Professional Documents

Culture Documents

TME Programming Manual IO

TME Programming Manual IO

Uploaded by

Jai KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TME Programming Manual IO

TME Programming Manual IO

Uploaded by

Jai KumarCopyright:

Available Formats

Programming

3

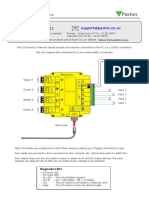

3.4.2 Advanced Application Builder / Inputs

c00285en.bmp

Fig. 3-12: Inputs

T ool T ool S top T ool

Start in Final Start

Stage

Start

Stage2

Inputs

I0. Application Select 0

I1. Application Select 1

I2. Application Select 2

I3. T ool Start

I4. R eject R elease

I5. T ool R everse

I6. T ool Enable

W ith Linking:

I7. R eset Linking /

Synchronization In

W ith Too l S ynch ronization :

I7. R eset Linking /

Synchronization In

c00288en.bmp

Fig. 3-13: Input Timing Diagram

inputs.txtS

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 41

3 Programming

Eight optically isolated, +24 V inputs are available at the Phoenix input connector under the right

side door and are defined as follows:

PIN 1 +24 VDC

PIN 2 Input 0

PIN 3 Input 1

PIN 4 Input 2

PIN 5 Input 3

PIN 6 Input 4

PIN 7 Input 5

Pin 8 Input 6

PIN 9 Input 7

PIN 10 Input Common

Pin 11 Signal Ground

Pin 12 Spare

Each of the physical inputs 0 - 7 can be programmed to have one of the following definitions:

Not Used Unused

Tool Enable When active, allows the tool to run in conjunction with Tool Start

Tool Start Starts the tool. Works in parallel with the start switch on the tool.

Tool Reverse When active, causes the tool to run in the counter-clockwise direc-

tion using the Backoff strategy. Works in parallel with the reverse

actuator on the tool

Tool Ready Prepares the controller for a new rundown. When active, the previ-

ous outputs are cleared, and the yellow LEDs flash

Appl. Select 0 Application Selects 0-7 are used to select Applications 1-255

Appl. Select 1 using a binary count of 0-254 where Appl. Select 0 is the

least significant bit. This feature overrides application

Appl. Select 2 changes from the keypad. When Linking is activated, the

Appl. Select 3 Tightening Group is selected with these inputs.

Appl. Select 4

Appl. Select 5

Appl. Select 6

Appl. Select 7

Synchronization Input If enabled from Advanced / System Settings, the tool is prevented

from continuing to the next stage until this input is active

Reset Linking When active, Linking (batch counting) is reset to position one

Reject Release Used when Reject Release is enabled from System Settings, and

the Release Method is "Release Input Toggle". When the tool is

disabled due to the reject limit being reached, it is re-enabled after

this input is toggled

42 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

Socket Tray Enable Socket Tray Enable is used along with Socket Tray Sel 0-2 to indi-

Socket Tray Sel 0 cate to the worker which socket to use.

Socket Tray Sel 1

Socket Tray Sel 2

Acknowledge When this signal is ON, the "results" output signals should be

cleared and the tool cannot be started; however, the tool LEDs

should still indicate the status of the previous rundown until

cleared by another tool start or the tool ready signal.

All inputs are active high. They are referenced to an isolated Input Common (pin 10). When using

the internal +24 V (pin 1) to activate these inputs, you must connect Input Common (pin 10) and

GND (pin 11). For hardware pin location please see page 19.

Note:

When active, the Fieldbus has the priority. Refer to help page for Advanced / Fieldbus.

inputs.txtE

3.4.3 Advanced Application Builder / Outputs

c00286en.bmp

Fig. 3-14: Outputs

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 43

3 Programming

T ool T ool Stop T ool

Start in F inal S tart

S tage

E nd Start

S tage1 Stage2

O utputs

O 0. C ycle O K As appropriate

O 1. C ycle N O K As appropriate

O 2. T orque H igh As appropriate

O 3. T orque Low As appropriate

O 4. Linking O K As appropriate

O 5. Linking N O K As appropriate

O 6. C ycle C om plete

W ith Linking:

O 7. Linking C om plete / As appropriate

S ynchronization O ut

W ith Tool S ynchronization :

O 7. Linking C om plete /

S ynchronization O ut

c00287en.bmp

Fig. 3-15: Output Timing Diagram

outputs.txtS

Eight relay outputs are available at the Phoenix output connector under the right side door and

are defined as follows:

PIN 1 +24 VDC

PIN 2 Output Common

PIN 3 Output 0

PIN 4 Output 1

PIN 5 Output 2

PIN 6 Output 3

PIN 7 Output 4

PIN 8 Output 5

PIN 9 Output 6

PIN 10 Output 7

PIN 11 Signal Ground

PIN 12 Spare

Each of the physical outputs 0-7 can be programmed to have one of the following definitions:

Not Used Unused

OK Active if Torque / Angle / Yield are within programmed limits

44 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

NOK Active if Torque / Angle / Yield are outside limits or some

other error has occurred

Torque Low Active if Peak Torque < Torque Low Limit

Torque High Active of Peak Torque > Torque High Limit

Angle Low Active if Angle < Angle Low Limit

Angle High Active of Angle > Angle High Limit

Torque OK Active if Peak Torque is within limits

Angle OK Active if Angle is within limits

Tool Running Active when the tool is running

Cycle Complete Active when a rundown has ended in the last stage

Linking Complete Active when rundowns of all positions of the selected batch

group are complete

Linking OK Active if all positions of Linking were OK

Linking NOK Active if one or more positions of Linking were NOK

Confirm App. Sel 0 Confirm application Selects 0-7 are used to indicate the

Confirm App. Sel 1 currently selected applications 1-255 using a binary count

of 0-254 where Appl. Select 0 is the least significant bit

Confirm App. Sel 2

Confirm App. Sel 3

Confirm App. Sel 4

Confirm App. Sel 5

Confirm App. Sel 6

Confirm App. Sel 7

Sync Output If enabled from Advanced / System Settings it is active at

the end of each stage to allow for synchronization with

other controllers

Tool In Reverse Indicates that a tool reverse input or actuator is set

Socket Tray Enable Pass-through of Socket Tray Enable input signal

Socket Tray Sel 0 Pass-through of Socket Tray select 0-2 input signals

Socket Tray Sel 1

Socket Tray Sel 2

Fault (Active Low) Indicates the servo module has detected an error (trans-

ducer, resolver etc)

All relay outputs are active high. One side of all of the relay contacts is tied to a common point

called Output Common (pin 2). When using the internal +24 V (pin 1) as a source for these out-

puts, you must connect Output Common (pin 2) and +24 V (pin 1). The outputs will then be refer-

enced to GND (pin 11). For hardware pin location please see page 19.

Note: When active, the Fieldbus inputs have priority. Refer to help page for Advanced / Fieldbus.

outputs.txtE

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 45

You might also like

- READ 180 Daily Lesson Plans - Workshop #1Document11 pagesREAD 180 Daily Lesson Plans - Workshop #1Carrie Cown Collins0% (1)

- XY1 Load Cell SimulatorDocument30 pagesXY1 Load Cell Simulatoraldo100% (1)

- Manual Laboratorio LaunchpadDocument54 pagesManual Laboratorio LaunchpadAnthony ACNo ratings yet

- Recoil Offgrid JuneJuly 2017 VK Com StopthepressDocument101 pagesRecoil Offgrid JuneJuly 2017 VK Com Stopthepressshenlong27100% (1)

- Document3 11/18/98 2:08 PM Page 1Document223 pagesDocument3 11/18/98 2:08 PM Page 1Evandro PavesiNo ratings yet

- 0 Series ControllerDocument13 pages0 Series ControllerSuresh RamachandranNo ratings yet

- Activity 4 - Digital InputsDocument18 pagesActivity 4 - Digital InputsJohn Genrich PilartaNo ratings yet

- CPE400 Lab3Document16 pagesCPE400 Lab3RUEL ALEJANDRONo ratings yet

- Microcontroller Visem EceDocument83 pagesMicrocontroller Visem EceManoj KumarNo ratings yet

- Dimension 1200 and 1200es BST/SST Troubleshooting GuideDocument30 pagesDimension 1200 and 1200es BST/SST Troubleshooting GuidekornjudisticNo ratings yet

- CA 180 Installation Instructions: Professional Installation Strongly RecommendedDocument25 pagesCA 180 Installation Instructions: Professional Installation Strongly RecommendedBogdan DanielNo ratings yet

- Manual Uwe W10Document27 pagesManual Uwe W10michigato100% (1)

- Power Focus 4000 Quick Guide PDFDocument42 pagesPower Focus 4000 Quick Guide PDFandycool2009No ratings yet

- EXPERIMENT 3: The Interrupt and Polling System.: EEEB371 E3 1Document4 pagesEXPERIMENT 3: The Interrupt and Polling System.: EEEB371 E3 1SalemAbaadNo ratings yet

- Lab Exercise #1 - Getting Started: Dr. Timber Yuen Rev 0Document9 pagesLab Exercise #1 - Getting Started: Dr. Timber Yuen Rev 0Pae TankNo ratings yet

- Softstarters: Type PSTX Fieldbus Communication, Anybus Compactcom Ethernet/IpDocument11 pagesSoftstarters: Type PSTX Fieldbus Communication, Anybus Compactcom Ethernet/Iprodrigo_rojas_22No ratings yet

- Abb PSTX Fieldbus ProfibusDocument11 pagesAbb PSTX Fieldbus ProfibusFarouk MechtaNo ratings yet

- GE-ANT-1C WorkflowDocument29 pagesGE-ANT-1C WorkflowNur Hidayat NurdinNo ratings yet

- I SEM Lab - 8051, AVRDocument138 pagesI SEM Lab - 8051, AVRimbharteshNo ratings yet

- C628 6xxx ManualDocument12 pagesC628 6xxx ManualseptixNo ratings yet

- Teacher Manual: Erts Lab IIT-BombayDocument6 pagesTeacher Manual: Erts Lab IIT-BombaySridhar JayaramanNo ratings yet

- Aquilla UserDocument35 pagesAquilla UserDương Ngọc QuốcNo ratings yet

- 1480 Start UpDocument13 pages1480 Start Upbakri fattalNo ratings yet

- Users Manual: Eimova 880, 572 01 Polička Czech Republic Tel.: +420 461 619 515 Fax: +420 461 619 513Document73 pagesUsers Manual: Eimova 880, 572 01 Polička Czech Republic Tel.: +420 461 619 515 Fax: +420 461 619 513freddyapazaNo ratings yet

- FANUC Input OutputDocument26 pagesFANUC Input OutputĐuka VidinovićNo ratings yet

- I-O BoardDocument7 pagesI-O BoardBoris MaldonadoNo ratings yet

- Manual ULTIMOS VARIADORES BANDA 2022.4.19Document11 pagesManual ULTIMOS VARIADORES BANDA 2022.4.19produccion multipackNo ratings yet

- Logixpro Lab 1.A: Digital I/O SimulatorDocument6 pagesLogixpro Lab 1.A: Digital I/O SimulatorSolderan TVNo ratings yet

- Tru-Sonic Manual NewDocument47 pagesTru-Sonic Manual Newpedropinocontreras100% (2)

- 89441a PDFDocument339 pages89441a PDFOYDWNo ratings yet

- Epoch: Instruction ManualDocument10 pagesEpoch: Instruction ManualDpt HtegnNo ratings yet

- Robo Pro TteDocument19 pagesRobo Pro TteŽeljko PosavecNo ratings yet

- FM4000E - CI-146 Iss3 FM4000E InstallationDocument15 pagesFM4000E - CI-146 Iss3 FM4000E InstallationHans RughoonathNo ratings yet

- E21 Operation Manual: (Version: V1.04)Document27 pagesE21 Operation Manual: (Version: V1.04)Тимур АлиевNo ratings yet

- Quick Guide SPI1021: 1. Display and ControlsDocument8 pagesQuick Guide SPI1021: 1. Display and ControlsHenrics MayoresNo ratings yet

- Power Focus Quick Guide UKDocument48 pagesPower Focus Quick Guide UKAkaridNo ratings yet

- PLC Lab ManualDocument27 pagesPLC Lab ManualSneha100% (1)

- Tutorial Notes 2014 - Part 1Document18 pagesTutorial Notes 2014 - Part 1Syed Shahriar Zaman ShibleeyNo ratings yet

- 70k07 e (Start Up)Document60 pages70k07 e (Start Up)Bakhtiar AkhmadNo ratings yet

- Operation Manual of The ParkingDocument21 pagesOperation Manual of The ParkingOsmel RegüeiferosNo ratings yet

- Experiment No. 4 To Perofrm Set Reset Using InputsDocument4 pagesExperiment No. 4 To Perofrm Set Reset Using InputsShashikant Prasad100% (1)

- Iot L2 Fa20-Bce-046Document14 pagesIot L2 Fa20-Bce-046fa20-bce-046No ratings yet

- Ripple Carry AdderDocument43 pagesRipple Carry Adderdfg125dsaNo ratings yet

- Tutorial 06 Function Block Diagram Programming With PLC TutorialDocument8 pagesTutorial 06 Function Block Diagram Programming With PLC Tutorialdony ramdhaniNo ratings yet

- Gergely 2009Document6 pagesGergely 2009zERONo ratings yet

- SNMP Web Card+Box User ManualDocument23 pagesSNMP Web Card+Box User ManualHelpDesk ChileNo ratings yet

- Laboratory2 IoTDocument11 pagesLaboratory2 IoTfa20-bce-046No ratings yet

- Programmable Logic Controllers: Laboratory EightDocument7 pagesProgrammable Logic Controllers: Laboratory EightLanreSKNo ratings yet

- Sv9000 Af Drives Svready User Manual Local/Remote Control ApplicationDocument41 pagesSv9000 Af Drives Svready User Manual Local/Remote Control ApplicationJov MitchNo ratings yet

- Aumatic Control Unit: Aumund Fördertechnik GMBHDocument7 pagesAumatic Control Unit: Aumund Fördertechnik GMBHBruno SantosNo ratings yet

- ECE371 Lab1Report Group2Document9 pagesECE371 Lab1Report Group2Le HieuNo ratings yet

- SPARKER TCI-P4 Version 80: HardwareDocument7 pagesSPARKER TCI-P4 Version 80: HardwarePierreNo ratings yet

- W4-UT Electric Control ManualDocument7 pagesW4-UT Electric Control ManualCleber AntonelliNo ratings yet

- As-Interface: Maintenance and Troubleshooting GuideDocument17 pagesAs-Interface: Maintenance and Troubleshooting GuidesvatantrayabhinavaNo ratings yet

- AKCP Manual E-Opto16 Securityprobe Expansion UnitDocument20 pagesAKCP Manual E-Opto16 Securityprobe Expansion UnitmoestbgNo ratings yet

- AHE27 User Manual: PrefaceDocument16 pagesAHE27 User Manual: PrefaceDinh NguyenNo ratings yet

- Eco Pro+ Vif - V 3.04 27082020Document31 pagesEco Pro+ Vif - V 3.04 27082020Gaurav Satywali100% (1)

- Module 2Document39 pagesModule 2gjtuyNo ratings yet

- Mach3 ManualDocument37 pagesMach3 ManualMilco PrisaganecNo ratings yet

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesFrom EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesRating: 5 out of 5 stars5/5 (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Conveyor Drive ManualDocument149 pagesConveyor Drive ManualJai KumarNo ratings yet

- Fp16plus-720 Eng Manual FellerDocument45 pagesFp16plus-720 Eng Manual FellerJai KumarNo ratings yet

- 131 Friday Evening Trip With UberDocument3 pages131 Friday Evening Trip With UberJai KumarNo ratings yet

- AC GST Tax Invoice 1Document1 pageAC GST Tax Invoice 1Jai KumarNo ratings yet

- Unity Tween EngineDocument20 pagesUnity Tween EngineBui Thanh TungNo ratings yet

- JBL Charge 4 TL - Service Manual v1.2 [DIAGRAMAS.COM.BR]Document49 pagesJBL Charge 4 TL - Service Manual v1.2 [DIAGRAMAS.COM.BR]fabio martinNo ratings yet

- Renesas Flexible Software Package (FSP) v410 User ManualDocument4,346 pagesRenesas Flexible Software Package (FSP) v410 User Manualmar_barudjNo ratings yet

- Terjemahan MBT 726 - 728Document2 pagesTerjemahan MBT 726 - 728Muchammad FauziNo ratings yet

- The Steel Pipe Buyer'S GuideDocument8 pagesThe Steel Pipe Buyer'S Guideramnadh803181No ratings yet

- UWW-301 WIRE WELDER FLYER v7 (August 2021)Document3 pagesUWW-301 WIRE WELDER FLYER v7 (August 2021)Chris TeohNo ratings yet

- Elk-3 420 1HC0029799 Aj21 enDocument20 pagesElk-3 420 1HC0029799 Aj21 enaalbaki1No ratings yet

- JCB Tracked Excavator JS 210 LC: Static DimensionsDocument8 pagesJCB Tracked Excavator JS 210 LC: Static DimensionsВолодимир КривкоNo ratings yet

- Final Date Sheet For Internal Class Test May 2023Document13 pagesFinal Date Sheet For Internal Class Test May 2023Manvi AroraNo ratings yet

- HWB Series: For Datasheets, 2D Prints, and 3D Models VisitDocument2 pagesHWB Series: For Datasheets, 2D Prints, and 3D Models VisitmathconsNo ratings yet

- EwrweDocument54 pagesEwrweyiuloi997023No ratings yet

- Secretary's Certificate - Vendor Name - DateDocument2 pagesSecretary's Certificate - Vendor Name - DateGenelyn MarcaidaNo ratings yet

- Smps Design GuideDocument36 pagesSmps Design Guidejobins123100% (4)

- Steps Involved in Text Recognition and Recent Research in OCR A StudyDocument6 pagesSteps Involved in Text Recognition and Recent Research in OCR A StudykkarthiksNo ratings yet

- A Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsDocument6 pagesA Nlp-Based Solution To Prevent From Privacy Leaks in Social Network PostsfareesaNo ratings yet

- Lesson Plan in Teaching Speaking-Etos, MyraDocument4 pagesLesson Plan in Teaching Speaking-Etos, MyraMyra EtosNo ratings yet

- Fieldvue DVC5000 Series Digital Valve ControllerDocument10 pagesFieldvue DVC5000 Series Digital Valve Controllerhocine1No ratings yet

- AG542Document2 pagesAG542Akaash RoepaNo ratings yet

- Frequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersDocument8 pagesFrequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersRoyer Guerra huamanNo ratings yet

- Manually Generating An Si5351 Register Map - AN619Document63 pagesManually Generating An Si5351 Register Map - AN619wayan.wandira8122No ratings yet

- Pengaruh Harga Dan Fasilitas Terhadap Keputusan Berkunjung Wisatawan Di Objek Wisata Bukit Gibeon Kecamatan Ajibata Kabupaten Toba SamosirDocument17 pagesPengaruh Harga Dan Fasilitas Terhadap Keputusan Berkunjung Wisatawan Di Objek Wisata Bukit Gibeon Kecamatan Ajibata Kabupaten Toba Samosirjalan hajetNo ratings yet

- Autonomous Car: Government College of Engineering, AmravatiDocument28 pagesAutonomous Car: Government College of Engineering, AmravatiSaritaNo ratings yet

- Anamorphic Art: Science, Math, and Art Make Magic?Document8 pagesAnamorphic Art: Science, Math, and Art Make Magic?a hNo ratings yet

- BSAIS-ISM 323 Information Sheet 2 PDFDocument15 pagesBSAIS-ISM 323 Information Sheet 2 PDFKaiNo ratings yet

- ATI Radeon HD 4350 EspecificacionesDocument2 pagesATI Radeon HD 4350 EspecificacionesSergio MarconiNo ratings yet

- CPSMSDocument3 pagesCPSMSsugandhikgsNo ratings yet

- Assignment-3 FM LeetDocument5 pagesAssignment-3 FM LeetŔÄHÙŁ ÇHÓÜĐHÃŔŸNo ratings yet

- Digital India - Step Towards The FutureDocument15 pagesDigital India - Step Towards The FutureAbishek Rajesh100% (4)

![JBL Charge 4 TL - Service Manual v1.2 [DIAGRAMAS.COM.BR]](https://imgv2-2-f.scribdassets.com/img/document/747745102/149x198/e54bffb473/1720057124?v=1)