Professional Documents

Culture Documents

5s Levels of Achivment

5s Levels of Achivment

Uploaded by

Muhamad Fahril Rohim0 ratings0% found this document useful (0 votes)

0 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

0 views2 pages5s Levels of Achivment

5s Levels of Achivment

Uploaded by

Muhamad Fahril RohimCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

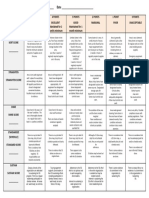

5s levels of achivment

LEVEL Sort Straighten Scrub Standardize

0 Needed and not needed Items are randomly Key are items checked Work area methods are

Just beginning items are mixed placed throughout the are nit identified and not always followed

throughout the area workplace are unmarked and are not

documented

1 Necessary and Needed items are safely Key area items are Work group has

Focus On Basics unnecessary items are stored and organized marked to check and documented area

identified; those not according to usage required level of arrangement and

needed are gone frequency performance noted controls

2 Initial cleanings is done Needed items are Visual controls and Aggrements on

Make it Visual mess sources are outlined, dedicated indicators are set and labelling, quantities,

known and corrected locations are labelled in marked for waork area and control are

planned quantities documented

3 Cleaning schedules and Minimal needed item Work area cleaning, Proven methods for

Focus On Reliability responsibilities are arranged in manner inspection, and supply area arrangement and

documented and based on retrieval restocking done daily practices are used in

followed frequency the area

4 Cleanliness problem Needed item can be Potential problems are Proven method for area

Continous areas are identified and retrieved in 30 seconds identified and arrangement and

Improvement mess prevention actions with minimum steps ccountermeasures practices are shared

are in place. docmented and used

You might also like

- 5S Audit SheetDocument3 pages5S Audit Sheetleansensei67% (3)

- 5 S' Checklist For Shop FloorDocument2 pages5 S' Checklist For Shop FloorAbhishekNo ratings yet

- 5S Level of AchievementDocument1 page5S Level of AchievementPepi Pe100% (1)

- 5S Audit SheetDocument2 pages5S Audit SheetSenthil_KNo ratings yet

- 5S - Excellence Assessment PDFDocument2 pages5S - Excellence Assessment PDFAshokNo ratings yet

- 6S Levels of Achievement Matrix Self AssessmentDocument3 pages6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- GSM Interview QuestionsDocument22 pagesGSM Interview QuestionsTayyab RazaNo ratings yet

- Organisation Culture Assessment 5SDocument1 pageOrganisation Culture Assessment 5SGaneshNo ratings yet

- 5S Assessment ToolDocument1 page5S Assessment ToolbenkNo ratings yet

- 5S Routine Checklist: Work Area / Zone: Performed By: 5S Level Description Improvement Opportunities 1 2 3 4 5 DateDocument1 page5S Routine Checklist: Work Area / Zone: Performed By: 5S Level Description Improvement Opportunities 1 2 3 4 5 DateLeankannanNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- 5 S Audit Checklist ANIMADocument1 page5 S Audit Checklist ANIMAMd Gulam SafiNo ratings yet

- 5S BasicsDocument25 pages5S BasicshardikNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklistRohit NegiNo ratings yet

- 5S BasicsDocument26 pages5S Basicsvijay2101No ratings yet

- Apply 5S ProcedureDocument18 pagesApply 5S ProcedureNigussie Berhanu90% (10)

- 5S MethodologyDocument51 pages5S Methodologyadham hatawiNo ratings yet

- 5S TrainingDocument28 pages5S TrainingShan Sundar ManiNo ratings yet

- Office 5S ChecklistDocument16 pagesOffice 5S ChecklistNga NguyenNo ratings yet

- 7 Steps of JHDocument2 pages7 Steps of JHRajesh DeshpandeNo ratings yet

- 5S Audit Form: Description ActionDocument2 pages5S Audit Form: Description Actionbodeks dexNo ratings yet

- 5S Implementation Kaizen MindsetDocument54 pages5S Implementation Kaizen MindsetMianAbrarAnjum100% (1)

- 5S TrainingDocument31 pages5S Trainingedward contreras100% (1)

- pt2.2-5S BasicsDocument26 pagespt2.2-5S BasicslulalalaNo ratings yet

- 6S Audit Report No 4Document17 pages6S Audit Report No 4Zul DiansyahNo ratings yet

- 5 SDocument65 pages5 SArianne100% (1)

- Audit Items: Area Audited Auditing Team SignaturesDocument3 pagesAudit Items: Area Audited Auditing Team SignaturesCarlos HernandezNo ratings yet

- PLS Office 5S + Safety Audit Form - Draft: Category Criteria Audit Period Scoring SystemDocument15 pagesPLS Office 5S + Safety Audit Form - Draft: Category Criteria Audit Period Scoring SystemMiz MedNo ratings yet

- Unorganized Work BenchesDocument2 pagesUnorganized Work BenchesKhang LêNo ratings yet

- 5S Audit MudaMastersDocument1 page5S Audit MudaMastersManoj ShahNo ratings yet

- Corrective Actions TrainingDocument14 pagesCorrective Actions TrainingMuhammad ZafarNo ratings yet

- 5S Audit ScorecardDocument1 page5S Audit ScorecardWidiastuty Irawati100% (1)

- Propec® 5S Audit Checklist: Work Area Completed by DateDocument1 pagePropec® 5S Audit Checklist: Work Area Completed by DatePratik SharmaNo ratings yet

- 5S PresentationDocument31 pages5S PresentationPrecious Mercado QuiambaoNo ratings yet

- 5S ModulDocument20 pages5S ModulnursaidahNo ratings yet

- 5S Program Audit Scorecard: Zone - DateDocument1 page5S Program Audit Scorecard: Zone - DateDhahri100% (1)

- Chromatography Solution: 5S AuditDocument3 pagesChromatography Solution: 5S Auditabhijit612No ratings yet

- Quality System Basic PDFDocument1 pageQuality System Basic PDFwan manNo ratings yet

- CLM Common 1 As of 020708am APPLY QUALITY STANDARDSDocument1 pageCLM Common 1 As of 020708am APPLY QUALITY STANDARDSEvaNo ratings yet

- Learning Outcomes Assessment Criteria Learning Concepts/Content Learning Activities Guide Questions Technology Science Math Eng/CommDocument1 pageLearning Outcomes Assessment Criteria Learning Concepts/Content Learning Activities Guide Questions Technology Science Math Eng/CommEvaNo ratings yet

- 5S - Checklist - Office RevisedDocument1 page5S - Checklist - Office Revisedsiddharth JoshiNo ratings yet

- Flujos 5S'sDocument5 pagesFlujos 5S'sjairo ricardo tapia muñozNo ratings yet

- 5S Organization: Levels of The 5s ProcessDocument2 pages5S Organization: Levels of The 5s Processdarff45No ratings yet

- LeanDocument55 pagesLeanAnand RajNo ratings yet

- 5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreDocument2 pages5S Production Area Audit: Location: Date: Scored By: Score: Previous ScoreGeeTheWhizz100% (1)

- Unit Title: Apply Quality Standards: Common CompetenciesDocument1 pageUnit Title: Apply Quality Standards: Common Competenciesthess22No ratings yet

- Chapter 5Document65 pagesChapter 5Nghĩa NgôNo ratings yet

- Supplemental Material:: Program Administration For 5S Roll-OutDocument21 pagesSupplemental Material:: Program Administration For 5S Roll-Outahmed nawazNo ratings yet

- Apply 5S ProcedureDocument14 pagesApply 5S Proceduremelkamu endale100% (4)

- Audit 5 SDocument6 pagesAudit 5 SGleone KaiserinNo ratings yet

- Certifcate Course in Basic Housekeeping Skills Curriculum/SyllabusDocument13 pagesCertifcate Course in Basic Housekeeping Skills Curriculum/SyllabusBonny ChackoNo ratings yet

- TR Housekeeping NC II (Repaired)Document69 pagesTR Housekeeping NC II (Repaired)Mae D. SaliringNo ratings yet

- The 5S Methodology Sort, Set, Shine, Standardize, Sustain in Quality Management. Lean TrainingDocument51 pagesThe 5S Methodology Sort, Set, Shine, Standardize, Sustain in Quality Management. Lean TrainingArunselvanNo ratings yet

- 5S Audit Checklist - Short VersionDocument1 page5S Audit Checklist - Short VersionLarry RamirezNo ratings yet

- B-Audit Check ListDocument3 pagesB-Audit Check Listmahesh KhatalNo ratings yet

- Performance Evaulation Key PointsDocument2 pagesPerformance Evaulation Key Pointscaxoro1799No ratings yet

- TR Fish Vending FINALDocument77 pagesTR Fish Vending FINALValcy MadzNo ratings yet

- 5s Japanese MethodDocument24 pages5s Japanese MethodPraful E. PawarNo ratings yet

- 5s Evaluation ChecksheetDocument4 pages5s Evaluation ChecksheetKristine Danielle RamirezNo ratings yet

- Notebook RubricDocument3 pagesNotebook RubricOliver VillanuevaNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Bom 217856Document7 pagesBom 217856BohordoNo ratings yet

- Autocad Mep User Guide English PDFDocument1,292 pagesAutocad Mep User Guide English PDFJose Angel Malpica PNo ratings yet

- Mimarlıkta Nanoteknolojinin YeriDocument11 pagesMimarlıkta Nanoteknolojinin YeriTuğçe ÖzdemirNo ratings yet

- GCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsDocument3 pagesGCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsOec EngNo ratings yet

- NCD5188002 FAT Jointing Cabinet SmallDocument2 pagesNCD5188002 FAT Jointing Cabinet SmallMaylen RivasNo ratings yet

- Paris Pompidou Building-SaurabhDocument8 pagesParis Pompidou Building-SaurabhVipin Kumar SharmaNo ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabHytech Pvt. Ltd.No ratings yet

- On E-BALL TechnologyDocument22 pagesOn E-BALL TechnologySharmaTanvi93% (14)

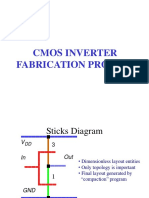

- CMOS Fabrication Steps 3Document54 pagesCMOS Fabrication Steps 3Yogesh MisraNo ratings yet

- Geanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13Document50 pagesGeanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13reza abriNo ratings yet

- Collect Stats DBMS JobDocument4 pagesCollect Stats DBMS Jobpat985946No ratings yet

- Flexim Fluxus F608 ManualDocument249 pagesFlexim Fluxus F608 Manualmarco luzaNo ratings yet

- Abaqus QuestionsDocument12 pagesAbaqus Questionsmadhu77No ratings yet

- Deliverable REALISEGRID Hvdc-HvacDocument75 pagesDeliverable REALISEGRID Hvdc-HvacJose ValdiviesoNo ratings yet

- Sacc-M12Msb-5Con-Pg9 SH Au: Order No.: 1507764Document5 pagesSacc-M12Msb-5Con-Pg9 SH Au: Order No.: 1507764andre_tfjrNo ratings yet

- Siteff-Model pdf3 PDFDocument1 pageSiteff-Model pdf3 PDFww starNo ratings yet

- Timetable HogwartsDocument36 pagesTimetable Hogwartsharshit.royNo ratings yet

- Triangulation (Social Science) : PurposeDocument4 pagesTriangulation (Social Science) : Purposelouis adonis silvestreNo ratings yet

- Nde Testing Work Requisition Register Flexible Program Management - Ho CONTRACT FOR NDE SERVICE No: SA-9415-0001-TF-SCI-05Document12 pagesNde Testing Work Requisition Register Flexible Program Management - Ho CONTRACT FOR NDE SERVICE No: SA-9415-0001-TF-SCI-05zat572000No ratings yet

- E Waste Management and Recycling Mechanism in Japan Sugimoto San PDFDocument17 pagesE Waste Management and Recycling Mechanism in Japan Sugimoto San PDFNadia KamaNo ratings yet

- Reflection Processing Using Matlab PDFDocument99 pagesReflection Processing Using Matlab PDFbagusNo ratings yet

- 2018 SpringDocument35 pages2018 SpringMladenNo ratings yet

- Price List - 2013Document11 pagesPrice List - 2013John MaNo ratings yet

- What Is The Complexity Cube?Document1 pageWhat Is The Complexity Cube?Wilson Perumal & Company100% (1)

- Cs 310Document377 pagesCs 310avira proNo ratings yet

- List of Acknowledgements: Chapter 1. Polyesters: Synthesis and Chemical AspectsDocument21 pagesList of Acknowledgements: Chapter 1. Polyesters: Synthesis and Chemical AspectsLailatulmuna MonaNo ratings yet

- Iit & Barc LeadsDocument24 pagesIit & Barc LeadsFrank HayesNo ratings yet

- Building Valuation DataDocument2 pagesBuilding Valuation DataChan Siew ChongNo ratings yet