Professional Documents

Culture Documents

Silde - Cswip - 3.1 079 156 17

Silde - Cswip - 3.1 079 156 17

Uploaded by

cswip2024Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silde - Cswip - 3.1 079 156 17

Silde - Cswip - 3.1 079 156 17

Uploaded by

cswip2024Copyright:

Available Formats

Thermal Cutting Objective

When this presentation has been completed you

will be able to recognise different cutting

methods and their advantages and limitations

over each other in respect to materials and

applicability.

Thermal Cutting Processes

Section 15

Copyright © TWI Ltd Copyright © TWI Ltd

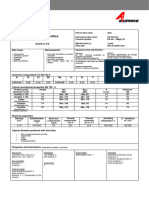

Oxyfuel Gas Cutting Process Oxyfuel Gas Cutting Process

A jet of pure oxygen reacts with iron, that has been preheated to The cutting torch

its ignition point, to produce the oxide Fe3O4 by exothermic

reaction. This oxide is then blown through the material by the

velocity of the oxygen stream.

Different types of fuel gases may be used for the pre-heating

flame in oxy fuel gas cutting: ie acetylene, hydrogen, propane

etc.

By adding iron powder to the flame we are able to cut most

metals - Iron Powder Injection.

Neutral cutting flame.

The high intensity of heat and rapid cooling will cause

hardening in low alloy and medium/high C steels - they are

thus pre-heated to avoid the hardening effect. Neutral cutting flame with

oxygen cutting stream.

Copyright © TWI Ltd Copyright © TWI Ltd

Oxyfuel Gas Cutting Related Terms Oxyfuel Gas Cutting Quality

Good cut - sharp top edge, fine and even drag lines, little oxide

and a sharp bottom edge.

Cut too slow - top edge is melted, Cut too fast - pronounced

deep groves in the lower portion, break in the drag line,

heavy scaling, rough bottom edge. irregular cut edge.

Copyright © TWI Ltd Copyright © TWI Ltd

15-1

You might also like

- Cross Reference Syntetic MWFDocument8 pagesCross Reference Syntetic MWFSuprastowo Bin SarinoNo ratings yet

- Sample Project Report For CNC Machine ShopDocument13 pagesSample Project Report For CNC Machine ShopKing50% (2)

- Aluminium Alloy 5083 PDFDocument5 pagesAluminium Alloy 5083 PDFrajanNo ratings yet

- Thermal Cutting ProcessesDocument18 pagesThermal Cutting ProcessesfinhayNo ratings yet

- Thermal Cutting ProcessesDocument18 pagesThermal Cutting ProcessesLương Hồ VũNo ratings yet

- Silde - Cswip - 3.1 079 156 18Document1 pageSilde - Cswip - 3.1 079 156 18cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 19Document1 pageSilde - Cswip - 3.1 079 156 19cswip2024No ratings yet

- 20 Cutting & Gouging Processes 30-03-07Document6 pages20 Cutting & Gouging Processes 30-03-07vineet chandra khanduriNo ratings yet

- Class 21 Gas Cutting MethodsDocument12 pagesClass 21 Gas Cutting MethodsSriharsha SarmaNo ratings yet

- Silde - Cswip - 3.1 079 156 01Document1 pageSilde - Cswip - 3.1 079 156 01cswip2024No ratings yet

- Nyalaan ApiDocument28 pagesNyalaan ApiIji XiiNo ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Cutting Process and EquipmentDocument8 pagesCutting Process and EquipmentwijiestNo ratings yet

- Silde - Cswip - 3.1 079 156 30Document1 pageSilde - Cswip - 3.1 079 156 30cswip2024No ratings yet

- Indian Institute of Welding-ANB: Refresher Course: Module-06Document64 pagesIndian Institute of Welding-ANB: Refresher Course: Module-06dayalramNo ratings yet

- Cswip - Section 15-Thermal Cutting ProcessesDocument10 pagesCswip - Section 15-Thermal Cutting ProcessesNsidibe Michael EtimNo ratings yet

- OXYFUEL Cutting Processes - Application of Oxyfuel Cutting - TWIDocument10 pagesOXYFUEL Cutting Processes - Application of Oxyfuel Cutting - TWIFarid Ahmed KhwajaNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- Hardfacing Solutions For Oil Gas Applications V1Document25 pagesHardfacing Solutions For Oil Gas Applications V1gacm98100% (1)

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet

- 6.product Tech Slide PresentationDocument158 pages6.product Tech Slide PresentationHadi MuchlisNo ratings yet

- Oxygen Piping Hazards and Customer Engineering ApproachDocument67 pagesOxygen Piping Hazards and Customer Engineering ApproachKom Nak100% (1)

- 7-Welded ConnectionsDocument54 pages7-Welded ConnectionsetemNo ratings yet

- CCMT09T304 MP3025Document1 pageCCMT09T304 MP3025sdhgwdNo ratings yet

- Product Technology (Welds)Document84 pagesProduct Technology (Welds)dvian100% (1)

- Welding Processes 11Document97 pagesWelding Processes 11akabhinav32100% (2)

- Unit III Tool MaterialsDocument7 pagesUnit III Tool Materialsabhishek thakurNo ratings yet

- Ra-253-Ma DB Us en PDFDocument12 pagesRa-253-Ma DB Us en PDFbadesharamkNo ratings yet

- Gas Welding Equipment PowerpointDocument12 pagesGas Welding Equipment Powerpointbhagat103No ratings yet

- St. Joseph'S College of Engineering: Chennai 119Document43 pagesSt. Joseph'S College of Engineering: Chennai 119Praba KaranNo ratings yet

- Flame Cutting Practice:: Jobs 7-J1-J3Document7 pagesFlame Cutting Practice:: Jobs 7-J1-J3Willy UioNo ratings yet

- Welding Upto Gas WeldingDocument26 pagesWelding Upto Gas Weldingrams789No ratings yet

- Oxyfuel Gas Welding (OFW) : ©2010 John Wiley & Sons, Inc. M P GrooverDocument12 pagesOxyfuel Gas Welding (OFW) : ©2010 John Wiley & Sons, Inc. M P GrooverMr-Mk MughalNo ratings yet

- 6 Shielding Gases For Welding Stainless Steels - Glenn Allen - TWI PDFDocument23 pages6 Shielding Gases For Welding Stainless Steels - Glenn Allen - TWI PDFhailay83No ratings yet

- Review of The Course Aircraft MaterialsDocument71 pagesReview of The Course Aircraft MaterialsMohammad NayefNo ratings yet

- Kaiser Aluminum 1100 Tube and PipeDocument2 pagesKaiser Aluminum 1100 Tube and PipeAhmed KandeelNo ratings yet

- Somta Tools User Guide PDFDocument150 pagesSomta Tools User Guide PDFAarón MarxellyNo ratings yet

- Process Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesDocument3 pagesProcess Suitability. Plasma Thermal Hvof: ISSUE: 04/15-1 SupercedesphuongNo ratings yet

- QHSE Bulletin 51Document3 pagesQHSE Bulletin 51wrangularNo ratings yet

- Silde - Cswip - 3.1 079 156 04Document1 pageSilde - Cswip - 3.1 079 156 04cswip2024No ratings yet

- Week No 3Document6 pagesWeek No 3surajit biswasNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- 6005 ProfilesDocument1 page6005 ProfilesBPP-Tech PythonNo ratings yet

- ESAB ExtractPage35-36DDocument16 pagesESAB ExtractPage35-36DDries VandezandeNo ratings yet

- 1-3 Cold Welding, EtcDocument50 pages1-3 Cold Welding, EtcUndertheroadNo ratings yet

- Aircraft MaterialsDocument71 pagesAircraft MaterialsArif AdjaNo ratings yet

- Manufacturing Process IIDocument98 pagesManufacturing Process IIolyad teshomeNo ratings yet

- Coating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in ServiceDocument6 pagesCoating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in Serviceharish mohammedNo ratings yet

- GougingDocument4 pagesGougingmail_younes6592No ratings yet

- Cutting of HARDOX Wear PlateDocument4 pagesCutting of HARDOX Wear PlateRinto SilalahiNo ratings yet

- Unit-V: Metal Joining ProcessesDocument110 pagesUnit-V: Metal Joining ProcessesSubbu Aynavilly100% (1)

- 15 MM 74Document28 pages15 MM 74Sravan Kumar50No ratings yet

- Sheet Coil & Plate Alloy 6061: Technical DataDocument2 pagesSheet Coil & Plate Alloy 6061: Technical DataSarat SrinivasNo ratings yet

- Joining Processes Chapter OutlineDocument7 pagesJoining Processes Chapter OutlineAjyant SuryaNo ratings yet

- PPTDocument18 pagesPPTKaushik SenguptaNo ratings yet

- Welcomes: Protecting The World From WearDocument30 pagesWelcomes: Protecting The World From WearRodolfoMarínNo ratings yet

- GE270 Cutting and Gouging Tips EnglishDocument8 pagesGE270 Cutting and Gouging Tips EnglishVijo JoseNo ratings yet

- Selecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingDocument2 pagesSelecting Tips, Speeds, and Pressures For Oxyfuel Gas CuttingRonny De La CruzNo ratings yet

- Welding MidsemDocument100 pagesWelding Midsemamit kumarNo ratings yet

- HLS2000 enDocument14 pagesHLS2000 enJoão PedroNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Silde - Cswip - 3.1 079 156 58Document1 pageSilde - Cswip - 3.1 079 156 58cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 48Document1 pageSilde - Cswip - 3.1 079 156 48cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 57Document1 pageSilde - Cswip - 3.1 079 156 57cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 56Document1 pageSilde - Cswip - 3.1 079 156 56cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 55Document1 pageSilde - Cswip - 3.1 079 156 55cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 54Document1 pageSilde - Cswip - 3.1 079 156 54cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 45Document1 pageSilde - Cswip - 3.1 079 156 45cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 50Document1 pageSilde - Cswip - 3.1 079 156 50cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 49Document1 pageSilde - Cswip - 3.1 079 156 49cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 47Document1 pageSilde - Cswip - 3.1 079 156 47cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 40Document1 pageSilde - Cswip - 3.1 079 156 40cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 46Document1 pageSilde - Cswip - 3.1 079 156 46cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 26Document1 pageSilde - Cswip - 3.1 079 156 26cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 39Document1 pageSilde - Cswip - 3.1 079 156 39cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 36Document1 pageSilde - Cswip - 3.1 079 156 36cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 22Document1 pageSilde - Cswip - 3.1 079 156 22cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 38Document1 pageSilde - Cswip - 3.1 079 156 38cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 37Document1 pageSilde - Cswip - 3.1 079 156 37cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 30Document1 pageSilde - Cswip - 3.1 079 156 30cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 27Document1 pageSilde - Cswip - 3.1 079 156 27cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 20Document1 pageSilde - Cswip - 3.1 079 156 20cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 15Document1 pageSilde - Cswip - 3.1 079 156 15cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 18Document1 pageSilde - Cswip - 3.1 079 156 18cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 19Document1 pageSilde - Cswip - 3.1 079 156 19cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 13Document1 pageSilde - Cswip - 3.1 079 156 13cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 16Document1 pageSilde - Cswip - 3.1 079 156 16cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 14Document1 pageSilde - Cswip - 3.1 079 156 14cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 12Document1 pageSilde - Cswip - 3.1 079 156 12cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 11Document1 pageSilde - Cswip - 3.1 079 156 11cswip2024No ratings yet

- Stainless Steel Grades 2008 01Document2 pagesStainless Steel Grades 2008 01Rahul LavandNo ratings yet

- Qap of CondenserDocument1 pageQap of CondenserPrakash TiwariNo ratings yet

- FRP ProcessingDocument12 pagesFRP ProcessingJhaPraNo ratings yet

- Module 5Document34 pagesModule 5chloe annNo ratings yet

- Esbc34 5005 AaDocument39 pagesEsbc34 5005 AaAlanevh AlanevhNo ratings yet

- En 24Document1 pageEn 24Puneet BNo ratings yet

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 pagesDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozNo ratings yet

- Specifications Electrical Works Materials WorkmanshipDocument96 pagesSpecifications Electrical Works Materials WorkmanshipAxay PanchalNo ratings yet

- Iif Foundry Talks - WR Magazine September 2023Document24 pagesIif Foundry Talks - WR Magazine September 2023Sajal GoelNo ratings yet

- Distributor - List of Companies in Delhi - Kompass DirectoryDocument20 pagesDistributor - List of Companies in Delhi - Kompass Directoryblr.visheshNo ratings yet

- Aisi 5140Document2 pagesAisi 5140rumabiswas853No ratings yet

- 03 - 2012 - Review of Copper Pyrometallurgical PracticeDocument27 pages03 - 2012 - Review of Copper Pyrometallurgical PracticeNussdy Gajardo PerezNo ratings yet

- Asme Section II A Sa-395Document12 pagesAsme Section II A Sa-395Anonymous GhPzn1xNo ratings yet

- The Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantDocument6 pagesThe Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantkiddNo ratings yet

- Wire Cut EDM PDFDocument5 pagesWire Cut EDM PDFgowtham raju buttiNo ratings yet

- Span Locksl20Document2 pagesSpan Locksl20Cathy PrikhodkoNo ratings yet

- Chapter 1 INTRODUCTION AND OVERVIEW OF MANUFACTURINGDocument2 pagesChapter 1 INTRODUCTION AND OVERVIEW OF MANUFACTURINGLinwoodNo ratings yet

- Pneumatic FittingsDocument7 pagesPneumatic FittingsZakir MunirNo ratings yet

- Galvanized Steel Wire Strands (GSW) JIS G 3537: 1994Document1 pageGalvanized Steel Wire Strands (GSW) JIS G 3537: 1994boedak korporatNo ratings yet

- Product Data Sheet: Sikacor® Eg-1Document4 pagesProduct Data Sheet: Sikacor® Eg-1Thompson LaiNo ratings yet

- UCON Lubricant MWL-4 TDS-EN PDFDocument1 pageUCON Lubricant MWL-4 TDS-EN PDFFadhli KusumaNo ratings yet

- Emerge UK - GeneralDocument9 pagesEmerge UK - GeneralNajib KiwanNo ratings yet

- Piping Erection MethodDocument10 pagesPiping Erection Methodari zeinNo ratings yet

- Tornillos y TuercasDocument128 pagesTornillos y TuercasJaime Islas TrinidadNo ratings yet

- Operation Management Case Studies CombinedDocument1,013 pagesOperation Management Case Studies CombinedRahulNo ratings yet

- Gr-10S Nut M24 MarkingDocument1 pageGr-10S Nut M24 MarkingSUMANTANo ratings yet

- Threaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Document7 pagesThreaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Cardoso MalacaoNo ratings yet

- PETSEA RO SWY 110 - 120 130 - 150 HmsaDocument10 pagesPETSEA RO SWY 110 - 120 130 - 150 HmsaAlexanderNo ratings yet

- Fabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Document7 pagesFabric Expansion Joint: Catalogue Flytech Engineering SDN BHD 1/1/2011Sejadah MaryamNo ratings yet