Professional Documents

Culture Documents

Concreting Part B

Concreting Part B

Uploaded by

haseebafghan1999Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concreting Part B

Concreting Part B

Uploaded by

haseebafghan1999Copyright:

Available Formats

NED University of Engineering and Technology, Karachi

CONCRETE CONSTRUCTION CONCRETE CONSTRUCTION

PRACTICES PRACTICES

• Concrete construction involves concrete • Transporting and Handling

batching, mixing, transporting, placing, • Placing and Consolidating

consolidating, finishing, and curing. • Finishing and Curing

• Hot-Weather Concreting

• Cold-Weather Concreting

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

Transporting and Handling Transporting and Handling

• Equipment commonly used includes wheelbarrows, • Wheelbarrows have

buggies, chutes, conveyors, pumps, buckets, and – a very limited capacity (about 1.5 cu ft or 0.04 m3)

trucks. – often used for transporting and placing small amounts of

• Regardless of the equipment used, care must be concrete.

taken to avoid segregation when handling concrete.

• Concrete pumps

• The height of free fall should be limited to about 5 ft – Capable of moving concrete from a truck directly into final

position

(1.5 m) unless downpipes or ladders are used to

– Up to heights of 500 ft (152 m) or more.

prevent segregation.

– Truck-mounted concrete pumps equipped with placement

booms are widely used in building construction.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 1

NED University of Engineering and Technology, Karachi

CONCRETE CONSTRUCTION

Transporting and Handling

PRACTICES

• Concrete conveyors are available to move concrete either

horizontally or vertically.

• Chutes are widely used for moving concrete from the mixer to

haul units and for placing concrete into forms.

• Truck mixers are equipped with integral retracting chutes that

may be used for discharging concrete directly into forms within

the radius of the chute. When chuting concrete, the slope of the

chute must be high enough to keep the chute clean but not high

enough to produce segregation of the concrete.

• Concrete buckets attached to cranes are capable of lifting

concrete to the top of highrise buildings and of moving concrete

over a wide area.

• Concrete buckets are equipped with a bottom gate and a

FIGURE 6-15. Concrete pump and truck mixer. (Courtesy of Morgen release mechanism for unloading concrete at the desired

Manufacturing Co.) location.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

Truck Mixer with Chute

Concrete conveyor System

Concrete Chute

Concrete buckets attached to cranes

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 2

NED University of Engineering and Technology, Karachi

Placing and Consolidating Placing and Consolidating

• When concrete is poured directly onto a subgrade, the

• The movement of plastic concrete into its final position (usually subgrade should be moistened or sealed by a moisture barrier

within forms) is called placing. to prevent the subgrade from absorbing water from the plastic

concrete.

• Before placing concrete, the underlying surface and the interior • When placing fresh concrete on top of hardened concrete, the

of all concrete forms must be properly prepared. surface of the hardened concrete should be roughened to

provide an adequate bond between the two concrete layers.

• Concrete forms must be clean and tight and their interior • To improve bonding between the layers, the surface of the

surfaces coated with form oil or a parting agent to allow removal hardened concrete should also be coated with grout or a layer

of the form from the hardened concrete without damaging the of mortar before the fresh concrete is placed.

surface of the concrete. • Concrete is usually placed in layers 6 to 24 in. (15 to 61 cm)

thick.

• When placing concrete in layers, care must be taken to ensure

that the lower layer does not take its initial set before the next

layer is poured.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

Placing and Consolidating Placing and Consolidating

• Strength, watertightness, durability, and wear resistance of • Concrete may also be pneumatically

concrete are largely determined by the water/cement ratio of the placed by spraying it onto a surface.

concrete mix.

• Concrete placed by this process is

called shotcrete and is also called

• Therefore, do not allow construction crews or transit mix

pneumatically applied concrete,

operators to add additional water to the mix for the purpose of gunned concrete, or gunite.

increasing the workability of the plastic concrete.

• Since a relatively dry mix is used,

• If a more workable mix is needed, the mix design should be shotcrete may be applied to overhead

modified accordingly. and vertical surfaces.

• The addition of workability agents should provide plastic • Shotcrete is often used for constructing

tanks, swimming pools, and tunnel

concrete with acceptable workability.

liners, as well as for repairing

damaged concrete structures.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 3

NED University of Engineering and Technology, Karachi

Placing and Consolidating Finishing

• Consolidation is the process of removing air voids in concrete as it • Finishing is the process of bringing the surface of concrete to its

is placed. final position and imparting the desired surface texture.

• Concrete vibrators are normally used for consolidating concrete, • Finishing operations include screeding, floating, troweling,and

but hand rodding or spading may be employed. brooming.

• Immersion-type electric, pneumatic, or hydraulic concrete vibrators – Screeding is the process of striking off the concrete in order to bring the

concrete surface to the required grade. When the concrete has hardened

are widely used.

sufficiently so that a worker’s foot makes only a small impression in the

• However, form vibrators or vibrators attached to the outside of the surface, the concrete is floated with a wood or metal float.

concrete forms are sometimes employed. – Floating smooths and compacts the surface while embedding aggregate

• Vibrators should not be used to move concrete horizontally,as this particles.

practice may produce segregation of the concrete mix. – Troweling with a steel trowel follows floating when a smooth dense surface

is desired.

• Vibrators should be inserted into the concrete vertically and – Finally, the concrete may be broomed by drawing a stiff broom across the

allowed to penetrate several inches into the previously placed layer surface. This technique is used when a textured skid-resistant surface is

of concrete. desired.

• The vibrator should be withdrawn and moved to another location

when cement paste becomes visible at the top of the vibrator.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CONCRETE CONSTRUCTION CONCRETE CONSTRUCTION

PRACTICES PRACTICES

FIGURE 6-16. Ride-on power trowel.

(Courtesy of Wacker Corporation)

FIGURE 6-17. Roller finisher being used on large slab pour. (Courtesy of

Terex Roadbuilding)

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 4

NED University of Engineering and Technology, Karachi

Curing Hot-Weather Concreting

• The completion of cement hydration requires that adequate

moisture and favorable temperatures be maintained after • The rate of hardening of concrete is greatly accelerated when

concrete is placed. concrete temperature is appreciably higher than the optimum

• The process of providing the required water and maintaining a temperature of 50 to 60° F (10 to 15.5° C).

favorable temperature for a period of time after placing • Ninety degrees Fahrenheit (32° C) is considered a reasonable

concrete is referred to as curing. upper limit for concreting operations.

• Methods used to retain adequate curing moisture include • In addition to reducing setting time, higher temperatures reduce

– covering the concrete surface with wet straw or burlap, the amount of slump for a given mix.

– ponding water on the surface, • If additional water is added to obtain the desired slump,

additional cement must also be added or the water-cement ratio

– covering the surface with paper or plastic sheets, and

will be increased with corresponding strength reduction.

– Applying curing compounds.

• High temperatures, especially when accompanied by winds and

• The use of sprayed-on curing compounds applied immediately low humidity, greatly increase the shrinkage of concrete and

after finishing has become widespread in recent years. often lead to surface cracking of the concrete.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

Hot-Weather Concreting Cold-Weather Concreting

• The temperature of the plastic concrete may be lowered by • The problems of cold-weather concreting are essentially

cooling the mixing water and/or aggregates before mixing. opposite to those of hot-weather concreting.

• Heat gain during hydration may be reduced by using Type IV • Concrete should not be placed on a frozen surface and must

(low-heat) cement or by adding a retarder. not be allowed to freeze during the first 24 h after placing to

avoid permanent damage and loss of strength.

• Air-entraining agents, water-reducing agents, or workability

agents may be used to increase the workability of the mix • Concrete forms and reinforcing steel should be free of frost,

without changing water/cement ratios. ice, and snow and at a temperature above freezing.

• It is also advisable to reduce the maximum time before • Specifications often require that, when air temperature is 40˚/F

discharge of ready-mixed concrete from the normal 11⁄2 to 1 h (5˚ C) or less, concrete be placed at a minimum temperature of

or less. 50˚ F (10˚ C) and that this temperature be maintained for at

least 3 d after placing.

• The use of shades or covers will be helpful in controlling the

temperature of concrete after placement. • However, ACI recommends that a temperature of 70˚ F (21˚ C)

be maintained for 3 d or 50˚ F (10˚ C) be maintained for 5 d

• Moist curing should start immediately after finishing and

after pouring to ensure that the concrete will attain its design

continue for at least 24 h.

strength.

CE-321-Construction Engineering CE-321-Construction Engineering

Dr. Farrukh Arif Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 5

NED University of Engineering and Technology, Karachi

Cold-Weather Concreting

• Type III (high early strength) cement or an accelerator may be

used to reduce concrete setting time during low temperatures.

• The air content of the concrete mix should be checked to ensure

that the air content does not exceed mix design specifications.

• Mix water and/or aggregates may be heated prior to mixing to

raise the temperature of the plastic concrete.

– However, cement should not be allowed to contact hot

water.

– Therefore, the aggregate should be mixed with the heated

water prior to adding cement to the mix.

• When heat is used for curing, the concrete must be allowed to

cool gradually at the end of the heating period or cracking may

result.

CE-321-Construction Engineering

Dr. Farrukh Arif

CE-321 Construction Engineering (Dr. Farrukh Arif) 6

You might also like

- 0.tunnel Form Technology-Case StudyDocument93 pages0.tunnel Form Technology-Case StudyP.K.MallickNo ratings yet

- CES525 - Assignment 2Document13 pagesCES525 - Assignment 2Alif AkhmizanNo ratings yet

- Block Wall - Risk AssessmentDocument19 pagesBlock Wall - Risk Assessmentfziza100% (3)

- Slip Formwork Use For ConstructionsDocument87 pagesSlip Formwork Use For Constructionscoepcesa67% (3)

- 01 Cast in Place and Pre CastBT5Document30 pages01 Cast in Place and Pre CastBT5Charlyn Marie DiegoNo ratings yet

- 01 Cast in Place and Pre CastBT5Document30 pages01 Cast in Place and Pre CastBT5Charlyn Marie DiegoNo ratings yet

- Construction Methods and Equipment M1Document75 pagesConstruction Methods and Equipment M1NITHIN A VNo ratings yet

- Bridge Construction TechniquesDocument71 pagesBridge Construction TechniquesAneetha VNo ratings yet

- 2.4 - Pre Stressing UploadDocument18 pages2.4 - Pre Stressing UploadathavanNo ratings yet

- SCC PosterDocument6 pagesSCC PosterSrinidhi GanesanNo ratings yet

- Technolgy Practice Part 1 and CompaniesDocument138 pagesTechnolgy Practice Part 1 and CompaniesKobciye ProductionNo ratings yet

- Cover Page Only 1Document15 pagesCover Page Only 1Zelalem TeshomeNo ratings yet

- 1901 AR323 BCT03 21 L08 (Building Framing Systems)Document25 pages1901 AR323 BCT03 21 L08 (Building Framing Systems)Jensine NgowNo ratings yet

- RCC Principles - Construction ProcessDocument44 pagesRCC Principles - Construction ProcessDharatiSote100% (1)

- Dot 18750 DS1Document102 pagesDot 18750 DS1Maisie SuyatNo ratings yet

- NCC Internship ReportDocument43 pagesNCC Internship ReportVIDHI YADAVNo ratings yet

- Concrete Tech 1 NotesDocument11 pagesConcrete Tech 1 NotesNaisi MASTERNo ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- 5927913concrete PPT 2 by Badal SirDocument20 pages5927913concrete PPT 2 by Badal Sirsakshm guptaNo ratings yet

- Unit-3Document22 pagesUnit-3Vijay VNo ratings yet

- Unit 3 & 4Document58 pagesUnit 3 & 4JAZPAKNo ratings yet

- 5447 - Concrete Box CulvertsDocument6 pages5447 - Concrete Box CulvertssdewssNo ratings yet

- Unit 528 Concrete Design Task 2Document14 pagesUnit 528 Concrete Design Task 2Shine AungNo ratings yet

- Precast Technology With The Case Study of BWSLDocument93 pagesPrecast Technology With The Case Study of BWSLer_hvpatelNo ratings yet

- 2-Batching, Mixing, Transporting and Handling ConcreteDocument57 pages2-Batching, Mixing, Transporting and Handling ConcreteMa ThiNo ratings yet

- Lec-1 Batching Transportation and Placing Od ConcreteDocument58 pagesLec-1 Batching Transportation and Placing Od ConcreteHasnain MehmoodNo ratings yet

- Concreting SopDocument9 pagesConcreting SopvivekNo ratings yet

- Bridge ConstructionDocument53 pagesBridge ConstructionRuthNo ratings yet

- CV324 Construction: Road & Marine ApplicationDocument55 pagesCV324 Construction: Road & Marine ApplicationTusanita MapuolaNo ratings yet

- Precast Concrete Manufacturing Techniques and InstallationDocument21 pagesPrecast Concrete Manufacturing Techniques and InstallationVIgneshNo ratings yet

- Advancement in RCC Construction PracticeDocument46 pagesAdvancement in RCC Construction PracticeAbhishek KumarNo ratings yet

- Methods of Construction of Prestressed MembersDocument20 pagesMethods of Construction of Prestressed Membersofreneo_joshua4437No ratings yet

- Pre Fabrication and Pre StressingDocument25 pagesPre Fabrication and Pre StressingIqRa JaVedNo ratings yet

- Method Statement For Footing Concrete PouringDocument9 pagesMethod Statement For Footing Concrete PouringKishore KumarNo ratings yet

- Precast ConcreteDocument6 pagesPrecast ConcreteRaja Sekhar Reddy KasuNo ratings yet

- Lift Slab Method&prestressed Concrete-71015Document19 pagesLift Slab Method&prestressed Concrete-71015Ravi ChandraNo ratings yet

- Transportation 2 Concrete 1Document7 pagesTransportation 2 Concrete 1Erick ochiengNo ratings yet

- Specialized Construction Techniques - FinalDocument102 pagesSpecialized Construction Techniques - FinalSabella JimenezNo ratings yet

- Structural Design of Railways and PavementsDocument57 pagesStructural Design of Railways and PavementsJannila PaulinoNo ratings yet

- Concrete Pumps and Mixers For Ready Made ConcreteDocument15 pagesConcrete Pumps and Mixers For Ready Made ConcreteRhythm SatyaNo ratings yet

- Methodology For Piling WorkDocument5 pagesMethodology For Piling WorkAftab AlamNo ratings yet

- Precast Concrete Precast ConcreteDocument32 pagesPrecast Concrete Precast Concreteflower lilyNo ratings yet

- Tools For RCC-1Document33 pagesTools For RCC-1Srushti NaikNo ratings yet

- FLORES - LGD - LP#3 CMPM Student TaskDocument15 pagesFLORES - LGD - LP#3 CMPM Student TaskLanze Gabreill FloresNo ratings yet

- Concrete Construction Article PDF - How To Plan A Large Tilt-Up ProjectDocument4 pagesConcrete Construction Article PDF - How To Plan A Large Tilt-Up Projectjon J SmithNo ratings yet

- ConcreteDocument4 pagesConcretesynpavanNo ratings yet

- Concrete Works: Cement OPC (Composition Quality) Aggregate Sand and Gravel (Size, Shape and Grading) Water (Quantity)Document14 pagesConcrete Works: Cement OPC (Composition Quality) Aggregate Sand and Gravel (Size, Shape and Grading) Water (Quantity)Abel BerhanemeskelNo ratings yet

- Cement Concrete PlantsDocument24 pagesCement Concrete PlantsajayNo ratings yet

- CONST. METHODOLOGY ILOCOS (Stadium)Document10 pagesCONST. METHODOLOGY ILOCOS (Stadium)Ralph GalvezNo ratings yet

- 4.3 - K F Tam, Gammon - PDFDocument11 pages4.3 - K F Tam, Gammon - PDFsouthchayNo ratings yet

- Precast Assignment - Docx AmerDocument2 pagesPrecast Assignment - Docx AmerMuhammad FaqrullahNo ratings yet

- Method Statement For Construction of Precast Concrete Pipe CulvertDocument4 pagesMethod Statement For Construction of Precast Concrete Pipe CulvertDanny NguNo ratings yet

- Foundations BookletDocument5 pagesFoundations BookletForbes KambaNo ratings yet

- Rohini 68390450227Document5 pagesRohini 68390450227P.Prithivi RajNo ratings yet

- AYERS Session 18Document58 pagesAYERS Session 18deepakNo ratings yet

- Methods of Transportation of Concrete - Dumpers, Trucks, Belt Conveyors, Monorail, TremieDocument3 pagesMethods of Transportation of Concrete - Dumpers, Trucks, Belt Conveyors, Monorail, TremieSRPC CIVILNo ratings yet

- Innovative Construction Technologies & Best Construction PracticesDocument57 pagesInnovative Construction Technologies & Best Construction Practices18CE040 :- Abhijit MhatarmareNo ratings yet

- Bridges - ConstrofacilitatorDocument22 pagesBridges - ConstrofacilitatorConstro FacilitatorNo ratings yet

- Building Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksFrom EverandBuilding Landmarks - Bridges, Tunnels and Buildings - Architecture and Design | Children's Engineering BooksNo ratings yet

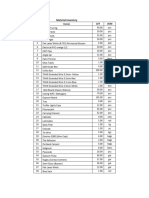

- Cost and EstimationDocument5 pagesCost and Estimationhaseebafghan1999No ratings yet

- Ce 19214Document11 pagesCe 19214haseebafghan1999No ratings yet

- Soil Mechanics-LDocument7 pagesSoil Mechanics-Lhaseebafghan1999No ratings yet

- Mos-Ll CEPDocument27 pagesMos-Ll CEPhaseebafghan1999No ratings yet

- CEP Structural AnalysisDocument16 pagesCEP Structural Analysishaseebafghan1999No ratings yet

- Dewatering PresentationDocument21 pagesDewatering Presentationhaseebafghan1999No ratings yet

- BO Modeler V3-N1 2007 JanFebDocument29 pagesBO Modeler V3-N1 2007 JanFebColin 't HartNo ratings yet

- Gps PillarDocument6 pagesGps PillarKosygin LeishangthemNo ratings yet

- Chengannur ReDocument1,077 pagesChengannur ReArul RajanNo ratings yet

- Reinforced Concrete 1 CE 309: Doç. Dr. Deniz GÜNEYDocument20 pagesReinforced Concrete 1 CE 309: Doç. Dr. Deniz GÜNEYoxana151No ratings yet

- Dura BlokDocument10 pagesDura BloktdzeienNo ratings yet

- Propadnje Drvenog BrodaDocument3 pagesPropadnje Drvenog BrodabartulNo ratings yet

- History of Architecture1Document7 pagesHistory of Architecture1Happy SaitamaNo ratings yet

- RSMFDocument7 pagesRSMFC V RNo ratings yet

- B8-1 - Jason Deruyver - Timber Bridge2Document35 pagesB8-1 - Jason Deruyver - Timber Bridge2Tony ParkNo ratings yet

- Test Report ASSET DOC LOC 66319Document22 pagesTest Report ASSET DOC LOC 66319Nyein ZawNo ratings yet

- Art Appreciation Midterm IIDocument50 pagesArt Appreciation Midterm IIPaul John MadrigalNo ratings yet

- GMP Control Facility 08 1260 05 DBE ListingDocument205 pagesGMP Control Facility 08 1260 05 DBE ListingJAGUAR GAMINGNo ratings yet

- Lesson 3.3Document12 pagesLesson 3.3Joylene Dayrit KIMNo ratings yet

- Exemplar Sustainable Bulding TechnologyDocument56 pagesExemplar Sustainable Bulding TechnologyIDEAL DRAGONSNo ratings yet

- Architectural Joint SystemsDocument7 pagesArchitectural Joint SystemsHusen ZahranNo ratings yet

- Concrete Pavements For Climate Resilient Low Volume Roads in Pacific Island CountriesDocument62 pagesConcrete Pavements For Climate Resilient Low Volume Roads in Pacific Island CountriesKhải TrươngNo ratings yet

- Case Studies in Structural Repair of Pretensioned Concrete ProductsDocument6 pagesCase Studies in Structural Repair of Pretensioned Concrete Productsmekkawi6650No ratings yet

- A Maize Ing Heat Owners Manual 620 9 English Rev 4Document40 pagesA Maize Ing Heat Owners Manual 620 9 English Rev 4MattNo ratings yet

- CEBEX100Document2 pagesCEBEX100mathi vijayNo ratings yet

- Msil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With CommentsDocument1 pageMsil KH SPCL Press (A+b) Column Lyt 155 Tce Approved With Commentsrohitbhagat005No ratings yet

- Construction and Building Materials: Viktor MechtcherineDocument11 pagesConstruction and Building Materials: Viktor MechtcherinesardarumersialNo ratings yet

- BLD 212 Lecture 1Document10 pagesBLD 212 Lecture 1Umar Bello NuhuNo ratings yet

- Code GAF Shingle Products ICC ESR1475Document12 pagesCode GAF Shingle Products ICC ESR1475oswaldoNo ratings yet

- Top 50+ Civil Engineering Interview Questions and Answers 2021Document9 pagesTop 50+ Civil Engineering Interview Questions and Answers 2021Irfan Awan100% (1)

- Chapter 8&9 FinalDocument91 pagesChapter 8&9 Finalsagar khanalNo ratings yet

- Wainscoting - Catalogue (New)Document4 pagesWainscoting - Catalogue (New)IfKitchen ConceptNo ratings yet

- OPSS 351 Nov15Document10 pagesOPSS 351 Nov15Muhammad UmarNo ratings yet

- Material InventoryDocument1 pageMaterial InventorylegallyhungryblueNo ratings yet

- C1116-C1116M - 10aDocument7 pagesC1116-C1116M - 10aElder SantosNo ratings yet

- Cap 123H Building (Refuse Storage and Material Recovery Chambers and Refuse Chutes (09-02-2012)Document22 pagesCap 123H Building (Refuse Storage and Material Recovery Chambers and Refuse Chutes (09-02-2012)Susan LamNo ratings yet