Professional Documents

Culture Documents

Silde - Cswip - 3.1 079 156 30

Silde - Cswip - 3.1 079 156 30

Uploaded by

cswip2024Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silde - Cswip - 3.1 079 156 30

Silde - Cswip - 3.1 079 156 30

Uploaded by

cswip2024Copyright:

Available Formats

MIG/MAG Welding Consumables MIG/MAG Welding Consumables

Wire designation acc AWS A-5.18: How to check the quality of welding wires:

Chemical composition of the solid Cast diameter

wire or of the weld metal in case Helix size - limited to 25mm

of composite electrodes to avoid problems with arc

Minimum UTS of weld metal (ksi)

wandering!

Standard number

Cast diameter improves the contact force and defines the contact

AWS A-5.18 ER 70 S-6 point; usually 400-1200mm.

Designate an electrode/rod (ER)

or only an electrode (E)

Solid (S) or composite (C) wire

Contact point close to Contact point remote from

contact tip end - GOOD! contact tip end - POOR!

Copyright © TWI Ltd Copyright © TWI Ltd

MIG/MAG Shielding Gases MIG/MAG Shielding Gases

Gas shielded Ar Ar-He He CO2

metal arc welding

MIG process (131) MAG process (135) Argon (Ar):

Higher density than air; low thermal conductivity - the arc

has a high energy inner cone; good wetting at the toes;

BS EN 14175 low ionisation potential.

Helium (He):

Lower density than air; high thermal conductivity -

uniformly distributed arc energy; parabolic profile; high

Group I - Ar, He Group R - Group M - Ar + Group C - ionisation potential.

and Ar-He Ar + H2 CO2/O2 CO2, CO2 + Carbon Dioxide (CO2):

mixtures (<35%) (<50/15%) O2 (<30%) Cheap; deep penetration profile; cannot support spray

transfer; poor wetting; high spatter.

Copyright © TWI Ltd Copyright © TWI Ltd

MIG/MAG Shielding Gases MIG/MAG Shielding Gases

Gases for dip transfer: Gases for spray transfer

CO2: Carbon steels only; deep penetration; fast Ar + (5-18)% CO2: Carbon steels; minimum

welding speed; high spatter levels. spatter; good wetting and bead contour.

Ar + up to 25% CO2: Carbon and low alloy Ar + 2% O2: Low alloy steels; minimise undercut;

steels; minimum spatter; good wetting and bead provides good toughness.

contour. Ar + 2% O2 or CO2: Stainless steels; improved

90% He + 7,5% Ar + 2,5% CO2: Stainless arc stability; provides good fusion.

steels; minimises undercut; small HAZ. Ar: Al, Mg, Cu, Ni, Ti and their alloys.

Ar: Al, Mg, Cu, Ni and their alloys on thin Ar + He mixtures: Al, Cu, Ni and their alloys;

sections. hotter arc than pure Ar to offset heat dissipation.

Ar + He mixtures: Al, Mg, Cu, Ni and their alloys Ar + (25-30)% N2: Cu alloys; greater heat input.

on thicker sections (over 3mm).

Copyright © TWI Ltd Copyright © TWI Ltd

16-10

You might also like

- Handy-Tig 210 AcdcDocument80 pagesHandy-Tig 210 AcdcEdin Edin100% (1)

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- 13 Mig & Mag WeldingDocument24 pages13 Mig & Mag WeldingMohamed BencharifNo ratings yet

- Silde - Cswip - 3.1 079 156 07Document1 pageSilde - Cswip - 3.1 079 156 07cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Welding Consumable Selection (MAG Welding)Document5 pagesWelding Consumable Selection (MAG Welding)tiepnh.ameccNo ratings yet

- TIG and MIG Welding Answer To QuestionsDocument3 pagesTIG and MIG Welding Answer To QuestionsJay EmNo ratings yet

- MAG Wire: Welding Consumables SelectionDocument5 pagesMAG Wire: Welding Consumables SelectionhudysyafrullahNo ratings yet

- Silde - Cswip - 3.1 079 156 13Document1 pageSilde - Cswip - 3.1 079 156 13cswip2024No ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- Book of Welding 2007 PDFDocument80 pagesBook of Welding 2007 PDFravi00098100% (1)

- Solliid WiireDocument6 pagesSolliid WiireVõĐìnhKhaNo ratings yet

- Silde - Cswip - 3.1 079 156 27Document1 pageSilde - Cswip - 3.1 079 156 27cswip2024No ratings yet

- O01 Core-TapsDocument2 pagesO01 Core-TapshuychungngNo ratings yet

- High Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlDocument4 pagesHigh Temperature Metal Sheathed Thermocouples - Type 27: TC LTD For Temperature Sensing, Measurement and ControlSyed Zakir Hussain ZaidiNo ratings yet

- TA201A Spring 2023 Class 8Document28 pagesTA201A Spring 2023 Class 8Aditya ShankarNo ratings yet

- Consumables General PowerpointDocument10 pagesConsumables General PowerpointMorg ActusNo ratings yet

- Silde - Cswip - 3.1 079 156 04Document1 pageSilde - Cswip - 3.1 079 156 04cswip2024No ratings yet

- IAB-252r3-16 M1-1.6 Introduction To Gas Shielded Arc Welding PDFDocument71 pagesIAB-252r3-16 M1-1.6 Introduction To Gas Shielded Arc Welding PDFkatfy1No ratings yet

- Silde - Cswip - 3.1 079 156 01Document1 pageSilde - Cswip - 3.1 079 156 01cswip2024No ratings yet

- 12 TIG Welding.Document9 pages12 TIG Welding.Anonymous 1NLfN2yhYNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- Consumables For MIG MAG & FCAWDocument46 pagesConsumables For MIG MAG & FCAWaravindanNo ratings yet

- Silde - Cswip - 3.1 079 156 02Document1 pageSilde - Cswip - 3.1 079 156 02cswip2024No ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Welcome YOU: Institute of Welding & Testing TechnologyDocument92 pagesWelcome YOU: Institute of Welding & Testing TechnologyHimanshu MishraNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- TDZ AlloyDocument1 pageTDZ AlloyIan MacMoyNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Weldability of Non-Ferrous AlloysDocument15 pagesWeldability of Non-Ferrous AlloyslebogangmarobaneNo ratings yet

- ER316LDocument1 pageER316LslowmosquitoNo ratings yet

- PPTDocument18 pagesPPTKaushik SenguptaNo ratings yet

- Arc WeldingDocument29 pagesArc WeldinguditNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- 1a Arc Weld ProcessesDocument45 pages1a Arc Weld ProcessesskgcNo ratings yet

- Soal Pembahasan-2Document22 pagesSoal Pembahasan-2xrsqcxcjxvNo ratings yet

- Shielding Gases ACM Vs CO2Document34 pagesShielding Gases ACM Vs CO2ukavathekar100% (2)

- WA Applications For HydropowerDocument6 pagesWA Applications For Hydropowersuharto ekoNo ratings yet

- WP I FCAW Sept 2010Document99 pagesWP I FCAW Sept 2010jhas988No ratings yet

- MPR-unit-V D.B.Patil NDocument14 pagesMPR-unit-V D.B.Patil NSakshi SalunkheNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- D-Sub 2018Document8 pagesD-Sub 2018samyghallabNo ratings yet

- Equivalencia Moldes Erico y CadwellDocument58 pagesEquivalencia Moldes Erico y CadwellCarlo Rocha ZapanaNo ratings yet

- Welding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RiboDocument51 pagesWelding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RibojswldeepNo ratings yet

- Welding Soldering BrazingDocument100 pagesWelding Soldering BrazingMore YashNo ratings yet

- WeldingDocument84 pagesWeldingJigar DodiaNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Gas Tungsten Arc WeldingDocument9 pagesGas Tungsten Arc Weldingweldingking1100% (1)

- Material Datasheet Cu-OFDocument2 pagesMaterial Datasheet Cu-OFmohsen_267No ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- Flux Cored WiireDocument25 pagesFlux Cored WiirehetpinNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

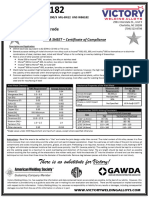

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Cu Ofe c10100 Pna 203 - enDocument2 pagesCu Ofe c10100 Pna 203 - enNitin KumarNo ratings yet

- Iso 14175Document12 pagesIso 14175Juan Carlos100% (3)

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- Silde - Cswip - 3.1 079 156 58Document1 pageSilde - Cswip - 3.1 079 156 58cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 48Document1 pageSilde - Cswip - 3.1 079 156 48cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 57Document1 pageSilde - Cswip - 3.1 079 156 57cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 56Document1 pageSilde - Cswip - 3.1 079 156 56cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 55Document1 pageSilde - Cswip - 3.1 079 156 55cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 54Document1 pageSilde - Cswip - 3.1 079 156 54cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 45Document1 pageSilde - Cswip - 3.1 079 156 45cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 50Document1 pageSilde - Cswip - 3.1 079 156 50cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 49Document1 pageSilde - Cswip - 3.1 079 156 49cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 47Document1 pageSilde - Cswip - 3.1 079 156 47cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 40Document1 pageSilde - Cswip - 3.1 079 156 40cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 46Document1 pageSilde - Cswip - 3.1 079 156 46cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 22Document1 pageSilde - Cswip - 3.1 079 156 22cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 39Document1 pageSilde - Cswip - 3.1 079 156 39cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 36Document1 pageSilde - Cswip - 3.1 079 156 36cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 21Document1 pageSilde - Cswip - 3.1 079 156 21cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 38Document1 pageSilde - Cswip - 3.1 079 156 38cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 37Document1 pageSilde - Cswip - 3.1 079 156 37cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 20Document1 pageSilde - Cswip - 3.1 079 156 20cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 27Document1 pageSilde - Cswip - 3.1 079 156 27cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 26Document1 pageSilde - Cswip - 3.1 079 156 26cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 19Document1 pageSilde - Cswip - 3.1 079 156 19cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 15Document1 pageSilde - Cswip - 3.1 079 156 15cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 17Document1 pageSilde - Cswip - 3.1 079 156 17cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 18Document1 pageSilde - Cswip - 3.1 079 156 18cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 13Document1 pageSilde - Cswip - 3.1 079 156 13cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 16Document1 pageSilde - Cswip - 3.1 079 156 16cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 14Document1 pageSilde - Cswip - 3.1 079 156 14cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 12Document1 pageSilde - Cswip - 3.1 079 156 12cswip2024No ratings yet

- Silde - Cswip - 3.1 079 156 11Document1 pageSilde - Cswip - 3.1 079 156 11cswip2024No ratings yet

- Doc053 52 35019Document4 pagesDoc053 52 35019Ricardo RamosNo ratings yet

- ChiralityDocument44 pagesChiralitysubra.s.224No ratings yet

- CPP-1 HA SN ReactionsDocument4 pagesCPP-1 HA SN ReactionsAstrix RogerNo ratings yet

- COORDINATION (With Reac. Mech) PPT Notes BY DR. Kuldeep GargDocument436 pagesCOORDINATION (With Reac. Mech) PPT Notes BY DR. Kuldeep Gargkadamankita600No ratings yet

- The Effect of Corrosion On Crude Oil Distillation Plants 1715509028Document9 pagesThe Effect of Corrosion On Crude Oil Distillation Plants 1715509028Ahmed ELmlahyNo ratings yet

- CHEMLOK 6224 Safety Data SheetDocument8 pagesCHEMLOK 6224 Safety Data Sheetgino.pontigoNo ratings yet

- Novichok HistoryDocument8 pagesNovichok HistorytommyrutagiraNo ratings yet

- Gr11 Phy P2 (ENG & AFR) June 2017 Possible AnswersDocument14 pagesGr11 Phy P2 (ENG & AFR) June 2017 Possible Answersyoungmarley457No ratings yet

- Bio CleanerDocument1 pageBio CleanerNirban sahaNo ratings yet

- Bitzer BSE 170Document7 pagesBitzer BSE 170Felipe MNo ratings yet

- Haloalkanes Haloarenes RAFTAAR Nitesh DevnaniDocument73 pagesHaloalkanes Haloarenes RAFTAAR Nitesh DevnaniTech MilitiaNo ratings yet

- Dronacharya II 2024 Sample Paper Class Xi p4 PCMDocument11 pagesDronacharya II 2024 Sample Paper Class Xi p4 PCMvihaansharma20No ratings yet

- Nickel SulfateDocument127 pagesNickel SulfateMayerly Giraldo AvilaNo ratings yet

- Facile Synthesis of TiO2 - MoS2 Composites With Co-Exposed High-Energy Facets For Enhanced Photocatalytic Performance - Niu - 2022Document17 pagesFacile Synthesis of TiO2 - MoS2 Composites With Co-Exposed High-Energy Facets For Enhanced Photocatalytic Performance - Niu - 2022leonardoNo ratings yet

- Pepsin EnzymeDocument5 pagesPepsin Enzymesaitama12343217No ratings yet

- STPM Chem Real Paper.Document9 pagesSTPM Chem Real Paper.Chin Ling ChiengNo ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22Jahangir KhanNo ratings yet

- Nano Select - 2023 - Mekuye - Nanomaterials An Overview of Synthesis Classification Characterization and ApplicationsDocument16 pagesNano Select - 2023 - Mekuye - Nanomaterials An Overview of Synthesis Classification Characterization and ApplicationsAmeer HamzaNo ratings yet

- FB28-11 2022 Assessing Compatibility of Glazing Materials ComponentsDocument6 pagesFB28-11 2022 Assessing Compatibility of Glazing Materials ComponentsLEONARDONo ratings yet

- SME Chemistry Topic 10 Organic Chemistry NotesDocument69 pagesSME Chemistry Topic 10 Organic Chemistry Notessiqi daiNo ratings yet

- ACS 04 To FBW Manual (Reprint April 2022)Document13 pagesACS 04 To FBW Manual (Reprint April 2022)ewsbiwrNo ratings yet

- Answers To Ut Homework Quest ChemistryDocument6 pagesAnswers To Ut Homework Quest Chemistryafetzhsse100% (1)

- ecoWARE HandleDocument12 pagesecoWARE HandleMohd FazlanNo ratings yet

- CC Part1 Notes Simply ConciseDocument9 pagesCC Part1 Notes Simply Conciserahuldolai24No ratings yet

- Acid BaseDocument5 pagesAcid Bases5mcfdr7ztNo ratings yet

- Astm A351 A351m 18Document4 pagesAstm A351 A351m 18Milady OyuelaNo ratings yet

- GMW11 2019 03 (Electrogalvanized Coating Sheet Steel)Document8 pagesGMW11 2019 03 (Electrogalvanized Coating Sheet Steel)dpfloresNo ratings yet

- Chemical Kinetics MCQ 2Document16 pagesChemical Kinetics MCQ 2vijayresup123No ratings yet

- Solder Joint Embrittlement Mechanisms Solutions Standards IpcDocument17 pagesSolder Joint Embrittlement Mechanisms Solutions Standards IpcRobert MartosNo ratings yet

- FORAY® ABC Multi Purpose Dry ChemicalDocument8 pagesFORAY® ABC Multi Purpose Dry ChemicalAnggiNo ratings yet