Professional Documents

Culture Documents

Silde - Cswip - 3.1 079 156 01

Silde - Cswip - 3.1 079 156 01

Uploaded by

cswip2024Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silde - Cswip - 3.1 079 156 01

Silde - Cswip - 3.1 079 156 01

Uploaded by

cswip2024Copyright:

Available Formats

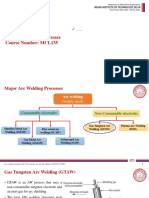

TIG Welding Sequence Purpose of These Functions

3 4 5

1

2 4 2

1 5

1. Purges the line, protect weld area, improve ionization.

1. Slope

2.

3.

4.

5. Postwelding

Pre

Main gas

welding

up

down

supply

current

gas

current

current

to

supply

protect 2. Prevent thermal shock to tungsten electrode.

Timeline

molten pool

prevents burn

upon

craterthrough,

cooling

cracks 3. Main welding current.

tungsten inclusions 4. Prevents thermal shock and crater cracking.

5. Protects weld and tungsten electrode from contamination.

Copyright © TWI Ltd Copyright © TWI Ltd

Shielding Gas Selection Gas Lens

Argon (Ar) He/Ar mixes Stainless steel

Suitable for welding Suitable for welding wire sieve

C-steel, stainless C-steel, stainless

Thread for gas

steel, Al and Mg. steel, Cu, Al and Mg.

ceramic

Lower cost, lower High cost, high flow

flow rates. rates. Thread for

torch body

More suitable for More suitable for

thinner materials thicker materials and

and positional materials of high Reduces eddies in gas flow.

welding. thermal conductivity. Extends length of laminar flow

prevents contamination.

Highly recommended for reactive

metals (eg Ti, Al).

Copyright © TWI Ltd Copyright © TWI Ltd

Commercially Available

Special Shielding Methods

Trailing Shields

Torch trailing shield Welding in protective tent

Copyright © TWI Ltd Copyright © TWI Ltd

11-8

You might also like

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- Silde - Cswip - 3.1 079 156 04Document1 pageSilde - Cswip - 3.1 079 156 04cswip2024No ratings yet

- Refractories For Steel MakingDocument36 pagesRefractories For Steel MakingradinasrNo ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 13Document1 pageSilde - Cswip - 3.1 079 156 13cswip2024No ratings yet

- Welding Processes 11Document97 pagesWelding Processes 11akabhinav32100% (2)

- Weller Tip LifetimeDocument32 pagesWeller Tip Lifetimeboba78No ratings yet

- Lattice Truss ConfigrationDocument12 pagesLattice Truss ConfigrationALFA ENGINEERINGNo ratings yet

- Ch-19 Gas Welding, Gas Cutting & Arc WeldingDocument30 pagesCh-19 Gas Welding, Gas Cutting & Arc WeldingJAYANT KUMARNo ratings yet

- Silde - Cswip - 3.1 079 156 27Document1 pageSilde - Cswip - 3.1 079 156 27cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 30Document1 pageSilde - Cswip - 3.1 079 156 30cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 22Document1 pageSilde - Cswip - 3.1 079 156 22cswip2024No ratings yet

- 1 Manual Metal Arc/Shielded Metal Arc Welding: (Mma/Smaw)Document1 page1 Manual Metal Arc/Shielded Metal Arc Welding: (Mma/Smaw)Dipesh PatelNo ratings yet

- Basics of WeldingDocument70 pagesBasics of Weldingamit kumarNo ratings yet

- TIG Welding TipsDocument4 pagesTIG Welding TipsEnrico959No ratings yet

- GTAWDocument39 pagesGTAWKoushik SarkarNo ratings yet

- 1.07 TIG Welding Part-2Document79 pages1.07 TIG Welding Part-2rohit mathanker100% (1)

- Tungsten Inert Gas or Gas Tungsten Arc WeldingDocument35 pagesTungsten Inert Gas or Gas Tungsten Arc WeldingLương Hồ Vũ75% (4)

- Welding of Austenitic Stainless Steel. Part 2: Home Technical Knowledge Job KnowledgeDocument8 pagesWelding of Austenitic Stainless Steel. Part 2: Home Technical Knowledge Job KnowledgeJlkKumarNo ratings yet

- MCL-135-Welding and Allied Processes - Class 11-15Document58 pagesMCL-135-Welding and Allied Processes - Class 11-15mHmNo ratings yet

- Kecacatan KimpalanDocument26 pagesKecacatan KimpalanMaruan MuhammadNo ratings yet

- ANTEOLA Module3.1Document7 pagesANTEOLA Module3.1Zoe Angel Mhae AnteolaNo ratings yet

- ASTM Welding Tips A410 To A643Document20 pagesASTM Welding Tips A410 To A643MARIO HUAMANNo ratings yet

- Wis5 Cons-ConsummablesDocument20 pagesWis5 Cons-Consummablesahmadibnqassam.21No ratings yet

- WIS5 Con 06Document30 pagesWIS5 Con 06QC-Metinca Prima Industrial WorksNo ratings yet

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Document8 pagesGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioNo ratings yet

- O01 Core-TapsDocument2 pagesO01 Core-TapshuychungngNo ratings yet

- Joining: TopicsDocument13 pagesJoining: TopicsKhalid El MasryNo ratings yet

- Welding MidsemDocument100 pagesWelding Midsemamit kumarNo ratings yet

- Part 1Document31 pagesPart 1May FadlNo ratings yet

- Silde - Cswip - 3.1 079 156 11Document1 pageSilde - Cswip - 3.1 079 156 11cswip2024No ratings yet

- Hard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1Document1 pageHard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1convmech enggNo ratings yet

- Titan TTSDocument5 pagesTitan TTSTibor KeményNo ratings yet

- Tungsten CarbideDocument32 pagesTungsten CarbideX800XLNo ratings yet

- Lec 8Document67 pagesLec 8Pejman HNo ratings yet

- Section 12 - Welding Consumables - Low Alloy SteelsDocument68 pagesSection 12 - Welding Consumables - Low Alloy SteelsFriedrich SchwimNo ratings yet

- 4.4 Welding Consumables: Copper-Nickel Welding and Fabrication - 9Document1 page4.4 Welding Consumables: Copper-Nickel Welding and Fabrication - 9satnamNo ratings yet

- A Comparative Study of Electrochemical Corrosion - 2019 - Journal of MaterialsDocument12 pagesA Comparative Study of Electrochemical Corrosion - 2019 - Journal of MaterialsFattah Maulana AlanNo ratings yet

- AdWelding PresentationDocument107 pagesAdWelding PresentationAdhanom G.No ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- Weldability PDFDocument60 pagesWeldability PDFS GoudaNo ratings yet

- High Performance Austenitic Welded Stainless Tubular ProductDocument2 pagesHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNo ratings yet

- Base Metal Alloys Used in Fixed and RemoveableDocument72 pagesBase Metal Alloys Used in Fixed and RemoveableKhushi DesaiNo ratings yet

- Technical Update Hard SurfacingDocument4 pagesTechnical Update Hard SurfacingADRIAN SUŁAWANo ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- Welding of Aerospace AlloysDocument46 pagesWelding of Aerospace Alloyscreativechand100% (1)

- Welding Types and DefectsDocument30 pagesWelding Types and DefectsHarisagar ThulasiramanNo ratings yet

- Hardfacing Solutions For Oil Gas Applications V1Document25 pagesHardfacing Solutions For Oil Gas Applications V1gacm98100% (1)

- Arc WeldingDocument29 pagesArc WeldinguditNo ratings yet

- Silde - Cswip - 3.1 079 156 50Document1 pageSilde - Cswip - 3.1 079 156 50cswip2024No ratings yet

- 2 UTP-Welding in Tool ShopDocument53 pages2 UTP-Welding in Tool ShopBilal AhmedNo ratings yet

- Welding ConsumablesDocument86 pagesWelding ConsumablesLương Hồ Vũ100% (1)

- RM01 - Arc Weld ProcessesDocument53 pagesRM01 - Arc Weld ProcessesAnonymous cgcKzFtXNo ratings yet

- Welcomes: Protecting The World From WearDocument30 pagesWelcomes: Protecting The World From WearRodolfoMarínNo ratings yet

- Welding For 2022 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- Silde - Cswip - 3.1 079 156 07Document1 pageSilde - Cswip - 3.1 079 156 07cswip2024No ratings yet

- Welding Fundamentals 3Document68 pagesWelding Fundamentals 3Saiprasad Thakar100% (1)

- Thermal Cutting ProcessesDocument18 pagesThermal Cutting ProcessesLương Hồ VũNo ratings yet

- Welding of Titanium and Its AlloysDocument3 pagesWelding of Titanium and Its AlloysMuhammed SulfeekNo ratings yet

- Silde - Cswip - 3.1 079 156 58Document1 pageSilde - Cswip - 3.1 079 156 58cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 48Document1 pageSilde - Cswip - 3.1 079 156 48cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 57Document1 pageSilde - Cswip - 3.1 079 156 57cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 56Document1 pageSilde - Cswip - 3.1 079 156 56cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 55Document1 pageSilde - Cswip - 3.1 079 156 55cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 54Document1 pageSilde - Cswip - 3.1 079 156 54cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 45Document1 pageSilde - Cswip - 3.1 079 156 45cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 50Document1 pageSilde - Cswip - 3.1 079 156 50cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 49Document1 pageSilde - Cswip - 3.1 079 156 49cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 47Document1 pageSilde - Cswip - 3.1 079 156 47cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 40Document1 pageSilde - Cswip - 3.1 079 156 40cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 46Document1 pageSilde - Cswip - 3.1 079 156 46cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 26Document1 pageSilde - Cswip - 3.1 079 156 26cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 39Document1 pageSilde - Cswip - 3.1 079 156 39cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 36Document1 pageSilde - Cswip - 3.1 079 156 36cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 22Document1 pageSilde - Cswip - 3.1 079 156 22cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 38Document1 pageSilde - Cswip - 3.1 079 156 38cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 37Document1 pageSilde - Cswip - 3.1 079 156 37cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 30Document1 pageSilde - Cswip - 3.1 079 156 30cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 27Document1 pageSilde - Cswip - 3.1 079 156 27cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 20Document1 pageSilde - Cswip - 3.1 079 156 20cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 17Document1 pageSilde - Cswip - 3.1 079 156 17cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 18Document1 pageSilde - Cswip - 3.1 079 156 18cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 19Document1 pageSilde - Cswip - 3.1 079 156 19cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 14Document1 pageSilde - Cswip - 3.1 079 156 14cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 15Document1 pageSilde - Cswip - 3.1 079 156 15cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 16Document1 pageSilde - Cswip - 3.1 079 156 16cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 13Document1 pageSilde - Cswip - 3.1 079 156 13cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 12Document1 pageSilde - Cswip - 3.1 079 156 12cswip2024No ratings yet

- Import ChinaDocument835 pagesImport ChinaNirav KhakhariaNo ratings yet

- Environmental, Social, and Economic Costs of Recycled Plastic BiocompositesDocument21 pagesEnvironmental, Social, and Economic Costs of Recycled Plastic BiocompositesPasan SubasingheNo ratings yet

- BS 7491-3-1994Document18 pagesBS 7491-3-1994FathyNo ratings yet

- Estimate SampleDocument26 pagesEstimate Sampleesg2917305No ratings yet

- Syllabus MtechDocument8 pagesSyllabus MtechYogesh BadheNo ratings yet

- Ec2 Aluminium ChlorohydrateDocument1 pageEc2 Aluminium ChlorohydrateIkhsan RamdhaniNo ratings yet

- PP05B - Asep - NSCP 2015 Update On CH4 Structural ConcreteDocument35 pagesPP05B - Asep - NSCP 2015 Update On CH4 Structural ConcretejimNo ratings yet

- Intumescent Paint For Aerospace Purposes - Specification: British Standard Aerospace Series BS X 37:2004Document12 pagesIntumescent Paint For Aerospace Purposes - Specification: British Standard Aerospace Series BS X 37:2004Vasco SorteNo ratings yet

- Welder Volume-I of II-TPDocument208 pagesWelder Volume-I of II-TPRupam RoyNo ratings yet

- Tds DV 5 53x Liquid Tile Penetrating SealerDocument1 pageTds DV 5 53x Liquid Tile Penetrating SealerJerry Roy DeytoNo ratings yet

- National Textile University, Faisalabad. Clearance Form For Employees ID. No.Document1 pageNational Textile University, Faisalabad. Clearance Form For Employees ID. No.Anaab FarhanNo ratings yet

- Silastic Q7-4720Document5 pagesSilastic Q7-4720CarlosNo ratings yet

- ChemDocument34 pagesChemAaghash A SNo ratings yet

- Nyy J Power CableDocument6 pagesNyy J Power Cableskipina74No ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- The Creasolv Process Is Neither A Solvolysis Nor Chemical RecyclingDocument11 pagesThe Creasolv Process Is Neither A Solvolysis Nor Chemical RecyclingAA GGNo ratings yet

- 2014 10 14 Pipework SpecificationDocument110 pages2014 10 14 Pipework SpecificationmionomeNo ratings yet

- Inter 2nd Year ChemistryDocument20 pagesInter 2nd Year ChemistryRsp Srinivas50% (4)

- Electrical Heating of Bars PDFDocument15 pagesElectrical Heating of Bars PDFsotos raptopoulosNo ratings yet

- Pemisahan Katoda AnodaDocument11 pagesPemisahan Katoda AnodaHamdi Zae malikNo ratings yet

- Astm D2517 (2000)Document5 pagesAstm D2517 (2000)SANKARAN.KNo ratings yet

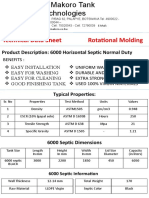

- Product Description: 6000 Horizontal Septic Normal DutyDocument4 pagesProduct Description: 6000 Horizontal Septic Normal DutyManoj KshirsagarNo ratings yet

- Inspection Thermal Spray WebinarDocument29 pagesInspection Thermal Spray WebinarShriya Soni100% (1)

- Primal CM 219 EF TDS PDFDocument7 pagesPrimal CM 219 EF TDS PDFAPEX SONNo ratings yet

- Acronal - Plus - 7023 - Jan 2020Document3 pagesAcronal - Plus - 7023 - Jan 2020Nikhil GoyalNo ratings yet

- Cassida Grease Eps 2 - Pi - (Gb-En)Document3 pagesCassida Grease Eps 2 - Pi - (Gb-En)CriVe OffeNo ratings yet

- Science Stage 9 Sample Paper 1 - tcm143-595707Document16 pagesScience Stage 9 Sample Paper 1 - tcm143-595707Ulug'bek Ibrohimov0% (1)

- Influence of Alkali Treatment On Internal Microstructure and Tensile Properties of Abaca FibersDocument9 pagesInfluence of Alkali Treatment On Internal Microstructure and Tensile Properties of Abaca FiberslintianananNo ratings yet

- 2020-Microbial Nanotechnology For Bioremediation of Industrial WastewaterDocument8 pages2020-Microbial Nanotechnology For Bioremediation of Industrial WastewaterAmin ZamaniNo ratings yet

- Experiment 1 Reaction of Aliphatic & Aromatic HydrocarbonDocument3 pagesExperiment 1 Reaction of Aliphatic & Aromatic HydrocarbonMuhammad NajmiNo ratings yet