Professional Documents

Culture Documents

Manual Rosemount DP Level Transmitters Diaphragm Seal Systems en 76026 - 1 - 1 - 47 - 1

Manual Rosemount DP Level Transmitters Diaphragm Seal Systems en 76026 - 1 - 1 - 47 - 1

Uploaded by

Teddy PahlewiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Rosemount DP Level Transmitters Diaphragm Seal Systems en 76026 - 1 - 1 - 47 - 1

Manual Rosemount DP Level Transmitters Diaphragm Seal Systems en 76026 - 1 - 1 - 47 - 1

Uploaded by

Teddy PahlewiCopyright:

Available Formats

Reference Manual Fill Fluids

00809-0100-4002 September 2022

5 Fill Fluids

This section discusses the process of selecting the appropriate fill fluid using vapor

pressure curves. To see the list of available Rosemount fill fluids, view the Rosemount DP

Level Fill Fluid Specifications Technical Note, or reference the Rosemount DP Level

Transmitters and 1199 Remote Seals Product Data Sheet or the 1299 Remote Seals

Product Data Sheet.

5.1 Quality

5.1.1 Specialized processing

Emerson has implemented proprietary processes to eliminate impurities and

contaminations in the fill fluid. This additional processing ensures stable measurement

and optimal performance under extreme temperatures and vacuum conditions. The

proprietary equipment and procedures used to build remote seal systems for high

temperature/high vacuum applications are continuously improved to deliver products

that meet ever increasing application demands. Tight quality control measures such as

helium leak checking of system welds ensures the reliability of every seal system.

Additional quality checks include continual station leak and health tests to confirm the fill

quality of the finished seal system.

5.1.2 Testing

Emerson’s vapor pressure curves are derived from empirical lab testing in real devices at

both vacuum conditions and at the maximum continuous temperature at one atmosphere

of pressure. The maximum continuous temperature at one atm of pressure correlates to

the thermal stability of the fill fluid, which is the maximum temperature the fill fluid will

remain in its original molecular form. Over time, exceeding the maximum recommended

temperature may result is the decomposition or vaporization of the fill fluid, resulting in

device failure.

5.2 Fill fluid selection

Fill fluid selection is very important to the safety and reliability of your measurement

application.

5.2.1 Type of fill fluid

Different types of fill fluids exist to meet the needs of different applications. An all-purpose

fill fluid can be used in most applications. However, some processes might require a fill

fluid that is chemically inert to avoid reactions with oxygen. In the food and

pharmaceutical industries, a hygienic fill fluid may be needed that meets various industry

standards.

Rosemount DP Level 93

You might also like

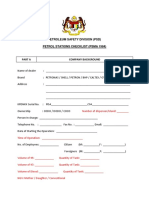

- Petrol Station Checklist AuditDocument10 pagesPetrol Station Checklist AuditrizamryNo ratings yet

- Boiler Control Systems Engineering, Second EditionFrom EverandBoiler Control Systems Engineering, Second EditionRating: 4.5 out of 5 stars4.5/5 (15)

- Process Industry Practices Insulation: PIP INEG1000 Insulation Design GuideDocument38 pagesProcess Industry Practices Insulation: PIP INEG1000 Insulation Design GuidethakrarhitsNo ratings yet

- Diaphragm Seal Filling GuideDocument14 pagesDiaphragm Seal Filling GuideKrishnaraj DhavalaNo ratings yet

- SCP Foxboro Control SimulationDocument4 pagesSCP Foxboro Control SimulationTeddy PahlewiNo ratings yet

- 998-20934418 Capabilities-BrochureDocument59 pages998-20934418 Capabilities-BrochureTeddy PahlewiNo ratings yet

- Invensys Foxboro IA Series Software ManualDocument18 pagesInvensys Foxboro IA Series Software ManualTeddy PahlewiNo ratings yet

- Corsair FSMDocument894 pagesCorsair FSMDanny MannoNo ratings yet

- Hydro Test ProcedureDocument10 pagesHydro Test Proceduresamer8saifNo ratings yet

- Labrie Optimizer Maintenance Manual PDFDocument81 pagesLabrie Optimizer Maintenance Manual PDFstainless31620039126100% (1)

- Astm E479-91 R00 PDFDocument5 pagesAstm E479-91 R00 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Diaphragm Pump - Room 3Document16 pagesDiaphragm Pump - Room 3VinNo ratings yet

- Astm e 999Document5 pagesAstm e 999KEN KNo ratings yet

- Air-Operated Diaphragm Pumps: The Complete Guide ToDocument14 pagesAir-Operated Diaphragm Pumps: The Complete Guide ToAnonymous Kr13NEBNo ratings yet

- Enviroaire T/Tvs Series: 75Kw-160Kw Oil-Free Rotary Screw Compressors Fixed & Variable SpeedDocument16 pagesEnviroaire T/Tvs Series: 75Kw-160Kw Oil-Free Rotary Screw Compressors Fixed & Variable SpeedSuresh NathNo ratings yet

- Flowcem: A Three-Component, Self-Smoothing, Epoxy-Cement Composite, Levelling Material For Uneven Substrate RepairDocument2 pagesFlowcem: A Three-Component, Self-Smoothing, Epoxy-Cement Composite, Levelling Material For Uneven Substrate RepairQuoc AnNo ratings yet

- IOM DUrcoDocument28 pagesIOM DUrcoAlex RodriguezNo ratings yet

- Bombas GrundfosDocument8 pagesBombas GrundfosLuis D. RodriguezNo ratings yet

- Chemical Resistance GuideDocument11 pagesChemical Resistance GuideMohamed NouzerNo ratings yet

- Tds Silfoam Se 90Document1 pageTds Silfoam Se 90laboratorioiqrhgNo ratings yet

- Go With The Flow: in Selecting The Right FluidDocument3 pagesGo With The Flow: in Selecting The Right FluidMetwally NaserNo ratings yet

- Pompa Lewa D1-450en Ecodos 04 11 Screen 09Document12 pagesPompa Lewa D1-450en Ecodos 04 11 Screen 0919poeNo ratings yet

- Nonvolatile Matter (Total Solids) in Water-Emulsion Floor Polishes, Solvent-Based Floor Polishes, and Polymer-Emulsion Floor PolishesDocument2 pagesNonvolatile Matter (Total Solids) in Water-Emulsion Floor Polishes, Solvent-Based Floor Polishes, and Polymer-Emulsion Floor PolishesTrầnXuânSơnNo ratings yet

- Astm D1353 13Document1 pageAstm D1353 13Doungjai PNo ratings yet

- AY e BSDocument156 pagesAY e BSJosias BorgesNo ratings yet

- Hydraulic Fluid Quality in Aircraft Hydraulic Systems PDFDocument13 pagesHydraulic Fluid Quality in Aircraft Hydraulic Systems PDFApanreza VitalyNo ratings yet

- AOC 2009corrosion Guide List of Chemicals To StoreDocument32 pagesAOC 2009corrosion Guide List of Chemicals To StoreDesmond KhorNo ratings yet

- Flexible Diaphragms Provide Solutions: Facebooktwitterlinkedin மே லும்Document9 pagesFlexible Diaphragms Provide Solutions: Facebooktwitterlinkedin மே லும்Udhayakumar VenkataramanNo ratings yet

- Chemical Guide Caen Ipex PVDFDocument18 pagesChemical Guide Caen Ipex PVDFAjyal Union Ltd. Co.No ratings yet

- ASTM E999 2005 Reapproved 2010 StandardDocument5 pagesASTM E999 2005 Reapproved 2010 StandardCK CkkouNo ratings yet

- DuPont Kalrez Brochure 2011 PDFDocument12 pagesDuPont Kalrez Brochure 2011 PDFTim kuNo ratings yet

- Dupont Material Compatibility General - Chemical - ResistanceDocument39 pagesDupont Material Compatibility General - Chemical - ResistanceCecep AtmegaNo ratings yet

- Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants Using A Rotational ViscometerDocument18 pagesLow-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants Using A Rotational ViscometerShaker QaidiNo ratings yet

- Oel Gas E 03 2015Document24 pagesOel Gas E 03 2015Dennis Koay GMNo ratings yet

- Types of Hydraulic FluidsDocument5 pagesTypes of Hydraulic FluidsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- Catalog HydrSeals PTD3350-ENDocument162 pagesCatalog HydrSeals PTD3350-ENMarcelo Godinho BatistaNo ratings yet

- FR3 Info Na3076878Document8 pagesFR3 Info Na3076878classicalgasNo ratings yet

- Sec 5 Se 999Document5 pagesSec 5 Se 999Jhon HernandezNo ratings yet

- Sec 5 Se 999Document5 pagesSec 5 Se 999Jhon HernandezNo ratings yet

- Mechanical Seal Failure Troubleshooting Guide: Bell & Gossett Centrifugal PumpsDocument18 pagesMechanical Seal Failure Troubleshooting Guide: Bell & Gossett Centrifugal Pumpsmasterplumber100% (2)

- E999 PDFDocument5 pagesE999 PDFAndy Quintero100% (1)

- Manual Instruction For Plastic Pumps Ver. 1.15Document36 pagesManual Instruction For Plastic Pumps Ver. 1.15Dmitry DauhalNo ratings yet

- Mobilfluid 125: Extra High Performance Power Transmission FluidDocument2 pagesMobilfluid 125: Extra High Performance Power Transmission FluidtribolasNo ratings yet

- Ipi SeminarDocument17 pagesIpi SeminarSakthivel PalaniNo ratings yet

- Catalog HydrSeals PDE3350-GB PDFDocument148 pagesCatalog HydrSeals PDE3350-GB PDFjcleon108082No ratings yet

- Catalog Pradifa Hydrseals Pde3350-GbDocument148 pagesCatalog Pradifa Hydrseals Pde3350-GbRafaelOlivaRaylaRNo ratings yet

- Diaphragm Seal Design GuideDocument3 pagesDiaphragm Seal Design GuideErnesto Orihuela100% (1)

- Wilden Whitepaper Selecting Diaphragms July14-WebDocument4 pagesWilden Whitepaper Selecting Diaphragms July14-Webcarlo fernandezNo ratings yet

- D1-170 LEWA Ecosmart en UsDocument20 pagesD1-170 LEWA Ecosmart en Uscandra trisilawatiNo ratings yet

- ASTM E1417-2013-Standard Practice For Liquid Penetrant TestingDocument11 pagesASTM E1417-2013-Standard Practice For Liquid Penetrant Testinggaboac88100% (1)

- Windshields: Hydraulic System Maintenance ChecklistDocument7 pagesWindshields: Hydraulic System Maintenance ChecklistPriyankaNo ratings yet

- Flowserve CPX CPXR CPXN Manual PDFDocument28 pagesFlowserve CPX CPXR CPXN Manual PDFHtet HlaingNo ratings yet

- Grundfosliterature 5271530Document10 pagesGrundfosliterature 5271530Muhammad Hasbi AsidiqiNo ratings yet

- Expert Series Diaphragm PumpsDocument56 pagesExpert Series Diaphragm PumpsratheeshNo ratings yet

- General Instructions 5715-735UKDocument5 pagesGeneral Instructions 5715-735UKmanuel sebastian avendanoNo ratings yet

- Pde3350 GB PDFDocument148 pagesPde3350 GB PDFstrafforNo ratings yet

- Antifoam Solutions Brochure InddDocument0 pagesAntifoam Solutions Brochure Inddhisham_00No ratings yet

- EN Brochure Frese Ref Industrial Cooling Applications PDFDocument8 pagesEN Brochure Frese Ref Industrial Cooling Applications PDFSushma PanditNo ratings yet

- Dow Therm J SpecificationsDocument28 pagesDow Therm J SpecificationsClintronicNo ratings yet

- INS201 6.0 FUELSTAT InstructionsDocument4 pagesINS201 6.0 FUELSTAT InstructionsFotis AndrianopoulosNo ratings yet

- Gum Content in Fuels by Jet Evaporation: Standard Test Method ForDocument6 pagesGum Content in Fuels by Jet Evaporation: Standard Test Method ForDan MatNo ratings yet

- AOC Corrosion GuideDocument36 pagesAOC Corrosion GuidebiondimiNo ratings yet

- 3M FAQ FluorinertDocument27 pages3M FAQ Fluorinertpaingod1No ratings yet

- ASTM D3933 Standard Guide For Preparation of Aluminum Surfaces For Structural Adhesives Bonding (Phosphoric Acid Anodizing)Document5 pagesASTM D3933 Standard Guide For Preparation of Aluminum Surfaces For Structural Adhesives Bonding (Phosphoric Acid Anodizing)sangho moonNo ratings yet

- Parker O RingDocument0 pagesParker O RingRazvan C GoranNo ratings yet

- Sampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts For Testing PurposesDocument3 pagesSampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts For Testing PurposesMaxNo ratings yet

- Gates - Industial Hose ProductsDocument88 pagesGates - Industial Hose ProductsicscoNo ratings yet

- Antifoam Solutions Brochure Indd PDFDocument12 pagesAntifoam Solutions Brochure Indd PDFRomán M Martín del CNo ratings yet

- Appendix D 210618 - 1 - 2 - 2 - 2 - 3Document2 pagesAppendix D 210618 - 1 - 2 - 2 - 2 - 3Teddy PahlewiNo ratings yet

- Appendix D 210618 - 1 - 2 - 2 - 2 - 2Document1 pageAppendix D 210618 - 1 - 2 - 2 - 2 - 2Teddy PahlewiNo ratings yet

- E M A S G: S A E T: Nergy Anagement Lgorithms in Mart Rids Tate of The RT and Merging RendsDocument21 pagesE M A S G: S A E T: Nergy Anagement Lgorithms in Mart Rids Tate of The RT and Merging RendsTeddy PahlewiNo ratings yet

- Ecostruxure Hybrid Dcs - Faq: - End UserDocument7 pagesEcostruxure Hybrid Dcs - Faq: - End UserTeddy PahlewiNo ratings yet

- Classroom Courses: Process Automation Learning ServicesDocument136 pagesClassroom Courses: Process Automation Learning ServicesTeddy PahlewiNo ratings yet

- 3750 Pulpress Pressurisation Unit: Installation and Operating InstructionsDocument14 pages3750 Pulpress Pressurisation Unit: Installation and Operating InstructionsRonNo ratings yet

- Massive Leak of Liquefied Chlorine GasDocument31 pagesMassive Leak of Liquefied Chlorine GasAbdullahNo ratings yet

- Desmi Esl 100-180Document32 pagesDesmi Esl 100-180Kostya ChevdarNo ratings yet

- Pipeline Condition Assessment - Peter Henley, WRC InfrastructureDocument6 pagesPipeline Condition Assessment - Peter Henley, WRC InfrastructureZAMIRNo ratings yet

- Bluegrass Living Propane Heater Installation GuideDocument32 pagesBluegrass Living Propane Heater Installation GuideJeremyNo ratings yet

- BS en 13160-1 2016Document26 pagesBS en 13160-1 2016CK CkkouNo ratings yet

- Cryogenic Pump 2011 3 (Nikisso)Document12 pagesCryogenic Pump 2011 3 (Nikisso)Leonidas PetrouNo ratings yet

- Non-Destructive Testing of Pipes and Tubes - : Methods ForDocument14 pagesNon-Destructive Testing of Pipes and Tubes - : Methods FordoyenofcastleNo ratings yet

- Air Testing TanksDocument2 pagesAir Testing TanksTatiana CruzNo ratings yet

- Checklist Before Taking Possession of Your New HomeDocument18 pagesChecklist Before Taking Possession of Your New HomeShashikant TripathiNo ratings yet

- Calibrated Leak OverviewDocument4 pagesCalibrated Leak OverviewSharat ChandraNo ratings yet

- Spm-Flow-Catalogue 19.11.2018-MinDocument65 pagesSpm-Flow-Catalogue 19.11.2018-MinChuoi Do100% (1)

- Piston Grasso 6 Installation and Maintenance Manual PDFDocument86 pagesPiston Grasso 6 Installation and Maintenance Manual PDFWilson Rodriguez BustamanteNo ratings yet

- Psa012b821bf EnglishDocument52 pagesPsa012b821bf EnglishDirt FilterNo ratings yet

- A 7Document139 pagesA 7cata1108100% (2)

- Me8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeDocument12 pagesMe8694 - Hydraulics and Pneumatics: Arulprakasam G Assistant Professor Dept - Of.mech - Engg., Kit-CbeArul Prakasam GNo ratings yet

- Reliable Leakage DetectionDocument14 pagesReliable Leakage DetectionNitin KaleNo ratings yet

- Advance UHT Processing Technical TraininDocument71 pagesAdvance UHT Processing Technical TraininĐivềphía Mặt Trời100% (2)

- Unitor ASSEMBLY MANUALDocument6 pagesUnitor ASSEMBLY MANUALSvetlana TNo ratings yet

- MN202001EN Transformador Pad MountedDocument32 pagesMN202001EN Transformador Pad MountedHector AnaribaNo ratings yet

- Amendment No. 2 February 2021 To Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerDocument8 pagesAmendment No. 2 February 2021 To Is 11329: 2018 Finned Type Heat Exchanger For Room Air ConditionerAMIT VERMANo ratings yet

- API Standard 653 - Tank Inspection, Repair, Alteration, and ReconstructionDocument14 pagesAPI Standard 653 - Tank Inspection, Repair, Alteration, and Reconstructionbakkali_bilalNo ratings yet

- Cylinder Pressure TestDocument4 pagesCylinder Pressure TestPILAR MARTINEZNo ratings yet

- AMOT Datasheet C Thermostatic Valve 0512 Rev6Document12 pagesAMOT Datasheet C Thermostatic Valve 0512 Rev6mlfaranoNo ratings yet