Professional Documents

Culture Documents

Process Breakdown

Process Breakdown

Uploaded by

Murtuza MuftiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Breakdown

Process Breakdown

Uploaded by

Murtuza MuftiCopyright:

Available Formats

Assignment

on

Measurement & Process Breakdown of

Basic T Shirt, Polo Shirt & Woven Shirt

Submitted to : Mohammad Obaidullah

Assistant Professor

BGMEA University of Fashion and Technology

Prepared by: Murtuza Mufti

ID: 241 – 007 – 0 – 121

Course title: Basic Garment Construction

Course Code: GMT – 1107

Submission Date: 26 June 2024

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:01

Basic T Shirt

(XL)

Size Chart

Name Measurement (cm) Name Measurement (cm)

Half Chest 57 Sleeve Length 21

Total Length 74 Back Neck drop 1

Half Waist 53.5 Round neck width open 17.5

Half Bottom 56.5 Round neck depth open 8

Shoulder Point 50.5 V-Neck width open 16

Armhole Straight 25 V-Neck depth open 14

Muscle 20 Collar Height 1.5

Sleeve opening 19

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:02

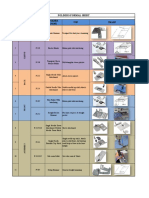

1. Process Breakdown of Round Neck T shirt.

SL Process Description Machine & Work Aid SMV

Stitch Class

1. PRINT ON BACK PART Printing Machine

( According to specification )

2. Back Moon Facing as per position 1 needle lock stitch Guide pressure feed

machine (class – 301) (G.P.F.)

3. Moon Facing Attach to Back Part 2 needle bottom Normal pressure feed Time Study

covering chain stitch (T.S.)

(class – 406)

4. Embroidery on chest as per guideline Embroidery Machine

lock stitch (class – 300)

5. Shoulder Join (front & back) Four thread over-lock

machine (class – 512/

514)

6. Top Stitch on Shoulder 1 needle double Guide pressure feed

thread chain stitch (G.P.F.)

(class – 401)

7. Neck Rib Join to Body Neck Four thread over-lock

machine (class – 512/

514)

8. Tape Attach to back neck 1 needle lock stitch N.P.F

machine (class – 301)

9. Tape close to back neck 1 needle lock stitch

machine (class – 301)

10. Sleeve Hem Sewing Four thread over-lock Feller folder

machine (class – 512/

514)

11. Sleeve join to back body arm hole Four thread over-lock N.P.F

machine (class – 512/

514)

12. Arm hole top stitch 1 needle double Guide pressure feed

thread chain stitch (G.P.F.)

(401)

13. Side Seam (care level at left side) Four thread over-lock N.P.F

machine (class – 512/

514)

14. Bottom Hem Sewing

15. Sleeve ends tuck 1 needle lock stitch

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:03

Polo Shirt

Size Chart

Name Measurement (inch) Name Measurement (inch)

HPS 29 Sleeve calf height 1.5

Chest 22 Straight Armhole 8

Width 21.5 Bicep 7

Bottom Hem 19.5 Across front 18

Side 1.8 Across back 18

Neck width 8.5 Front neck drop 9

Across Shoulder 20 Placket 6.5

Sleeve Length 8.5 Packet width 1.5

Sleeve Opening 6.5 Placket box 0.5

2. Process Breakdown of Polo shirt.

SL Process Description Machine & Work Aid SMV

Stitch Class

PRINT ON BACK PART Printing Machine

( According to specification )

Back Moon Facing as per position 1 needle lock stitch Guide pressure feed

machine (class – 301) (G.P.F.)

Moon Facing Attach to Back Part 2 needle bottom Normal pressure feed Time Study

covering chain stitch (T.S.)

(class – 406)

Embroidery on chest as per guideline Embroidery Machine

lock stitch (class – 300)

Shoulder Join (front & back) Four thread over-lock

machine (class – 512/

514)

Collar Attach 2 needle bottom

covering chain stitch

(class – 406)

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:04

Top Stitch on Shoulder 1 needle double Guide pressure feed

thread chain stitch (G.P.F.)

(class – 401)

Neck Rib Join to Body Neck Four thread over-lock

machine (class – 512/

514)

Tape Attach to back neck 1 needle lock stitch N.P.F

machine (class – 301)

Tape close to back neck 1 needle lock stitch

machine (class – 301)

Sleeve Hem Sewing Four thread over-lock Feller folder

machine (class – 512/

514)

Sleeve join to back body arm hole Four thread over-lock N.P.F

machine (class – 512/

514)

Arm hole top stitch 1 needle double Guide pressure feed

thread chain stitch (G.P.F.)

(401)

Side Seam (care level at left side) Four thread over-lock N.P.F

machine (class – 512/

514)

Bottom Hem Sewing

Sleeve ends tuck 1 needle lock stitch

Woven Shirt

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:05

3. Process Breakdown of Woven Shirt

Body Target Cycle Layout

SL Operation Resource SMV

Part (100%) Time(s) MP

Fusing attach at front Assistant

1 Placket 0.42 143 25.20 1

placket Operator

Front placket mark n

2 Placket Sewing Iron 0.75 80 45.00 2

press

3 Placket Placket make upper SNL Auto 0.54 111 32.40 2

4 Placket Placket make Lower SNL Auto 0.54 111 32.40 2

Upper placket 1/4 top-

5 Placket SNL Auto 0.48 125 28.80 2

stitch

6 Placket Deco. Placket press Sewing Iron 0.38 158 22.80 1

Front n back part Assistant

7 Assembly 0.28 214 16.80 1

match Operator

Shoulder join with/

8 Assembly 4T OL Auto 0.30 200 18.00 1

without tape

9 Assembly Shoulder topstitch 1NDL FL 0.28 214 16.80 1

Fusing attach at

10 Collar Sewing Iron 0.42 143 25.20 2

collar/collar stand

Assistant

11 Collar Collar mark 0.20 300 12.00 1

Operator

12 Collar Collar make SNL-VT 0.83 72 49.80 3

Assistant

13 Collar Corner cut n turn collar 0.30 200 18.00 1

Operator

14 Collar Collar 1/4 topstitch SNL Auto 0.58 103 34.80 2

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:06

15 Collar Collar edge close n cut SNL-VT 0.28 214 16.80 1

16 Collar Collar band rolling SNL Auto 0.38 158 22.80 1

Mark n arrange match Assistant

17 Collar 0.35 171 21.00 1

collar with band Operator

Collar attach with collar

18 Collar SNL-VT 1.08 56 64.80 3

band sandwich stitch

Collar band turn n

19 Collar press with necessary Sewing Iron 0.35 171 21.00 1

scissoring

20 Collar Collar n neck mark SNL Auto 0.32 188 19.20 1

21 Collar Attach collar to body SNL Auto 0.65 92 39.00 2

22 Collar Collar close SNL Auto 0.75 80 45.00 2

23 Collar Collar band topstitch SNL Auto 0.56 107 33.60 2

24 Sleeve Sleeve side seam 4T OL Auto 0.55 109 33.00 2

Sleeve side seam

25 Sleeve 2T FL Auto 0.62 97 37.20 2

topstitch

26 Assembly Side seam join 4T OL Auto 0.55 109 33.00 2

27 Label Care Label make SNL Auto 0.24 250 14.40 1

28 Label Care label tack at side SNL Auto 0.26 231 15.60 1

Sleeve & Body sticker

29 Sleeve SNL Auto 0.56 107 33.60 2

match & Sleeve tack

30 Sleeve Sleeve attach round 4T OL Auto 1.00 60 60.00 3

Bottom hem edge

31 Back Part SNL Auto 0.75 80 45.00 2

rolling

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:07

Assistant

32 Placket Sleeve mark for placket 0.44 136 26.40 2

Operator

Assistant

33 Sleeve Sleeve cut for placket 0.40 150 24.00 1

Operator

Sleeve lower placket

34 Sleeve Flat Bed 0.41 146 24.60 2

binding n trims

35 Placket Secure placket base SNL Auto 0.30 200 18.00 1

Sleeve upper placket

36 Placket Sewing Iron 0.42 143 25.20 2

fusing attach n half fold

Upper placket attach n

37 Placket SNL Auto 1.00 60 60.00 3

1/16 topstitch

Sleeve upper placket

38 Placket SNL Auto 0.80 75 48.00 3

close

Upper placket 1/16

39 Placket SNL Auto 0.56 107 33.60 2

topstitch

Sleeve placket fishtail

40 Placket SNL Auto 0.72 83 43.20 2

secure

Sleeve placket box

41 Placket SNL Auto 1.08 56 64.80 3

make

Pleat make with mark

42 Placket SNL Auto 0.64 94 38.40 2

at sleeve opening

Assistant

43 Cuff Fusing attach at cuff 0.28 214 16.80 1

Operator

44 Cuff Cuff rolling SNL Auto 0.45 133 27.00 2

45 Cuff Cuff mark n make SNL Auto 0.95 63 57.00 3

Cuff turn n press with

46 Cuff Sewing Iron 0.40 150 24.00 1

necessary scissoring

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:08

Cuff mark n match Assistant

47 Cuff 0.40 150 24.00 1

arrange with body Operator

Cuff attach at sleeve

48 Assembly SNL Auto 0.83 72 49.80 3

opening

49 Cuff Cuff close SNL Auto 0.96 63 57.60 3

50 Cuff Cuff top-stitch SNL Auto 0.75 80 45.00 2

Sticker remove and Assistant

51 Assembly 0.26 231 15.60 1

GMTs turn Operator

Button hole position Assistant

52 Assembly 0.78 77 46.80 2

mark Operator

Button hole make at

53 Placket BH Auto 0.54 111 32.40 2

Sleeve placket X4

Button hole make at

54 Placket BH Auto 1.26 48 75.60 3

front placket X9

Assistant

55 Assembly Button position mark 0.98 61 58.80 3

Operator

Button attach at

56 Placket BA Auto 1.20 50 72.00 3

placket X9 + Spare X1

Button attach at sleeve

57 Sleeve BH Auto 0.48 125 28.80 2

placket X4

Assistant

58 Assembly Button close 0.55 109 33.00 2

Operator

Assistant

59 Assembly Thread trims 0.45 133 27.00 2

Operator

– – – Total 33.84 – – 110

Murtuza Mufti ID: 241 – 007 – 0 – 121 Page:09

You might also like

- (English) MEGACITIES of The World (Season 1 - Complete)Document58 pages(English) MEGACITIES of The World (Season 1 - Complete)Sveta EnglishNo ratings yet

- Stitches and Seams in Polo TshirtDocument30 pagesStitches and Seams in Polo TshirtAyesha Sumreen100% (1)

- Lab Report Fluid Mixing (Compile)Document28 pagesLab Report Fluid Mixing (Compile)Nor Elina Ahmad100% (1)

- Apparel Production Techniques of Formal ShirtDocument19 pagesApparel Production Techniques of Formal ShirtSWARNIKA SRIVASTAVANo ratings yet

- A. Shirt Section 1: Measurement Chart (Unit: Inch)Document5 pagesA. Shirt Section 1: Measurement Chart (Unit: Inch)Ánh NguyễnNo ratings yet

- AP - Jury Assignment - TechpackDocument11 pagesAP - Jury Assignment - TechpackDivyanshi GoelNo ratings yet

- T Shirt Process BreakdownDocument4 pagesT Shirt Process BreakdownMurtuza MuftiNo ratings yet

- Sewing MachineDocument11 pagesSewing MachinePritomNo ratings yet

- Measurement Sheet: E3 Neck To NeckDocument1 pageMeasurement Sheet: E3 Neck To Neckmanuel radulescuNo ratings yet

- T ShirtDocument12 pagesT Shirtmovie mailNo ratings yet

- Labour Saving DevicesDocument53 pagesLabour Saving DevicesSugandha Rathore100% (1)

- Basic Kid Wear For Girls. (Table)Document17 pagesBasic Kid Wear For Girls. (Table)Malakai sangmaNo ratings yet

- Assignment 2 Capsule Range & Tech Packs (Group 9)Document49 pagesAssignment 2 Capsule Range & Tech Packs (Group 9)vbawan11No ratings yet

- Sourcing and Costing of Apparel products-SHUSWALINI-assignment 2 PDFDocument13 pagesSourcing and Costing of Apparel products-SHUSWALINI-assignment 2 PDFPooja Gupta100% (1)

- AQM-1 Spec Sheet PDFDocument13 pagesAQM-1 Spec Sheet PDFPunith KumarNo ratings yet

- Architechtural BriefDocument54 pagesArchitechtural Briefashpika100% (3)

- Welcome To Our PresentationDocument14 pagesWelcome To Our PresentationPritomNo ratings yet

- Skill GradingDocument114 pagesSkill GradingumaNo ratings yet

- Pom - Shahood ShahidDocument12 pagesPom - Shahood ShahidShahood JuttNo ratings yet

- SR No POM Full Half Front Back OverlapDocument1 pageSR No POM Full Half Front Back OverlapShahood JuttNo ratings yet

- Size Set Jacket Zoltan MenDocument2 pagesSize Set Jacket Zoltan MenSopwatulBahriNo ratings yet

- TMS PDFDocument8 pagesTMS PDFIrish RomNo ratings yet

- TAP AssignmentDocument12 pagesTAP Assignmenttiwarianubhav22No ratings yet

- Product Analysis and Development: Product: Printed Crop TopDocument22 pagesProduct Analysis and Development: Product: Printed Crop TopLia AmmuNo ratings yet

- Idm Sem 3 Tech PackDocument11 pagesIdm Sem 3 Tech PackAnkit AkashNo ratings yet

- 5095 Plaid L-SDocument7 pages5095 Plaid L-SBrian ClaytonNo ratings yet

- M PortfolioDocument24 pagesM PortfolioParul SardanaNo ratings yet

- Rogues Gallery: Proto 1st Proto Remake 2nd Proto RemakeDocument9 pagesRogues Gallery: Proto 1st Proto Remake 2nd Proto RemakeBrian ClaytonNo ratings yet

- PJ Top - RF Set in Sleeve Henley Neck - SS17 Key Line Tech PackDocument6 pagesPJ Top - RF Set in Sleeve Henley Neck - SS17 Key Line Tech Packtahayemen42No ratings yet

- Appc Assignment-3: Industry Visit ReportDocument6 pagesAppc Assignment-3: Industry Visit ReportVishal kumarNo ratings yet

- Specification Sheet of JeggingsDocument8 pagesSpecification Sheet of JeggingsYogesh SharmaNo ratings yet

- Jean AttachmentDocument17 pagesJean AttachmentReena VermaNo ratings yet

- PP Meeting Report.Document5 pagesPP Meeting Report.M A. Mannan BiswasNo ratings yet

- Shirt FoldersDocument1 pageShirt FoldersAKSHAY NATHNo ratings yet

- Tutorial: White Teddy Fur SkirtDocument21 pagesTutorial: White Teddy Fur Skirtdaisy22100% (1)

- Tutorial: Shift DressDocument10 pagesTutorial: Shift Dressdaisy22No ratings yet

- 686 683 Technical DataDocument2 pages686 683 Technical Dataathalim1463No ratings yet

- Recruitment Format Paper For Gomoty Top UrgentDocument2 pagesRecruitment Format Paper For Gomoty Top UrgentrummanbscNo ratings yet

- SMV of Different GarmentsDocument17 pagesSMV of Different GarmentsHarisha PahwaNo ratings yet

- 4106 - Tutorial-MinDocument6 pages4106 - Tutorial-MinHella KissNo ratings yet

- Advanced GCDocument9 pagesAdvanced GCSanjeev SinglaNo ratings yet

- 2D Apparel Cad and GradingDocument2 pages2D Apparel Cad and GradingES MaxternNo ratings yet

- Basic Garment Construction-ReportDocument30 pagesBasic Garment Construction-Reportsporti1412No ratings yet

- Sewn Products and Machinery Equipments Jury AssignmentDocument24 pagesSewn Products and Machinery Equipments Jury AssignmentSreejita MahapatraNo ratings yet

- Aw-19 Mens Front Zipper Sweat Shirts Spec.Document1 pageAw-19 Mens Front Zipper Sweat Shirts Spec.Sunny SharanNo ratings yet

- Garment Spec Sheet - ShirtDocument21 pagesGarment Spec Sheet - ShirtAneesha PandaNo ratings yet

- P 4121 001 MensDocument28 pagesP 4121 001 Mensjitu342No ratings yet

- Inline Inspection (1 A) Inline Inspection (3 A) Inline Inspection (4 A) Inline Inspection (5A) Inline Inspection (6 A)Document3 pagesInline Inspection (1 A) Inline Inspection (3 A) Inline Inspection (4 A) Inline Inspection (5A) Inline Inspection (6 A)GreeshmaNo ratings yet

- PJ Top - RF Set in Sleeve Crew Neck - SS17 Key Line Tech PackDocument6 pagesPJ Top - RF Set in Sleeve Crew Neck - SS17 Key Line Tech Packtahayemen42No ratings yet

- Tech Pack AssignmentDocument7 pagesTech Pack Assignmentanisha gautamNo ratings yet

- Understanding Apparel QualityDocument6 pagesUnderstanding Apparel QualityShubham SahNo ratings yet

- Specification SheetDocument3 pagesSpecification SheetJyoti RawalNo ratings yet

- Folders and Attachments in Sewing MachinesDocument8 pagesFolders and Attachments in Sewing MachinesJyoti RawalNo ratings yet

- Wrangler Mens PoloDocument5 pagesWrangler Mens PoloAnwar AnwardeenNo ratings yet

- 8600 - Xplore Technical Data: Traditional SewingDocument4 pages8600 - Xplore Technical Data: Traditional Sewingathalim1463No ratings yet

- Machines Types For Garment PDFDocument22 pagesMachines Types For Garment PDFDezyne Ecole100% (5)

- PDMDocument3 pagesPDMclouser3d10No ratings yet

- SPECIFICATION For tNKTOP NOWDocument7 pagesSPECIFICATION For tNKTOP NOWTranNo ratings yet

- Tailored Trousers FrontsDocument1 pageTailored Trousers FrontsFani RuizNo ratings yet

- Features & Common Application of Stitch ClassesDocument6 pagesFeatures & Common Application of Stitch Classessporti1412No ratings yet

- Teach Yourself Stitch Craft and Dressmaking Volume V: Introduction to Sleeves and Collars - Drafting Patterns for Stitching Sleeves and CollarsFrom EverandTeach Yourself Stitch Craft and Dressmaking Volume V: Introduction to Sleeves and Collars - Drafting Patterns for Stitching Sleeves and CollarsNo ratings yet

- Loom Knitting Stitches: My Top Ten Volume IFrom EverandLoom Knitting Stitches: My Top Ten Volume IRating: 4.5 out of 5 stars4.5/5 (6)

- T Shirt Process BreakdownDocument4 pagesT Shirt Process BreakdownMurtuza MuftiNo ratings yet

- Speaking TestDocument17 pagesSpeaking TestMurtuza MuftiNo ratings yet

- Hematology ReportDocument1 pageHematology ReportMurtuza MuftiNo ratings yet

- SSC English - Cadet College-5Document10 pagesSSC English - Cadet College-5Murtuza MuftiNo ratings yet

- SSC English 2nd Paper - Question2Document2 pagesSSC English 2nd Paper - Question2Murtuza Mufti100% (1)

- SSC English 2nd Paper - Question2Document2 pagesSSC English 2nd Paper - Question2Murtuza Mufti100% (1)

- Lendell - Engine CatalogueDocument27 pagesLendell - Engine CatalogueRommel Orozco CastellónNo ratings yet

- CBSE Class 9 Computers Notes and Assignments - 0 PDFDocument18 pagesCBSE Class 9 Computers Notes and Assignments - 0 PDFPonk ManNo ratings yet

- Methods of Volume StudyDocument13 pagesMethods of Volume StudyJaiminkumar SutharNo ratings yet

- Horizontal Well Drill String DesignDocument23 pagesHorizontal Well Drill String DesignTarek HassanNo ratings yet

- Form 1 Admission Application (SE2)Document4 pagesForm 1 Admission Application (SE2)trueNo ratings yet

- Budesonide (Drug Study)Document3 pagesBudesonide (Drug Study)Franz.thenurse6888No ratings yet

- Bettin Bots - False FavouritesDocument41 pagesBettin Bots - False Favouriteskaalingaa starNo ratings yet

- Solution Assignment 5Document9 pagesSolution Assignment 5sushant sharmaNo ratings yet

- Regal Owners ManualDocument268 pagesRegal Owners Manuallukas.hopkinsNo ratings yet

- CME355 MATERIAL HANDLING AND SOLID PROCESSING EQUIPMENT SyallabusDocument1 pageCME355 MATERIAL HANDLING AND SOLID PROCESSING EQUIPMENT SyallabusGanapathiappan VelukumarNo ratings yet

- En ERouting SLM v4050 Chap 1 Lab153Document4 pagesEn ERouting SLM v4050 Chap 1 Lab153victor teopezNo ratings yet

- Post Office Custom Declaration FormDocument1 pagePost Office Custom Declaration Formw2vijayNo ratings yet

- Jurnal Ekonomi SyariahDocument5 pagesJurnal Ekonomi Syariahjubaidahnurhayati100% (1)

- AN1671 MC145170 PSpice Modeling KitDocument14 pagesAN1671 MC145170 PSpice Modeling KitfahkingmoronNo ratings yet

- 555 Timer IcDocument23 pages555 Timer IcCircuits BazaarNo ratings yet

- Auvinet State of The Art 0Document7 pagesAuvinet State of The Art 0khernandez6491No ratings yet

- Article LOUATIphenicienpuniqueDocument20 pagesArticle LOUATIphenicienpuniqueDabdoubidabdoubi DabdoubiNo ratings yet

- Yugen (Profile)Document15 pagesYugen (Profile)Aayat ChoudharyNo ratings yet

- 101 Electronics Projects 1977Document100 pages101 Electronics Projects 1977نهمياسباريراNo ratings yet

- WEG cfw500 Manual Do Usuario 10001278006 Manual Portugues BR PDFDocument134 pagesWEG cfw500 Manual Do Usuario 10001278006 Manual Portugues BR PDFLeandroNo ratings yet

- Teacher ReflectionDocument3 pagesTeacher Reflectionapi-283337613No ratings yet

- May 2016 Computer Science Exam Paper, Paper 2 in English Time Zone 0Document15 pagesMay 2016 Computer Science Exam Paper, Paper 2 in English Time Zone 0Vidya DubeyNo ratings yet

- You As An Entrepreneur: SOFTNET Information Technology Center IncDocument7 pagesYou As An Entrepreneur: SOFTNET Information Technology Center IncVirnadette OlinaresNo ratings yet

- London Is Open: Kurtis Bevan, Manon Raja, Cristian Spinu, Jacob BarryDocument10 pagesLondon Is Open: Kurtis Bevan, Manon Raja, Cristian Spinu, Jacob BarryManon RajaNo ratings yet

- Full Blast 2 TestsDocument3 pagesFull Blast 2 TestsСветлана ГребневаNo ratings yet

- Bircher Reglomat Switching Units PDFDocument18 pagesBircher Reglomat Switching Units PDFghita100% (2)

- Achiever (Nov 2014)Document56 pagesAchiever (Nov 2014)gauravsukraliyaNo ratings yet

- Quarter 4 - Week 1 Daily Lesson PlanDocument3 pagesQuarter 4 - Week 1 Daily Lesson PlanAvegail Montemayor Orladan-MacanlalayNo ratings yet