larger down take to facilitate circulation of high brix material. Circulation of

thick Massecuitte is of utmost importance in the design of Calendria and this is brought about by providing large

down-take for the ascending stream of mass through the tubes. As a result of heat transfer from the steam or vapor to

the Massecuitte it raises in the tubes and on reaching the top of upper tube plate descends through the down take.

This efficiency and speed of circulation of mass is an important characteristic of any Calendria pan design. In a

conventional design of 30m3 capacity pan, the Calendria is fitted with 100 mm. O.D. and 96 mm I.D. brass tubes of

1.1 m. length, with end portions expanded and fixed in two plates of 25 mm. thickness with a ligament of 16 mm. In

the Calendria of M.S. construction the down take is provided with deflector of fanned shape at an angle of 45° at the

upper end of the downtake opening to prevent short circuiting of Massecuitte flow. Usually one steam connection is

provided and the condensates drained from the opposite side into a tank located on ground floor. The shell of pan

body is of 12 mm. M.S. construction and has an internal catchall in the top dome which is connected to vapor

Pipe going to condenser. The conical bottom is bolted to the Calendria or even welded in some case and the pan

discharge valve is located in the centre. The feed is connected to the bottom cone away from the discharge valve but

in some designs the feed enters the pan in the downtake. A cut over line is connected to the bottoms of all pans and

seed or vacuum crystallizer. The conical bottom of each pan is joined to the cutover line through an opening and

valve. The diameter of central cylindrical down take is 40-50% of that of the Calendria. The heating surface to

volume ratio has to be 6-6.5 m2 per m3 of working volume but for good circulation the height of boiling Massecuitte

should not exceed 1.5 m. and to achieve these twin objectives the size of the pan belt above the upper tube plate of

Calendria is increased in diameter. Thus the diameter of Massecuitte belt is made larger than that of Calendria by 0.6

12348 www.ijariie.com 1120

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

- 1.6 m. the two being joined to each other by a sloping cone. The advantages of low head pans are

(a) Low graining or footing volume, about 25-30% the strike volume,

(b) Good natural circulation of Massecuitte even when the strike level reaches the maximum limit, resulting in

reduced time of boiling,

(c) Higher H.S. to volume ratio can be maintained which adds to the speed of boiling

2.0 MAJOR DESIGN CONSIDERATIONS

In pan boiling along with speed of boiling a strike, it is important that no pockets of stagnant mass remain inside the

pan which will not only affect the quality of sugar but will bring about destruction of sugar also. In vacuum pan

operation maximum exhaustion of mother liquor is aimed at along with proper development of crystal size and

shape. The factors which come into play in achieving the desired results in respect of pan design are as under—

(a) Even distribution of steam in the steam belt and effective removal of incondensable gases are inter-linked in the

sense that the steam path is so arranged as to drive the incondensable gases to the points of their removal. In pans of

large capacities two steam entry points are provided in the Calendria. Needless to state that the condensate

extraction from the bottom of the calandria should leave no accumulation. The steam must reach all pockets of the

Calendria, in a uniform manner for efficient heat transmission to the Massecuitte in the tubes.

(b) Low graining volume or footing volume is useful when a footing is to be cut into a vacuum crystallizer or

another pan and similarly it reduces the amount of footing the pan is to be filled up with. Low volume is very helpful

for grain development in high grade boiling and purity control in low grade boiling.

(c) The height of the strike when full above the top tube plate of Calendria has to be low for two reasons—

(i) The high hydrostatic head raises the boiling point of mass in contact with heating surface particularly in the lower

portions of the Calendria,

(ii) Circulation rate is lowered at top portion as height of strike increases, which in other words means that the

velocity of movement of Massecuitte through the tubes upwards and its return to the bottom is reduced.

(d) Introduction of feed of syrup or molasses in the system has to be such that the feed is quickly dispersed

uniformly in the upward moving mass.

(e) With the recent trend of employing vapor from pre-evaporator for vapor boiling, it is essential that the pan design

in respect of heating surface to strike volume ratio and distribution of vapor should be suitable for boiling pan at

about 0.2 kg/cm2.

(f) Entrainment separation has to be efficient as during early stages of the strike boiling, when the brix is

comparatively low chances of carryover of liquid with vapor make it necessary to effect efficient separation of liquid

from the rising vapor.

3.0 DIFFERENT DESIGNS OF VACUUM PAN IN SUGAR INDUSTRY

In view of the above requirements of the pan boiling, and for improving circulation characteristics, different designs

of pans have been introduced, some of which are as follows—

(a) Floating Calendria

In a floating type Calendria, in place of central down take the downward movement of the descending Massecuitte is

provided in the annular space. The heated Massecuitte rises towards the top and flows radically towards shell and

downwards through the annular space. In one design the Calendria is conical shaped at the bottom and flat at the top,

which has added to the heating surface. In the conical bottom type floating Calendria designed by Hugot10 the

steam connection is provided at the centre through pipe passing through the save all at the top. One great

isadvantage with floating Calendria pans is that mechanical circulator cannot be installed in such pan.

Segura pan—

This pan has a floating type Calendria with some special features with respect to steam entry and peripheral down

take. The top tube plate is in horizontal plane but the bottom tube plate possesses the shape of inverted cone with

tubes becoming shorter from centre to periphery. In the down take are fitted 20 inclined baffle plates to guide the

Massecuitte. The steam entry is provided at the centre of Calendria, the steam pipe entering in the steam chest, at the

bottom. The steam pipe is shielded by larger pipe inside the pan and vacuum is maintained in the gap between the

steam pipe and outer pipe to avoid overheating of Massecuitte above the upper tube plate. The pan feed of syrup or

molasses is arranged through an outside pipe forming a ring from which feed enters the peripheral down take at

12348 www.ijariie.com 1121

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

different points. This pan design permits fast boiling and use of low pressure vapor or steam. Moreover the footing

volume is also low. In view of the good circulation characteristics the pan needs no mechanical circulation.

(b) Conical Calendria-

This type of Calendria has a central down take but the tube plates of the Calendria are inclined towards the centre,

the lower tube plate being at 25° and the upper one at 10°-25°. The idea behind the top tube plate sloping towards

centre is to render washing and cleaning of top of Calendria easy after the pan is dropped. The inclined conical

shape provides higher heating surface, less idle space in the bottom cone and lower graining volume as compared to

conventional central down take straight type Calendria.

(C)Ring Type Calendria

The Grantzdorffer design of calandria11 is characterized by concentric rings which are on the same level at the

top but are extended downwards so as to form a conical bottom conforming to the shape of bottom cone of the p a n

. The Massecuitte circulates through the rings and the central down take. In t he improved version of this type of

Calendria designed by Tate & Lyle the rings a r e

Made of ribbons.12a The steam inlet for the rings is at the top while the condensate drains out from bottom of the

elements. The annular ring design is good for efficient circulation and these are widely adopted in refineries. The

refinery strikes can be concentrated to 95° Bx due to ease of discharge and very high yields of sugar a r e obtained.

(d) Horizontal Design

In a recent design of horizontal pan of Fives Lille-Cail the heating surface is provided by hollow plate type elements

vertically placed. The shape of t h e pan permits of low footing volume (up to 26%). The heights of elements

increase towards the centre from the periphery. The Massecuitte is dropped through t h r ee openings at the bottom.

The ratio of heating surface to strike volume can be v a r i ed from 6 to 7.5 m2/m3.

(e) Rotary Horizontal Pan-

Lafeuille design13 has the merit of low hydrostatic head a n d rapid boiling on account of low resistance to

circulation and good heat transmission. Nests of tubes constitute the heating surface and the space between these n e

s ts provides passage for Massecuitte circulation. Fixed connections for steam, vacuum, incondensable gases are

attached to the plain ends of the rotary cylinder. T h e

discharge of strike is effected through 2-3 openings. One such pan was installed at Ravalgaon for producing extra

white sugar of large size from melt.14 this pan c a n boil strikes to a very high brix. However this rotary type

construction of pans has n o t found much favor with manufacturers of sugar machinery or technologists.

(f) Other Designs

In one pan designed in India the steam feed is provided at the c e n t re as in Segura design, the steam pipe being

extended to the bottom of Calendria and t h e pipe inside the Calendria has openings for radial distribution of steam.

The pan h a s peripheral down take for circulation of massecuite.16 The saucer bottom p a n developed in Hawaii

has a shallow bottom shaped to assist circulation of Massecuitte. The Calendria is of conventional central down take

type but because of the special shape of the bottom the footing volume is low and the discharge valve is on one s i d

e at the lowest level. In the Fletcher design the down take of Calendria is almost half in diameter of the Calendria

and the syrup and molasses feed is arranged in the central portion of the down take so as to get mixed with the

descending Massecuitte before it

12348 www.ijariie.com 1122

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

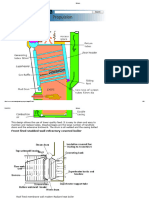

Fig No-01(G.A OF VACCUM PAN)

12348 www.ijariie.com 1123

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

4.0 DESIGNS OF VACUUM PAN IN SUGAR INDUSTRY

a) To Find the Number of Tubes in the Vacuum Pan-

Inputs-

Massecuitte Density-1.428 T/m3

S/V Ratio-6.6

Internal Diameter of Tube (D)-102mm

Output-

First we have to find the volume of pan by using above input parameters

A) Volume of Pan= Total Capacity of Pan/Density of Massecuitte

V=42/1.428

V=29.41 m3

b) Heating Surface Area of Pan (S)= Volume of Pan X (S/V) Ratio

S=29.41 X 6.6

S=194.1176 m2

c) Effective Length of Tube(Let)= Total Length of Tube-Thickness of top tube plate-Thickness of bottom tube

plate-5-5

Let= 740-25-25-10

Let=690 mm= 0.690 m

d) Number of Tubes(N)= Total Heating Surface Area/ (3.14 X D X Let)

N=194.1176/(3.14 X 0.694 X 0.102)

N=819 Nos

e) To Calculate Vapour Inlet Pipe Diameter for Pan Calculation

Inputs-

Massecuite Density-1.428 T/m3

S/V Ratio-6.6

The Heating Surface Area (S) is-194.1176m2

The Vapour Outlet Velocity- 30 m/s.

The Vapour inlet Temprature-100 deg

The Evaporation Rate of Pan-65 kg/cm2/hr

Output-

The Vapour Produced in Pan per hour= Heating Surface Area X The Evaporation Rate

=194.1176 X 65

=12617.65 Kg/hr

We have to Consider the Extra Margin of Vapour Produced , we can take it 10% Extra

Vapour calculated by considering margin=(10/100) X 12617.65=13879.41 kg/hr

Vapour Produced per Second=13879.41/3600=3.855 kg/s

We have to take help of steam table and we have to find out the Specific Volume of vapor at given temperature i.e

100 deg and from steam table it is 9.584 m3/kg

12348 www.ijariie.com 1124

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

The Volume of Vapour Entered per Second = Volume of Vapour produced per second X Specific Volume at given

temperature.

=3.855 X 9.584

=36.95 m3/sec

We Know,

Q=A X V

36.95= 0.7854 X D2 X 30

D=1253 mm

f) To Calculate Vapour Outlet Pipe Diameter for Pan Calculation

Inputs-

Massecuitte Density-1.428 T/m3

S/V Ratio-6.6

The Heating Surface Area (S) is-194.1176 m2

The Vapour Outlet Velocity- 48 m/s.

The Vapour inlet Temprature-100 deg

The Vapour outlet Temprature-55 deg

The Evaporation Rate of Pan-65 kg/cm2/hr

Outputs-

Specific Volume of Vapour for given temperature is 9.3 from steam table

Final Amount of Vapour Generated by considering margin is 3.85 X 9.3 equals 35.85 m3

We Know,

Q= A X V

35.85=0.7854 X D2 X 48

D=975mm

g) Various Diameters and Height Calculations of Sugar Vacuum Pan:-

To Find the Diameter of Calendria Shell for Vacuum Pan

Pitch of Tubes (P)= OD of Tube + Ligament

P=102 +16=118 mm

Total Number of Tubes(Nt)= Calculated Number of Tubes(N) + Number of Stay Rods/Bolts to support the Top

Tube plate + Number of Tubes to eject the noxious gases generated in the Pan

Nt=819 + 8 + 10

Nt= 837 Nos

Dcal= 1.24 X P X N^0.5

Dcal=1.24 X 118 X 837^ 0.5

Dcal= 4233.3 mm

Now we have to consider the 5 % margin because material can vary its quantity , so by keeping safer side we have

considered this amount , after considering the margin we have to calculate the Calendria shell diameter and we have

to round figure it appropriately for manufacturing point of view.

Dcal= (5/100) X 4233.3 +4233.3

Dcal=4445 mm

By Round Figure,

Dcal= 4450 m……This will be final Calendria Diameter.

12348 www.ijariie.com 1125

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

h) To Find Thickness of Calendria Shell of Vacuum Pan-

Inputs-

Working Pressure (P) - 3 Kg/cm2

Allowable Pressure (F)-9 kg/cm2

Joint Efficiency (J)-0.7

Calendria Diameter (Dcal) - 4450 mm

Constant(C) - 1.5

Outputs-

Tcal= ((P X Dcal)/200 X F X J- P)+C)

Tcal=((3 X 4450)/200 X 9 X 0.7-9)+ 1.5)

Tcal=12.1 mm

Considering Weight of mass, Nox gas connection, stay rods/bots for supporting the top tube plate

of vacuum pan , we have to consider appropriate margin,

By considering above margin,

Tcal=18 mm

i) To find the down take diameter of Vacuum Pan-

We have to always take diameter of down take diameter equals to 45 % of Calculated Calendria shell diameter, as

per Hugot.

Ddt= (45/100) X 4450

Ddt=2002.5 mm………. we have to round Figure it

Ddt=2000mm……………Final Down take diameter

j) To Find the Height of Vapour Space-

Inputs-

Pan Volume-29.412 m3

Total Volume of Pan(Vt)- 100 %

Graining Volume (Vg)-42 %

Height of Strike Level-2000mm…This height is required to avoid the entrainment of Vapour

Calendria Diameter- 4450 mm

Outputs-

Working Volume-100-42=58 %

Volume above top tube plate of working volume = (58/100) X 29.412=17.059 m3

We have to find out the height of vapor space so we have to apply general equation of volume,

Vpan=0.7854 X Dcal 2 X Hs

17.059=0.7854 X 4450 X 4450 X Hs

Hs= 911.72 mm

Final Height of Vapour Space= Strike Level Height + Calculated height of Vapour Space

Final Height of Vapour Space=2000 + 911=2911 …Round Figure it

Final Height of Vapour Space=3000 mm

12348 www.ijariie.com 1126

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

k) Various Heights and Diameters of Vacuum Pan

Fig No-02 (VARIOUS HEIGHTS OF PAN)

Various Diameters of Pans

D1 =Calendria Shell diameter ….Already Calculated

D2-=Down take diameter …….….Already Calculated

D3 =Vapour Body diameter …Equals to D1..

D4 =Vapour Dome diameter =2 X dvi=2 X 1250= 2500 mm=2600 mm by considering FOS

D5 =Discharge diameter (for 40 Ton it is 700 mm to be considered)….Standard Assumptions

Dvo = Vapour Outlet diameter… Already Calculated

Dvi =Vapour Inlet diameter……. Already Calculated

Various Heights of Pans

H1 =Calendria shell height ( Depends on tube height)… ….Already Calculated

H2 =Strike level height from the top tube plate ( Depends on graining volume of pan).. ….Already Calculated

H3 =Vapour space above the strike level (1500mm to 2000 mm )

H4 =(D3-D4) x Tan α (α = 20 to 30)=4450-2500 X x Tan 30 =1125mm=1150mm

H5= Height of the Vapour dome =1.75 X Dvo= 1.75 X 1250 =2187.5=2200 mm

H6 =Bottom ring ( 150mm to 400 mm)..Standard Assumption

H7 = (D1-D5) x Tan α (α= 17 to 25)=4450-700 X tan 17=1146=1150 mm

H8 =150mm to 200mm…. Standard Assumption

12348 www.ijariie.com 1127

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

5.0 VACUUM PAN MODELLING

Vacuum Pan Environment

Operating in semi batch mode, it is in the vacuum pans where the sugar is separated from the juice which is

extracted from the sugar beets by means of a crystallization method controlled by evaporation in a vacuum

environment.

Initially, a sub saturated sugary juice known as standard liquor which is stored in standard liquor tanks is pumped

into the vacuum pan. This standard liquor is then heated in vacuum conditions in order to reduce the boiling point

and prevent thermal decomposition of the sucrose (a process known as caramelisation). When this juice becomes

Supersaturated, it is seeded into small crystals and grown by adding more liquor and maintaining the supersaturated

conditions. When the maximum level is reached in the vacuum pan, the contents are discharged and the pan is

cleaned, ready for a new cycle. To heat the juice and evaporate part of the water, the vacuum pans are equipped with

a heating Element known as the Calendria. Steam flows through the Calendria at a pressure above that of

atmospheric pressure and as it condenses, it releases heat to the Massecuitte in the vacuum pan. The steam is

supplied to the vacuum pans through steam supply pipes which form a closed circuit that runs around the complete

industrial plant. To maintain a partial vacuum (0.2-0.3 bar) in the vacuum pan in order to evaporate the water at low

temperature (65-70°C), the vacuum pan must be connected to a barometric condenser. This condenser maintains a

determined vacuum as it Absorbs the steam coming from the vacuum pans and condenses it by means of cooling.

The cooling effect is obtained by the entry of water which is carried via pipes from the outside. The vacuum

produced in the condenser depends on the outside temperature, which means it works better in winter. Once the

crystallization process of the sucrose in the vacuum pan is completed, the resulting Massecuitte is discharged into

horizontal tanks. In the tanks it is kept moving at a determined temperature so as to maintain its consistency until it

can proceed to one of the centrifugals. In the centrifugals the crystallized sugar is separated from the mother liquor

as the batch is centrifuged at high speed, leaving the crystals retained by a screen. The process takes just a few

minutes. The mother liquor is separated into syrup for seed magna and syrup for Massecuitte which is distributed

according to the needs of the plant. Above Figure shows what a vacuum pan looks like in overall aspect in sugar

industry boiling house.

As per the calculations done , the model has been prepared in Solid Edge ST9 Software for better clarity of

manufacturing

6.0 MODEL OF VACCUM PAN PREPARED IN SOLID EDGE ST9

Fig no-03( front view)

12348 www.ijariie.com 1128

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

FIG NO-04( TOP VIEW)

Fig no-05(PAN bottom view (isometric))

12348 www.ijariie.com 1129

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

FIG NO-06( ISOMETRIC VIEW

7.0 CONCLUSION

From Above design calculations it has been found that For following are the calculated parameters

Volume of Pan ( V) is 29.41 m3

Heating Surface Area of Pan (S) is 194.1176m2

Effective Length of Tube (Let ) is 0.690 m

Numbers of Tubes (N) are 819 Nos

Vapour Inlet Pipe Diameter is 1250 mm

Vapour Outlet Pipe Diameter =975mm

Diameter of Calendria Shell (Dcal)=4450 mm

Thickness of Calendria Shell (Tcal)=18 mm

Down take diameter of Vacuum Pan( Ddt)=2000mm

Height of Vapour Space (Hs) 911.72 mm

Final Height of Vapour Space=3000 mm

Vapour Dome diameter = 2500 mm

Height of the Vapour dome =2200 mm

8.0 REFERENCES

[1] Austmeyer E 2013 Analysis of sugar boiling and its technical consequences; Part II , Heat transfer during sugar

boiling . Int Sugar J.88(1046);23-29

[2] Stephens, D.W. 2008. Studies on modeling circulation in sugar vacuum pans. PhD. Thesis, Univ. James Cook.

12348 www.ijariie.com 1130

Vol-6 Issue-4 2020 IJARIIE-ISSN(O)-2395-4396

[3]. Stobie, R.M. 2015 Pneumatic agitation of high grade massecuite. Int. Sugar J. 101(1206):302-306.

[4] Van der Poel, 2004 P.W., H. Schiweck, and T. Schwartz. 1998. Sugar Technology. Verlag, Bartens, Berlin.

[5] Webre, A.L. 2006 Natural and mechanical circulation in vacuum pans. Pages: 394-452. In: Principles of Sugar

Technology, Vol. 2, Crystallization. P. Honig, ed. Elsevier, Netherlands.

[6]Wright, P.G. 2000 Circulation movements in sugar vacuum pans. Proc. Queensland Soc. Sugar Cane Technol.

33:179-184.

[7] Bergeron, S., and G. Carline. 2003. Changing the heating surface to volume ratio on a low grade batch pan. J.

Amer. Soc. Sugar Cane Technol. (abstract) 24: In press.

[8] Bosworth, R. 2008. Luis Fernando Echeverri Measurements and computations of the flow in

full-scale sugar evaporative-crystallizers and in labscale models

[9] Brown, D.J., K. Alexander, and F. Boysan. 2008 Crystal growth measurement and modeling of fluid flow in a

crystallizer. Zuckerind 117(1):35-39.

[10] E.E.A. ROUILLARD 1985 a study of boiling parameters under conditions of laminar and non Newtonian flow

with massecuite boiling reference

[11] Chen, J., and C. Chou. 2015. Cane Sugar Handbook. John Wiley & Sons, 12th Ed.

[12]Chetty, S., S.B. Davis, A. Raghunandan, and S. Maharaj. 2002. A successful modification to the Dorr 444

clarifier. Proc. S. Afr. Sugar Technol. Assoc. 76:433-434.

12348 www.ijariie.com 1131

You might also like

- Best 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTDocument32 pagesBest 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTRaju Maity100% (5)

- Marine Machinery CourseDocument452 pagesMarine Machinery CourseMerrel Ross100% (1)

- Boiler Preservation Methods Dry and WetDocument14 pagesBoiler Preservation Methods Dry and WetTin Aung KyiNo ratings yet

- Steam Condensers and Their Application in Sugar FactoriesDocument11 pagesSteam Condensers and Their Application in Sugar FactoriesRamon PeyegrinNo ratings yet

- Bubble Cap FucntionDocument4 pagesBubble Cap FucntionPujo PurwantoNo ratings yet

- 500mwboilermahagenco 140115124304 Phpapp02Document38 pages500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanNo ratings yet

- BoilersDocument26 pagesBoilersDeepak GawdeNo ratings yet

- Jigger Tube - IsSCT Technical PaperDocument10 pagesJigger Tube - IsSCT Technical PapermaithanhhaiNo ratings yet

- Better Understand BoilersDocument6 pagesBetter Understand BoilersdigecaNo ratings yet

- Don't Send Money Down The Drain: Steam ManagementDocument3 pagesDon't Send Money Down The Drain: Steam ManagementAnonymous lqsJIe6l5No ratings yet

- Application of HEat PipeDocument29 pagesApplication of HEat PipeNikhil ShahNo ratings yet

- Marine Machinary CourseDocument452 pagesMarine Machinary CourseMc Liviu100% (1)

- Smoke Tube Boilers: Tank (Scotch) BoilerDocument4 pagesSmoke Tube Boilers: Tank (Scotch) BoilerMeghanath AdkonkarNo ratings yet

- 1981 - Addison - Large Falling Film EvaporatorsDocument3 pages1981 - Addison - Large Falling Film EvaporatorsshondabagueNo ratings yet

- Distillation Column DesignDocument7 pagesDistillation Column DesignTouhidBinAnwarNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Steam 1Document5 pagesSteam 1NaNo ratings yet

- Intelligent Gas LiftDocument17 pagesIntelligent Gas Liftmemos2011No ratings yet

- Steam Boiler Feedwater Storage Technology White PaperDocument16 pagesSteam Boiler Feedwater Storage Technology White Paperchristiancandido100% (1)

- Ideal Steam DrumDocument6 pagesIdeal Steam DrumFahad RockingNo ratings yet

- pp57-65 MS06Document9 pagespp57-65 MS06vikaskatheriaNo ratings yet

- Tube Settlers CatalogueDocument10 pagesTube Settlers CatalogueIlu Singh100% (1)

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumar100% (1)

- Steam BoilerDocument9 pagesSteam BoilerzaidinNo ratings yet

- Boilers Basic Components (Att. VIII)Document28 pagesBoilers Basic Components (Att. VIII)Vijay RajNo ratings yet

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdNo ratings yet

- THERMAL-1 Experiment 1 Part ADocument7 pagesTHERMAL-1 Experiment 1 Part Anishith ranaNo ratings yet

- E101 3240 Industrial Water Tube Package Boilers Babcock WilcoxDocument12 pagesE101 3240 Industrial Water Tube Package Boilers Babcock Wilcoxa_parratNo ratings yet

- Improving Bagasse Boiler PerformanceDocument9 pagesImproving Bagasse Boiler PerformanceUsama MalikNo ratings yet

- Thermal Cracking - Delayed Coking 2Document8 pagesThermal Cracking - Delayed Coking 2Anonymous rUs4PjYo5No ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011Pradyot DeoliaNo ratings yet

- ConstructionDocument38 pagesConstructionChakravarthi NagaNo ratings yet

- Manual On Boiler Tube FailureDocument69 pagesManual On Boiler Tube Failureyogeshmangal1974100% (2)

- Tower Tray Oil and Gas IndustryDocument11 pagesTower Tray Oil and Gas IndustryHeet PatelNo ratings yet

- Replacing A Steam Boiler - ES MagazineDocument10 pagesReplacing A Steam Boiler - ES MagazineBorkoBGNo ratings yet

- Cochran and Babcock & Wilcox BoilersDocument3 pagesCochran and Babcock & Wilcox BoilersAshish VermaNo ratings yet

- Pages - Steam Mains and DrainageDocument10 pagesPages - Steam Mains and DrainageSPK 27No ratings yet

- BOILERfinal - Print Out PDFDocument25 pagesBOILERfinal - Print Out PDFRahulBhartiNo ratings yet

- Presentation TemplateDocument18 pagesPresentation Templatesaibabu sai100% (1)

- Section A.6 Steam and Water Cycle EquipmentDocument19 pagesSection A.6 Steam and Water Cycle EquipmentChava TejaNo ratings yet

- Quantity Unit Description Item: Brand New Acid Blending PlantDocument4 pagesQuantity Unit Description Item: Brand New Acid Blending Plantgplese0No ratings yet

- Optimizing The Design of Splitter TowersDocument6 pagesOptimizing The Design of Splitter TowersZangNo ratings yet

- FCSG For SAGDDocument7 pagesFCSG For SAGDaugur886No ratings yet

- Steam Mains and Drainage Spirax PDFDocument19 pagesSteam Mains and Drainage Spirax PDFsachin nagavkarNo ratings yet

- Water Tube Boiler What You Need To KnowDocument7 pagesWater Tube Boiler What You Need To KnowBrilliano Wahyu RamadhanNo ratings yet

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass Valvesadehriya100% (2)

- Chemtreat Challenges of Industrial Boiler Water TreatmentDocument17 pagesChemtreat Challenges of Industrial Boiler Water TreatmentKhondoker Nayeem ul haqueNo ratings yet

- Westco PumpDocument8 pagesWestco PumpWorapat PuttakasemNo ratings yet

- Basic Mechanical Engineering Lab Manual: April 2011Document34 pagesBasic Mechanical Engineering Lab Manual: April 2011ankit trivediNo ratings yet

- Concentric-Coiled-Tubing Well Vacuuming For Complex Horizontal WellsDocument3 pagesConcentric-Coiled-Tubing Well Vacuuming For Complex Horizontal WellsAQUILES CARRERANo ratings yet

- TB1-019 Off-Line Boiler Protection OptionsDocument1 pageTB1-019 Off-Line Boiler Protection Optionsjesus_manrique2753No ratings yet

- Steam Distribution Economical PipingDocument4 pagesSteam Distribution Economical PipingmohdnazirNo ratings yet

- Bottom Ash Hopper CollectionsDocument11 pagesBottom Ash Hopper Collectionsatgsganesh0% (1)

- Surface Condenser HEIDocument7 pagesSurface Condenser HEIJesús Santiago QuijadaNo ratings yet

- Experiment One-To Study The Cochran and Babcock and Wilcox BoilersDocument8 pagesExperiment One-To Study The Cochran and Babcock and Wilcox BoilersHasib IslamNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901From EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Hints on cheese-making, for the dairyman, the factoryman, and the manufacturerFrom EverandHints on cheese-making, for the dairyman, the factoryman, and the manufacturerNo ratings yet

- Moon Landing (1) NewDocument2 pagesMoon Landing (1) NewHamza AliNo ratings yet

- Safety MeasuresDocument5 pagesSafety MeasuresHamza AliNo ratings yet

- 11 - Gas-Liquid MixingDocument56 pages11 - Gas-Liquid MixingHamza AliNo ratings yet

- 7 - PowerFlow CharacteristicsDocument63 pages7 - PowerFlow CharacteristicsHamza AliNo ratings yet

- 1.basic Concepts of Thermo - Spring 2020Document48 pages1.basic Concepts of Thermo - Spring 2020Hamza AliNo ratings yet

- MTExam-1 2021Document2 pagesMTExam-1 2021Hamza AliNo ratings yet

- 1st Law For Open Systems - Spring 2020Document63 pages1st Law For Open Systems - Spring 2020Hamza AliNo ratings yet

- Chapter 25Document10 pagesChapter 25Hamza AliNo ratings yet

- Chapter 13 - Sections 13.6-13.8Document34 pagesChapter 13 - Sections 13.6-13.8Hamza AliNo ratings yet

- Chapter 17Document37 pagesChapter 17Hamza AliNo ratings yet

- Feed:: PropyleneDocument7 pagesFeed:: PropyleneHamza AliNo ratings yet

- Simulation of Carbon Dioxide - Monoethanolamine - Water System Using Equilibrium ApproachDocument47 pagesSimulation of Carbon Dioxide - Monoethanolamine - Water System Using Equilibrium ApproachHamza AliNo ratings yet

- Unit Operations - FExam-2 - 2021Document1 pageUnit Operations - FExam-2 - 2021Hamza AliNo ratings yet

- Avogadro's Number LinkdinDocument2 pagesAvogadro's Number LinkdinHamza AliNo ratings yet

- Maxwell RelationsDocument1 pageMaxwell RelationsHamza AliNo ratings yet

- Topic 2 - 2021 - Updated 9-20-21Document15 pagesTopic 2 - 2021 - Updated 9-20-21Hamza AliNo ratings yet

- Some of The Graphical Transient Solutions in Higher ResolutionDocument2 pagesSome of The Graphical Transient Solutions in Higher ResolutionHamza AliNo ratings yet

- Acutal GraphDocument2 pagesAcutal GraphHamza AliNo ratings yet

- FORMULA SHEET - Final Exam - CHME312Document2 pagesFORMULA SHEET - Final Exam - CHME312Hamza AliNo ratings yet

- Cryogenic DistillationDocument5 pagesCryogenic DistillationHamza AliNo ratings yet

- Column Pressure SelectionDocument2 pagesColumn Pressure SelectionHamza AliNo ratings yet

- APPENDIX B2 Constants For The Antoine Equation For Vapor Pressures of Pure SpeciesDocument1 pageAPPENDIX B2 Constants For The Antoine Equation For Vapor Pressures of Pure SpeciesHamza AliNo ratings yet

- Saftey ConsiderationDocument2 pagesSaftey ConsiderationHamza AliNo ratings yet

- HYDRAcap MAXDocument2 pagesHYDRAcap MAXHamza AliNo ratings yet

- Flash CalculationsDocument10 pagesFlash CalculationsHamza AliNo ratings yet

- Ahmed Deyab: Senior Process Engineer Process Simulation ConsultantDocument154 pagesAhmed Deyab: Senior Process Engineer Process Simulation ConsultantHamza AliNo ratings yet

- Jarso DoyoDocument82 pagesJarso DoyoDawit NegussieNo ratings yet

- Ferguson's FormulaDocument5 pagesFerguson's FormulaShrey AgarwalNo ratings yet

- Detailed Lesson Plan For Senior HighDocument3 pagesDetailed Lesson Plan For Senior HighSora HazelbitzNo ratings yet

- Against Wind Farms: A Short EssayDocument7 pagesAgainst Wind Farms: A Short EssayJaci RaeNo ratings yet

- Mat Score and Its InterpretationDocument2 pagesMat Score and Its InterpretationSHASHANK SINGHNo ratings yet

- Improving Grammatical Range and Accuracy: Test Section - Speaking Part 2Document9 pagesImproving Grammatical Range and Accuracy: Test Section - Speaking Part 2Cengizhan AkdağNo ratings yet

- The Legend of Malin KundangDocument3 pagesThe Legend of Malin KundangSiti Evayanti100% (3)

- Psychological Assessment - Learning Guide 2024Document14 pagesPsychological Assessment - Learning Guide 2024murendeni.025No ratings yet

- JHS Detailed Lesson PlanDocument9 pagesJHS Detailed Lesson PlanJewelNo ratings yet

- Effects of Abm Subjects To The Content Knowledge in Abm StudentsDocument10 pagesEffects of Abm Subjects To The Content Knowledge in Abm StudentsJENNELLE LORILLANo ratings yet

- Thermal Recovery MethodDocument25 pagesThermal Recovery Methodmahmud masudNo ratings yet

- Recycled CarpetsDocument10 pagesRecycled Carpetsken riveraNo ratings yet

- Letting Go of Stress, Anxiety, and Fear During Study and Test TakingDocument3 pagesLetting Go of Stress, Anxiety, and Fear During Study and Test TakingRamonNo ratings yet

- IEQ Micro ProjectDocument22 pagesIEQ Micro ProjectMoiz SayyedNo ratings yet

- The World of Lapp: Innovations 2017 18Document48 pagesThe World of Lapp: Innovations 2017 18Andrew LowNo ratings yet

- Bren Davy LetterDocument2 pagesBren Davy LetterAbril Biente SincoNo ratings yet

- Physics: FlashbackDocument2 pagesPhysics: FlashbackWonderlapseNo ratings yet

- Activity PR ItoDocument4 pagesActivity PR ItoSamantha Nicolle QuierraNo ratings yet

- MaximumDocument3 pagesMaximumJowiNo ratings yet

- Payback BC MethodDocument1 pagePayback BC MethodJam LarsonNo ratings yet

- SeismoStruct User Manual PDFDocument325 pagesSeismoStruct User Manual PDFStr Engr Mohammad AliNo ratings yet

- Etp Progress Report - g70Document18 pagesEtp Progress Report - g70EeHuey ChooNo ratings yet

- Course Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesDocument1 pageCourse Code: MTOE10 Course Title: Non Destructive Testing and Failure Analysis Number of Credits 3 Prerequisites (Course Code) : Nil Course Type: Oe Course Learning ObjectivesNags DevaNo ratings yet

- DE THI TUYEN SINH CUA S 4 Năm NayDocument17 pagesDE THI TUYEN SINH CUA S 4 Năm Nay[][][][][][][][]No ratings yet

- Datamaster DMT Breath Test Operator Training Course ManualDocument147 pagesDatamaster DMT Breath Test Operator Training Course ManualMetalAnonNo ratings yet

- Ug Catalog 21-22 0Document243 pagesUg Catalog 21-22 0Faisal Abdul MalakNo ratings yet

- Bridge Ergonomic Design A ReviewDocument7 pagesBridge Ergonomic Design A ReviewLibrary Jasaan CampusNo ratings yet

- Lee Moi Wong Chief Research Officer Kuala LumpurDocument2 pagesLee Moi Wong Chief Research Officer Kuala LumpurTony MathewNo ratings yet

- Chapter 4 Thesis Sample FilipinoDocument7 pagesChapter 4 Thesis Sample Filipinojum1p0tonip3100% (2)

- Ciam T10Document3 pagesCiam T10Nino SilvaNo ratings yet