Professional Documents

Culture Documents

Bridge Structure

Bridge Structure

Uploaded by

purnawanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Structure

Bridge Structure

Uploaded by

purnawanCopyright:

Available Formats

Project Name = Document No.

=

Client = Rev. No =

Equipment Name = Page No. =

Tag. No. =

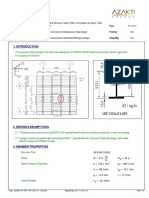

BRIDGE CALCULATION

8 DESIGN LOAD & MOMENT

1 Design Load w = 40 ton/m

Figure 1

Lateral Beam w = 40 ton/m

Point 1 Point 2

Joint Reaction

1 Moment maximum at point - 1 ( Tension Stress )

From analysis structure software ( SAP 2000 ver. 7.42 ), moment maximum at point - 1 follow as below :

M = 72980787 N mm

1 Moment maximum at point - 2 ( Compression Stress )

From analysis structure software ( SAP 2000 ver. 7.42 ), moment maximum at point - 2 follow as below :

M = 82075422 N mm

8 DESIGN STRESS

1 Definition of allowable stress ( Ref. Pressure Vessel Hand Book12th Edd, Eugene F Megyesy )

a Beam Use Profile W 12 X 50

- Material = A 36

- Min. Yield Stress Fy = 36000 Psi ( 248.21 N/mm2 )

- Allowable tension & compression stress

sc = 0.6 * Fy = 0.6 * 248.21 = 148.93 N/mm2

- Allowable bending

sb = 0.66 * Fy = 0.66 * 248.21 = 163.82 N/mm2

- Elastis Properties x-x Axis

I x-x = 165000000 mm4

d = 310 mm

a Lateral Beam Use Profile MC 6 X 16,3

- Material = A 36

- Min. Yield Stress Fy = 36000 Psi ( 248.21 N/mm2 )

- Allowable tension & compression stress

sc = 0.6 * Fy = 0.6 * 248.21 = 148.93 N/mm2

- Allowable bending

sb = 0.66 * Fy = 0.66 * 248.21 = 163.82 N/mm2

- Elastis Properties x-x Axis

I x-x = 1080000 mm4

d = 152 mm

1 Actual Stress

a Bending stress at Point - 1

s-ab = M. 0.5d / I x-x = 1.1312E+10 / 165000000

= 68.6 N/mm2 < 163.82 N/mm2 Satisfactory

a Bending stress at Point - 2

s-ab = M. 0.5d / I x-x = 1.2722E+10 / 165000000

= 77.1 N/mm2 < 163.82 N/mm2 Satisfactory

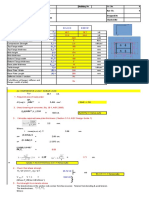

Project Name = Document No. =

Client = Rev. No =

Equipment Name = Page No. =

Tag. No. =

BRIDGE CALCULATION

8 DESIGN LOAD & MOMENT

1 Design Load F = 65.75 ton From joint reaction (see figure 1)

Figure 2

F F F F

Point 1

1000 1000

1250 1250 1250

1 Moment maximum at point - 1 ( Tension Stress )

From analysis structure software ( SAP 2000 ver. 7.42 ), moment maximum at point - 1 follow as below :

M = 74743338 N mm

8 DESIGN STRESS

1 Definition of allowable stress

a Beam Use Profile W 12 X 72

- Material = A 36

- Min. Yield Stress Fy = 36000 Psi ( 248.21 N/mm2 )

- Allowable tension & compression stress

sc = 0.6 * Fy = 0.6 * 248.21 = 148.93 N/mm2

- Allowable bending

sb = 0.66 * Fy = 0.66 * 248.21 = 163.82 N/mm2

- Elastis Properties x-x Axis

I x-x = 248000000 mm4

d = 311 mm

1 Actual Stress

a Bending stress at Point - 1

s-ab = M. 0.5d / I x-x = 1.1623E+10 / 248000000

= 46.8653 N/mm2 < 163.82 N/mm2 Satisfactory

You might also like

- Specification For Bare Stainless Steel Welding Electrodes andDocument33 pagesSpecification For Bare Stainless Steel Welding Electrodes andpurnawanNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Sds Screw DesignDocument3 pagesSds Screw DesignvtalexNo ratings yet

- Deck Plate Check at Upper Deck: Proj No Calc No X Deck Plating CheckDocument2 pagesDeck Plate Check at Upper Deck: Proj No Calc No X Deck Plating Checkhk089No ratings yet

- Design of Joint ConnectionDocument2 pagesDesign of Joint ConnectionSantosh BapuNo ratings yet

- One Way Continuous SlabDocument12 pagesOne Way Continuous Slabvenkatesh19701No ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- 1) in This Load Management Significance of Load Case - 1 & 2 (SW-SUM & STG-SUM) Is Not Understood. Could You Please Explain What Does This Signifies?Document10 pages1) in This Load Management Significance of Load Case - 1 & 2 (SW-SUM & STG-SUM) Is Not Understood. Could You Please Explain What Does This Signifies?Ashish GNo ratings yet

- Steel Beam DesignDocument4 pagesSteel Beam Designanshutomar7915100% (1)

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Design of MACH Deck Panel - Slab (300mm THK)Document7 pagesDesign of MACH Deck Panel - Slab (300mm THK)Sankar AnandNo ratings yet

- Design Data: Design For Base Plate (Fixed)Document4 pagesDesign Data: Design For Base Plate (Fixed)Wibawa WorksNo ratings yet

- Master of Lifting CalculationDocument7 pagesMaster of Lifting CalculationSudar MyshaNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Lifting SubDocument3 pagesLifting SubAndhika Satria PrakosoNo ratings yet

- Design CalculationsDocument8 pagesDesign CalculationsJIBEESH01No ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Tension Member Double AngleDocument1 pageTension Member Double AnglechaNo ratings yet

- Aa - Bracket DesignDocument2 pagesAa - Bracket Design4geniecivilNo ratings yet

- R.C. Slab Design (BS 8110: Part 1: 1985)Document1 pageR.C. Slab Design (BS 8110: Part 1: 1985)sallysel90No ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Pad FootingDocument1 pagePad FootingKingsley ChukwuNo ratings yet

- 1 Input Data: WWW - Hilti.usDocument7 pages1 Input Data: WWW - Hilti.usLaurence SarmientoNo ratings yet

- Calculation For Transsport BoxDocument9 pagesCalculation For Transsport Boxthanhtrung87No ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- Steel Staircase DesignDocument6 pagesSteel Staircase DesignMario FeghaliNo ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- Slab CrackwidthDocument15 pagesSlab CrackwidthMohammed Saleem Syed KhaderNo ratings yet

- Appendix - 4ADocument15 pagesAppendix - 4Amoumita mukherjeeNo ratings yet

- Type3 D2 OversizeDocument7 pagesType3 D2 OversizeDoğan ArslanNo ratings yet

- S2 Slab Calculation PDFDocument1 pageS2 Slab Calculation PDFashishNo ratings yet

- Design of Face Mounted BracketDocument4 pagesDesign of Face Mounted Bracketvishal tomarNo ratings yet

- Design of Torsion ReviseDocument6 pagesDesign of Torsion ReviseAnton_Young_1962No ratings yet

- Elastomeric Bearing 21.6mDocument8 pagesElastomeric Bearing 21.6mnaresh KUMARNo ratings yet

- Round Bar Suppot Plate Design CalculationDocument3 pagesRound Bar Suppot Plate Design CalculationinnovativekarthiNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Lifting Lug CalculationsDocument1 pageLifting Lug CalculationsshazanNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Design of Steel BeamDocument18 pagesDesign of Steel BeamOuseppachan Ambooken100% (4)

- GergDocument18 pagesGergOuseppachan AmbookenNo ratings yet

- RC Beam Torsion Design BS8110Document2 pagesRC Beam Torsion Design BS8110saman2580No ratings yet

- Simulation and ModelingDocument23 pagesSimulation and ModelingVincent Lasconia Jr.No ratings yet

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDocument105 pagesJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNo ratings yet

- Calculation Sheet: Test Job Member Design For SB2Document2 pagesCalculation Sheet: Test Job Member Design For SB2bungykitNo ratings yet

- Slab Design Vehicle MovementDocument21 pagesSlab Design Vehicle MovementsivaNo ratings yet

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- Padeye CalcDocument11 pagesPadeye CalcShridhar AmatiNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Procedure Tube expansion-BHTV008Document6 pagesProcedure Tube expansion-BHTV008purnawanNo ratings yet

- Optimization of Electric Power GenerationDocument10 pagesOptimization of Electric Power GenerationpurnawanNo ratings yet

- General Spec. For Vertical Atmospheric Tank-BHTV002Document13 pagesGeneral Spec. For Vertical Atmospheric Tank-BHTV002purnawanNo ratings yet

- Hydrostatic Test Procedure For Vessel-BHTV006Document11 pagesHydrostatic Test Procedure For Vessel-BHTV006purnawanNo ratings yet

- Fastenal Technical Reference GuideDocument54 pagesFastenal Technical Reference GuidepurnawanNo ratings yet

- Procedure Weld Repair-BHTV004Document6 pagesProcedure Weld Repair-BHTV004purnawanNo ratings yet

- MotorDocument3 pagesMotorpurnawanNo ratings yet

- Pressure Reducing ValveDocument2 pagesPressure Reducing ValvepurnawanNo ratings yet

- BWG - Birmingham Wire GaugeDocument8 pagesBWG - Birmingham Wire GaugepurnawanNo ratings yet

- Understanding Pitting Corrosion BehaviourofX-65CarbonSteelinCO2SaturatedEnvironmentsDocument29 pagesUnderstanding Pitting Corrosion BehaviourofX-65CarbonSteelinCO2SaturatedEnvironmentspurnawanNo ratings yet

- 02 UnpDocument1 page02 UnppurnawanNo ratings yet

- Aqua Setter Cat P2Document1 pageAqua Setter Cat P2purnawanNo ratings yet

- Fabrication Schedule: Bulk Storage Tank Cap.58M3 & 92M3Document2 pagesFabrication Schedule: Bulk Storage Tank Cap.58M3 & 92M3purnawanNo ratings yet

- David Palmer CPPDocument24 pagesDavid Palmer CPPpurnawanNo ratings yet

- Fab - Schedule WO.034-05 VICODocument2 pagesFab - Schedule WO.034-05 VICOpurnawanNo ratings yet

- Bs en 264Document14 pagesBs en 264purnawanNo ratings yet

- GP-17 BiomassDocument52 pagesGP-17 BiomasspurnawanNo ratings yet

- Fielding Notching and Drilling of Glued Laminated Timber BeamsDocument1 pageFielding Notching and Drilling of Glued Laminated Timber BeamsTimothy CruseNo ratings yet

- Science9 - q4 - CLAS4 - Conservation-of-Mechanical-Energy - V67-Copy - RHEA ANN NAVILLADocument13 pagesScience9 - q4 - CLAS4 - Conservation-of-Mechanical-Energy - V67-Copy - RHEA ANN NAVILLAParangue Manuel Karen Ann100% (1)

- Chapter 6 ReDocument17 pagesChapter 6 ReJohnson AnthonyNo ratings yet

- Design of Bearing PadDocument3 pagesDesign of Bearing Padaris tanNo ratings yet

- (Original) Cui Et. Al., 2022Document8 pages(Original) Cui Et. Al., 2022Carolina CamposNo ratings yet

- Fundamentals of Multiferroic Materials and Their Possible ApplicationsDocument39 pagesFundamentals of Multiferroic Materials and Their Possible Applicationsdapper otaku662No ratings yet

- Heat Exchanger DesignDocument27 pagesHeat Exchanger DesignTri Vicca WibisonoNo ratings yet

- Propulsion QPDocument4 pagesPropulsion QPdennyfrancis19No ratings yet

- ME100-Kinematics of A ParticleDocument18 pagesME100-Kinematics of A ParticleMuhammad NabeelNo ratings yet

- Fluid Mechanics (MEC 303) NIT SrinagarDocument111 pagesFluid Mechanics (MEC 303) NIT Srinagargetahun esubalew100% (1)

- ME 452 Fluid Machinery 11.4.2011.doc Under RevisionDocument234 pagesME 452 Fluid Machinery 11.4.2011.doc Under RevisionfranciskwofiejnrNo ratings yet

- 4 Analysis and Design of Steel Deck - Concrete Composite SlabsDocument112 pages4 Analysis and Design of Steel Deck - Concrete Composite SlabsLê Ngọc-Hà100% (2)

- Strain Modeling of Transpressional and Transtensional DeformationDocument12 pagesStrain Modeling of Transpressional and Transtensional Deformationmehenna ouidjaNo ratings yet

- Atwood'S Machine: Driving Question - ObjectiveDocument7 pagesAtwood'S Machine: Driving Question - ObjectiveDimitrije RandjelovicNo ratings yet

- Lab ConclusionDocument2 pagesLab Conclusionapi-287882693No ratings yet

- ElectricityDocument21 pagesElectricityVinayKumarNo ratings yet

- Frequency of Free Damped Vibrations (Viscous Damping)Document8 pagesFrequency of Free Damped Vibrations (Viscous Damping)ذوالفقار علي حسينNo ratings yet

- CFDDocument59 pagesCFDSabrinaFuschetto0% (1)

- Chapter 1 - Intro To ThermodynamicsDocument42 pagesChapter 1 - Intro To ThermodynamicsKrishnan MohanNo ratings yet

- 9709 w15 QP 53Document4 pages9709 w15 QP 53yuke kristinaNo ratings yet

- Stability Chapter 05Document8 pagesStability Chapter 05abimalainNo ratings yet

- Noise Pollution and Its ControlDocument40 pagesNoise Pollution and Its ControlDhananjay ShimpiNo ratings yet

- Analysis Strength of Scaffolding Structure On Stack HRSG For Cable TightDocument5 pagesAnalysis Strength of Scaffolding Structure On Stack HRSG For Cable TighthendraNo ratings yet

- A Vena Contracta: OrificesDocument6 pagesA Vena Contracta: OrificesMichael LangatNo ratings yet

- Thermal Concrete CrackingDocument7 pagesThermal Concrete Crackingignacio_vazquez_18No ratings yet

- ME2112 - (Part 1) - Shear Stress in Beams-L1 PDFDocument4 pagesME2112 - (Part 1) - Shear Stress in Beams-L1 PDFShang PingNo ratings yet

- Academic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-I Properties of MatterDocument52 pagesAcademic Year 2020 - 2021 - ODD Semester PH8151 - Engineering Physics Unit-I Properties of MatterBala NandaNo ratings yet

- Design of Steel Structure Module 4Document61 pagesDesign of Steel Structure Module 4ShazNo ratings yet

- 60 SETS PhysicsDocument8 pages60 SETS PhysicsAhmed Hossain100% (1)

- Damping of Matrls Undr Biaxial StressDocument53 pagesDamping of Matrls Undr Biaxial StresshurmakmuhNo ratings yet