Professional Documents

Culture Documents

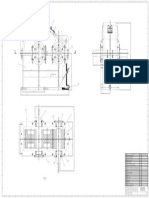

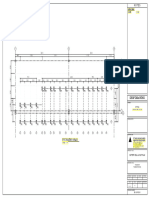

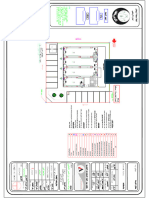

ASSY NO.-508943900154N: Bending Table WRT Part Co-Ordinate

ASSY NO.-508943900154N: Bending Table WRT Part Co-Ordinate

Uploaded by

Pritamauto mechOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASSY NO.-508943900154N: Bending Table WRT Part Co-Ordinate

ASSY NO.-508943900154N: Bending Table WRT Part Co-Ordinate

Uploaded by

Pritamauto mechCopyright:

Available Formats

1 2 3 4 5 6 7 8

Nominal Tolerance

Do not scale the drawing. in m(microns)

Dimension

Unless otherwise stated, 1. All dimensions in mm. Refer IS919-2

2. Drawing drawn to first angle projection

If in doubt, ask. - -

A Y

3

X 1

4

1

P1

B B

P6

5

1 ASSY NO.-508943900154N

B BENDING TABLE wrt PART CO-ORDINATE

PTS X Y Z RADIUS

P1 0 0 0

P5

P2 309 0 0 40

METAL PIPE 18 OD X 1.5 THK. P3 307 59 -169 40 P4

P4 307 59 -560 40 P3

1 P2

1 P5 170 61 -785 40

P6 -78 61 -785 ISOMETRIC VIEW

TOTAL DEVELOPED LENGTH 1368

2

1

A A

BILL OF MATERIAL

SR.No. PART NO. QTY

1 508943906904N 1

2 206743906801 1

3 277043806802 1

4 277643903305N 1

E

5 277043806805 1 For all Vehicle Components

& Assemblies,

Tata Group Mark & Part No. to be marked as per TS 10806

For M1 & N1 class of vehicles, applicable standards are:

SECTION B-B SECTION VIEW-2 TS11414,TS11418,TS11419

& TS11420

SECTION A-A SECTION VIEW-4 Material description,size,spec.std No.

SECTION VIEW DETAIL REFER SECTION VIEW DETAIL SEE NOTE

FROM METAL PIPE DRG. FROM DRG. 5066 4390 00 03

SECTION

SECTION VIEW VIEW DETAILS

DETAILS Classification of characteristics:

Critical, Key Instruction

Major, (None) Minor 23/11 18PM

Applies to upper limit 2018 406 000 - - NEW RELEASE PRA MVS

Applies to lower limit Date Mod. No. Sl No. Zone Modification Chkd Appd

NOTES :- This drawing is the sole property2018 SIGN DATE Envelope Final mass Surface protection as per standard

1) TUBE TO BE ZINC PLATED INSIDE AND OUT SIDE. of Tata Motors Limited. Dimensions in kg.

2) SURFACE PROTECTION OF METAL PIPES END FITTINGS AS PER Fe Zn 8 Cr III YSS8451 S2. It should not be copied or Drawn RRS 23/11 SEE NOTES

communicated to any person

3) REMOVE ALL SHARP EDGES. without the written approval Chkd PRA 816.82 x 92.85 x 409.87 0.960 Tolerance as per standard -

F 4) END FITTINGS SHOULD BE PROTECTED of Tata Motors Limited.

Appd MVS Product/Group No. Replaces Drg -

WITH PLASTIC CAP TO AVOID DAMAGE AND ENTRANCE OF DUST.

5) MISALIGNMENT ALLOWABLE # 1 $ . Scale:1:1 E SERIES 3018T

Reference Drg No. -

6) RECOMMENDED TIGHTENING TORQUE L-18 NUT 7.O - 1O.0 kgfm. LENGTH DEVIATIONS Opposite Hand Drg/Part No. -

7) METAL PIPE ROUTING AS PER PIPE CO-ORDINATES SYSTEM.

8) PIPE MATERIAL IS CEW 1 ANLD SS:4045 & OTHER PARTS MATERIAL REFER INDIVIDUAL DRAWING. RANGE OVER 0 1000 2500 4000 Drg/Part Designation Drg/Part No.

IN mm UP TO 1000 2500 4000 6000

MOTORS LIMITED

METAL PIPE ASSY,

JOINT2 TO JOINT3

5089 4390 01 54

TOLERANCE IN mm ERC - PUNE Sheet No....

1.... of ....

1.... Sheets

For explanation of drawing format contents, refer to TS11103

8845 4130 70 68 PCF- 073(R2) 6/2011 Original drawing size A2

You might also like

- Olympic 1918 08may2012 PartsDocument3 pagesOlympic 1918 08may2012 PartsLogan Cerna100% (1)

- Elscan enDocument28 pagesElscan enQuý Đình Mai MaiNo ratings yet

- Brookdale Lincroft Campus MapDocument2 pagesBrookdale Lincroft Campus MappipercravenNo ratings yet

- Value Stream Mapping ProcessDocument40 pagesValue Stream Mapping ProcessAtifKhan100% (10)

- Historical Development in Science and TechnologyDocument31 pagesHistorical Development in Science and TechnologyMecaella Bondoc100% (7)

- Bending Table WRT Part Co-Ordinate: Scale: 1:10 (1:1) - (1:5)Document1 pageBending Table WRT Part Co-Ordinate: Scale: 1:10 (1:1) - (1:5)Pritamauto mechNo ratings yet

- ASSY NO.-508943900155N: Bending Table WRT Part Co-OrdinateDocument1 pageASSY NO.-508943900155N: Bending Table WRT Part Co-OrdinatePritamauto mechNo ratings yet

- Latest 19.10.2020Document1 pageLatest 19.10.2020pankaj kumarNo ratings yet

- Bending Table WRT Part Co-OrdinateDocument1 pageBending Table WRT Part Co-OrdinatePritamauto mechNo ratings yet

- (Adriano Celentano) Azzuro TAB NOTDocument3 pages(Adriano Celentano) Azzuro TAB NOTmiromarkoNo ratings yet

- Schema Electrica AGT 12003 DSEADocument1 pageSchema Electrica AGT 12003 DSEACsaba WielandNo ratings yet

- 3 ColourDocument9 pages3 Colourregnaidu12No ratings yet

- B Bga144Document1 pageB Bga144Yargen GonzalezNo ratings yet

- A3-106304-02009-01-A General Arrangement S311Document1 pageA3-106304-02009-01-A General Arrangement S311Chandra KanthNo ratings yet

- Ansamblu ReductorDocument1 pageAnsamblu ReductortimothyNo ratings yet

- Aluminium 2Document1 pageAluminium 2Istvan DedeNo ratings yet

- DwgDelivRqmts AppendBDocument1 pageDwgDelivRqmts AppendBChad GallowayNo ratings yet

- Olympic 1917grey PartsDocument3 pagesOlympic 1917grey PartsLogan CernaNo ratings yet

- LC 05Document1 pageLC 05Ramadan GhanmNo ratings yet

- Flexibilidad 1Document2 pagesFlexibilidad 1nicol.nvc.5No ratings yet

- Fix Foundation Assembly 21-02-2024Document3 pagesFix Foundation Assembly 21-02-2024khoirullanwar13No ratings yet

- Flexibilidad 1Document2 pagesFlexibilidad 1nicol.nvc.5No ratings yet

- PINE H6 Model B 20181212 SchematicDocument18 pagesPINE H6 Model B 20181212 SchematicAllam Karthik MudhirajNo ratings yet

- GỬI NGUYỆNDocument1 pageGỬI NGUYỆNPhúcMậpNo ratings yet

- DZX-1051 ADocument2 pagesDZX-1051 AZain UddinNo ratings yet

- Va536 3Document1 pageVa536 3陆军No ratings yet

- SECT."K-K": Port Harcourt Refinery Project Rehabilitation ofDocument1 pageSECT."K-K": Port Harcourt Refinery Project Rehabilitation ofamitNo ratings yet

- Panel LP8-10Document7 pagesPanel LP8-10electra munasirNo ratings yet

- Tomalon Residence - For HOA Approval - 20211021Document5 pagesTomalon Residence - For HOA Approval - 20211021Edg ManapolNo ratings yet

- Ball Rollers (For Upward Facing) : Milled Stainless SteelDocument1 pageBall Rollers (For Upward Facing) : Milled Stainless SteelLộcLộcNo ratings yet

- Major Arpeggio: Boondog & Snakey Music PublicationsDocument1 pageMajor Arpeggio: Boondog & Snakey Music PublicationsGuilherme SimãoNo ratings yet

- PA Loudspeaker & Junction Box Wiring Schematic RLMUDocument22 pagesPA Loudspeaker & Junction Box Wiring Schematic RLMUVenkatesh PrasathNo ratings yet

- Wiring Diagram ATS 135Document5 pagesWiring Diagram ATS 135Septian Pandjie100% (1)

- Liguei Pra Dizer Que Te Amo - Alan & AladimDocument3 pagesLiguei Pra Dizer Que Te Amo - Alan & AladimMário CésarNo ratings yet

- Reverse Engineering PLTA Kaluku: PT - PLN (Persero) Sektor Pembangkitan BakaruDocument1 pageReverse Engineering PLTA Kaluku: PT - PLN (Persero) Sektor Pembangkitan Bakarusyaifulfuad19No ratings yet

- D C B A: DissipadorDocument2 pagesD C B A: DissipadorCesar FleuryNo ratings yet

- ProgramDocument3 pagesProgramaryasaurabh54No ratings yet

- Gasorex Apfc PanelDocument1 pageGasorex Apfc PanelRAJESH PATRANo ratings yet

- First Floor Plan - Recover - recover-REIN.Document1 pageFirst Floor Plan - Recover - recover-REIN.Gajendra SNo ratings yet

- 5افياش الارضيDocument1 page5افياش الارضيFawwazNo ratings yet

- Fonte Philco TV Ph-32e PH-32M4 40-P152C0-PWG1XG PW152C0 E56334 PDFDocument3 pagesFonte Philco TV Ph-32e PH-32M4 40-P152C0-PWG1XG PW152C0 E56334 PDFJose Davalillo100% (1)

- 4844 803 +superDocument2 pages4844 803 +superBudi WaskitoNo ratings yet

- Wiring Diagram ATS 25kva AtyS-Revisi1Document5 pagesWiring Diagram ATS 25kva AtyS-Revisi1Andira ElectrikNo ratings yet

- LVMDP Fashion StitchDocument1 pageLVMDP Fashion StitchSULISTYOWATINo ratings yet

- (Celine Dion) My Heart Will Go On TAB NOTDocument5 pages(Celine Dion) My Heart Will Go On TAB NOTmiromarkoNo ratings yet

- Ge2100309.Pg017-Pg018 E01.3+r1 132kv Line Tie Bay Protection PanelDocument40 pagesGe2100309.Pg017-Pg018 E01.3+r1 132kv Line Tie Bay Protection PanelFrancis KoomsonNo ratings yet

- User's Manual: 1:rev 2:Plt 3:dly 4:GEQDocument43 pagesUser's Manual: 1:rev 2:Plt 3:dly 4:GEQYury OranskyNo ratings yet

- 8DJH36-23865 SwgGra 20200228130231Document3 pages8DJH36-23865 SwgGra 20200228130231NedyHortetlNo ratings yet

- 400scale A350-1000 JASDocument1 page400scale A350-1000 JASMohamed DhiaaNo ratings yet

- RENR69730001Document2 pagesRENR69730001Bienvenu MassouanguiNo ratings yet

- Schematic: L15 0 Conf General Installation 00Document1 pageSchematic: L15 0 Conf General Installation 00toto-gmbhNo ratings yet

- 0.001mm Dial IndicatorDocument11 pages0.001mm Dial Indicatorรุ่งทิวา ทวีทรัพย์No ratings yet

- Schemi Elettrici Vari MesDocument1,251 pagesSchemi Elettrici Vari MesE. S. MecchiNo ratings yet

- 0000 DRG WD ST 009 PDFDocument1 page0000 DRG WD ST 009 PDFabidimisamNo ratings yet

- Party Line (PHONE) Wiring Schematic RLMUDocument7 pagesParty Line (PHONE) Wiring Schematic RLMUVenkatesh PrasathNo ratings yet

- Xyzsmsch 1Document1 pageXyzsmsch 1dulcampid100% (2)

- Xingsheng CatalogDocument61 pagesXingsheng Catalogmaurizio.capone461No ratings yet

- Spinal Cord and Brain by MaazDocument9 pagesSpinal Cord and Brain by MaazSamad AlamNo ratings yet

- Aatch Ent LayoutDocument1 pageAatch Ent LayoutVINOD KUMARNo ratings yet

- J-16 132kV - Layout1Document1 pageJ-16 132kV - Layout1ahmedNo ratings yet

- VTU-26-12-2018 12:36:05pm: TG - TG - TG - TG - TG - TG - TG - TG - TGDocument2 pagesVTU-26-12-2018 12:36:05pm: TG - TG - TG - TG - TG - TG - TG - TG - TGEEE TCE GadagNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Overlay NetworksDocument7 pagesOverlay NetworksSuganya PeriasamyNo ratings yet

- Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Document1 pageJob Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Jayvee Baradas ValdezNo ratings yet

- Instruction Manual: Made in The U.S.ADocument16 pagesInstruction Manual: Made in The U.S.ACarlos Rincon0% (2)

- Report 5 Signalling and Train Control Systems PDFDocument255 pagesReport 5 Signalling and Train Control Systems PDFPedro HenriquesNo ratings yet

- Preguntas Cap 27 Manufactura ModernaDocument2 pagesPreguntas Cap 27 Manufactura ModernaJavierNo ratings yet

- SyllabusDocument17 pagesSyllabusVandita GroverNo ratings yet

- Industrial Reverse Osmosis SystemsDocument4 pagesIndustrial Reverse Osmosis Systemsashtj2000No ratings yet

- WWW Thisisclassicalguitar Com Francisco Tarrega Free Sheet MDocument11 pagesWWW Thisisclassicalguitar Com Francisco Tarrega Free Sheet Mpsk346No ratings yet

- Fluid Loading On Offshore Structures Vol-1 (OTH 90-322)Document297 pagesFluid Loading On Offshore Structures Vol-1 (OTH 90-322)Anonymous 7fIHDkX22pNo ratings yet

- Elastomeric Seals and Materials at Cryogenic TemeraturesDocument81 pagesElastomeric Seals and Materials at Cryogenic Temeraturesjohndoe_218446No ratings yet

- DIANA Elements Spring 2010 PDFDocument9 pagesDIANA Elements Spring 2010 PDFAlessandroAleottiNo ratings yet

- Operational Efficiency With Simatic Pcs 7: White PaperDocument32 pagesOperational Efficiency With Simatic Pcs 7: White Paperpalash_monNo ratings yet

- Zhejiang Sanye Catelogue-Fittings2019Document80 pagesZhejiang Sanye Catelogue-Fittings2019Danyang YUNo ratings yet

- General Product Information: Rocktech S (Slab) SeriesDocument4 pagesGeneral Product Information: Rocktech S (Slab) SeriesPhan LongNo ratings yet

- A-Dec 541 Duo Delivery System and 545 Assistant's InstrumentationDocument16 pagesA-Dec 541 Duo Delivery System and 545 Assistant's InstrumentationGreg RehmsNo ratings yet

- Chapter 2Document17 pagesChapter 2shabbirjamali0% (1)

- Television Genres - IntertextualityDocument8 pagesTelevision Genres - IntertextualityAldy MaulanaNo ratings yet

- Solar Radiation MeasurementsDocument38 pagesSolar Radiation MeasurementsDitsha100% (1)

- QMT437 Lect1 Intro To OR - 2Document42 pagesQMT437 Lect1 Intro To OR - 2Khairul PakhrudinNo ratings yet

- 5G IntroductionDocument2 pages5G IntroductionVincentNo ratings yet

- The Global Wgs 84 CoordinateDocument3 pagesThe Global Wgs 84 CoordinateBenedicta Dian AlfandaNo ratings yet

- 2124 4919 1 SMDocument13 pages2124 4919 1 SMISNAN NURDIANSYAHNo ratings yet

- C115 A DC1051-Rev01 IT-EN-ESDocument596 pagesC115 A DC1051-Rev01 IT-EN-ESLuis Bastias ChacanaNo ratings yet

- 610 10th Ed Datasheets (SI)Document11 pages610 10th Ed Datasheets (SI)sjois_hsNo ratings yet

- Erp Sap Cours PDFDocument2 pagesErp Sap Cours PDFMattNo ratings yet

- Finnish Industrial Wastewater GuideDocument183 pagesFinnish Industrial Wastewater Guidelifemillion2847No ratings yet