Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 views3 s2.0 B9780323852104200015 Main

3 s2.0 B9780323852104200015 Main

Uploaded by

afdalflyweel341Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Principles of Polymer EngineeringDocument403 pagesPrinciples of Polymer EngineeringWs Lim83% (6)

- Cement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFDocument325 pagesCement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFAngel Baraoed100% (3)

- 10 1016@j Jclepro 2019 119679Document87 pages10 1016@j Jclepro 2019 119679CIVIL ENGINEERINGNo ratings yet

- (117 122) V13N1CTDocument6 pages(117 122) V13N1CTNaveen KumarNo ratings yet

- BF02708502Document4 pagesBF02708502N SHYAMANANDA SINGHNo ratings yet

- Chemical EngineeringDocument287 pagesChemical EngineeringSleek KastrowNo ratings yet

- Reference Book On Chemical Eng 1Document363 pagesReference Book On Chemical Eng 1Belal Abduallh Naser86% (7)

- IndexDocument15 pagesIndexAkhwari W. PamungkasjatiNo ratings yet

- Strength Properties of Fly Ash and GGBSDocument9 pagesStrength Properties of Fly Ash and GGBSVaishnavi HallikarNo ratings yet

- MétallurgieDocument7 pagesMétallurgieOUSSAMA BEN OMARNo ratings yet

- E P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariaDocument13 pagesE P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariamajedsalehNo ratings yet

- Sustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source MaterialsDocument11 pagesSustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source Materialsjyothi ramaswamyNo ratings yet

- Workability and Mechanical Properties of Alkali Activated Slag ConcreteDocument4 pagesWorkability and Mechanical Properties of Alkali Activated Slag ConcretesanjusamsonNo ratings yet

- 1 s2.0 S2214509522005472 MainDocument13 pages1 s2.0 S2214509522005472 MainSuwan De SilvaNo ratings yet

- Porcelana de Revestimento Elétrico - Argamassa AutonivelanteDocument16 pagesPorcelana de Revestimento Elétrico - Argamassa AutonivelanteDjalma NetoNo ratings yet

- Degirmenci CS 2017 0033 PDFDocument11 pagesDegirmenci CS 2017 0033 PDFRAHUL GUNDEBOMMUNo ratings yet

- Principles of Polymer EngineeringDocument403 pagesPrinciples of Polymer Engineeringtobias vazanoNo ratings yet

- 42 JMES Belmokhtar 2016 PDFDocument7 pages42 JMES Belmokhtar 2016 PDFJesha LibreaNo ratings yet

- Minor Project PPT Stage 2Document20 pagesMinor Project PPT Stage 2abhishekpatil008855No ratings yet

- Influence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesDocument16 pagesInfluence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesShaker QaidiNo ratings yet

- IndxDocument10 pagesIndxIhab AbbadiNo ratings yet

- Salinan 79 - E - KPT - 2023 - SINERGI - SINTA 1 - 31 Agustus 2023Document10 pagesSalinan 79 - E - KPT - 2023 - SINERGI - SINTA 1 - 31 Agustus 2023Ian IanNo ratings yet

- (183 190) V8N7CTDocument8 pages(183 190) V8N7CTMichael GelongNo ratings yet

- Final Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDocument8 pagesFinal Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDr. P SWAMY NAGA RATNA GIRINo ratings yet

- Effect of GGBS On Corrosion of Rebar in ConcreteDocument9 pagesEffect of GGBS On Corrosion of Rebar in ConcreteSrinivas AyyalasomayajulaNo ratings yet

- Index - 2016 - Industrial Chemical Process Analysis and DesignDocument11 pagesIndex - 2016 - Industrial Chemical Process Analysis and DesignSa SaNo ratings yet

- Index: To ofDocument5 pagesIndex: To ofAswin GNo ratings yet

- Multisored BuildingDocument61 pagesMultisored BuildingKaushiki KambojNo ratings yet

- S235271022100797XDocument12 pagesS235271022100797XVidyadhara VNo ratings yet

- LolDocument9 pagesLolCesar DuarteNo ratings yet

- Impact of Electric Arc Furnace Slag On Geopolymer Composites Exposed To Sulphate SolutionDocument15 pagesImpact of Electric Arc Furnace Slag On Geopolymer Composites Exposed To Sulphate SolutionHamada Shoukry MohammedNo ratings yet

- Mechanical Properties of Fly Ash Based Geopolymer Concrete With Addition of GgbsDocument6 pagesMechanical Properties of Fly Ash Based Geopolymer Concrete With Addition of GgbskarskotNo ratings yet

- 31 Properties of Fly Ash and Slag BlendedDocument6 pages31 Properties of Fly Ash and Slag Blendedaishwarya badkulNo ratings yet

- 3 s2.0 B9780443192159200017 MainDocument10 pages3 s2.0 B9780443192159200017 Main7fkqx7zh7pNo ratings yet

- Reference Book On Chemical Engineering V.I - D. Sen - 1 Ed (Libro Ingles)Document363 pagesReference Book On Chemical Engineering V.I - D. Sen - 1 Ed (Libro Ingles)Fercho CortesNo ratings yet

- Propiedades Mecánicas Del Hormigón Autocompactante Con Diferentes Aditivos Minerales Tras Exposición A Altas TemperaturasDocument8 pagesPropiedades Mecánicas Del Hormigón Autocompactante Con Diferentes Aditivos Minerales Tras Exposición A Altas TemperaturasJuan Diego LeonNo ratings yet

- 1 s2.0 S2352710221015564 MainDocument15 pages1 s2.0 S2352710221015564 MainjavedisrafNo ratings yet

- Analysis of Mix Design of Concrete Using Ceramic WasteDocument6 pagesAnalysis of Mix Design of Concrete Using Ceramic WasteEditor IJAERDNo ratings yet

- Sulphate Resistance and Eco-Friendliness of Geopolymer ConcretesDocument11 pagesSulphate Resistance and Eco-Friendliness of Geopolymer Concretessriram852852No ratings yet

- 2021 Evaluation of The Red Mud and Quartz Sand On Reinforced Metazeolite-Based Geopolymer CompositesDocument11 pages2021 Evaluation of The Red Mud and Quartz Sand On Reinforced Metazeolite-Based Geopolymer CompositesnurulmienNo ratings yet

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureDocument9 pagesEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelNo ratings yet

- ProjectDocument43 pagesProjectPavan Kalyan JennyNo ratings yet

- DR - Mohamed Ali-UCLA PresentationDocument10 pagesDR - Mohamed Ali-UCLA PresentationDr. Mohamed AliNo ratings yet

- Reuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsDocument10 pagesReuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsfoufouNo ratings yet

- Targan 2002Document8 pagesTargan 2002SÜLEYMAN ÖZENNo ratings yet

- 2017 Strength Permeability and Micro-Structural Characteristics of Low Calcium Fly Ash Based GeopolymersDocument10 pages2017 Strength Permeability and Micro-Structural Characteristics of Low Calcium Fly Ash Based GeopolymersAjmal MuhammedNo ratings yet

- Puertas, Vazquez - 1999 - Puertas1999.PDF - Cement and Concrete ResearchDocument8 pagesPuertas, Vazquez - 1999 - Puertas1999.PDF - Cement and Concrete ResearchmushfiqueNo ratings yet

- 1 s2.0 S027288422200181X MainDocument13 pages1 s2.0 S027288422200181X MainSAMANT RANANo ratings yet

- Laporan Penyelidikan - MsiDocument58 pagesLaporan Penyelidikan - MsiMohd Shahrom IsmailNo ratings yet

- IndexDocument16 pagesIndexHamiltonNo ratings yet

- Draft Proof HiDocument25 pagesDraft Proof Hilahcen essNo ratings yet

- Effect of Spinel Addition On Properties of Mag-Carbon BricsDocument51 pagesEffect of Spinel Addition On Properties of Mag-Carbon BricsSandip KumarNo ratings yet

- Effects of Nano-Silica On Slag Based Geopolymer: A Project Report Submitted byDocument52 pagesEffects of Nano-Silica On Slag Based Geopolymer: A Project Report Submitted byNa oo Saki GarodNo ratings yet

- Author Version ManuscriptDocument24 pagesAuthor Version Manuscriptlahcen essNo ratings yet

- Ms. A.Uma Maheswari: Geopolymer ConcreteDocument25 pagesMs. A.Uma Maheswari: Geopolymer ConcreteKomali Vidya KomaliNo ratings yet

- Experimental Modeling of Temperature Rise of Mass Concrete by FDM MethodDocument8 pagesExperimental Modeling of Temperature Rise of Mass Concrete by FDM Methodcalvin wongNo ratings yet

- Strength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeDocument6 pagesStrength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeJason BorejszoNo ratings yet

- Cementitious Materials for Nuclear Waste ImmobilizationFrom EverandCementitious Materials for Nuclear Waste ImmobilizationRating: 4 out of 5 stars4/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

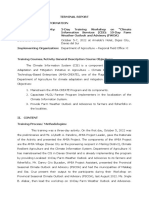

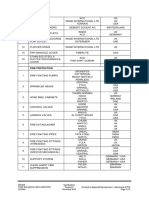

- Terminal-Report - 10-Day FwoaDocument4 pagesTerminal-Report - 10-Day FwoaChristan John AbrenicaNo ratings yet

- Lawson 1996Document8 pagesLawson 1996Gönenç Can AltunNo ratings yet

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinNo ratings yet

- War in PeaceDocument10 pagesWar in PeacePaoloViarengoNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/33 May/June 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/33 May/June 2022Muhammad MuddassirNo ratings yet

- METHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthyDocument8 pagesMETHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthySikandar KhanNo ratings yet

- Storage and Utilization of Biological Fuels.: Goodman HM. Basic Medical Endocrinology, 4 Ed. 2009. Elsevier, PhiladelphiaDocument23 pagesStorage and Utilization of Biological Fuels.: Goodman HM. Basic Medical Endocrinology, 4 Ed. 2009. Elsevier, PhiladelphiaVita Arya UtamiNo ratings yet

- Voorbeeldtentamen Wiskunde B 1 - ENDocument9 pagesVoorbeeldtentamen Wiskunde B 1 - ENRishika GoswamiNo ratings yet

- First Impressions of Mexico CityDocument2 pagesFirst Impressions of Mexico City4186072620893No ratings yet

- Ion PropulsionDocument16 pagesIon PropulsionMimsisiNo ratings yet

- British Universal Columns and BeamsDocument4 pagesBritish Universal Columns and BeamsblaqhaqarNo ratings yet

- N4のことばDocument18 pagesN4のことばFergianoNo ratings yet

- Vendor ListDocument1 pageVendor ListbhimaNo ratings yet

- Hardox® 600: General Product DescriptionDocument2 pagesHardox® 600: General Product DescriptionTimur SonkayaNo ratings yet

- Psychometric Success Mechanical Reasoning Practice Test 1Document0 pagesPsychometric Success Mechanical Reasoning Practice Test 1felixdelaliNo ratings yet

- Unit III Part XIDocument11 pagesUnit III Part XIPrakash KatdareNo ratings yet

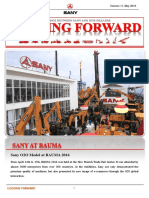

- SANY CRM TrainingDocument9 pagesSANY CRM Traininggirish_patkiNo ratings yet

- 30MHZ AM ReceiverDocument1 page30MHZ AM ReceiverrujNo ratings yet

- Jurnal Belimbing WuluhDocument6 pagesJurnal Belimbing WuluhPuspitasari NurulNo ratings yet

- Livingston County Eclipse GuideDocument4 pagesLivingston County Eclipse GuideThe Livingston County NewsNo ratings yet

- 06 - Admin & ShopsDocument3 pages06 - Admin & ShopsfebousNo ratings yet

- SD MaterialsDocument8 pagesSD MaterialsJp LevisteNo ratings yet

- Going CriticalDocument495 pagesGoing CriticalStoica Mariana FlorentinaNo ratings yet

- Winning Woodwinds!: Beginning Band Method Book Supplement For: FluteDocument49 pagesWinning Woodwinds!: Beginning Band Method Book Supplement For: Flutewe weNo ratings yet

- Drummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkaDocument18 pagesDrummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkamikeXF100% (1)

- Q-A Ch-4 Tribals, DikusDocument3 pagesQ-A Ch-4 Tribals, Dikusyuvraj singhNo ratings yet

- Axis Horizontal Mounting-TamburrinoDocument4 pagesAxis Horizontal Mounting-TamburrinoGabriela RomeroNo ratings yet

- Civil Engineering SustainabilityDocument55 pagesCivil Engineering SustainabilityEinstine Opiso100% (1)

- Gradable and Non GradableDocument3 pagesGradable and Non GradableMaria Radew-KornackaNo ratings yet

- GNPF Practical Manual FinalDocument46 pagesGNPF Practical Manual FinalMonalisa SahooNo ratings yet

3 s2.0 B9780323852104200015 Main

3 s2.0 B9780323852104200015 Main

Uploaded by

afdalflyweel3410 ratings0% found this document useful (0 votes)

0 views9 pagesOriginal Title

3-s2.0-B9780323852104200015-main

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views9 pages3 s2.0 B9780323852104200015 Main

3 s2.0 B9780323852104200015 Main

Uploaded by

afdalflyweel341Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 9

Index

Note: ‘Page numbers followed by “f ” indicate figures those followed by “t” indicate tables.’

A Global Forum on Maintenance and Asset

Abrasion resistance, silica fume, 72 Management (GFMAM) Landscape,

Acid attack, 271 340

Aggregate interlock mechanism, 202, 202f human and technological resources,

Aggregate market, 1 357e358

Alite (tri-calcium silicate), 20e21 implementation plan, 340

Alkali activated materials, red mud macro environment, 357

cements and pastes physical engineering assets, 338

composition and properties, 292t production infrastructure, 358e359

compressive strength, 293, 293f Publicly Available Specification 55

dry cement systems, 293 (PAS 55), 338

shrinkage deformations, 293, 294f, 294t Series ISO 55000 asset management,

soluble glass density, 293 339e340

concretes Aurora Max, 166

alkaline component, 295 Australian cements

characteristics, 294, 295t general blended type (GB) cement, 29

compressive strength, 295f general purpose type (GP) cement, 29

mix design and properties, 296te297t properties, 30t

pressed materials standards, 28, 30t

mesopore size distribution, 299e300, types, 29t

300f

micropore volume, 300e301, 301f B

N2 adsorption/desorption isotherms, Bauxite red mud alkali activated cements

299f and concretes. See Red mud (bauxite

porosity and specific surface area, residue)

298e301 Belite (di-calcium silicate), 21e22

sample’s mix design, 299t Bending resistance

Alkali-silica reaction (ASR), 275e276 conservative approach, 212

Aluminate phase (tri-calcium aluminate), 22 histograms, design parameters, 213e214

Asset management systems and standards, 8 moment resistance, 211, 212te213t

asset, 338 parabolic rectangular stress-block, 211f

contextual factors scatterplots, 214, 214f

organizational context, 352e355 stress-strain distribution, 211

political context, 345e348 Blast furnace slag (BFS)

technological context, 348e352 chemical composition, 135, 136t

decision-support tools, 342e344 cooling process, 134

definition, 338 crystallized slag, 134

366 Index

Blast furnace slag (BFS) (Continued) Chicago O’Hare Modernization Project,

physical properties, 134e136, 135t 255e256

Blended cements, 27e28 Chloride penetration resistance, 269e271

Australian cements, 29 Circular economy, 119, 234f, 325e326,

comparative strength development, 28f 347e348

Bogue equations, 18 Clinker phase

Bond strength calculations, 18

bond stress, 208 composition, 17e20

database removal, 209 determination, 17e20

histograms, 210f direct methods, 18

pullout failure and splitting failure, indirect methods, 18

208e209 modified Bogue method, 18e20

scatterplot, 210, 210f mineralogical composition, 17

statistics, 209t properties, 20e23, 23t

Bricks, 127 Coal fly ash

Bridge construction, silica fume, 72 chemical characterization, 140, 141t

Burnt clay, 27 classification, 139t

coal combustion residue (CCR), 137

C physical properties, 140, 140t

Calcium silicate cement production, 12 pozzolans, 137

Carbonation resistance, 273e274 Coal power plant, 47f

Cement kiln dust, 330 Coarse recycled aggregates, 222, 244

Cement production coarse fraction, 196

cement types, 26e35 concrete waste, 197e198

chemical composition, 16e17 natural and recycled aggregate, 195, 196f

clinker phase particle size, mortar content, 196t

composition, 17e20 structural concrete, 195

hydration, 19e20, 20t Compressive strength, 186

properties, 20e23 Concrete

environmental impact, 35e42 flyash, 59

global, 11, 12f global warming, 162

hydration products, 24e26 landfills, 161e162

hydraulic cements, 11 natural resources, 162

manufacture recycling system, 165f

cement clinker, 14e15 silica fume, 71e73

clinker composition, 13 Construction and demolition waste (CDW)

dry process, 14e15 aggregates production, 119

pozzolanic reaction, 12 in Australia, 2e3

semidry process, 13 characteristics, 349e350

semiwet process, 13 in China, 2

tri-calcium silicates, 12 circular economy, 2, 234f

wet process, 13 definition, 1e2

Certifiable environmental standards, 352 in Europe, 2

Chemical attacks European aggregate production, 120

acid attack, 271 forms, 233

chloride penetration resistance, fractions, 1e2

269e271 generation, 348e349

sulfate, 268e269 organizational context, 354e355

Chemical resistance, silica fume, 72 plant on-site, 350e351

Index 367

recycled aggregates Environmental impact, cement production

construction practices, 120e121 CO2 emission, 35, 36f

recycled concrete aggregate (RCA). See life cycle assessment, 35e38

Recycled aggregate concrete (RAC) Environmental Life Cycle Assessment

recycled masonry aggregate (RMA). See (E-LCA), 310

Recycled masonry aggregate (RMA) Environmental Product Declarations (EPD),

water absorption (WA), 131 348

recycling centers, 351e352 European cements

urban solid wastes, 119 clinker and constituents, 30e31

Construction Product Regulation (CPR), EN 197-1 standard, 31

348 strength classes, 33, 33t

Construction waste management (CWM) types and composition, 31te32t

model, 344 European Circular Construction Alliance

Corrosion resistance, 71, 274e275 (ECCA), 348

Cost Breakdown Structure (CBS), 343e344 European Portland cement clinkers, 19t

COVID-19, 1

Cradle-to-gate system boundary, 315f F

Cradle-to-grave system boundary, 315f Ferrite phase (tetra-calcium alumino-ferrite),

Crystallized slag, 134 22e23

Flexural strength, 188

D Fly ash

Demolished concrete, 161 characteristics, 48e49

Differential thermal analysis (DTA), chemical composition, 49, 50te51t

185e186 chemical requirements, 54, 55t

Diffusivity, 266e267 classification, 52e54

Dry process, 14e15 coal, 47

Durability color and size, 48

alkali-silica reaction (ASR), 275e276 concrete, 59

carbonation resistance, 273e274 construction industry, 54e59

chemical attacks, 268e271 elemental oxides, 52

corrosion resistance, 274e275 global production, 48, 48f

definition, 265 life cycle assessment (LCA), 93

external factors, 265 physical properties, 48, 49t

freeze and thaw cycles, 271e273 physical requirements, 54, 56te57t

gas penetration, 276e277 SEM micrograph, 49f

permeability, 266e267 utilization, 54

Dynamic Life Cycle Assessment (LCA) Foundry sand

framework, 327 chemical properties, 152

mechanical properties, 152t

E physical properties, 152t

Electric arc furnace slag (EAF-slag) Fracture energy, 201e202, 201t

chemical composition, 137, 138t Freeze and thaw cycles, 271e273

feed materials, 136 Frost resistance, 272, 273t

function, 136

mineral phases, 137 G

physical properties, 137, 137t General blended type (GB) cement, 29

Energy-disperse X-ray fluoresce (EDXRF), General purpose type (GP) cement, 29

17 Geopolymerization, 180e181

368 Index

Global Forum on Maintenance and Asset in concrete, 71e73

Management (GFMAM) Landscape, dry silica fume, 67

340 physical properties, 68e69

Granulated blast furnace slag (gbfs), 27 pozzolanic reaction, 69e71

Green Public Procurement (GPP), 347 production, 68f

Gypsum, 127 standards, 69

sugarcane bagasse ash (SCBA)

H characterization, 77e81

Hardened cement composites chemical composition, 81, 82t

compressive strength, 186 color variation, 79f

flexural strength, 188 physical properties, 78e81

Heating-rubbing method, 175 pozzolanic activity, 83

High strength concrete, silica fume, 72 waste glass. See Waste glass

Human and technological resources, Inert/incinerated sewage sludge

357e358 chemical characterization, 147t

Hydration products, cement distributions, 146f

calcium hydroxide crystals, 25 in EU, USA and China, 146t

calcium sulfate dissolution, 26 physical characteristics, 144e146, 146t

chemical composition, 24 International Institute for Sustainable

chemical reactions, 24e25 Development (IISD), 310

chemical shrinkage, 26

induction/dormant period, 24 L

Hydraulic cements, 11 Landfill Directive (99/31/EC), 346

Leaching, 127

I Life Cycle Assessment (LCA)

Industrial and agro-waste materials circular economy, 325e326

fly ash CO2 emission, 35

benefits, 54e59 concrete constituents, 324e325

characteristics, 48e49 databases available, 317e318, 318f

chemical requirements, 54 data reliability, 323e324

classification, 52e54 dynamic framework, 327

elemental oxides, 52 environmental impact, 4

as mineral admixture, 54 environmental impacts and management,

physical requirements, 54 329e330

utilization, 54 Environmental Life Cycle Assessment

life cycle assessment (LCA), 90e96 (E-LCA), 310

rice husk ash (RHA) fly ash, 93

ash characteristics, 73 four-phase framework, 310

burning, 73 functional unit (FU), 38e39, 39te40t

calorific value, 74e75 goal and scope

chemical composition, 75e76, 76t allocation method, 316

mechanical grinding, 75 concrete analysis, 312

microstructure changes, 73f functional unit, 313e314

physical properties, 75, 76t ISO 14040 standard, 312

pozzolanic activity, 77 objective, 311e312

processing, 74e75 product system, 313, 313f

utilization, 77 recycling stage, 313

silica fume reference flows, 313e314

chemical composition, 69 system boundary, 314

Index 369

interpretation, 42 elements in, 143

interpretation process, 322 mineral phases, 144

ISO 14040 and 14044 guidelines, 4, 311 physical properties, 143, 144t

Life Cycle Impact Assessment (LCIA),

41e42, 319e322 N

Life Cycle Inventory (LCI), 41, 316e317 Natural coarse aggregate (NCA), 166

Life Cycle Sustainability Assessment Nonstructural applications, 6

(LCSA) method, 327e329 case studies

palm oil fuel ash, 95 Chicago O’Hare Modernization Project,

phases, 342e343, 343t 255e256

Portland cement production, 37e38 “green” masonry bricks in China,

product phases, 4 257e258

rice husk ash, 94 Pelican Self Storage, 256e257

silica fume, 93 cement composites’ properties, 235te243t

software tools, 318e319, 319f recycled aggregate adoption, 249te253t

sugarcane bagasse ash, 95 coarse and fine types, 244

system boundary, 39te40t glass fiber reinforced polymer (GFRP),

systems thinking, 342 254

target audiences, 310 load-bearing members, 248

waste glass powder, 96 mechanical properties, 248e254

Life Cycle Costing (LCC), 343e344 microstructure, 245f

Life Cycle Impact Assessment (LCIA), 4, “parent” concrete, 245

41e42, 311 practices and issues, 246e247

characterization method, 321 selected regulations/standards, 247t

classification, 320 substitution rate, 244e245

endpoint method, 320 surface cracking, 244e245

grouping step, 322 technical studies, 234e245

impact categories, 319e320 TiO2 particles, 255f

mandatory parts, 319e320 supplementary cementitious materials

midpoint method, 320 (SCMs), 247

normalization process, 321e322

steps, 319, 320f O

weighting step, 322 Ordinary Portland cement, 26e27

Life Cycle Inventory (LCI), 4, 41, 316e317 Organizational partnerships, 353e354

Life Cycle Sustainability Assessment

(LCSA) method, 327e329 P

Los Angeles (LA) abrasion test, 133 Palm oil fuel ash (POFA)

Loss on ignition (LOI) chemical composition, 87e88, 89t

flyash, 52 color, 86

sugarcane bagasse ash (SCBA), 81 extraction and POFA production, 84

fineness, 86

M life cycle assessment (LCA), 95

Magnesium oxide (MgO), fly ash, 52 palm oil, 84

Mixed recycled aggregate (MRA), 122, 131 palm oil waste (POW), 85

Modified Bogue method, 18e20 physical properties, 85e86, 86te87t

Municipal solid waste (MSW) combustor pozzolanic activity, 88e90

ash shape, 86

bottom ash, 143 Palm oil waste (POW), 85

composition, 145t Parabolic rectangular stress-block, 211f

370 Index

Parent concrete, 245 hardened cement composites, 186e188

Pelican Self Storage, 256e257 recycling products properties, 184

Permeability and diffusivity supplementary cementitious material

natural aggregates, 266 (SCM), 185e186

pores volume and size, 267 pulsed power technology application. See

porosity, 266, 266f Pulsed power technology

standard water absorption test, 267 recycled concrete aggregate (RCA)

water absorption and RCA content, concrete mixture proportion, 169t

266e267, 267f crushing method, 165

water-cement ratio (W/C), 266e267 mechanical properties, 168e171, 169t

Portland cement, 11 physical properties, 168, 169f

chemical composition, 16e17 production and treatment, 167e171

chemical, fineness and heat of hydration, residual mortar, 165

34t surface hardness, 170

clinker phases thermal-mechanical-chemical process,

composition, 17e20 167e175

determination, 20e23 thermal-mechanical process, 167

properties, 20e23 treatment approaches, 166

hydration products, 24e26 ultrasonic pulse velocity (UPV),

life cycle assessment, 35e38 170e171, 171f

manufacture, 11e15 water absorption, 166

production, 11 removed residual mortar

types, 33e34, 33te34t geopolymerization, 180e181

Pozzolanic activity, 12 partial substitution, portland cement,

palm oil fuel ash (POFA), 88e90 179e180

rice husk ash (RHA), 77 vaterite conversion, 177e178

silica fume, 69e71

sugarcane bagasse ash (SCBA), 83 R

Precalcination, 14 Radon exhalation and emanation, 303e304

Production infrastructure, 358e359 Rapid infrastructure development, 162

Publicly Available Specification 55 (PAS 55), Recycled aggregate concrete (RAC)

338 adhered mortar, 124e125

Pulsed power technology application alkalis, 123e124

discharge treated concrete, 174f Belgian grading limits, 128f

discharge treatment, 171e172 ceramic, 121f

principles, 171 chloride content, 123

pulsed power generator, 171, 172f composition, 122e133

recycled concrete aggregate (RCA) contaminants, 126e127

vs. heating-rubbing method, 175 durability

prototype processor, 175, 176f alkali-silica reaction (ASR), 275e276

quality, 173e175, 175f carbonation resistance, 273e274

X-ray CT image, 172e173, 173f chemical attacks, 268e271

corrosion resistance, 274e275

Q definition, 265

Quality improvement external factors, 265

concrete rubble recycling, thermo- freeze and thaw cycles, 271e273

mechanical treatment gas penetration, 276e277

comprehensive recycling technology, permeability, 266e267

182e184 Japanese grading limits, 129f

Index 371

leaching, 127 composition, 121e133

mechanical behavior contaminants, 126e127

aggregate interlock mechanism, 202 density, 131

compressive strength, 199, 200f leaching, 127

fracture energy, 201e202 physical properties

vs. natural aggregate concrete (NAC), density, 131

196f Los Angeles (LA) coefficient, 133

shear strength, 202 water absorption (WA), 132

shrinkage, 200 sulfate content, 123

stiffness, 199e200 Red mud (bauxite residue)

stress-strain behavior, 199 alkali activated cement, 287, 288t

tensile strength, 200e201 alkali activated materials

Young’s modulus, 200 cements and pastes, 293e294

model uncertainty composition and properties, 292t

bending resistance, 211e214 concretes, 294e298

bond strength, 208e210 pressed materials, 298e301

concrete mix design, 205 radiological characterization, 301e304

definition, 205 alkali activation, 286

methodology, 206e207 alumina extraction, 283

reinforcement detailing and geometry, chemical and mineralogical composition,

205 284e286, 285t

resistance mechanisms, 205e206, disposal issues, 7

221e222 hardened cement paste, 287e291

resistance models, 205 electron microscopy studies, 290e291

shear resistance, 215e219 hydration products, 288

nonstructural applications. See klinoferrosilite, 289e290

Nonstructural applications microstructure formation, 288

physical properties phase composition, 288e289

density, 130e131 pore space, 291

resistance, 133 X-ray phase diffraction analysis, 289,

shape, 130 289f

size, 128e130 particle analysis, 286

water absorption (WA), 132 production and distribution, 283e284,

quality improvement. See Quality 283t

improvement safe disposal, 284

structural applications. See Structural RE4 project, 346

applications Resistance models, 205

structural behavior, 203e204 Rice husk ash (RHA)

sulfate content, 123 ash characteristics, 73

Recycled cement mortar (RCM) burning, 73

differential thermal analysis (DTA), calorific value, 74e75

185e186 chemical composition, 75e76, 76t

strength activity index (SAI), 185 life cycle assessment (LCA), 94

thermogravimetry (TG), 185e186 mechanical grinding, 75

Recycled masonry aggregate (RMA) microstructure changes, 73f

adhered mortar, 124 physical properties, 75, 76t

alkalis, 123e124 pozzolanic activity, 77

ceramic, 121f processing, 74e75

chloride content, 123 utilization, 77

372 Index

S shear resistance, 215e219

Saturated Surface-Dried Density (SSDD), structural elements, 203e204

131 Sugarcane bagasse ash (SCBA)

Scrap tires characterization, 77e81

composition, 142 chemical composition, 81, 82t

disposal, 142, 142t color variation, 78, 79f

physical properties, 142, 143t density, 81

Semidry process, 13 life cycle assessment (LCA), 95

Semiwet process, 13 physical properties, 78e81

Series ISO 55000 asset management, pozzolanic activity, 83

339e340 processing and ash production, 78f

Shear resistance specific gravity, 78

beams with shear reinforcement, 221f specific surface area (SSA), 81

beam validation, 216 Sulfate resistance, silica fume, 71

compression strut, 215 Supplementary cementitious materials

database inclusion, 216 (SCMs)

databases histograms, 217f categories, 28

elements without shear reinforcement, 215, chemical and microstructural

217t, 219t improvements, 27

NAC and RAC100 databases, 219, 220t granulated blast furnace slag (gbfs), 27

resistance model, 215 Surface hardness, 170

scatterplot, 218f

Shotcrete, silica fume, 72 T

Silica fume Thermal-mechanical-chemical processes,

chemical composition, 67, 69, 70t 164, 167e168

in concrete, 71e73 Thermal-mechanical process, 167

dry silica fume, 67 Tortuous fracture surfaces, 202

life cycle assessment (LCA), 93 Tunnel and mining operations, silica fume,

physical properties, 68e69, 69t 72

pozzolanic reaction, 69e71

production, 68f U

standards, 69, 71t Urban plastic waste

Soda-lime glass, 60 in municipal solid waste, 149t

Strength activity index (SAI), 185, 186f physical and chemical properties, 148e149

Strengths, Weaknesses, Opportunities, and production, 148f

Threats (SWOT) analysis, 344 volume, 148, 148f

Structural applications, 6 USA cements, 33e35

coarse recycled aggregates, 222

coarse fraction, 196 W

concrete waste, 197e198 Waste Framework Directive, 346

natural and recycled aggregate, 195, 196f Waste glass

particle size, mortar content, 196t amorphous silica, 60e61

structural concrete, 195 cementitious and supplementary

recycled aggregate concrete cementitious materials (SCMs), 67f

bending resistance, 211e214 chemical properties, 62e63, 64te65t, 151,

bond strength, 208e210 151t

mechanical behavior, 198e203 concrete manufacture, 61

methodology, 206e207 landfilling, 60

model uncertainty, 204e219 life cycle assessment (LCA), 96

Index 373

mechanical properties, 150t Waterproofing, silica fume, 72

as partial aggregate replacement, 66 Wave-disperse X-ray fluorescence

as partial cement replacement, 66 (WDXRF), 17

physical properties, 62, 63t, 150, 150t Wet process, 13

physicochemical properties, 61e63 Whole-life costing, 343e344

recycling, 60

role of, 61 X

soda-lime glass, 60 X-ray Fluorescence (XRF) analysis, 16e17,

Waste Management Plan (WMP), 354 81

Water absorption (WA), 131

You might also like

- Principles of Polymer EngineeringDocument403 pagesPrinciples of Polymer EngineeringWs Lim83% (6)

- Cement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFDocument325 pagesCement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFAngel Baraoed100% (3)

- 10 1016@j Jclepro 2019 119679Document87 pages10 1016@j Jclepro 2019 119679CIVIL ENGINEERINGNo ratings yet

- (117 122) V13N1CTDocument6 pages(117 122) V13N1CTNaveen KumarNo ratings yet

- BF02708502Document4 pagesBF02708502N SHYAMANANDA SINGHNo ratings yet

- Chemical EngineeringDocument287 pagesChemical EngineeringSleek KastrowNo ratings yet

- Reference Book On Chemical Eng 1Document363 pagesReference Book On Chemical Eng 1Belal Abduallh Naser86% (7)

- IndexDocument15 pagesIndexAkhwari W. PamungkasjatiNo ratings yet

- Strength Properties of Fly Ash and GGBSDocument9 pagesStrength Properties of Fly Ash and GGBSVaishnavi HallikarNo ratings yet

- MétallurgieDocument7 pagesMétallurgieOUSSAMA BEN OMARNo ratings yet

- E P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariaDocument13 pagesE P H V S C G T C: Mohd Warid Hussin, Lim Siong Kang, Fadhadli ZakariamajedsalehNo ratings yet

- Sustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source MaterialsDocument11 pagesSustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source Materialsjyothi ramaswamyNo ratings yet

- Workability and Mechanical Properties of Alkali Activated Slag ConcreteDocument4 pagesWorkability and Mechanical Properties of Alkali Activated Slag ConcretesanjusamsonNo ratings yet

- 1 s2.0 S2214509522005472 MainDocument13 pages1 s2.0 S2214509522005472 MainSuwan De SilvaNo ratings yet

- Porcelana de Revestimento Elétrico - Argamassa AutonivelanteDocument16 pagesPorcelana de Revestimento Elétrico - Argamassa AutonivelanteDjalma NetoNo ratings yet

- Degirmenci CS 2017 0033 PDFDocument11 pagesDegirmenci CS 2017 0033 PDFRAHUL GUNDEBOMMUNo ratings yet

- Principles of Polymer EngineeringDocument403 pagesPrinciples of Polymer Engineeringtobias vazanoNo ratings yet

- 42 JMES Belmokhtar 2016 PDFDocument7 pages42 JMES Belmokhtar 2016 PDFJesha LibreaNo ratings yet

- Minor Project PPT Stage 2Document20 pagesMinor Project PPT Stage 2abhishekpatil008855No ratings yet

- Influence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesDocument16 pagesInfluence of Recycling Waste Glass As Fine Aggregate On The Concrete PropertiesShaker QaidiNo ratings yet

- IndxDocument10 pagesIndxIhab AbbadiNo ratings yet

- Salinan 79 - E - KPT - 2023 - SINERGI - SINTA 1 - 31 Agustus 2023Document10 pagesSalinan 79 - E - KPT - 2023 - SINERGI - SINTA 1 - 31 Agustus 2023Ian IanNo ratings yet

- (183 190) V8N7CTDocument8 pages(183 190) V8N7CTMichael GelongNo ratings yet

- Final Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDocument8 pagesFinal Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDr. P SWAMY NAGA RATNA GIRINo ratings yet

- Effect of GGBS On Corrosion of Rebar in ConcreteDocument9 pagesEffect of GGBS On Corrosion of Rebar in ConcreteSrinivas AyyalasomayajulaNo ratings yet

- Index - 2016 - Industrial Chemical Process Analysis and DesignDocument11 pagesIndex - 2016 - Industrial Chemical Process Analysis and DesignSa SaNo ratings yet

- Index: To ofDocument5 pagesIndex: To ofAswin GNo ratings yet

- Multisored BuildingDocument61 pagesMultisored BuildingKaushiki KambojNo ratings yet

- S235271022100797XDocument12 pagesS235271022100797XVidyadhara VNo ratings yet

- LolDocument9 pagesLolCesar DuarteNo ratings yet

- Impact of Electric Arc Furnace Slag On Geopolymer Composites Exposed To Sulphate SolutionDocument15 pagesImpact of Electric Arc Furnace Slag On Geopolymer Composites Exposed To Sulphate SolutionHamada Shoukry MohammedNo ratings yet

- Mechanical Properties of Fly Ash Based Geopolymer Concrete With Addition of GgbsDocument6 pagesMechanical Properties of Fly Ash Based Geopolymer Concrete With Addition of GgbskarskotNo ratings yet

- 31 Properties of Fly Ash and Slag BlendedDocument6 pages31 Properties of Fly Ash and Slag Blendedaishwarya badkulNo ratings yet

- 3 s2.0 B9780443192159200017 MainDocument10 pages3 s2.0 B9780443192159200017 Main7fkqx7zh7pNo ratings yet

- Reference Book On Chemical Engineering V.I - D. Sen - 1 Ed (Libro Ingles)Document363 pagesReference Book On Chemical Engineering V.I - D. Sen - 1 Ed (Libro Ingles)Fercho CortesNo ratings yet

- Propiedades Mecánicas Del Hormigón Autocompactante Con Diferentes Aditivos Minerales Tras Exposición A Altas TemperaturasDocument8 pagesPropiedades Mecánicas Del Hormigón Autocompactante Con Diferentes Aditivos Minerales Tras Exposición A Altas TemperaturasJuan Diego LeonNo ratings yet

- 1 s2.0 S2352710221015564 MainDocument15 pages1 s2.0 S2352710221015564 MainjavedisrafNo ratings yet

- Analysis of Mix Design of Concrete Using Ceramic WasteDocument6 pagesAnalysis of Mix Design of Concrete Using Ceramic WasteEditor IJAERDNo ratings yet

- Sulphate Resistance and Eco-Friendliness of Geopolymer ConcretesDocument11 pagesSulphate Resistance and Eco-Friendliness of Geopolymer Concretessriram852852No ratings yet

- 2021 Evaluation of The Red Mud and Quartz Sand On Reinforced Metazeolite-Based Geopolymer CompositesDocument11 pages2021 Evaluation of The Red Mud and Quartz Sand On Reinforced Metazeolite-Based Geopolymer CompositesnurulmienNo ratings yet

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureDocument9 pagesEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelNo ratings yet

- ProjectDocument43 pagesProjectPavan Kalyan JennyNo ratings yet

- DR - Mohamed Ali-UCLA PresentationDocument10 pagesDR - Mohamed Ali-UCLA PresentationDr. Mohamed AliNo ratings yet

- Reuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsDocument10 pagesReuse of Fly Ash and Dredging Marine Sediments On Self-Compacting BackfillsfoufouNo ratings yet

- Targan 2002Document8 pagesTargan 2002SÜLEYMAN ÖZENNo ratings yet

- 2017 Strength Permeability and Micro-Structural Characteristics of Low Calcium Fly Ash Based GeopolymersDocument10 pages2017 Strength Permeability and Micro-Structural Characteristics of Low Calcium Fly Ash Based GeopolymersAjmal MuhammedNo ratings yet

- Puertas, Vazquez - 1999 - Puertas1999.PDF - Cement and Concrete ResearchDocument8 pagesPuertas, Vazquez - 1999 - Puertas1999.PDF - Cement and Concrete ResearchmushfiqueNo ratings yet

- 1 s2.0 S027288422200181X MainDocument13 pages1 s2.0 S027288422200181X MainSAMANT RANANo ratings yet

- Laporan Penyelidikan - MsiDocument58 pagesLaporan Penyelidikan - MsiMohd Shahrom IsmailNo ratings yet

- IndexDocument16 pagesIndexHamiltonNo ratings yet

- Draft Proof HiDocument25 pagesDraft Proof Hilahcen essNo ratings yet

- Effect of Spinel Addition On Properties of Mag-Carbon BricsDocument51 pagesEffect of Spinel Addition On Properties of Mag-Carbon BricsSandip KumarNo ratings yet

- Effects of Nano-Silica On Slag Based Geopolymer: A Project Report Submitted byDocument52 pagesEffects of Nano-Silica On Slag Based Geopolymer: A Project Report Submitted byNa oo Saki GarodNo ratings yet

- Author Version ManuscriptDocument24 pagesAuthor Version Manuscriptlahcen essNo ratings yet

- Ms. A.Uma Maheswari: Geopolymer ConcreteDocument25 pagesMs. A.Uma Maheswari: Geopolymer ConcreteKomali Vidya KomaliNo ratings yet

- Experimental Modeling of Temperature Rise of Mass Concrete by FDM MethodDocument8 pagesExperimental Modeling of Temperature Rise of Mass Concrete by FDM Methodcalvin wongNo ratings yet

- Strength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeDocument6 pagesStrength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeJason BorejszoNo ratings yet

- Cementitious Materials for Nuclear Waste ImmobilizationFrom EverandCementitious Materials for Nuclear Waste ImmobilizationRating: 4 out of 5 stars4/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Ultra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsFrom EverandUltra-High Temperature Ceramics: Materials for Extreme Environment ApplicationsWilliam G. FahrenholtzNo ratings yet

- Terminal-Report - 10-Day FwoaDocument4 pagesTerminal-Report - 10-Day FwoaChristan John AbrenicaNo ratings yet

- Lawson 1996Document8 pagesLawson 1996Gönenç Can AltunNo ratings yet

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinNo ratings yet

- War in PeaceDocument10 pagesWar in PeacePaoloViarengoNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/33 May/June 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/33 May/June 2022Muhammad MuddassirNo ratings yet

- METHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthyDocument8 pagesMETHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthySikandar KhanNo ratings yet

- Storage and Utilization of Biological Fuels.: Goodman HM. Basic Medical Endocrinology, 4 Ed. 2009. Elsevier, PhiladelphiaDocument23 pagesStorage and Utilization of Biological Fuels.: Goodman HM. Basic Medical Endocrinology, 4 Ed. 2009. Elsevier, PhiladelphiaVita Arya UtamiNo ratings yet

- Voorbeeldtentamen Wiskunde B 1 - ENDocument9 pagesVoorbeeldtentamen Wiskunde B 1 - ENRishika GoswamiNo ratings yet

- First Impressions of Mexico CityDocument2 pagesFirst Impressions of Mexico City4186072620893No ratings yet

- Ion PropulsionDocument16 pagesIon PropulsionMimsisiNo ratings yet

- British Universal Columns and BeamsDocument4 pagesBritish Universal Columns and BeamsblaqhaqarNo ratings yet

- N4のことばDocument18 pagesN4のことばFergianoNo ratings yet

- Vendor ListDocument1 pageVendor ListbhimaNo ratings yet

- Hardox® 600: General Product DescriptionDocument2 pagesHardox® 600: General Product DescriptionTimur SonkayaNo ratings yet

- Psychometric Success Mechanical Reasoning Practice Test 1Document0 pagesPsychometric Success Mechanical Reasoning Practice Test 1felixdelaliNo ratings yet

- Unit III Part XIDocument11 pagesUnit III Part XIPrakash KatdareNo ratings yet

- SANY CRM TrainingDocument9 pagesSANY CRM Traininggirish_patkiNo ratings yet

- 30MHZ AM ReceiverDocument1 page30MHZ AM ReceiverrujNo ratings yet

- Jurnal Belimbing WuluhDocument6 pagesJurnal Belimbing WuluhPuspitasari NurulNo ratings yet

- Livingston County Eclipse GuideDocument4 pagesLivingston County Eclipse GuideThe Livingston County NewsNo ratings yet

- 06 - Admin & ShopsDocument3 pages06 - Admin & ShopsfebousNo ratings yet

- SD MaterialsDocument8 pagesSD MaterialsJp LevisteNo ratings yet

- Going CriticalDocument495 pagesGoing CriticalStoica Mariana FlorentinaNo ratings yet

- Winning Woodwinds!: Beginning Band Method Book Supplement For: FluteDocument49 pagesWinning Woodwinds!: Beginning Band Method Book Supplement For: Flutewe weNo ratings yet

- Drummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkaDocument18 pagesDrummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkamikeXF100% (1)

- Q-A Ch-4 Tribals, DikusDocument3 pagesQ-A Ch-4 Tribals, Dikusyuvraj singhNo ratings yet

- Axis Horizontal Mounting-TamburrinoDocument4 pagesAxis Horizontal Mounting-TamburrinoGabriela RomeroNo ratings yet

- Civil Engineering SustainabilityDocument55 pagesCivil Engineering SustainabilityEinstine Opiso100% (1)

- Gradable and Non GradableDocument3 pagesGradable and Non GradableMaria Radew-KornackaNo ratings yet

- GNPF Practical Manual FinalDocument46 pagesGNPF Practical Manual FinalMonalisa SahooNo ratings yet