Professional Documents

Culture Documents

HAI BROCHURE DATA - Draft 2

HAI BROCHURE DATA - Draft 2

Uploaded by

yash.chauhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAI BROCHURE DATA - Draft 2

HAI BROCHURE DATA - Draft 2

Uploaded by

yash.chauhanCopyright:

Available Formats

Helical Anchor Inc

Company Description

• Located in Minneapolis, Minnesota, USA.

• Helical Anchor Inc is a part of Jindal Saw Limited, India.

About Product

• World’s Strongest Helical Pile

• Patented Welding Process

• ICC – ES and ISO Certified Company

• Custom Size and Length Manufacturing

• Shorter Lead Times

• Worldwide Shipping Capability

• Helical Anchor Manufacturing Range:

1) Circular Shaft Helical Anchors Sizes Offered:

Installation

Shaft Wall Ultimate

Shaft Size Available Length Helix Plate Torque

Thickness Capacity -Kip

(Inch) (Feet) (Inch) Factor

(Inch) (lbs)

(k)

2 3/8 0.254 5,7,10 8-10-12-14 9-10 76

2 7/8 0.217 5,7,10 8-10-12-14 8-9 100

2 7/8 0.276 5,7,10 8-10-12-14 8-9 122

3 1/2 0.254 5,7,10 10-12-14 6.5-8 122

3 1/2 0.368 5,7,10 10-12-14 6.5-8 183

4 1/2 0.254 5,7,10 10-12-14 5-6.5 185

4 1/2 0.337 5,7,10 10-12-14 5-6.5 295

5 0.362 5,7,10 10-12-14-16 4.5-6 392

5 1/2 0.361 5,7,10 10-12-14-16 4-5.5 440

7 0.362 5,7,10 12-14-16-18 3-4.5 675

7 0.498 5,7,10 12-14-16-18 3-4.5 732

• Helical Anchor Inc also manufacture helical piles in bigger Shaft sizes 7 5/8”, 8 5/8”, 9

5/8”, 10 ¾” , 12 ¾” in coupled sections. These Helical Piles are manufactured at

customized length and flights configurations.

2) Round Corner Square Helical Anchors Size Range Offered:

Installation

Shaft Size Available Length Helix Plate Ultimate Capacity -Kip

Torque Factor

(Inch) (Feet) (Inch) (lbs)

(k)

RCS 1.5 5,7,10 8-10-12-14 10 71

RCS 1.75 5,7,10' 8-10-12-14 10 110

RCS 2.0 5,7,10 8-10-12-14 10 160

3) Termination Accessories Offered:

• Standard Duty Bracket (80K)

• Heavy Duty Bracket (120K)

• New Construction Caps

• Tie Back Assemblies

• Customized L Brackets/Caps

• Customized U Brackets/Caps

• Customized T Pipes

• Custom Designs as per your requirements.

4) What makes Helical Anchor Inc Different from Others

Grade of Steel Inertia Welding Process

• Mid Body – N80 KSI or Better Higher Toque which creates highest torque

• Competitors – 50 KSI rating capacities in the market.

• Pin Connection- 4140/4137 Heat Faster Manufacturing Process

• Heat Treated Alloy Bar (28-32 HRC)

• Box Connection – 107 KSI (min)

• Competitors- 50 KSI

You might also like

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- TREK Flex Battery Replacement InstructionsDocument4 pagesTREK Flex Battery Replacement InstructionsDan PopoviciNo ratings yet

- Assignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueDocument8 pagesAssignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueRahul SarkarNo ratings yet

- What Is VersaFlex® Liner Hanger SystemDocument24 pagesWhat Is VersaFlex® Liner Hanger Systemadvantage025100% (1)

- Dayton Lite DutyDocument44 pagesDayton Lite DutyMiyer Gonzalo Montenegro Lizarazo100% (1)

- TWS 600SDocument44 pagesTWS 600Sfrank vNo ratings yet

- Fujitsu General Ash7asc-W - 9710k1222Document16 pagesFujitsu General Ash7asc-W - 9710k1222Liuda Scutaru Zarisneac100% (2)

- Hydril GK Annular DataDocument2 pagesHydril GK Annular DataAndrés Ramírez100% (3)

- Kirloskar Kos Openwell Submersible Pumps PDFDocument1 pageKirloskar Kos Openwell Submersible Pumps PDFSuraj SNo ratings yet

- BJ Model SV-5 Cement Retainer PDFDocument2 pagesBJ Model SV-5 Cement Retainer PDFmohammad teimuriNo ratings yet

- Across The Civilizations: Transporting WaterDocument20 pagesAcross The Civilizations: Transporting WaterKoduru SiddharthNo ratings yet

- NEISCO HDPE PIPES CatalougeDocument16 pagesNEISCO HDPE PIPES CatalougeAhmed HussienNo ratings yet

- ORI Catalogue - Pipe and Fittings Table DataDocument63 pagesORI Catalogue - Pipe and Fittings Table DataMuhammad Aidil FitrahNo ratings yet

- 2000 DataDocument1 page2000 DataAlexis PradoNo ratings yet

- Utility Anchors Catalog 2017-10-10Document26 pagesUtility Anchors Catalog 2017-10-10Shung Tak ChanNo ratings yet

- Victaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905Document8 pagesVictaulic Refuse-to-Fuse Coupling For Plain End HDPE Pipe Style 905maycolvNo ratings yet

- Tuberia HFD.Document16 pagesTuberia HFD.Gerardo Noé Cruz RodríguezNo ratings yet

- HDD Product Catalogue - Us-FormatDocument20 pagesHDD Product Catalogue - Us-FormatWinson LamNo ratings yet

- Lifting ShacklesDocument8 pagesLifting Shacklesgechaves1No ratings yet

- 4145MDocument2 pages4145McelestialmusicianNo ratings yet

- 3 WO Copper NickelDocument78 pages3 WO Copper NickelAnonymous Kr13NEBNo ratings yet

- Actuadores Neumaticos TS - AdasDocument25 pagesActuadores Neumaticos TS - AdasDaniel SanNo ratings yet

- Hose HydraulicDocument14 pagesHose HydraulicLto 750No ratings yet

- Submittal Information: Dynabolt SleeveDocument2 pagesSubmittal Information: Dynabolt Sleeveanto081287No ratings yet

- 500rm FlyerDocument2 pages500rm FlyermateoNo ratings yet

- Jaw CrusherDocument2 pagesJaw Crusherschizomarcus20100% (1)

- Victaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionDocument13 pagesVictaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionCinthya Yesenia Cruz MedinaNo ratings yet

- 7x7 and 7x19 Aircraft CableDocument1 page7x7 and 7x19 Aircraft CablePedroFarfanMartelNo ratings yet

- For The Design of Cold-Formed Steel Structural MembersDocument3 pagesFor The Design of Cold-Formed Steel Structural Membersjohnking5555No ratings yet

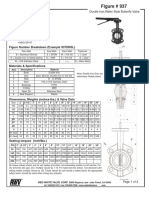

- 937 - Válvula Mariposa (Bridada)Document2 pages937 - Válvula Mariposa (Bridada)Rafael SalazarNo ratings yet

- OANDO OES-Energy-Services-Brochure-2010 PDFDocument16 pagesOANDO OES-Energy-Services-Brochure-2010 PDFJack NobleNo ratings yet

- Tuberia Cedula 40Document1 pageTuberia Cedula 40Ronquillo FireNo ratings yet

- Casing & Tubing Specs PDFDocument2 pagesCasing & Tubing Specs PDFAvil BadreeNo ratings yet

- Roller Bearing Supported Mills FINAL LRDocument8 pagesRoller Bearing Supported Mills FINAL LRHiresomannavar MahanteshNo ratings yet

- DOZERDocument2 pagesDOZERJackson PhinniNo ratings yet

- BVA HD-Series D/A CatalogDocument1 pageBVA HD-Series D/A CatalogTitanplyNo ratings yet

- Nut (Hardware) : Bolts & Screws NutsDocument13 pagesNut (Hardware) : Bolts & Screws NutsIDTR JamshedpurNo ratings yet

- Tulsa Triplex Tt-600Document2 pagesTulsa Triplex Tt-600miguelgarciamartinezNo ratings yet

- Dextra - Marine Tie RodsDocument6 pagesDextra - Marine Tie Rodspangalengan zaxNo ratings yet

- WMC Venturi ViperDocument2 pagesWMC Venturi ViperPedro Antonio Mejia SuarezNo ratings yet

- LS 13Document1 pageLS 13Alfred GandNo ratings yet

- AD 1+Tension+PackerDocument2 pagesAD 1+Tension+PackerHamid Reza BabaeiNo ratings yet

- Rotary Drilling Products Raise Bore PDFDocument3 pagesRotary Drilling Products Raise Bore PDFmanuel_plfNo ratings yet

- Hydraulic & Offshore Supplies: Ring Joint Flanges CatalogueDocument6 pagesHydraulic & Offshore Supplies: Ring Joint Flanges CatalogueKris YapNo ratings yet

- Cilindro Hidraulico Custom Hoists 85-402-235Document6 pagesCilindro Hidraulico Custom Hoists 85-402-235Daniel FarfanNo ratings yet

- Proposed DesignDocument6 pagesProposed DesignAyo Emmanuel KunleNo ratings yet

- C A 2018 DIAB DesigninfoDocument2 pagesC A 2018 DIAB Designinfoaandueza_1No ratings yet

- Catalogo KemperDocument28 pagesCatalogo KemperDaniel ChiribogaNo ratings yet

- Mekanord 430HSDocument2 pagesMekanord 430HSĐặng MinhNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- PermaCylDocument2 pagesPermaCylJosePsdNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- Sucker Rod SpecificationsDocument2 pagesSucker Rod SpecificationsMichelangeloTiberiiNo ratings yet

- Building On A: Marine Power LegacyDocument24 pagesBuilding On A: Marine Power LegacyEko PrasetyoNo ratings yet

- Ring Joint Flanges Product Range CatalogueDocument6 pagesRing Joint Flanges Product Range CatalogueHans SarmientoNo ratings yet

- 18 - Pipa HDPE v.1910Document2 pages18 - Pipa HDPE v.1910Ribur AritonangNo ratings yet

- PL5 Coupling BrochureDocument2 pagesPL5 Coupling BrochurePablo MagnoniNo ratings yet

- Torques Con Lubricante y UpgradeDocument17 pagesTorques Con Lubricante y UpgradeJed MayNo ratings yet

- CP Series: M-D Pneumatics Rotary Positive Displacement BlowersDocument4 pagesCP Series: M-D Pneumatics Rotary Positive Displacement BlowersHUNGNo ratings yet

- INTRODUCTIONDocument8 pagesINTRODUCTIONCastorNo ratings yet

- Setup And Repair Your Skateboard: A Guide To Assembling And Maintaining Your Skateboard For LongevityFrom EverandSetup And Repair Your Skateboard: A Guide To Assembling And Maintaining Your Skateboard For LongevityNo ratings yet

- Al Nimir Steel Book PDFDocument52 pagesAl Nimir Steel Book PDFSathish KumarNo ratings yet

- Aas Vora Jain - Nit Rourkela - DaaDocument1 pageAas Vora Jain - Nit Rourkela - DaaYasha voraNo ratings yet

- Real Dating Format PDFDocument1 pageReal Dating Format PDFadejareadekunle191No ratings yet

- ResumeDocument2 pagesResumeEmmah PetersNo ratings yet

- Study Material: Free Master Class SeriesDocument21 pagesStudy Material: Free Master Class SeriesTinku SinglaNo ratings yet

- Slab Using Staad ProDocument13 pagesSlab Using Staad ProErnesto SuarezNo ratings yet

- It's Getting Better: Andy Timmons That Was Then, This Is NowDocument12 pagesIt's Getting Better: Andy Timmons That Was Then, This Is NowyesscaballeroNo ratings yet

- Emotion Focused CopingDocument8 pagesEmotion Focused CopingMahrukh KhalidNo ratings yet

- 2nd Physics Short Ans + MCQDocument23 pages2nd Physics Short Ans + MCQAsif Rasheed Rajput83% (63)

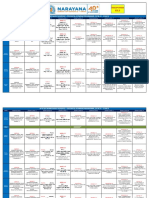

- AP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Document3 pagesAP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Raj RaoNo ratings yet

- SPM CHP 01 IntroductionDocument65 pagesSPM CHP 01 Introductionyorukage29No ratings yet

- 2nd Year ExamDocument4 pages2nd Year ExamFares HaifNo ratings yet

- Body of Knowledge: AWS Certified Welding InspectorDocument1 pageBody of Knowledge: AWS Certified Welding InspectorobanizeNo ratings yet

- Business Ethics 1Document15 pagesBusiness Ethics 1Nikita VithlaniNo ratings yet

- Solid Rivets ComparisonDocument3 pagesSolid Rivets ComparisonManoj ManoharanNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Jin Jogot Web PDFDocument125 pagesJin Jogot Web PDFMubarak HossainNo ratings yet

- Class 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)Document19 pagesClass 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)AnanyaNo ratings yet

- JeopardyDocument51 pagesJeopardyapi-509133063No ratings yet

- MSD7831 Z01 Da1Document1 pageMSD7831 Z01 Da1idonisNo ratings yet

- Salt Analysis - Lead AcetateDocument2 pagesSalt Analysis - Lead AcetateSwarnabha BhattacharyyaNo ratings yet

- Ignou - CTS - PgdcaDocument3 pagesIgnou - CTS - PgdcaNSS Unit GDC SihuntaNo ratings yet

- React On What Is Asserted LP EDITED AND FINAL To Be PrintedDocument8 pagesReact On What Is Asserted LP EDITED AND FINAL To Be PrintedEUNICE RIVAS100% (3)

- Accident Identifications With Vibration Sensor and Using RF CommutationDocument2 pagesAccident Identifications With Vibration Sensor and Using RF CommutationAnil ReddyNo ratings yet

- PDMS Course SyllabusDocument3 pagesPDMS Course SyllabusBalu MuruganNo ratings yet

- The Use of Audiovisual Materials To Teach Pronunciation in The ESL:EFL ClassroomDocument14 pagesThe Use of Audiovisual Materials To Teach Pronunciation in The ESL:EFL ClassroomClaudia AntunesNo ratings yet