Professional Documents

Culture Documents

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

Uploaded by

Mark TaylorCopyright:

Available Formats

You might also like

- JTM K 07Document11 pagesJTM K 07Stiven Giraldo NuñezNo ratings yet

- CAP I - Paper 3B - MCQDocument59 pagesCAP I - Paper 3B - MCQNisarga Pokharel100% (1)

- ASTM D3195. Rotameter Calibration Std.Document4 pagesASTM D3195. Rotameter Calibration Std.Princess NobleNo ratings yet

- Final Report v.1-1Document31 pagesFinal Report v.1-1Damien NaiduNo ratings yet

- Methods of Calibration and Characterization of Temperature Controlled EnvironmentsDocument14 pagesMethods of Calibration and Characterization of Temperature Controlled EnvironmentsboddarambabuNo ratings yet

- Example of Measurement Uncertainty EstimationDocument7 pagesExample of Measurement Uncertainty EstimationCristiano PernichelliNo ratings yet

- ANSI_AHRI_Standard_1350_I-P_2014_with_Addendum_1_0Document40 pagesANSI_AHRI_Standard_1350_I-P_2014_with_Addendum_1_0hug.mer.muNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- MIC 2010 3 1haugenDocument13 pagesMIC 2010 3 1haugenIvan CujiaNo ratings yet

- CMC Review Protocol - Relative HumidityDocument7 pagesCMC Review Protocol - Relative HumidityNdra PompomorinNo ratings yet

- Determining The Coefficient of Thermal Expansion of ConcreteDocument8 pagesDetermining The Coefficient of Thermal Expansion of ConcreteLe PhamNo ratings yet

- Liebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorDocument6 pagesLiebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorCristian MendezNo ratings yet

- SOP10 - 20141022 - ReglasDocument9 pagesSOP10 - 20141022 - ReglasDiego LincangoNo ratings yet

- PRCCHA2 Sick Test1 2022 MemoDocument9 pagesPRCCHA2 Sick Test1 2022 Memopulezanele11No ratings yet

- Understanding The Technology: Estimation Method For Temperature Uncertainty of Temperature Chambers (JTM K 08)Document15 pagesUnderstanding The Technology: Estimation Method For Temperature Uncertainty of Temperature Chambers (JTM K 08)Rafael DiasNo ratings yet

- 1391 1Document26 pages1391 1Aaron AngNo ratings yet

- Book For Cooling LoadDocument9 pagesBook For Cooling LoadeanestNo ratings yet

- JTM K 08 Estimation Temperature Uncertainty Temperature Chambers PDFDocument14 pagesJTM K 08 Estimation Temperature Uncertainty Temperature Chambers PDFStiven Giraldo NuñezNo ratings yet

- Technical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Document6 pagesTechnical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Murphy's LawNo ratings yet

- Experiment 2: Heat Transfer From Finned SurfacesDocument5 pagesExperiment 2: Heat Transfer From Finned SurfacesAlexNo ratings yet

- Lab F Linear MPCDocument2 pagesLab F Linear MPCHabiyaremye JosephNo ratings yet

- Kalibrasi EnclosurDocument20 pagesKalibrasi Enclosurmuslim1583No ratings yet

- 3361701Document7 pages3361701josephNo ratings yet

- Flow Measurement by Orifice Meter and by Ventury Meter BOMBAYDocument7 pagesFlow Measurement by Orifice Meter and by Ventury Meter BOMBAYCedric GallusNo ratings yet

- Gas ChromatographDocument20 pagesGas ChromatographkstaziNo ratings yet

- Bubblg Effect EvaporaturDocument4 pagesBubblg Effect Evaporaturnn1129374No ratings yet

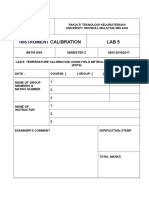

- Lab 5 - Thermocouple Temperature Calibration (PRTS)Document7 pagesLab 5 - Thermocouple Temperature Calibration (PRTS)Slim ShaddysNo ratings yet

- Thermodynamics Lab1Document20 pagesThermodynamics Lab1Alina AbdikadyrNo ratings yet

- D1071-83 (2008) Standard Test Methods For Volumetric Measurement of Gaseous Fuel SamplesDocument13 pagesD1071-83 (2008) Standard Test Methods For Volumetric Measurement of Gaseous Fuel SamplesIrsanNo ratings yet

- Characterization and Analysis of The Efficiency of A Hermetic CompressorDocument7 pagesCharacterization and Analysis of The Efficiency of A Hermetic CompressorMohammed Naim UddinNo ratings yet

- Testo 184 ManualDocument18 pagesTesto 184 Manualmirnes cakarNo ratings yet

- TSD 02 PDFDocument5 pagesTSD 02 PDFgeetanjaliNo ratings yet

- Worded It PDF RenderDocument28 pagesWorded It PDF RenderRoyale StudentsNo ratings yet

- Confort SensoresDocument14 pagesConfort SensoresReynaldo AparicioNo ratings yet

- HT302 C3bDocument17 pagesHT302 C3bAnuj BhawsarNo ratings yet

- Labreport 2 Pegtestatbmgroup 2 Section 2Document15 pagesLabreport 2 Pegtestatbmgroup 2 Section 2Fathi IrsyadNo ratings yet

- 10 18038-Estubtda 1217193-2823853Document9 pages10 18038-Estubtda 1217193-2823853Can EkiciNo ratings yet

- 1391 2 2018 AMD4 Reff2022Document82 pages1391 2 2018 AMD4 Reff2022Abhishek SrivastvaNo ratings yet

- Modelling of Supply Air Jet From Diffusers of Four-Way Packaged Air-Conditioner For CFD Analysis On Unsteady Airflow in RoomDocument10 pagesModelling of Supply Air Jet From Diffusers of Four-Way Packaged Air-Conditioner For CFD Analysis On Unsteady Airflow in RoomdineshkanthtpNo ratings yet

- Models - Cfd.displacement VentilationDocument20 pagesModels - Cfd.displacement VentilationMarioNo ratings yet

- C 1155 - 95 - QzexntutotuDocument8 pagesC 1155 - 95 - QzexntutotuMuhammad NaumanNo ratings yet

- Technical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control SystemDocument126 pagesTechnical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control Systemh logoNo ratings yet

- Iso 7726-1998Document8 pagesIso 7726-1998felo345No ratings yet

- PWC 2003 TC12 021Document3 pagesPWC 2003 TC12 021AripinNo ratings yet

- L 03 (SS) (Ia&c) ( (Ee) Nptel)Document10 pagesL 03 (SS) (Ia&c) ( (Ee) Nptel)Abdelraheem S. AlkuorNo ratings yet

- C680Document22 pagesC680dinhtung2210100% (2)

- Effect of Thermostat Time Constant On Temperature Control and Energy ConsumptionDocument6 pagesEffect of Thermostat Time Constant On Temperature Control and Energy ConsumptionRagi Geetha RajendranNo ratings yet

- TP 2Document10 pagesTP 2Saint lazarusNo ratings yet

- A. Operation Manual Glossary: AppendixDocument10 pagesA. Operation Manual Glossary: AppendixГоран ГорановNo ratings yet

- 100 Nicol FinalDocument9 pages100 Nicol Finalshalini4071979No ratings yet

- Humidity/Temp. Barometer: Operation ManualDocument13 pagesHumidity/Temp. Barometer: Operation ManualTécnicos Volúmen CaliNo ratings yet

- MK Inkubator LaboratoryDocument4 pagesMK Inkubator LaboratoryFaris HadyanNo ratings yet

- Model Based ControlDocument6 pagesModel Based ControlIvan RadovicNo ratings yet

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDocument27 pagesCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenNo ratings yet

- ARTIGO Multi Input Single Output Control For Extending The Operating Range Generalized Slipt RangeDocument11 pagesARTIGO Multi Input Single Output Control For Extending The Operating Range Generalized Slipt RangerafaelfbacharelNo ratings yet

- Sample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyDocument30 pagesSample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyM.R.ZNo ratings yet

- Guidelines For Assessment of Temperature UniformitDocument4 pagesGuidelines For Assessment of Temperature UniformitGiaraf100% (1)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Factors Affecting The Willingness of Micro Enterprises To Adopt E-WalletsDocument9 pagesFactors Affecting The Willingness of Micro Enterprises To Adopt E-WalletsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Answer Sheet For Integrated Data Analysis Exercise1Document5 pagesAnswer Sheet For Integrated Data Analysis Exercise1Yul Bryan TolentinoNo ratings yet

- SAT Math5 AnswersDocument50 pagesSAT Math5 AnswersLuiza Andrade100% (1)

- Problem IDocument13 pagesProblem IJialu YangNo ratings yet

- A Project Submitted Towards Partial Fulfillment of The Requirements of For The Degree ofDocument67 pagesA Project Submitted Towards Partial Fulfillment of The Requirements of For The Degree ofBaiq LenyNo ratings yet

- Chapter 2 .2statDocument134 pagesChapter 2 .2statSherry-Ann TulauanNo ratings yet

- ASTM E 178 Dealing With Outlying ObservationsDocument11 pagesASTM E 178 Dealing With Outlying Observationsiel84749No ratings yet

- 1.05 Portfolio Mathematics - AnswersDocument7 pages1.05 Portfolio Mathematics - AnswersThe SpectreNo ratings yet

- Standard DeviationDocument9 pagesStandard DeviationPresana VisionNo ratings yet

- Stat 4091 Exercise2Document4 pagesStat 4091 Exercise2Random Existence100% (1)

- CFA 2024 Level I - Schweser QuicksheetDocument6 pagesCFA 2024 Level I - Schweser Quicksheetmichaelfamura97No ratings yet

- Statistics in ResearchDocument26 pagesStatistics in ResearchStevoh100% (2)

- ISO 17994-2014 Water-Compare Relative Recovery Microb Two MethodDocument30 pagesISO 17994-2014 Water-Compare Relative Recovery Microb Two MethodTrung Tín TrầnNo ratings yet

- Soal UTS Statekbis Genap 2019 2020 Set 1Document13 pagesSoal UTS Statekbis Genap 2019 2020 Set 1avri firdausNo ratings yet

- 2024 Specimen Mark Scheme Paper 2Document21 pages2024 Specimen Mark Scheme Paper 2nananananannanananaNo ratings yet

- OM 11 2023 Topic Demand ForecastingDocument63 pagesOM 11 2023 Topic Demand ForecastingKishan sahaniNo ratings yet

- M3003-The-expression-of-uncertainty-and-confidence-in-measurement-Edition 6-March, 2024Document106 pagesM3003-The-expression-of-uncertainty-and-confidence-in-measurement-Edition 6-March, 2024thekraze5050No ratings yet

- E-Journal GJMBR A Vol 18 Issue 1pdf - Io2Document10 pagesE-Journal GJMBR A Vol 18 Issue 1pdf - Io2nilesh.kNo ratings yet

- F23 Final Exam ReviewDocument12 pagesF23 Final Exam ReviewBrandi Burchell-LeedomNo ratings yet

- Measures of DispersionDocument28 pagesMeasures of DispersionTushar AgrawalNo ratings yet

- 21.RPA1300143 MyarticleDocument13 pages21.RPA1300143 Myarticlevarsha02jadhavNo ratings yet

- Capability InfoDocument14 pagesCapability Infoantipstore004No ratings yet

- B.com. (Computer Applications)Document66 pagesB.com. (Computer Applications)JNCW CollegeNo ratings yet

- Measures of DispersionDocument3 pagesMeasures of DispersionAbrar AhmadNo ratings yet

- Accessing The TikTok Influencer Marketing On ConsuDocument20 pagesAccessing The TikTok Influencer Marketing On ConsuLynley SantosNo ratings yet

- Udd Med Filipino Summer Midterm ExamDocument6 pagesUdd Med Filipino Summer Midterm Exambryl john lawrence villamarNo ratings yet

- Unit 5 - Practice SheetDocument11 pagesUnit 5 - Practice Sheet75227sumitNo ratings yet

- National Achievement Test Reviewer in Statistics and ProbabilityDocument5 pagesNational Achievement Test Reviewer in Statistics and ProbabilityJacinthe Angelou D. PeñalosaNo ratings yet

- PeerDocument5 pagesPeerjainsaloni856No ratings yet

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

Uploaded by

Mark TaylorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

RevisionOfSupportingDocumentationAndGuidanceForConfirmationOfThePerformanceOfTemperature Humidity Chambers

Uploaded by

Mark TaylorCopyright:

Available Formats

ESPEC Technical Information

Technical Report

JIS C60068-3-5:2020, JIS C60068-3-6:2020

Revision of Supporting Documentation and Guidance for

Confirmation of the Performance of Temperature (Humidity)

Chambers

Koichi Kodera, Development Headquarters, ESPEC CORP.

(Chairman of the Subcommittee for Climatic Environmental testing equipment,

Technical Committee for Environmental Testing Equipment,

Japan Testing Machine Association)

Abstract

Following the 2018 revision of IEC standards IEC 60068-3-5 and IEC 60068-3-6, which provide

guidance for confirmation of performance of temperature (humidity) chambers, “JIS C 60068-3-

5:2020 Supporting documentation and guidance - Confirmation of the performance of temperature

chambers” and “JIS C 60068-3-6:2020 Supporting documentation and guidance - Confirmation of

the performance of temperature/humidity chambers” were issued on September 23, 2020 as an

identical standard (IDT).

This report presents a comparison of the revised JIS standards with the 2006 and 2008 editions,

as well as an overview of the standards.

This report is only an overview. For details, please refer to the published JIS standards.

This report is a modified and expanded version of information presented in TEST Vol. 58 (Issued

January 2021), a public relations magazine published by the Japan Testing Machine Association.

1. Introduction

The Japan Testing Machine Association (JTM) has been working on standardization of

“performance test methods and performance indication methods” for general-purpose temperature

(humidity) chambers used in a wide range of fields since the early stages of their development,

and in 1985 became the first Japanese JTM standard to be established and widely used.

Subsequently, IEC 60068-3-5 and IEC 60068-3-6 were established in 2001 as guidance for

confirmation of the performance of temperature (humidity) chambers as part of the IEC standards,

which are international standards.

Based on this, JIS C 60068-3-5 and JIS C 60068-3-6 were established in 2006 and 2008,

respectively, as IDTs as part of the JIS standards. However, these IEC and JIS standards did not

describe specific measurement methods (measurement position, measurement time) or

calculation methods.

The Japan Testing Machine Association (JTM) conducted a complete review of the JTM

Test Navi Report No. 43 (Vol. 137) 2022 1

ESPEC Technical Information

standards, focusing on operational aspects and maintaining consistency with JIS, and established

“JTM K07 Temperature chambers - Test and indication method for performance” in 2007 and “JTM

K09 Temperature/Humidity chambers - Test and indication method for performance” in 2009.

The revision of the IEC and JIS standards incorporated the measurement methods and the

calculation methods of JTM K07 and JTM K09.

2. Terms Used to Describe the Performance of Temperature (Humidity) Chambers

The catalogs and specifications of temperature (humidity) chambers whose performance has

been confirmed by JIS C60068-3-5 and JIS C60068-3-6 use terms that are consistent with these

standards.

Since each term is a translation of an IEC standard, it can be difficult to understand precisely

what it means from the Japanese wording. Figure 1 below shows the explanation and figures

related to the terms.

2.1 Temperature (humidity) fluctuation

This indicates the degree of temporal fluctuation of the atmosphere in the chamber and the

degree to which the temperature (humidity) in the chamber is stable.

2.2 Temperature (humidity) gradient

The degree of spatial variation in the chamber. This term indicates the degree to which the value

differs depending on the position in the chamber.

2.3 Spatial temperature (humidity) variation

The degree of spatial variation in a chamber. This term indicates the difference in values

relative to the center position in the chamber.

Fluctuation

(Position away from the

center of the working

space)

Temperature

Variation

/Humidity

Gradient

Fluctuation

(Center of the working

space)

Fluctuation

(Position away from the

center of the working

space)

Time

Figure 1 Relationship between temperature (humidity) chamber fluctuation, variation, and

1)

gradient

Test Navi Report No. 43 (Vol. 137) 2022 2

ESPEC Technical Information

2.4 Temperature rate of change

This shows the ability of the chamber to change temperature. It indicates the rate at which the

atmosphere temperature changes per minute.

3. Main Changes in the Revised Standard

The main change in this revision is that specific measurement and calculation methods are now

provided. In addition, the contents of these methods are adopted from those established in the

JTM standard. The main changes in this revision are shown in Table 1.

Table 1 Changes in the revised standard

Description in previous

Item Description in the 2020 edition

editions

Any point in the working

Center of the working space

space

Specified points within the working

Measurement space

position All points in the working *8 points at 1/10 inside from each

space corner and 1point at the chamber

center (when the capacity is up to

2000 L )

Measurement time No description 30 minutes or longer

Measurement 10 or more times at equal intervals

No description

interval over 30 minutes

Temperature

(humidity) fluctuation

Temperature

No description of calculation Description of specific calculation

(humidity) gradient

method method

Temperature

(humidity) variation

in space

Description of highest and

Temperature

lowest temperatures attained Deleted from the terms

extremes

and their definitions

4. Outline of the Standards (JIS C60068-3-5, JIS C60068-3-6)

4.1 Scope

These standards specify reproducible measurement methods to verify that temperature

(humidity) chambers conform to the requirements of climatic test procedures JIS C 60068-2. These

standards is intend for users when conducting regular temperature (humidity) cham ber

performance monitoring.

4.2 Working space

The working space is defined as the area 1/10 inside from each corner of the test area in the

temperature (humidity) chamber.

Test Navi Report No. 43 (Vol. 137) 2022 3

ESPEC Technical Information

(Chamber

center)

2)

Figure 2 Working space and measurement location (for a capacity up to 2000 L)

4.3 Achieved temperature (humidity), temperature (humidity) stabilization

In order to establish the conditions for measuring the performance items introduced in section

2, achieved temperature (humidity) and temperature (humidity) stabilization are specified. The

achieved temperature (humidity) is defined as the stabilized temperature (humidity) maintained

within the allowable range at the center of the working space for 30 minutes or more, and the

temperature (humidity) stabilization is defined as the state where the nine points, eight points at

each corner of the working space plus at the center point, enters within the allowable range and

is maintained for 30 minutes.

The temperature (humidity) fluctuation, temperature (humidity) gradient, and temperature

(humidity) variation in space are to be measured under temperature (humidity) stabilization, and

the achieved temperature (humidity) at that time is the temperature (humidity) at which

performance is confirmed.

4.4 Temperature (humidity) fluctuation

Measurement position: 9 points, from each corner and the center of the working space

Time/interval: 10 or more equally spaced measurements over a period of 30 minutes or longer

Calculation method: Calculate the standard deviation σn-1 from the measured value for each

measurement position.

The temperature (humidity) range shall be ±2σn-1. The largest value among

the 9 points shall be the temperature (humidity) fluctuation.

Test Navi Report No. 43 (Vol. 137) 2022 4

ESPEC Technical Information

4.5 Temperature (humidity) gradient

Measurement position: 9 points, from each corner and the center of the working space

Time/interval: No clear description

Calculation method: Average value is obtained from the measured values at each measurement

position

The highest and lowest average values are selected from the 9 measurement

points, and the difference between them is the temperature (humidity)

gradient.

4.6 Temperature (humidity) variation in space

Measurement position: 9 points, from each corner and the center of the working space

Time/interval: No clear description

Calculation method: Obtain the average value from the measured values for each measurement

position.

Find the all of the differences between the average values.

The maximum value among them is the temperature (humidity) gradient.

*Items 4.5 and 4.6 above do not describe the measurement time or intervals, but in practice, they

can be calculated using the data from the temperature (humidity) fluctuation measurements.

4.7 Temperature rate of change (Figure 3)

Measurement position: Center of the working space

Procedure: 1) Wait until the temperature stabilizes at the lowest specified temperature.

2) Monitor the time between 10% and 90% of the temperature range in accordance

with the highest specified temperature.

3) Wait until the temperature stabilizes at the highest specified temperature.

4) Monitor the time between 10% and 90% of the temperature range in accordance

with the lowest specified temperature.

Calculation method: The temperature rate of change is obtained by dividing the temperature

range change time, between 10% and 90% at heat up and cool down, by

the temperature range.

Test Navi Report No. 43 (Vol. 137) 2022 5

ESPEC Technical Information

Heat-up time Cool-down time

Highest temperature

Lowest temperature

2)

Figure 3: Temperature rate of change

5. Conclusion

The Japan Testing Machine Association has established the JTM Standard, which defines the

measurement and calculation methods for the performance indication of temperature (humidity)

chambers, and has endeavored to enable users to check and compare performance based on the

same standards. As explained above, the JTM standard has been adopted in the IEC and JIS

standards as a result of this revision, and the measurement methods for each performance item

have been clarified.

Previously, even if these IEC or JIS standards were stated in the performance description of a

temperature (humidity) chamber, it was not known whether the measurement and calculation

methods were the same. The revised version allows the same standards to be used for

performance indication.

With the globalization of corporate activities, it has become easier to determine conformity to

climatic test standards for temperature (humidity) chambers in various countries and to compare

the performance of chambers.

References

1) JIS C 60068-3-5:2020, “Environmental testing -- Part 3-5: Supporting documentation and

guidance -- Confirmation of the performance of temperature chambers,” Japanese Industrial

Standards

2) JTM K07:2007, “Temperature chambers – Test and indication method for Performance” Japan

Testing Machine Association standards

Test Navi Report No. 43 (Vol. 137) 2022 6

You might also like

- JTM K 07Document11 pagesJTM K 07Stiven Giraldo NuñezNo ratings yet

- CAP I - Paper 3B - MCQDocument59 pagesCAP I - Paper 3B - MCQNisarga Pokharel100% (1)

- ASTM D3195. Rotameter Calibration Std.Document4 pagesASTM D3195. Rotameter Calibration Std.Princess NobleNo ratings yet

- Final Report v.1-1Document31 pagesFinal Report v.1-1Damien NaiduNo ratings yet

- Methods of Calibration and Characterization of Temperature Controlled EnvironmentsDocument14 pagesMethods of Calibration and Characterization of Temperature Controlled EnvironmentsboddarambabuNo ratings yet

- Example of Measurement Uncertainty EstimationDocument7 pagesExample of Measurement Uncertainty EstimationCristiano PernichelliNo ratings yet

- ANSI_AHRI_Standard_1350_I-P_2014_with_Addendum_1_0Document40 pagesANSI_AHRI_Standard_1350_I-P_2014_with_Addendum_1_0hug.mer.muNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- MIC 2010 3 1haugenDocument13 pagesMIC 2010 3 1haugenIvan CujiaNo ratings yet

- CMC Review Protocol - Relative HumidityDocument7 pagesCMC Review Protocol - Relative HumidityNdra PompomorinNo ratings yet

- Determining The Coefficient of Thermal Expansion of ConcreteDocument8 pagesDetermining The Coefficient of Thermal Expansion of ConcreteLe PhamNo ratings yet

- Liebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorDocument6 pagesLiebmann - Testing Temperature Uniformity On A Flat-Plate Infrared CalibratorCristian MendezNo ratings yet

- SOP10 - 20141022 - ReglasDocument9 pagesSOP10 - 20141022 - ReglasDiego LincangoNo ratings yet

- PRCCHA2 Sick Test1 2022 MemoDocument9 pagesPRCCHA2 Sick Test1 2022 Memopulezanele11No ratings yet

- Understanding The Technology: Estimation Method For Temperature Uncertainty of Temperature Chambers (JTM K 08)Document15 pagesUnderstanding The Technology: Estimation Method For Temperature Uncertainty of Temperature Chambers (JTM K 08)Rafael DiasNo ratings yet

- 1391 1Document26 pages1391 1Aaron AngNo ratings yet

- Book For Cooling LoadDocument9 pagesBook For Cooling LoadeanestNo ratings yet

- JTM K 08 Estimation Temperature Uncertainty Temperature Chambers PDFDocument14 pagesJTM K 08 Estimation Temperature Uncertainty Temperature Chambers PDFStiven Giraldo NuñezNo ratings yet

- Technical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Document6 pagesTechnical Note How To Calculate Pressure Transmitter Calibration Intervals en 7432098Murphy's LawNo ratings yet

- Experiment 2: Heat Transfer From Finned SurfacesDocument5 pagesExperiment 2: Heat Transfer From Finned SurfacesAlexNo ratings yet

- Lab F Linear MPCDocument2 pagesLab F Linear MPCHabiyaremye JosephNo ratings yet

- Kalibrasi EnclosurDocument20 pagesKalibrasi Enclosurmuslim1583No ratings yet

- 3361701Document7 pages3361701josephNo ratings yet

- Flow Measurement by Orifice Meter and by Ventury Meter BOMBAYDocument7 pagesFlow Measurement by Orifice Meter and by Ventury Meter BOMBAYCedric GallusNo ratings yet

- Gas ChromatographDocument20 pagesGas ChromatographkstaziNo ratings yet

- Bubblg Effect EvaporaturDocument4 pagesBubblg Effect Evaporaturnn1129374No ratings yet

- Lab 5 - Thermocouple Temperature Calibration (PRTS)Document7 pagesLab 5 - Thermocouple Temperature Calibration (PRTS)Slim ShaddysNo ratings yet

- Thermodynamics Lab1Document20 pagesThermodynamics Lab1Alina AbdikadyrNo ratings yet

- D1071-83 (2008) Standard Test Methods For Volumetric Measurement of Gaseous Fuel SamplesDocument13 pagesD1071-83 (2008) Standard Test Methods For Volumetric Measurement of Gaseous Fuel SamplesIrsanNo ratings yet

- Characterization and Analysis of The Efficiency of A Hermetic CompressorDocument7 pagesCharacterization and Analysis of The Efficiency of A Hermetic CompressorMohammed Naim UddinNo ratings yet

- Testo 184 ManualDocument18 pagesTesto 184 Manualmirnes cakarNo ratings yet

- TSD 02 PDFDocument5 pagesTSD 02 PDFgeetanjaliNo ratings yet

- Worded It PDF RenderDocument28 pagesWorded It PDF RenderRoyale StudentsNo ratings yet

- Confort SensoresDocument14 pagesConfort SensoresReynaldo AparicioNo ratings yet

- HT302 C3bDocument17 pagesHT302 C3bAnuj BhawsarNo ratings yet

- Labreport 2 Pegtestatbmgroup 2 Section 2Document15 pagesLabreport 2 Pegtestatbmgroup 2 Section 2Fathi IrsyadNo ratings yet

- 10 18038-Estubtda 1217193-2823853Document9 pages10 18038-Estubtda 1217193-2823853Can EkiciNo ratings yet

- 1391 2 2018 AMD4 Reff2022Document82 pages1391 2 2018 AMD4 Reff2022Abhishek SrivastvaNo ratings yet

- Modelling of Supply Air Jet From Diffusers of Four-Way Packaged Air-Conditioner For CFD Analysis On Unsteady Airflow in RoomDocument10 pagesModelling of Supply Air Jet From Diffusers of Four-Way Packaged Air-Conditioner For CFD Analysis On Unsteady Airflow in RoomdineshkanthtpNo ratings yet

- Models - Cfd.displacement VentilationDocument20 pagesModels - Cfd.displacement VentilationMarioNo ratings yet

- C 1155 - 95 - QzexntutotuDocument8 pagesC 1155 - 95 - QzexntutotuMuhammad NaumanNo ratings yet

- Technical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control SystemDocument126 pagesTechnical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control Systemh logoNo ratings yet

- Iso 7726-1998Document8 pagesIso 7726-1998felo345No ratings yet

- PWC 2003 TC12 021Document3 pagesPWC 2003 TC12 021AripinNo ratings yet

- L 03 (SS) (Ia&c) ( (Ee) Nptel)Document10 pagesL 03 (SS) (Ia&c) ( (Ee) Nptel)Abdelraheem S. AlkuorNo ratings yet

- C680Document22 pagesC680dinhtung2210100% (2)

- Effect of Thermostat Time Constant On Temperature Control and Energy ConsumptionDocument6 pagesEffect of Thermostat Time Constant On Temperature Control and Energy ConsumptionRagi Geetha RajendranNo ratings yet

- TP 2Document10 pagesTP 2Saint lazarusNo ratings yet

- A. Operation Manual Glossary: AppendixDocument10 pagesA. Operation Manual Glossary: AppendixГоран ГорановNo ratings yet

- 100 Nicol FinalDocument9 pages100 Nicol Finalshalini4071979No ratings yet

- Humidity/Temp. Barometer: Operation ManualDocument13 pagesHumidity/Temp. Barometer: Operation ManualTécnicos Volúmen CaliNo ratings yet

- MK Inkubator LaboratoryDocument4 pagesMK Inkubator LaboratoryFaris HadyanNo ratings yet

- Model Based ControlDocument6 pagesModel Based ControlIvan RadovicNo ratings yet

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDocument27 pagesCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenNo ratings yet

- ARTIGO Multi Input Single Output Control For Extending The Operating Range Generalized Slipt RangeDocument11 pagesARTIGO Multi Input Single Output Control For Extending The Operating Range Generalized Slipt RangerafaelfbacharelNo ratings yet

- Sample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyDocument30 pagesSample For Solution Manual Theory and Design For Mechanical Measurements 6th Edition by Figliola & BeasleyM.R.ZNo ratings yet

- Guidelines For Assessment of Temperature UniformitDocument4 pagesGuidelines For Assessment of Temperature UniformitGiaraf100% (1)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Factors Affecting The Willingness of Micro Enterprises To Adopt E-WalletsDocument9 pagesFactors Affecting The Willingness of Micro Enterprises To Adopt E-WalletsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Answer Sheet For Integrated Data Analysis Exercise1Document5 pagesAnswer Sheet For Integrated Data Analysis Exercise1Yul Bryan TolentinoNo ratings yet

- SAT Math5 AnswersDocument50 pagesSAT Math5 AnswersLuiza Andrade100% (1)

- Problem IDocument13 pagesProblem IJialu YangNo ratings yet

- A Project Submitted Towards Partial Fulfillment of The Requirements of For The Degree ofDocument67 pagesA Project Submitted Towards Partial Fulfillment of The Requirements of For The Degree ofBaiq LenyNo ratings yet

- Chapter 2 .2statDocument134 pagesChapter 2 .2statSherry-Ann TulauanNo ratings yet

- ASTM E 178 Dealing With Outlying ObservationsDocument11 pagesASTM E 178 Dealing With Outlying Observationsiel84749No ratings yet

- 1.05 Portfolio Mathematics - AnswersDocument7 pages1.05 Portfolio Mathematics - AnswersThe SpectreNo ratings yet

- Standard DeviationDocument9 pagesStandard DeviationPresana VisionNo ratings yet

- Stat 4091 Exercise2Document4 pagesStat 4091 Exercise2Random Existence100% (1)

- CFA 2024 Level I - Schweser QuicksheetDocument6 pagesCFA 2024 Level I - Schweser Quicksheetmichaelfamura97No ratings yet

- Statistics in ResearchDocument26 pagesStatistics in ResearchStevoh100% (2)

- ISO 17994-2014 Water-Compare Relative Recovery Microb Two MethodDocument30 pagesISO 17994-2014 Water-Compare Relative Recovery Microb Two MethodTrung Tín TrầnNo ratings yet

- Soal UTS Statekbis Genap 2019 2020 Set 1Document13 pagesSoal UTS Statekbis Genap 2019 2020 Set 1avri firdausNo ratings yet

- 2024 Specimen Mark Scheme Paper 2Document21 pages2024 Specimen Mark Scheme Paper 2nananananannanananaNo ratings yet

- OM 11 2023 Topic Demand ForecastingDocument63 pagesOM 11 2023 Topic Demand ForecastingKishan sahaniNo ratings yet

- M3003-The-expression-of-uncertainty-and-confidence-in-measurement-Edition 6-March, 2024Document106 pagesM3003-The-expression-of-uncertainty-and-confidence-in-measurement-Edition 6-March, 2024thekraze5050No ratings yet

- E-Journal GJMBR A Vol 18 Issue 1pdf - Io2Document10 pagesE-Journal GJMBR A Vol 18 Issue 1pdf - Io2nilesh.kNo ratings yet

- F23 Final Exam ReviewDocument12 pagesF23 Final Exam ReviewBrandi Burchell-LeedomNo ratings yet

- Measures of DispersionDocument28 pagesMeasures of DispersionTushar AgrawalNo ratings yet

- 21.RPA1300143 MyarticleDocument13 pages21.RPA1300143 Myarticlevarsha02jadhavNo ratings yet

- Capability InfoDocument14 pagesCapability Infoantipstore004No ratings yet

- B.com. (Computer Applications)Document66 pagesB.com. (Computer Applications)JNCW CollegeNo ratings yet

- Measures of DispersionDocument3 pagesMeasures of DispersionAbrar AhmadNo ratings yet

- Accessing The TikTok Influencer Marketing On ConsuDocument20 pagesAccessing The TikTok Influencer Marketing On ConsuLynley SantosNo ratings yet

- Udd Med Filipino Summer Midterm ExamDocument6 pagesUdd Med Filipino Summer Midterm Exambryl john lawrence villamarNo ratings yet

- Unit 5 - Practice SheetDocument11 pagesUnit 5 - Practice Sheet75227sumitNo ratings yet

- National Achievement Test Reviewer in Statistics and ProbabilityDocument5 pagesNational Achievement Test Reviewer in Statistics and ProbabilityJacinthe Angelou D. PeñalosaNo ratings yet

- PeerDocument5 pagesPeerjainsaloni856No ratings yet