Professional Documents

Culture Documents

Acceptance Stds Radiographic

Acceptance Stds Radiographic

Uploaded by

Ajmal KhanCopyright:

Available Formats

You might also like

- Acceptance Criteria For CSWIP 3.1Document19 pagesAcceptance Criteria For CSWIP 3.1Muhammed Abo-Fandood100% (5)

- Acceptance Level TWI SampleDocument1 pageAcceptance Level TWI SampleFadhlan D Luffy100% (1)

- RT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Document6 pagesRT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Kader KaderNo ratings yet

- Benteller Pipe Cataloque PDFDocument2 pagesBenteller Pipe Cataloque PDFGarry Bernard NelsonNo ratings yet

- Implementing A Generic Data Access Layer inDocument25 pagesImplementing A Generic Data Access Layer inSantosh SutarNo ratings yet

- MEM 660 Theory of Elasticity: Course Syllabus Instructor InformationDocument3 pagesMEM 660 Theory of Elasticity: Course Syllabus Instructor Informationnick10686No ratings yet

- Welding Acceptance Criteria On Pipe LineDocument2 pagesWelding Acceptance Criteria On Pipe Linewahyu100% (1)

- Steel CatalogueDocument8 pagesSteel CatalogueKen MugambiNo ratings yet

- Apex Steel Catalogue PDFDocument7 pagesApex Steel Catalogue PDFDaniel Edward OmondiNo ratings yet

- Denso FB 30 TapeDocument2 pagesDenso FB 30 TapefoamtrailerNo ratings yet

- RT Acceptance Criteria All Code+Document1 pageRT Acceptance Criteria All Code+Shabbir ali100% (2)

- TC120TD5Document1 pageTC120TD5Gheorghita VladNo ratings yet

- Tolerances: Important To Interchangeability and Provision For Replacement PartsDocument48 pagesTolerances: Important To Interchangeability and Provision For Replacement PartsDineshNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Apex Steel Catalogue PDFDocument16 pagesApex Steel Catalogue PDFArifsalim0% (1)

- Flexitallic Spiralwound CgiDocument1 pageFlexitallic Spiralwound CgiDiego Martínez FernándezNo ratings yet

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarNo ratings yet

- Focal 33v1Document1 pageFocal 33v1KamilNo ratings yet

- Tata Steel HR & CR SteelDocument2 pagesTata Steel HR & CR SteelSaravanan KNo ratings yet

- RT Acceptance All CodeDocument1 pageRT Acceptance All Codeeka prasetyaNo ratings yet

- RT Acceptance Criteria All CodeDocument1 pageRT Acceptance Criteria All Codevikas100% (1)

- RT Acceptance Criteria: API-1104 AWS D1.1Document1 pageRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- RT Acceptance Criteria All Code - 220202 - 125414Document1 pageRT Acceptance Criteria All Code - 220202 - 125414Sandrino CheNo ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- NEW - ALL Codes For Accptance Criteria For RTDocument4 pagesNEW - ALL Codes For Accptance Criteria For RTnerdsarmyNo ratings yet

- Acceptance Criteria Welding API 1104 (Printed)Document1 pageAcceptance Criteria Welding API 1104 (Printed)mohammedNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- P B M T: Remcote Utyl Astic APEDocument2 pagesP B M T: Remcote Utyl Astic APEIm ChinithNo ratings yet

- NEW - ALL Codes For Accptance Criteria For RTDocument4 pagesNEW - ALL Codes For Accptance Criteria For RTBALA CHANDAR M100% (1)

- STD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsDocument2 pagesSTD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsMichael CovillNo ratings yet

- What It Is: Concrete Pipe and Manhole GasketsDocument3 pagesWhat It Is: Concrete Pipe and Manhole GasketslasryzaNo ratings yet

- Nastri Lastre Rame ENGDocument4 pagesNastri Lastre Rame ENGSyed Wajahat BukhariNo ratings yet

- 100CA1Document1 page100CA1Johnathan JonesNo ratings yet

- Piping Properties 2008 Designer2Document2 pagesPiping Properties 2008 Designer2stridehjfNo ratings yet

- 40Mm & 50Mm Severe Service GaugeDocument6 pages40Mm & 50Mm Severe Service GaugeadNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamed100% (1)

- Fiche Technique 21wxDocument1 pageFiche Technique 21wxduduleNo ratings yet

- Ps 165 VwooferDocument1 pagePs 165 VwooferWk NgNo ratings yet

- Astm A500 Pipe Tolerances (Round Tubing)Document1 pageAstm A500 Pipe Tolerances (Round Tubing)Anwarul AfrojNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- PDF of Astm A53 Standard SpecificationDocument4 pagesPDF of Astm A53 Standard Specificationmarcelo10003No ratings yet

- Fiche Technique 6w3Document1 pageFiche Technique 6w3sady keleNo ratings yet

- Technical Specifications: PlateDocument2 pagesTechnical Specifications: PlateIgnacio LopezNo ratings yet

- ADPL718 Catalog Page 27Document1 pageADPL718 Catalog Page 27Sugeng DarmintoNo ratings yet

- D 11.1 KPTMDocument6 pagesD 11.1 KPTMNayan RamyaNo ratings yet

- Flexi ConnectorDocument1 pageFlexi ConnectorArstNo ratings yet

- 2T12 U0-G25 HS GP: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2T12 U0-G25 HS GP: Technical Data Sheet Conveyor and Process BeltsDaniel GarcíaNo ratings yet

- Heat Exchanger Selection GuideDocument2 pagesHeat Exchanger Selection GuiderodrigoperezsimoneNo ratings yet

- CO2 Laser Preventive Maintenance Check SheetDocument9 pagesCO2 Laser Preventive Maintenance Check SheetGiang NguyenNo ratings yet

- Chiorino Conveyor Belts For Packed Food 26jan11Document1 pageChiorino Conveyor Belts For Packed Food 26jan11navneet jainNo ratings yet

- Chiorino Conveyor Belts For Packed Food 26jan11Document1 pageChiorino Conveyor Belts For Packed Food 26jan11navneet jainNo ratings yet

- Arc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Document1 pageArc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Wojciech SpychalskiNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- USSOR 2010 New 2Document57 pagesUSSOR 2010 New 2manik rajakNo ratings yet

- Bass Pulse15: General SpecificationsDocument1 pageBass Pulse15: General SpecificationsDaniel MambuscayNo ratings yet

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21Document1 pageSteel Standards: ASTM A252 ASTM A500 CSA G40.21Candra YuniartoNo ratings yet

- Aluminum Wear Strips - McMaster-Carr PDFDocument3 pagesAluminum Wear Strips - McMaster-Carr PDFHassan HelmyNo ratings yet

- Testresultat För DASAG TERAZZO PlattorDocument1 pageTestresultat För DASAG TERAZZO PlattorMEHDI FARROKHINo ratings yet

- Arn 188 05 4 enDocument2 pagesArn 188 05 4 engbaNo ratings yet

- 2M8 U0-V5 A: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2M8 U0-V5 A: Technical Data Sheet Conveyor and Process Beltsnavneet jainNo ratings yet

- Hand Over FormateDocument1 pageHand Over FormateAjmal KhanNo ratings yet

- Sis Casting DefectsDocument27 pagesSis Casting DefectsAjmal KhanNo ratings yet

- Casting Defect BriefDocument1 pageCasting Defect BriefAjmal KhanNo ratings yet

- How Do Boats FloatDocument1 pageHow Do Boats FloatAjmal KhanNo ratings yet

- Mobile Crane Load Test Report FormDocument4 pagesMobile Crane Load Test Report FormAjmal KhanNo ratings yet

- BSLM InstallationDocument1 pageBSLM InstallationAjmal KhanNo ratings yet

- Galvanized CoatingsDocument3 pagesGalvanized CoatingsAjmal KhanNo ratings yet

- Yarn TestingDocument41 pagesYarn Testingabc0% (1)

- Controller DatasheetDocument3 pagesController DatasheetsureshkanuboyinaNo ratings yet

- Kericho 2015 Geography 1.anspdfDocument4 pagesKericho 2015 Geography 1.anspdfedward mokayaNo ratings yet

- 4PH0 1P Que 20140515Document28 pages4PH0 1P Que 20140515ramexistsNo ratings yet

- Enabler PDFDocument16 pagesEnabler PDFJose Luis Caceres SeverinoNo ratings yet

- BPM1701 Calculus and Statistics: Lesson 3c Roots of Equations Quadratic EquationDocument9 pagesBPM1701 Calculus and Statistics: Lesson 3c Roots of Equations Quadratic EquationAnonymous sSQyq7I1zNo ratings yet

- Discussion LAB Experiment 4 LIPIDDocument2 pagesDiscussion LAB Experiment 4 LIPIDYurie RiriNo ratings yet

- Addendum: Manual Updates Addendum: Manual Updates: 48 Door Type 1 - 8Document13 pagesAddendum: Manual Updates Addendum: Manual Updates: 48 Door Type 1 - 8Zoran Borojević-TeslaNo ratings yet

- Motion Graphs Displacement-Time GraphsDocument11 pagesMotion Graphs Displacement-Time GraphsprimalNo ratings yet

- NTPC Badarpur Mechanical ReportDocument68 pagesNTPC Badarpur Mechanical Reportdeveshsingh0760% (20)

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- Description Start Here If... : EvaluationDocument5 pagesDescription Start Here If... : EvaluationWorh FalexNo ratings yet

- Ece V Digital Signal Processing (10ec52) NotesDocument160 pagesEce V Digital Signal Processing (10ec52) NotesVijay SaiNo ratings yet

- CHORD MASTERY by Claude JohnsonDocument68 pagesCHORD MASTERY by Claude Johnsonp0ndra100% (1)

- 4 - SOME ANY..... Con SolucionesDocument4 pages4 - SOME ANY..... Con SolucionesMartaNo ratings yet

- 1/22/13 12:01 PM C:/Users/Sol... /uwb - SV - Model - CT - 15 - 4a.m 1 of 3Document3 pages1/22/13 12:01 PM C:/Users/Sol... /uwb - SV - Model - CT - 15 - 4a.m 1 of 3Solo NunooNo ratings yet

- COBOL QuesbankDocument23 pagesCOBOL Quesbankapi-27095622No ratings yet

- Ac Bridge: EEE 457: Measurement & InstrumentationDocument13 pagesAc Bridge: EEE 457: Measurement & InstrumentationTareqNo ratings yet

- 2019 Paper 2 GceDocument21 pages2019 Paper 2 GcePatrick NkowaniNo ratings yet

- Monte Carlo Methods For Radiation Transport: Fundamentals and Advanced Topics 1st Edition Oleg N. Vassiliev (Auth.)Document43 pagesMonte Carlo Methods For Radiation Transport: Fundamentals and Advanced Topics 1st Edition Oleg N. Vassiliev (Auth.)david.mager792100% (20)

- MiFlash Result@2021719Document2 pagesMiFlash Result@2021719Kehidupan Dalam JendelaNo ratings yet

- 350204011ws Class 4Document62 pages350204011ws Class 4Namita Sahu100% (1)

- Phillips Science of Dental Materials 4 (Dragged) (Dragged) 6Document1 pagePhillips Science of Dental Materials 4 (Dragged) (Dragged) 6asop06No ratings yet

- Yield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessDocument9 pagesYield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessAMAANINo ratings yet

- L e A D 6th Grade Science FinalDocument60 pagesL e A D 6th Grade Science Finalapi-260611241No ratings yet

- Fluid QueDocument48 pagesFluid QueMushfique AhmedNo ratings yet

- Oferta Rusartis Premiumcut Soft Crea 14.04.2021Document3 pagesOferta Rusartis Premiumcut Soft Crea 14.04.2021Eugen CozianuNo ratings yet

- Mos For SteelguardDocument4 pagesMos For SteelguardAnonymous 7IKdlmNo ratings yet

Acceptance Stds Radiographic

Acceptance Stds Radiographic

Uploaded by

Ajmal KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acceptance Stds Radiographic

Acceptance Stds Radiographic

Uploaded by

Ajmal KhanCopyright:

Available Formats

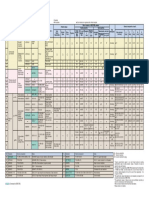

Tanks & Pr.

Piping (UG) Pr. Vessels Ref. Piping Power Boiler Tanks Piping Pr. Vessels

Vessels

API 1104 ASME-VIII (100%) ASME - 4

Type of Discontinuity ASME B31.4 API 650

ASME-VIII (Spot)

ANSI B31.3 ASME B31.1 BS 2654 BS 2971 BS 5500

& Code ASME B31.6 API 620 Boilers

Vertical None Max 25 mm Length in

Depth 0.8 mm Length

Incomplete Max 25.4mm Not Acceptable Not Acceptable 38 mm in 160 mm Not Acceptable

permitted. 100 mm

Not Acceptable

Penetration (LOP) Horizontal Max 10% of Max 20% of weld

Length

Thk. thickness

Mis Match & Vertical None Max 25 mm Length in

permitted. 100 mm

Incomplete Max 50.8mm Not Acceptable Not Acceptable Not Acceptable Not Acceptable

Horizantal Max 10% of Max 20% of weld

Not Acceptable

penetration Thk. thickness

Incomplete Fusion Max 25.4 mm Not Acceptable Not Acceptable None Permitted Not Acceptable Not Acceptable -- Not Acceptable

(LOF)

Cold Lap Max 50.8 mm Not Acceptable Not Acceptable None Permitted Not Acceptable Not Acceptable -- Not Acceptable

Non Fusion

Density not to exceed 2/3T When T is

Internal Concavity parent metal density

Not Acceptable

thickness of plate

Treat as LOP Treat as LOP -- Not Acceptable

Not Acceptable. Treat as

Burn Through Not to exceed 6.35 mm Treat as Concavity Treat as Concavity Not Listed Not Listed Not Listed Not Listed

cavities

Max length 50.8 mm width 6.3mm for 19mm <1/3 weld thk 6.3mm for 19mm Max 2/3 T to 19mm, 3mm for 50mm

Slag Inclusion 1.59 mm Pipe 1/3T for 19-57 mm

2/3 when T is thickness

<2.4mm weld thk in 1/3T for 19-57mm indication less than Not Listed 4.6mm for 50-75mm

Elongated of plate

0<60.3 mm 3T Max Length 19mm for over 57mm 12 x weld thk length. 19mm for over 57mm 6mm acceptable 6mm for >75mm

Max T in a length of Max T in a length of

Max T in a length of 6T

Max length 12.7 mm width 12T when distance <1/3 weld thk 12T when distance

Slag Inclsuion & 3.17 mm. Pipe between indications

2/3 when T is thickness

<2.4mm weld thk in between indications

when distance between

Not Listed

Cumulative length >

group of plate indications is> 3 times 100mm width 4mm max.

0<60.3 mm 2T Max Length exceed 6L where L is 12 x weld thk length. exceed 6L where L is

the longest indication

longest indication longest indication

3mm or 25% of weld 3mm for 60mm

Max size of individual pore

As per charts & thickness sum not to 4.5mm for 50-75mm

Porosity Cluster 3.17 mm max of group 12.7 As per charts & Tables Not a factor

Tables

As per charts & Tables As per charts & Tables

exceed 10mm in 6.0mm for >75mm 2% by

mm individual size 1.59 mm

25mm weld length area

Hollow Bead Max length 12.7 mm Not listed Not listed Not listed Not listed Not listed Not listed Not acceptable

Crater or star length

Crakes <3.96mm

Not acceptable Not acceptable Not acceptable Not acceptable Not acceptable Not acceptable Not acceptable

Not to exceed 1/6th of weld

Undercutting length

Not listed Not listed 0.8mm or T/4 Not Listed Not Listed Not Listed Not Listed

Accumulate Aggregate length in 300mm

Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable

Discontinuity not to exceed 50.8mm

copper incl not permitted.

Solid Inclusion Not listed Not listed Not listed Not listed Not listed Not listed Not listed Tungsten incl treat as

porosity.

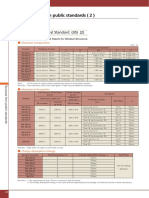

Piping (UG) Tanks & Pr. Vessels Pressure Vessels Ref. Piping Power Boiler Pressure Vessels

API 1104 ASME-VIII (100%) ASME - 4

Type of Discontinuity ASME B31.4 API 650

ASME-VIII (Spot)

ANSI B31.3 ASME B31.1 BS 5500

& Code ASME B31.6 API 620 Boilers

Incomplete Max 25 mm. Aggreate Lg 25mm

Not Acceptable Not Acceptable

Depth 0.8 mm Length 38 mm

Not Acceptable Not Acceptable

Penetration (LOP) in 300mm weld length in 160 mm Length

Mis Match &

Max 50mm. Aggreate Lg 75mm

Incomplete in 300mm weld length

Not Acceptable Not Acceptable Not Acceptable Not Acceptable Not Acceptable

penetration

Max 25 mm. Aggreate Lg 25mm

Incomplete Fusion in 300mm weld length

Not Acceptable Not Acceptable None Permitted Not Acceptable Not Acceptable

(LOF) a) 8% of weld length if Lg <

300mm.

Cold Lap Max 50mm. Aggreate Lg 50mm

Not Acceptable Not Acceptable None Permitted Not Acceptable Not Acceptable

Non Fusion in 300mm weld length

2/3t When t is thickness of

plate

Any length accepted, provided Sum not more than t in length When there is any abrupt

Internal Concavity Density not to exceed parent Not Acceptable of 60mm, seperated by 3L, L is change in density, Not Not Acceptable

metal density longest indication. acceptable

Max acc. length is 19mm.

<6mm is acc. For all thk.

OD>2"--Not to exceed 6 mm.

Not Acceptable. Treat as

Burn Through Sum of BT's 13mm in 300mm Not Acceptable Treat as concavity Not Listed Not Listed

cavities

Lg.of weld

Max length 50 mm, width

2/3 t where t is thickness of

1.59 mm .Pipe 0D<60.3 mm 3t 6mm for t < 19mm <1/3 weld thk 6mm for t< 19mm

Slag Inclusion Max Length. 1/3t for t 19-57 mm

plate. Sum of indication not > t

<2.4mm weld thk in 12 x weld 1/3t for t 19 to 57mm

L= t ≤ 100mm, Width = t/10 ≤

Elongated in a length of 6t, seperated by 4mm.

Aggrigate Lg.50mm in 300lg. 19mm for t over 57mm thk length. 19mm for t> 57mm

3L, L is longest indication.

Weld

Aggregate length > t in a length

Max t in a length of 12t when Isolated pore in group

Max length 13 mm width3mm. of 12t when distance between <1/3 weld thk

Slag Inclsuion & indications exceed 6L where L

2/3 when T is thickness of

<2.4mm weld thk in 12 x weld

distance between indications 3mm for 50mm

group plate exceed 6L where L is longest 4.5mm for 50-75mm

0D<60.3 mm 2t Max Length is the longest indication in thk length.

indication 6mm for >75mm

group

0.3mm for t <3mm

0.4mm for 3 to 6mm

Max size of individual pore 3 mm 0.8mm for t 6 to 50mm Isolated pore in group

max.Dia of cluster-13mm, 1.6mm for t >50mm 3mm for 50mm

Porosity Cluster In cluster individual size2mm. Max size shall be smaller of Not a factor As per charts & Tables Appendix A 250 ASME Sec-I 4.5mm for 50-75mm

Aggrigate Lg.13mm in 300 Weld 1/4t or 4mm except indication 6.0mm for >75mm

Lg. seperated by 25mm or more. 2% by area for t≤ 50mm.

T>50mm, max size is 10mm.

See charts.

Max length 13 mm

Aggrigate Lg.50mm in 300 Weld

Hollow Bead Lg.Individual 6mm Seperated

Not listed Not listed Not listed Not listed Not acceptable

by2".

Crakes Crater or star length <3.96mm Not acceptable Not acceptable Not acceptable Not acceptable Not acceptable

Aggrigate Lg.50mm in 300 Weld

Undercutting Lg.

Not listed Not listed 0.8mm or T/4 Not Listed Not Listed

Accumulate Aggregate length in 300mm not

Not applicable Not applicable Not applicable Not applicable Not applicable

Discontinuity to exceed 50mm

copper incl not permitted.

Solid Inclusion Not listed Not listed Not listed Not listed Not listed

Tungsten incl treat as porosity.

You might also like

- Acceptance Criteria For CSWIP 3.1Document19 pagesAcceptance Criteria For CSWIP 3.1Muhammed Abo-Fandood100% (5)

- Acceptance Level TWI SampleDocument1 pageAcceptance Level TWI SampleFadhlan D Luffy100% (1)

- RT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Document6 pagesRT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Kader KaderNo ratings yet

- Benteller Pipe Cataloque PDFDocument2 pagesBenteller Pipe Cataloque PDFGarry Bernard NelsonNo ratings yet

- Implementing A Generic Data Access Layer inDocument25 pagesImplementing A Generic Data Access Layer inSantosh SutarNo ratings yet

- MEM 660 Theory of Elasticity: Course Syllabus Instructor InformationDocument3 pagesMEM 660 Theory of Elasticity: Course Syllabus Instructor Informationnick10686No ratings yet

- Welding Acceptance Criteria On Pipe LineDocument2 pagesWelding Acceptance Criteria On Pipe Linewahyu100% (1)

- Steel CatalogueDocument8 pagesSteel CatalogueKen MugambiNo ratings yet

- Apex Steel Catalogue PDFDocument7 pagesApex Steel Catalogue PDFDaniel Edward OmondiNo ratings yet

- Denso FB 30 TapeDocument2 pagesDenso FB 30 TapefoamtrailerNo ratings yet

- RT Acceptance Criteria All Code+Document1 pageRT Acceptance Criteria All Code+Shabbir ali100% (2)

- TC120TD5Document1 pageTC120TD5Gheorghita VladNo ratings yet

- Tolerances: Important To Interchangeability and Provision For Replacement PartsDocument48 pagesTolerances: Important To Interchangeability and Provision For Replacement PartsDineshNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Apex Steel Catalogue PDFDocument16 pagesApex Steel Catalogue PDFArifsalim0% (1)

- Flexitallic Spiralwound CgiDocument1 pageFlexitallic Spiralwound CgiDiego Martínez FernándezNo ratings yet

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarNo ratings yet

- Focal 33v1Document1 pageFocal 33v1KamilNo ratings yet

- Tata Steel HR & CR SteelDocument2 pagesTata Steel HR & CR SteelSaravanan KNo ratings yet

- RT Acceptance All CodeDocument1 pageRT Acceptance All Codeeka prasetyaNo ratings yet

- RT Acceptance Criteria All CodeDocument1 pageRT Acceptance Criteria All Codevikas100% (1)

- RT Acceptance Criteria: API-1104 AWS D1.1Document1 pageRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- RT Acceptance Criteria All Code - 220202 - 125414Document1 pageRT Acceptance Criteria All Code - 220202 - 125414Sandrino CheNo ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- NEW - ALL Codes For Accptance Criteria For RTDocument4 pagesNEW - ALL Codes For Accptance Criteria For RTnerdsarmyNo ratings yet

- Acceptance Criteria Welding API 1104 (Printed)Document1 pageAcceptance Criteria Welding API 1104 (Printed)mohammedNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- P B M T: Remcote Utyl Astic APEDocument2 pagesP B M T: Remcote Utyl Astic APEIm ChinithNo ratings yet

- NEW - ALL Codes For Accptance Criteria For RTDocument4 pagesNEW - ALL Codes For Accptance Criteria For RTBALA CHANDAR M100% (1)

- STD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsDocument2 pagesSTD-ENGPROC-OTH-039 App.6 - Acceptance Crireria For WeldsMichael CovillNo ratings yet

- What It Is: Concrete Pipe and Manhole GasketsDocument3 pagesWhat It Is: Concrete Pipe and Manhole GasketslasryzaNo ratings yet

- Nastri Lastre Rame ENGDocument4 pagesNastri Lastre Rame ENGSyed Wajahat BukhariNo ratings yet

- 100CA1Document1 page100CA1Johnathan JonesNo ratings yet

- Piping Properties 2008 Designer2Document2 pagesPiping Properties 2008 Designer2stridehjfNo ratings yet

- 40Mm & 50Mm Severe Service GaugeDocument6 pages40Mm & 50Mm Severe Service GaugeadNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Radiography Acceptance Criteria As Per B 31.3Document2 pagesRadiography Acceptance Criteria As Per B 31.3mohamed100% (1)

- Fiche Technique 21wxDocument1 pageFiche Technique 21wxduduleNo ratings yet

- Ps 165 VwooferDocument1 pagePs 165 VwooferWk NgNo ratings yet

- Astm A500 Pipe Tolerances (Round Tubing)Document1 pageAstm A500 Pipe Tolerances (Round Tubing)Anwarul AfrojNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- PDF of Astm A53 Standard SpecificationDocument4 pagesPDF of Astm A53 Standard Specificationmarcelo10003No ratings yet

- Fiche Technique 6w3Document1 pageFiche Technique 6w3sady keleNo ratings yet

- Technical Specifications: PlateDocument2 pagesTechnical Specifications: PlateIgnacio LopezNo ratings yet

- ADPL718 Catalog Page 27Document1 pageADPL718 Catalog Page 27Sugeng DarmintoNo ratings yet

- D 11.1 KPTMDocument6 pagesD 11.1 KPTMNayan RamyaNo ratings yet

- Flexi ConnectorDocument1 pageFlexi ConnectorArstNo ratings yet

- 2T12 U0-G25 HS GP: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2T12 U0-G25 HS GP: Technical Data Sheet Conveyor and Process BeltsDaniel GarcíaNo ratings yet

- Heat Exchanger Selection GuideDocument2 pagesHeat Exchanger Selection GuiderodrigoperezsimoneNo ratings yet

- CO2 Laser Preventive Maintenance Check SheetDocument9 pagesCO2 Laser Preventive Maintenance Check SheetGiang NguyenNo ratings yet

- Chiorino Conveyor Belts For Packed Food 26jan11Document1 pageChiorino Conveyor Belts For Packed Food 26jan11navneet jainNo ratings yet

- Chiorino Conveyor Belts For Packed Food 26jan11Document1 pageChiorino Conveyor Belts For Packed Food 26jan11navneet jainNo ratings yet

- Arc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Document1 pageArc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Wojciech SpychalskiNo ratings yet

- Stoody 104Document1 pageStoody 104JUAN DAVID ESPITIANo ratings yet

- USSOR 2010 New 2Document57 pagesUSSOR 2010 New 2manik rajakNo ratings yet

- Bass Pulse15: General SpecificationsDocument1 pageBass Pulse15: General SpecificationsDaniel MambuscayNo ratings yet

- Steel Standards: ASTM A252 ASTM A500 CSA G40.21Document1 pageSteel Standards: ASTM A252 ASTM A500 CSA G40.21Candra YuniartoNo ratings yet

- Aluminum Wear Strips - McMaster-Carr PDFDocument3 pagesAluminum Wear Strips - McMaster-Carr PDFHassan HelmyNo ratings yet

- Testresultat För DASAG TERAZZO PlattorDocument1 pageTestresultat För DASAG TERAZZO PlattorMEHDI FARROKHINo ratings yet

- Arn 188 05 4 enDocument2 pagesArn 188 05 4 engbaNo ratings yet

- 2M8 U0-V5 A: Technical Data Sheet Conveyor and Process BeltsDocument2 pages2M8 U0-V5 A: Technical Data Sheet Conveyor and Process Beltsnavneet jainNo ratings yet

- Hand Over FormateDocument1 pageHand Over FormateAjmal KhanNo ratings yet

- Sis Casting DefectsDocument27 pagesSis Casting DefectsAjmal KhanNo ratings yet

- Casting Defect BriefDocument1 pageCasting Defect BriefAjmal KhanNo ratings yet

- How Do Boats FloatDocument1 pageHow Do Boats FloatAjmal KhanNo ratings yet

- Mobile Crane Load Test Report FormDocument4 pagesMobile Crane Load Test Report FormAjmal KhanNo ratings yet

- BSLM InstallationDocument1 pageBSLM InstallationAjmal KhanNo ratings yet

- Galvanized CoatingsDocument3 pagesGalvanized CoatingsAjmal KhanNo ratings yet

- Yarn TestingDocument41 pagesYarn Testingabc0% (1)

- Controller DatasheetDocument3 pagesController DatasheetsureshkanuboyinaNo ratings yet

- Kericho 2015 Geography 1.anspdfDocument4 pagesKericho 2015 Geography 1.anspdfedward mokayaNo ratings yet

- 4PH0 1P Que 20140515Document28 pages4PH0 1P Que 20140515ramexistsNo ratings yet

- Enabler PDFDocument16 pagesEnabler PDFJose Luis Caceres SeverinoNo ratings yet

- BPM1701 Calculus and Statistics: Lesson 3c Roots of Equations Quadratic EquationDocument9 pagesBPM1701 Calculus and Statistics: Lesson 3c Roots of Equations Quadratic EquationAnonymous sSQyq7I1zNo ratings yet

- Discussion LAB Experiment 4 LIPIDDocument2 pagesDiscussion LAB Experiment 4 LIPIDYurie RiriNo ratings yet

- Addendum: Manual Updates Addendum: Manual Updates: 48 Door Type 1 - 8Document13 pagesAddendum: Manual Updates Addendum: Manual Updates: 48 Door Type 1 - 8Zoran Borojević-TeslaNo ratings yet

- Motion Graphs Displacement-Time GraphsDocument11 pagesMotion Graphs Displacement-Time GraphsprimalNo ratings yet

- NTPC Badarpur Mechanical ReportDocument68 pagesNTPC Badarpur Mechanical Reportdeveshsingh0760% (20)

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- Description Start Here If... : EvaluationDocument5 pagesDescription Start Here If... : EvaluationWorh FalexNo ratings yet

- Ece V Digital Signal Processing (10ec52) NotesDocument160 pagesEce V Digital Signal Processing (10ec52) NotesVijay SaiNo ratings yet

- CHORD MASTERY by Claude JohnsonDocument68 pagesCHORD MASTERY by Claude Johnsonp0ndra100% (1)

- 4 - SOME ANY..... Con SolucionesDocument4 pages4 - SOME ANY..... Con SolucionesMartaNo ratings yet

- 1/22/13 12:01 PM C:/Users/Sol... /uwb - SV - Model - CT - 15 - 4a.m 1 of 3Document3 pages1/22/13 12:01 PM C:/Users/Sol... /uwb - SV - Model - CT - 15 - 4a.m 1 of 3Solo NunooNo ratings yet

- COBOL QuesbankDocument23 pagesCOBOL Quesbankapi-27095622No ratings yet

- Ac Bridge: EEE 457: Measurement & InstrumentationDocument13 pagesAc Bridge: EEE 457: Measurement & InstrumentationTareqNo ratings yet

- 2019 Paper 2 GceDocument21 pages2019 Paper 2 GcePatrick NkowaniNo ratings yet

- Monte Carlo Methods For Radiation Transport: Fundamentals and Advanced Topics 1st Edition Oleg N. Vassiliev (Auth.)Document43 pagesMonte Carlo Methods For Radiation Transport: Fundamentals and Advanced Topics 1st Edition Oleg N. Vassiliev (Auth.)david.mager792100% (20)

- MiFlash Result@2021719Document2 pagesMiFlash Result@2021719Kehidupan Dalam JendelaNo ratings yet

- 350204011ws Class 4Document62 pages350204011ws Class 4Namita Sahu100% (1)

- Phillips Science of Dental Materials 4 (Dragged) (Dragged) 6Document1 pagePhillips Science of Dental Materials 4 (Dragged) (Dragged) 6asop06No ratings yet

- Yield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessDocument9 pagesYield, Viscosity, and Gel Strength of Wami Tilapia (Oreochromis Urolepis Hornorum) Skin Gelatin: Optimization of The Extraction ProcessAMAANINo ratings yet

- L e A D 6th Grade Science FinalDocument60 pagesL e A D 6th Grade Science Finalapi-260611241No ratings yet

- Fluid QueDocument48 pagesFluid QueMushfique AhmedNo ratings yet

- Oferta Rusartis Premiumcut Soft Crea 14.04.2021Document3 pagesOferta Rusartis Premiumcut Soft Crea 14.04.2021Eugen CozianuNo ratings yet

- Mos For SteelguardDocument4 pagesMos For SteelguardAnonymous 7IKdlmNo ratings yet