Professional Documents

Culture Documents

Sandblasting Prepared Operational Risk Analysis

Sandblasting Prepared Operational Risk Analysis

Uploaded by

ScribdTranslations0 ratings0% found this document useful (0 votes)

1 views1 pageThis document presents an operational risk analysis for welding and grinding activities that will be carried out in a workshop in Barranquilla. Describes the tasks to be performed, the work area and equipment, and identifies dangers such as COVID-19 contagion and musculoskeletal injuries. It recommends controls such as social distancing, use of personal protective equipment, warm-up exercises, and good posture to prevent risks.

Original Description:

This document presents an operational risk analysis for welding and grinding activities that will be carried out in a workshop in Barranquilla. Describes the tasks to be performed, the work area and equipment, and identifies dangers such as COVID-19 contagion and musculoskeletal injuries. It recommends controls such as social distancing, use of personal protective equipment, warm-up exercises, and good posture to prevent risks.

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document presents an operational risk analysis for welding and grinding activities that will be carried out in a workshop in Barranquilla. Describes the tasks to be performed, the work area and equipment, and identifies dangers such as COVID-19 contagion and musculoskeletal injuries. It recommends controls such as social distancing, use of personal protective equipment, warm-up exercises, and good posture to prevent risks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageSandblasting Prepared Operational Risk Analysis

Sandblasting Prepared Operational Risk Analysis

Uploaded by

ScribdTranslationsThis document presents an operational risk analysis for welding and grinding activities that will be carried out in a workshop in Barranquilla. Describes the tasks to be performed, the work area and equipment, and identifies dangers such as COVID-19 contagion and musculoskeletal injuries. It recommends controls such as social distancing, use of personal protective equipment, warm-up exercises, and good posture to prevent risks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

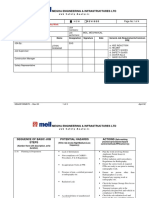

CODE: SIG-

O s or R c OPERATIONAL RISK ANALYSIS FO-109 VERSION:

02

APPROVED:

Location BARRANQUILLA 06/19/2020

Date of elaboration: Valid from: Until:

The welder performs a series of tasks aimed at :

Activity to joining metal elements of different thicknesses, Work

be using SORC/PREFABRICATION AND

welding installations, electric arc, as well as

performed: metal cutting work, by grinders, with monitoring of area: WELDING WORKSHOP

pipes which, through the plane, specify

dimensions for cutting and welding.

Hoses, Hoppers, nozzles),• Minor Tool,• Abrasive

of baitMaterial (sand),•

withScreen,• Anti-whip cable in

hose joints,• Pallets.• Notices.• Short gloves and/or cloth vinyl dots ,• Painting

Tools and/or Equipment (Airless),• Environmental Conditions Meter,• Anchor Profile Meter,• Gauges for wet

film measurement,• Dry film meter,• Diving suit,• Basic PPE (cup-type hearing protection when

equipment: applicable, Gloves, Boots, Face Masks), • Half Face Mask (Vapors and Particulate Material), •

Tyvek Suits.

Hierarchy of controls Elimination •> Replacement Engineering controls Administrative

PPE => •>

Ordered sequence of Associated Required controls Responsible for

Consequences (according to the

steps hazards hierarchy of controls) control

3. daily

health condition report; WELDERS

4. Rais

e awareness on the use PIPE ASSISTANT

GRINDERS

Biological (covid-19 of respiratory protectors QUALITY

Dry cough, fever, sore and face masks;

contagion between

individuals, insect bites, throat, general malaise,

respiratory conditions, 3. Soci INSPECTOR

snake bites, canine al distancing during STORER

attacks lack of oxygen lunch hours, maintain a

safe distance of 2 meters HSEQ ENGINEER

between individuals;

4. Appli OF

cation and dissemination PROJECTS

of general biosafety

1. Perf

orm warm-up and

stretching exercises; WELDERS

2. Main GRINDERS

tain good postural ASSISTANTS

Musculoskeletal

Manual handling of loads injuries, maintained, loads; hygiene when lifting PIPE QUALITY

1, Perimeter closure (position rotation of INSPECTOR

and signage of the area forced, repetitive 3. Ben WAREHOUSER

to intervene (before security columns) postures d your knees and keep

during, m after the the load close to your HSEQ

tasks have been body; PROJEC

completed) 4. Use T ENGINEER

mechanical aids or ask

another colleague for

help

Customer if facilities;

lifting travel or

through areas

determined by the client.

2. Oper

ate the vehicle at a WELDERS

speed not exceeding 20 PIPE ASSISTANT

GRINDERS

Bumps, wounds, K/h; QUALITY

Verif INSPECTOR

bruises, miscellaneous 3. y that the vehicle STORER

traffic accidents trauma, property documents are current

damage (SOAT, mechanical HSEQ

technical inspection); ENGINEER

4. Verif OF

y that the driver has a PROJECTS

valid property card and

driver's license;

5. Carr

y2. out pre-operational Res

pect the existing WELDERS

signage in the facilities; PIPE ASSISTANT

3. Rep GRINDERS

ort identified unsafe QUALITY

2,Transfer of materials Locative (Falls at the Bumps, wounds, 4. conditions; INSPECTOR

and tools to the work same level) bruises, sprains, the event of any event, In STORER

area vehicular traffic sprains report immediately to

provide first aid and, if HSEQ ENGINEER

necessary, go to the OF

nearest care center; PROJECTS

5. Kee

p the MEDEVAC list and

close to the body;

4. Use

mechanical aids when

transporting loads

greater than 25 kg;

TRUCK-

Musculoskeletal DIFFERENTIALS (2)

injuries, maintained tain 5. Main WELDERS

postures, forced, updated emergency PIPE ASSISTANT

GRINDERS

repetitive, entrapments directory and MEDEVAC QUALITY

Manual load handling between the load and list; INSPECTOR

Mechanical cargo accessories, 6. Prov STORER

overturning of the load, ide first aid in the event

handling overturning of the of an event. HSEQ

equipment, being hit by ENGINEER

7. To

moving or fixed objects, REMNANTS transport OF

property damage to an

ecological point, do not PROJECTS

exceed the stipulated

3,Unloading of weight of 25 kg.

materials at the work 8. •

site, lifting loads: Ensure that personnel

are not located below

suspended loads at any

safety, safety boots,

safety glasses, safety

helmet); special attention

to PPE for cutting WELDERS

activities with a polisher

(use of bib, safety visor, PIPE ASSISTANT

GRINDERS

Mechanical (Contact with safety guard and QUALITY

materials, equipment and Blows, equipment-specific pre- INSPECTOR

wounds, operational

tools, projection of inspection) STORER

particles bruises, sprains. 2. epp HSEQ

inspection;

3. Rep ENGINEER

ort of unsafe conditions; OF

4. Main PROJECTS

tain an updated

MEDEVAC list and

emergency directory;

2. Insp WELDERS

ect hearing protection PIPE ASSISTANT

elements; GRINDERS

3. Give

Noise due to use of

Hearing disorders talks to staff about the QUALITY INSPECTOR

polisher protection of the hearing

system and appropriate STORER

use of hearing protectors

according to exposure HSEQ ENGINEER

and noise level;

2. Take WELDERS

active breaks; PIPE ASSISTANT

3. Insp GRINDERS

ect equipment before QUALITY

Vibration due to use of Alterations in the and during the INSPECTOR

nervous system, development of activities; STORER

polisher muscular alterations 4. Use

personal protection HSEQ

elements: Safety gloves - OF ENGINEER

Know the symbols of

danger and toxicity. PROJECTS

3 .

Disclosure of possible

risks that direct contact

with this material may

have. WELDERS

(Safety data Sheet); PIPE ASSISTANT

4 . If GRINDERS

Chemical (handling: you have contact with QUALITY

electrode, gas inhalation, Respiratory

and

conditions the

allergic skin safety product, follow the INSPECTOR

3,Execution of tasks: burns metal vapor fumes), reactions recommendations STORER

Cutting, alignment, of the SDS;

welding. 5 . In HSEQ ENGINEER

the event of any event,

report immediately to OF

provide first aid and, if PROJECTS

necessary, go to the

nearest care center.

6 .Kno

w the symbols of danger

1. Hydr PIPE ASSISTANT

physical:High GRINDERS

temperatures, non- Dehydration, fatigue, ation

2.

with s ta n t e

Tak QUALITY

ionizing radiation, arc e scheduled breaks of 5- INSPECTOR

radiation, heat stroke

10 minutes every two STORER

complete, safety gloves

d );

2. PPE

inspection ;

3. Rep WELDERS

ort safety conditions to PIPE ASSISTANT

GRINDERS

substandards

4. Verif QUALITY

Mechanical (Particle

Projection), contact with Eye injuries, wounds y the proper use of the INSPECTOR

sharp edges equipment (The position STORER

of the guard must HSEQ

prevent particles from ENGINEER

being projected towards

the operator 's body OF PROJECTS

when in operation;

5. Verif

y that the guard is

installed , secured and

covers more

which go: one than to halftheof

sand hopper, and

another to the lung (to

supply oxygen to the

sandblaster). Check anti-

Eye injuries, wounds, whip connections.

Dehydration, fatigue, 5.Once the connections

heatstroke, Respiratory are secured within the

conditions and allergic safety parameters, the

dust collector will turn on

skin reactions, Hearing the compressor and

Chemical: Use of paint, disorders,

wounds,

Bumps,

bruises, regulate the outlet

Sand blasting and inhalation of particles, pressure, which should

painting activity: Biological (contagion of sprains,Musculoskeletal be in a range of 90 to

Preoperational covid-19 between injuries, run over, 110 psi. 6.The

inspection of equipment, individuals, insect bites, Progressive pain in sandblastero will

hoppers, nozzles, hoses, snake bites, canine upper limbs: neck and regulate the air outlet SANDBLASTERO,

hose nails and couplings attacks, physical: High lower back areas.-Eye pressure of the lung, HOPPER

(gaskets and safety temperatures, safety damage -soft tissues which should be between AUXILIARY

clips) and (safety valves, condition: vehicular due to projection of 40 to 60 psi.

pressure gauges, traffic, ergonomic: particulate material in Every time the amount of

operating valves) with maintained postures, precession,-Damage to sand in the hopper runs

their respective pre- forced, repetitive, equipment due to out, the outlet valves are

operational, adverse environmental improper handling,- closed and the

conditions. Permanent or

temporary damage to equipment is turned off.

The dust collector will

the ears due to high load sand into the

decibels,-Fracture,

blows due to hopper again, while the

sandblaster hydrates and

disconnection of hoses. rests. Verify that the

work permit signed by

the issuer and executor

is present and that it

corresponds to the

activity and place of the

task to be carried out.

1. Carr

y out prior inspections of

the places where you are

going to travel, removing

obstacles;

2. Respect the

existing

signage in the

Locative (Falls at the facilities; WELDERS

same level) sprains, ankle sprains, 3. Rep GRINDERS

vehicular traffic, musculoskeletal ort identified unsafe ASSISTANTS

biological conditions; PIPE QUALITY

4. order and (transmission injuries, skin allergies, 4.

and contagion In INSPECTOR

contagion of covid), and the event of any event, WAREHOUSER

general cleanliness transmission

biomechanical, due to coronavirus. of report immediately to

prolonged and provide first aid and, if HSEQ

maintained postures necessary , go to the PROJEC

nearest care center; T ENGINEER

5. Kee

p the MEDEVAC list

and Emergency

Directory up to date.

6. Atte

ntion to the environment

and self - care 7. forklift

Identification of environmental aspects and impacts

Environmental aspects Environmental impact Operational controls

1,

recyclable solid wasteGeneration

Waste of generation:

similar 1 .Waste

Plastic bags, plastic 1. Minimize the production

to urban waste:

packaging Paper,

(plastic, glass,cardboard, containers, polishing

metal), cardboard, merchandise packaging,

discs, electrodes of waste and emissions.

organic waste, rags and clothing. 2 .Depletion of 2. Correct management of the waste

2, Inert industrial resources generated, avoiding environmental damage.

waste: Remains of metals, items,

metal from

3 .Using 3. Comply with current regulations for the

electricity activity

tubes, miscellaneous coal or natural gas combustion and have all the permits and licenses

electrodes,lenses plastics, necessary to carry out the activity.

glasses

screens. and old tools, 4

protective plants.

most of the materials. .Not making the 4. Promote savings of materials, water and

energy.

3,

waste: Metallic Hazardous

particles and 5metalpollution

remains. .Not reusing 5. Use materials with

powders, extraction hood certifications that prove adequate

aerosols, toxic

packaging, products

batteries. and filters,

their 6Air

7

from welding. .Emitting gases environmental management.

6. Correct environmental management.

4, Emissions into the atmosphere: 8 .With the ozone

c. c. Name Post Signature

8,487,526 GERSON LOPEZ COOR.

1 1

Approval

DC Name Post Signature

1,002,133951 Adalberto Altamar HSE

c. c. DC Post

You might also like

- Jota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)Document5 pagesJota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)long chanNo ratings yet

- Risk Assessment: Bunkering in GeneralDocument2 pagesRisk Assessment: Bunkering in Generaloto saviour0% (1)

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- SOP of Idler ChangeDocument9 pagesSOP of Idler ChangeDwitikrushna RoutNo ratings yet

- HIRADCDocument56 pagesHIRADCAli Rizki Budiman100% (1)

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- Assignment 1Document4 pagesAssignment 1Ahmed IsahNo ratings yet

- Sample United States Navy Maintenance Requirement Card PDFDocument3 pagesSample United States Navy Maintenance Requirement Card PDFInaamNo ratings yet

- SWMS2 Confined Space EntryDocument9 pagesSWMS2 Confined Space EntryIslam Sarhan100% (1)

- 321 SCT NBN m2092 Vol Id Hse Plan Hseocp - 61 Rev01 1607509233Document13 pages321 SCT NBN m2092 Vol Id Hse Plan Hseocp - 61 Rev01 1607509233Abusaada2012No ratings yet

- AHA Floor InstalationDocument3 pagesAHA Floor Instalationanilkumaranoop74No ratings yet

- 0 Roa Format OvpDocument46 pages0 Roa Format OvpRafael N. ArellanoNo ratings yet

- Ta Hsse Induction FinalDocument31 pagesTa Hsse Induction FinalAndre SalandyNo ratings yet

- Melab 2 Final ReportDocument5 pagesMelab 2 Final ReportVierzon TiamzonNo ratings yet

- HRA Form For Submittingv2Document2 pagesHRA Form For Submittingv2Colin GirdwoodNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- 01.40.01.701 Personal Protective Equipment (PPE)Document6 pages01.40.01.701 Personal Protective Equipment (PPE)Cris KasongoNo ratings yet

- AHA Painting WorkDocument3 pagesAHA Painting Workanilkumaranoop74No ratings yet

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Document3 pagesStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- 003 Elect - Electrical Earthing System Installation PDFDocument110 pages003 Elect - Electrical Earthing System Installation PDFbisworupmNo ratings yet

- 2.0 EHS Risk - Dismantling and Installation of Roof and G.I TubularDocument21 pages2.0 EHS Risk - Dismantling and Installation of Roof and G.I TubularWarren DiwaNo ratings yet

- NASGC-IMS-PR26-F1 - Daily HSE Inspection ChecklistDocument1 pageNASGC-IMS-PR26-F1 - Daily HSE Inspection ChecklistinternationalambassadorsltdNo ratings yet

- Method Statement For Anti Termite TreatmentDocument7 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Waverley RAMSDocument16 pagesWaverley RAMSJakub WiechaNo ratings yet

- Risk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksDocument6 pagesRisk Assessment Guide Ref No. 69 Assessment For: LEAD BURNING/PLUMBING WORK - Lead Burning (Welding) of Lead Sheet or Pipe Significant RisksemmyNo ratings yet

- 1 - Condition MonitoringDocument45 pages1 - Condition MonitoringmemoaljawiNo ratings yet

- 01 March SHO Monthly Report PDFDocument6 pages01 March SHO Monthly Report PDFBuwanah Selvaaraj0% (1)

- Technical Profile Life 1095-IntDocument2 pagesTechnical Profile Life 1095-IntAlejandra VargasNo ratings yet

- Technical Profile Life 1095-IntDocument2 pagesTechnical Profile Life 1095-IntAlejandra VargasNo ratings yet

- Compact Notes OSHDocument4 pagesCompact Notes OSHWaizMuqrieNo ratings yet

- Health & Safety Plan - Hot Line StringingDocument10 pagesHealth & Safety Plan - Hot Line Stringingpadambhandarimb_5088No ratings yet

- Safe Operating Procedure No: TS - WE02 Hot Work ProceduresDocument9 pagesSafe Operating Procedure No: TS - WE02 Hot Work ProceduresDaniel DDDNo ratings yet

- HRA Form For Submittingv2Document3 pagesHRA Form For Submittingv2Colin GirdwoodNo ratings yet

- Rules and Guidelines For Safety in E&P Operations & Contingency PlanningDocument18 pagesRules and Guidelines For Safety in E&P Operations & Contingency PlanningRavikumar mahadevNo ratings yet

- Method Statement FormatDocument11 pagesMethod Statement FormatPrem Preetham Dsouza100% (1)

- Method Statement For MpsDocument14 pagesMethod Statement For MpsAhmed NasserNo ratings yet

- JUMONG VET User Manual - Ver 1.2Document119 pagesJUMONG VET User Manual - Ver 1.2CineFilm CANo ratings yet

- Safety For Sars-Cov-2 Antigen RDT TestingDocument27 pagesSafety For Sars-Cov-2 Antigen RDT Testingbimaindra97No ratings yet

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- Steri-Record Dental-BMS: Batch Monitoring System (Dental-BMS) For Steam Sterilization ProcessesDocument4 pagesSteri-Record Dental-BMS: Batch Monitoring System (Dental-BMS) For Steam Sterilization ProcessesHemant SinghNo ratings yet

- ECA Environmental Monitoring Live Online TrainingDocument4 pagesECA Environmental Monitoring Live Online TrainingCésar Adair Blas RuízNo ratings yet

- Sterilization of Explosive Delivery Systems Entering Normet WorkshopsDocument4 pagesSterilization of Explosive Delivery Systems Entering Normet WorkshopsPEDRONo ratings yet

- Method Statement - Contractor SampleDocument9 pagesMethod Statement - Contractor SampleMohammed AlharbiNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- Leakage TestDocument5 pagesLeakage TestScribdTranslationsNo ratings yet

- L&T SOP - Hydro TestDocument18 pagesL&T SOP - Hydro Testrsrajyadav88No ratings yet

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Ohha - Ceha Action PlanDocument11 pagesOhha - Ceha Action Plancrni rokoNo ratings yet

- Mohamad Hamad Engineering ControlDocument7 pagesMohamad Hamad Engineering ControlMohamad HamadNo ratings yet

- Interview PreparationDocument10 pagesInterview Preparationosama ShahzadNo ratings yet

- Plant Hazard ReportDocument4 pagesPlant Hazard ReportNader DallejNo ratings yet

- Work Plan (Drain Pipe, Sprinkler and Hose Reel Dismantle and Modification Work)Document4 pagesWork Plan (Drain Pipe, Sprinkler and Hose Reel Dismantle and Modification Work)Ahgilan VijayanNo ratings yet

- WIKA 732. Operating InstructionsDocument60 pagesWIKA 732. Operating Instructionsinstrument.assist.slpNo ratings yet

- MLSP Prelim NotesDocument12 pagesMLSP Prelim Notesfjbaluyut1573pamNo ratings yet

- Health and Safety FCX-HS17Document5 pagesHealth and Safety FCX-HS17berry trisnamuktiNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Dosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsFrom EverandDosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsNo ratings yet

- Natural History of Parkinson's DiseaseDocument49 pagesNatural History of Parkinson's DiseaseScribdTranslationsNo ratings yet

- Ethnicity, Language and IdentityDocument4 pagesEthnicity, Language and IdentityScribdTranslationsNo ratings yet

- Abbreviated File-Process Case 01 Marco A. and CounterclaimDocument25 pagesAbbreviated File-Process Case 01 Marco A. and CounterclaimScribdTranslationsNo ratings yet

- Musical Instruments of EuropeDocument3 pagesMusical Instruments of EuropeScribdTranslationsNo ratings yet

- Retirement Instructions Unemployment PorvenirDocument6 pagesRetirement Instructions Unemployment PorvenirScribdTranslationsNo ratings yet

- Chapter X. Precision Shooting From Naval Air PlatformsDocument24 pagesChapter X. Precision Shooting From Naval Air PlatformsScribdTranslationsNo ratings yet

- SYLLABUS Mechanical Drawing 2Document7 pagesSYLLABUS Mechanical Drawing 2ScribdTranslationsNo ratings yet

- Tourist PlanningDocument39 pagesTourist PlanningScribdTranslationsNo ratings yet

- Application of Copper Sulfate in AquacultureDocument2 pagesApplication of Copper Sulfate in AquacultureScribdTranslationsNo ratings yet

- Types of Banks Based On OwnershipDocument2 pagesTypes of Banks Based On OwnershipScribdTranslationsNo ratings yet

- Comparative Table of Rationalism and EmpiricismDocument7 pagesComparative Table of Rationalism and EmpiricismScribdTranslationsNo ratings yet

- Reading Comprehension and Contextual Vocabulary Exercises 4th Middle #8.Document5 pagesReading Comprehension and Contextual Vocabulary Exercises 4th Middle #8.ScribdTranslationsNo ratings yet

- History and Evolution of Reciprocating MotorsDocument32 pagesHistory and Evolution of Reciprocating MotorsScribdTranslationsNo ratings yet

- Practical Work The Familiar PDFDocument1 pagePractical Work The Familiar PDFScribdTranslationsNo ratings yet

- Legal Aspects GuatemalaDocument20 pagesLegal Aspects GuatemalaScribdTranslationsNo ratings yet

- Driver's Manual in TexasDocument109 pagesDriver's Manual in TexasScribdTranslationsNo ratings yet

- Boxing PDFDocument49 pagesBoxing PDFScribdTranslationsNo ratings yet

- 5th Grade Plan - Block 4 GeographyDocument12 pages5th Grade Plan - Block 4 GeographyScribdTranslationsNo ratings yet

- Sixth Grade Reading Comprehension AssessmentDocument8 pagesSixth Grade Reading Comprehension AssessmentScribdTranslationsNo ratings yet

- Project On Electricity For ChildrenDocument13 pagesProject On Electricity For ChildrenScribdTranslationsNo ratings yet

- iTEP in - House PDFDocument12 pagesiTEP in - House PDFScribdTranslationsNo ratings yet

- PH Portfolio Recovery ProposalDocument3 pagesPH Portfolio Recovery ProposalScribdTranslationsNo ratings yet

- Expo22 Daily ExperienceDocument6 pagesExpo22 Daily ExperienceScribdTranslationsNo ratings yet

- Application of Regulations in The Financial SystemDocument74 pagesApplication of Regulations in The Financial SystemScribdTranslationsNo ratings yet

- Applied StatisticsDocument209 pagesApplied StatisticsScribdTranslationsNo ratings yet

- Chemistry Laboratory Report 1Document14 pagesChemistry Laboratory Report 1ScribdTranslationsNo ratings yet

- Examples of Operant ConditioningDocument1 pageExamples of Operant ConditioningScribdTranslationsNo ratings yet

- Vibrational Sound Therapy ManualDocument12 pagesVibrational Sound Therapy ManualScribdTranslationsNo ratings yet

- Security of Accounting Information SystemsDocument2 pagesSecurity of Accounting Information SystemsScribdTranslationsNo ratings yet

- Event Security ProtocolDocument7 pagesEvent Security ProtocolScribdTranslationsNo ratings yet

- ISO 2063 INTERNATIONAL STANDARD. Thermal Spraying Metallic and Other Inorganic Coatings Zinc, Aluminium and Their AlloysDocument20 pagesISO 2063 INTERNATIONAL STANDARD. Thermal Spraying Metallic and Other Inorganic Coatings Zinc, Aluminium and Their AlloysLong TomahawkNo ratings yet

- Epoxy Painting & Sand Blasting JobDocument11 pagesEpoxy Painting & Sand Blasting JobStrategic ThinkingNo ratings yet

- Shot Blasting RoomsDocument12 pagesShot Blasting RoomsDui MarianaNo ratings yet

- A Guide To Understanding Steel Grit andDocument3 pagesA Guide To Understanding Steel Grit andPreety sharmaNo ratings yet

- CIP Questions & AnsversDocument9 pagesCIP Questions & Ansversmajdi jerbi100% (1)

- Progress Report Michelin (A.p.t.t.u.pihilianga)Document27 pagesProgress Report Michelin (A.p.t.t.u.pihilianga)uththamathiliniaptNo ratings yet

- Iso 8501-2Document178 pagesIso 8501-2Talha UmairNo ratings yet

- Bs en Iso 08503 1 2012Document20 pagesBs en Iso 08503 1 2012Ajay RayNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Koc-P-004 Part 8 Rev 2Document41 pagesKoc-P-004 Part 8 Rev 2Hari KrishnanNo ratings yet

- BS 7079-2009 General Introduction To Standards For The Preparation of Steel Substrates Before Application of Paints and Related ProductsDocument18 pagesBS 7079-2009 General Introduction To Standards For The Preparation of Steel Substrates Before Application of Paints and Related ProductsGavinNo ratings yet

- HoldTight PDS 7 29Document2 pagesHoldTight PDS 7 29Quirino Ramírez VeronicaNo ratings yet

- Grit Blasting ProcedureDocument2 pagesGrit Blasting ProcedureDhinesh RajendiranNo ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- Office Copy ThesisDocument109 pagesOffice Copy ThesisJoel ArumbakanNo ratings yet

- Chemfix 11 Water ProofingDocument2 pagesChemfix 11 Water ProofingSheikh BeryalNo ratings yet

- Jotamastic 70Document9 pagesJotamastic 70Muhammad HanafiNo ratings yet

- TDS-EN-Condur 41 - Rev 007-Jun 22Document2 pagesTDS-EN-Condur 41 - Rev 007-Jun 22LONG LASTNo ratings yet

- Method Statement For Crude Oil Tank Coating and PaintingDocument94 pagesMethod Statement For Crude Oil Tank Coating and PaintingMogul KhanNo ratings yet

- Practical Aspects Corr Protect EngDocument217 pagesPractical Aspects Corr Protect Eng이선엽No ratings yet

- Specification and Product Images May Change Without Notice Specification and Product Images May Change Without NoticeDocument14 pagesSpecification and Product Images May Change Without Notice Specification and Product Images May Change Without NoticerezahezkiaNo ratings yet

- Corrosion Control - Jack-Up - SP-CO-ENG-CON-06-01Document37 pagesCorrosion Control - Jack-Up - SP-CO-ENG-CON-06-01evenNo ratings yet

- Iso 08504-2Document16 pagesIso 08504-2Akram DriraNo ratings yet

- AIR AbrasionDocument5 pagesAIR Abrasionzubair ahmedNo ratings yet

- Es 00000 27280 002Document21 pagesEs 00000 27280 002Hasan arif KısaalioğluNo ratings yet

- IG2 Mohamed HassanienDocument30 pagesIG2 Mohamed HassanienAyman ElHapashy0% (1)

- Ly304 100 3PS NX00 00001 - 00Document18 pagesLy304 100 3PS NX00 00001 - 00Mehmet AtabayNo ratings yet

- Printed in FranceDocument9 pagesPrinted in FranceYusron AzharyNo ratings yet

- Koroglass 1000Document3 pagesKoroglass 1000Sandeep gangulyNo ratings yet