Professional Documents

Culture Documents

HIRA WORK SHEET Blasting and Painting. Download

HIRA WORK SHEET Blasting and Painting. Download

Uploaded by

itzfarhan1048Copyright:

Available Formats

You might also like

- Risk Assessment For ScaffoldingDocument6 pagesRisk Assessment For Scaffoldingطارق رضوان100% (2)

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (3)

- Audit Checklist For Purified Water SystemDocument2 pagesAudit Checklist For Purified Water Systempradeep28100171% (7)

- Risk Assessment of Flag PolesDocument5 pagesRisk Assessment of Flag Polesطارق رضوانNo ratings yet

- #Hiradec - DeaeratorDocument6 pages#Hiradec - DeaeratorPankaj PandeyNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- 24.# Hiradec EH Oil PumpDocument5 pages24.# Hiradec EH Oil PumpPankaj PandeyNo ratings yet

- 14 Risk Assessment of CleaningDocument12 pages14 Risk Assessment of Cleaningطارق رضوان100% (1)

- 23.# Hiradec CEP PumpDocument7 pages23.# Hiradec CEP PumpPankaj PandeyNo ratings yet

- Department: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJDocument12 pagesDepartment: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJabhrrajjit SANo ratings yet

- Appendix 5. ALDAR Projects OSH Risk Assessment ModelDocument2 pagesAppendix 5. ALDAR Projects OSH Risk Assessment Modelerwin.tamayo1982No ratings yet

- Concrete Repair RISK ASSESSMENTDocument5 pagesConcrete Repair RISK ASSESSMENTVimal ViswanathNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- Aldar Risk Assessment ModelDocument2 pagesAldar Risk Assessment ModelSam AzzNo ratings yet

- #Hiradec - Cooling TowerDocument8 pages#Hiradec - Cooling TowerPankaj PandeyNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Iosh Risk Assessment Project v2000867 PDF Fires Personal Protective EquipmentDocument1 pageIosh Risk Assessment Project v2000867 PDF Fires Personal Protective EquipmentMohammed A MarzaniNo ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- Risk - Draft 02Document3 pagesRisk - Draft 02ThabaneNo ratings yet

- Hirardc 1Document4 pagesHirardc 1Dwi Windi AjiNo ratings yet

- HIRAC-Erection of Aerodynamics or Other Small StructuresDocument6 pagesHIRAC-Erection of Aerodynamics or Other Small StructuresPinaki BhattacharjeeNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- RA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)Document3 pagesRA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)RAMY ABOU AL DAHABNo ratings yet

- HIRA 4r Utility Identification CMRL 09.05.17Document3 pagesHIRA 4r Utility Identification CMRL 09.05.17mahesh naikNo ratings yet

- Risk Assessment of Confined SpaceDocument29 pagesRisk Assessment of Confined Spaceطارق رضوانNo ratings yet

- Soil Protection - Risk AssessmentDocument2 pagesSoil Protection - Risk AssessmentLeoniv Arviz LiboroNo ratings yet

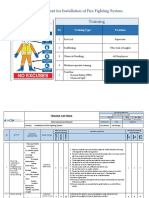

- Risk Assessment For Installation of Fire Fighting SystemDocument12 pagesRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

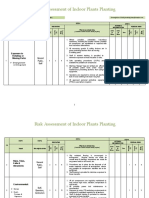

- Risk Assessment of Indoor Plants PlantingDocument5 pagesRisk Assessment of Indoor Plants Plantingطارق رضوانNo ratings yet

- Risk Assessment For Ms Installation of Precast BoundrywallDocument11 pagesRisk Assessment For Ms Installation of Precast BoundrywallSajid ShahNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- Blasting and Painting of Fire Fighting PipingDocument3 pagesBlasting and Painting of Fire Fighting PipingRAMY ABOU AL DAHABNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- Risk Matrix: Project: ID: Start Date: End DateDocument2 pagesRisk Matrix: Project: ID: Start Date: End Dateketac100% (1)

- Annexure3 HIRA 2Document5 pagesAnnexure3 HIRA 2kanna gNo ratings yet

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Risk Assessment RA-FormatDocument5 pagesRisk Assessment RA-FormatImran ZamanNo ratings yet

- 4.oetc Hse o CRR F 000 FormatDocument2 pages4.oetc Hse o CRR F 000 FormatTATI HSENo ratings yet

- Important Risk Assessment of Wind FarmDocument3 pagesImportant Risk Assessment of Wind FarmRaza Muhammad SoomroNo ratings yet

- Royal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesDocument2 pagesRoyal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesLenaj Ebron100% (3)

- AMB 172-016 LiftingDocument3 pagesAMB 172-016 LiftingRues AgNo ratings yet

- RA - EIA ErgonomicsDocument2 pagesRA - EIA ErgonomicsعمروNo ratings yet

- 5.2.2.9 Laydown Drill Pipes1Document2 pages5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- 31.# Hiradec-CSTDocument2 pages31.# Hiradec-CSTPankaj PandeyNo ratings yet

- C6. #Hiradec For Vibration AnalysisDocument1 pageC6. #Hiradec For Vibration AnalysisPankaj PandeyNo ratings yet

- Manhole Construction - ShoringDocument1 pageManhole Construction - Shoringasr.engineering2023No ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- RA - EIA Neon LampsDocument2 pagesRA - EIA Neon Lampsعمرو100% (1)

- Hirac Man Trasnfer BasketDocument4 pagesHirac Man Trasnfer BasketPinaki BhattacharjeeNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- Hira Interior Activities - RevisedDocument148 pagesHira Interior Activities - Revisedassac5741No ratings yet

- Risk Assessment: CCTV Inspection - Al MerifDocument9 pagesRisk Assessment: CCTV Inspection - Al MerifSaim AliNo ratings yet

- UEP-HSE-DISC-RA-02 - 30V DC System Shifting & Installation of LV ESDB Works Inside GS - Rev-0Document5 pagesUEP-HSE-DISC-RA-02 - 30V DC System Shifting & Installation of LV ESDB Works Inside GS - Rev-0balaNo ratings yet

- Health and Safety Risk Assessment FormDocument4 pagesHealth and Safety Risk Assessment Formbasil aliNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- Chapter 4 PLANTDocument3 pagesChapter 4 PLANTSedsed QuematonNo ratings yet

- WB P500L ManualDocument158 pagesWB P500L ManualsunhuynhNo ratings yet

- Pronoun and Preposition ExerciseDocument4 pagesPronoun and Preposition Exerciselena meldianaNo ratings yet

- Prometheus PDFDocument12 pagesPrometheus PDFFernán OteroNo ratings yet

- Nama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071Document11 pagesNama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071shalsaNo ratings yet

- A Three Phase Induction Motor Is Basically A Constant Speed Motor So ItDocument39 pagesA Three Phase Induction Motor Is Basically A Constant Speed Motor So ItManish MakwanaNo ratings yet

- STS Finals ReviewerDocument11 pagesSTS Finals Reviewerjulian.cuyaNo ratings yet

- Chapter 2 JFET AC AnalysisDocument47 pagesChapter 2 JFET AC AnalysisRazman RamedanNo ratings yet

- The Hot Air Balloon HistoryDocument3 pagesThe Hot Air Balloon HistoryRonnel ManrezaNo ratings yet

- Region III Tourism MasterPlanDocument34 pagesRegion III Tourism MasterPlanVenus Leilani Villanueva-GranadoNo ratings yet

- Extrusion and Drawing PDFDocument16 pagesExtrusion and Drawing PDFAravindhan AnbalaganNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gNo ratings yet

- 18222Document392 pages18222Lias JayNo ratings yet

- WWW - Swrs.ap - Gov.in: of 1753 Vacant Posts of Teachers, Special Teachers & Staff NursesDocument14 pagesWWW - Swrs.ap - Gov.in: of 1753 Vacant Posts of Teachers, Special Teachers & Staff NursesVijay KsheresagarNo ratings yet

- Drummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkaDocument18 pagesDrummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkamikeXF100% (1)

- SANY CRM TrainingDocument9 pagesSANY CRM Traininggirish_patkiNo ratings yet

- Questions - 7th EASA AD WorkshopDocument4 pagesQuestions - 7th EASA AD WorkshopFrank MasonNo ratings yet

- نسخة 12- Lecture Hematological DisordersDocument12 pagesنسخة 12- Lecture Hematological DisordersRoxe BroNo ratings yet

- Polymers in Sensor ApplicationsDocument68 pagesPolymers in Sensor ApplicationsAbc_scribdNo ratings yet

- Image Processing and Pattern Recoginition Lab ManualDocument38 pagesImage Processing and Pattern Recoginition Lab ManualDeepa SNo ratings yet

- Nice Classification For TrademarksDocument4 pagesNice Classification For Trademarkskagootukile80No ratings yet

- Jurnal Pruritus SenilisDocument19 pagesJurnal Pruritus Seniliszubair zainalNo ratings yet

- LO WEEK 6 IPHP Q1 W7 8 The Human Person and The Environment Gualdo Benguet DeletedDocument10 pagesLO WEEK 6 IPHP Q1 W7 8 The Human Person and The Environment Gualdo Benguet Deletedgordon boswayNo ratings yet

- Structural Organisation by Rakshita SinghDocument68 pagesStructural Organisation by Rakshita SinghS MUHAMMAD RAAHILNo ratings yet

- Columbia University College of Physicians and SurgeonsDocument12 pagesColumbia University College of Physicians and SurgeonsMichael SellersNo ratings yet

- Designing A Modern ICU - From An Architect PerspectiveDocument23 pagesDesigning A Modern ICU - From An Architect PerspectiveMuneeb Haider AbidiNo ratings yet

- Objective 4Document8 pagesObjective 4api-662676619No ratings yet

- API Chemical Synthesis Trends in Reactor Heat Transfer DesignDocument9 pagesAPI Chemical Synthesis Trends in Reactor Heat Transfer DesignDHAVALESH AMNo ratings yet

- GeographyDocument13 pagesGeographyRao RaasNo ratings yet

HIRA WORK SHEET Blasting and Painting. Download

HIRA WORK SHEET Blasting and Painting. Download

Uploaded by

itzfarhan1048Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HIRA WORK SHEET Blasting and Painting. Download

HIRA WORK SHEET Blasting and Painting. Download

Uploaded by

itzfarhan1048Copyright:

Available Formats

HIRA WORK SHEET

Blasting and Painting.

Uploaded by Madhu Electricals & Engineering on May 25, 2023

100% (3) · 1K views · 10 pages

AI-enhanced description

Document Information

This document provides a hazard identification and …

Original Description:

Download now

Download as xlsx, pdf, or txt

Date uploaded

May 25, 2023

Copyright

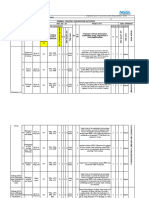

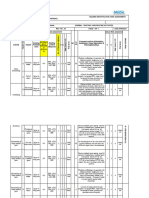

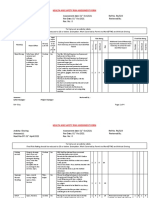

DOCUMENT:1 REVISION: 1

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA) SHEET

JOB LOCATION :G-BLOCK

© © All Rights Reserved

Inital Risk Ratng Residual Risk Ratng

Sl

Actviy Hazard Risk Whom a Risk Conrol Measures Responsibiliy

No. Probabiliy (P) Severiy (S)

Risk Ratng R=

Risk Classifcaton Probabiliy (P)

Severiy Risk Ratng Risk

PXS (S) R= PXS Classifcaton

GRID BLASTING

Available Formats

1.Inspecton o be done or he equipmen / ool

ha shall be used or griding (such as ai hose

damage, Hoses, pump ec.) prior o work.

Sie

Deectve Tools / 2.The equipmen and ools o be grounded o

moderae supervisor,gride

Equipmen (air Physical injuries. Worker and Sa 2 4 8 preven elecriciy hazards. 1 3 3 Low risk

risk blaser and

hose damage) 3.Mainenance o be done regularly.

XLSX, PDF, TXT or read online from Scribd

Sie inhcarge.

4. Required PPE ( Helme, Caridge mask, hair cap,

chemical breahable goggles, use and hrough

coverall, ant slipery shoes o be used.

1.STOP he shiing operaton when sar high wind

saey

Share this document

blowing more han 35km/hr and dusy climae.

shifting Operation ocer,operaor

Personal Injury workers 3 4 12 High risk 2.Bring he boom down and STOP he engine o he 1 1 1 Low risk

in High wind and sie

Crane.

supervisor

Trap, caught in 1. While crane operaton oher han signal men do

sie incharge,ag

between no allow enry o any oher personnel.

Personal Injury, Fatality Helper and rigger 1 4 4 low risk man,and sie 1 2 2 Low risk

due to crane 2. During crane operaton Barricade he operaton

movement

supervisor

area.

1. Enclose he blastng area wih shees and pos

warning notce.

2. Sprinkle waer prior o blastng actviy on nearby

Facebook Twitter

surace.

3. Ensure adequae and appropriae PPE usage while

enering ino operatonal area.

Abrasive grids

Physical injuries, 4. Ear mus / ear plugs shall be used. sie

exposure wih dus Operaop and he Helper 1 3 3 low risk 1 2 2 Low risk

environmenal issues 5. Mainenance o equipmen o be done regularly. incharge,blaser

and noise

5. Ensure dead Man handle” should be insalled on

he blastng hoses o conrol he ow o gris & is

lever should no be ted wih wire o m ainain

contnuous ow o gris.

6. Ensure all he high p ressure hose ar'n crosses he

pah way.

Read this document in other languages

AD Download to read ad-free.

Español

Did you find this document useful?

Is this content inappropriate? Report this Document

1. Suiable fre extnguishers mus be kep ready

nearby he paintng area and sorage area.

2. Isolaton o equipmen o be done rom all source

o energy when no in use.

3. Firefghtng & frs aid raining o be provided o sie

Physical injuries, moderae

Fire & Explosion Worker, Sa and vehicles 2 4 8 minimum number o workers (2). incharge,blaser, 1 2 2 Low risk

1 environmenal issues risk

4. Do no leave unaended he blastng Hose wih saey ocer

on conditon.

5. Ensure here is no naked ame or spark

generatng equipmen in he area where grid

blastng is o be done.

Ergonomical blaser,sie

Operaop and he Helper 2 3 6 modere risk 1. Provide adequae inerval o avoid numbness, 1 1 1 Low risk

Hazard supervisor

Numbness because o while using high pressure blastng gun.

contnues operaton

1.All power cables are roued hrough 30 mA RCCB.

2.Only

compeen elecrician will perorm elecrical repairs

and mainenance.

3.Elecrician will wear adequaed raed rubber hand

glves while working wih elecriciy.

4.Only use power cables wih

good qualiy and adequae raed capaciy.

5.Workers,sa and visiors

are alered on accidens relaed o elecriciry and

precautonary measures.

6.Danger sign borads/demarcatons shall

provided on elecrical appliances and near he

aeced areas.

7. Use always double insuled power ools preerably

having bad conducor maerial body.

8. Avoid meal body hand ools. Ensure proper Sie

Elecrocuton EARTHING arrangemen. Power supply should come supervisor,elecri

Elecriciy Faaliy, Personal Worker, Sa and visior 5 4 20 Exreme risk hrough ELCB or GFCI. 3 2 6 Moderae risk

cian and Sie

injury 9. Elecric power cables should be checked in inhcarge.

10.Regular inervals avoid joins in i. Use indusrial

sockes.

11. • All he lightng cables mus be roued above

head level horough poles wih adequae clamping

arrangemen in order o preven rom damage and

rip.

1. Proper wind up & housekeeping o be done a

worksie.

2. Place each and every ools and ackles in a sie supervisor,

Slip, rip and assored area. Sie inhcarge

Physical injuries Operaop and he Helper 4 4 16 Exreme risk 3. All he placemens o suppors mus be provided 2 2 4 Low risk

alling hazard and saey

wih proper access and egress. ocer

AD Download to read ad-free.

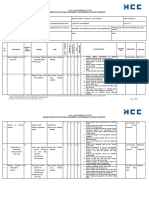

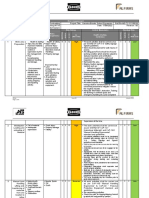

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA) SHEET

Inital Risk Ratng Residual Risk Ratng

Sl

Actviy Hazard Risk Whom a Risk Conrol Measures Responsibiliy Risk

No. Probabiliy Severiy Risk Ratng Risk Probabiliy Severiy Risk

Ratng

(P) (S) R= PXS Classifcaton (P) (S) Classifcaton

R= PXS

1.Inspecton o be done or he equipmen / ool ha shall be used or

Deectve Tools / paintng (such as Spray Pain Gun, Hoses, pump ec.) prior o work.

Equipmen (Spray Physical injuries, Moderae 2.The equipmen and ools o be grounded o preven elecriciy hazards. Sie supervisor, painer and

Worker and Sa 2 4 8 1 4 4 Low risk

Pain Gun, Hoses, environmenal issues risk 3.Mainenance o be done regularly. Sie inhcarge.

pump) 4. Required PPE ( Helme, Ca ridge mask, hair cap, chemical breahable

goggles, use and hrough coverall, ant slipery shoes o be used.

1. Obain MSDS or he pain as well as hinner mus be placed in

operatonal area.

Worker, Sa Sie supervisor, painer and

Harmul vapour Healh issues 2 2 4 Low risk 2. Ensure proper ventlaton o he paintng booh or paintng area. 1 2 2 Low risk

and visior Sie inhcarge.

3. Placing barricaton and sign boards regarding paintng is ongoing

auhourized personals only allowed.

1. Suiable fre extnguishers mus be kep ready nearby he paintng area

and sorage area.

2. Isolaton o equipmen o be done rom all source o energy when no in

use.

Physical injuries, Worker, Sa 3. Firefghtng & frs aid raining o be provided o minimum wo workers. sie supervisor,saey

Fire & Explosion 2 4 8 mojor risk 1 2 2 Low risk

environmenal issues and vehicles 3. Sore pain & hinners in sae & designaed locaton away rom source o ocer,nurse.

igniton wih proper humidiy and fre proecton.

4. Do no leave unaended he Spray Pain Gun & Hose wih on conditon.

1 Paintng 5. Ensure here is no naked ame or spark generatng equipmen in he area

where spray paintng is o be done.

1.All power cables are roued hrough 30 mA RCCB.

2.Only compeen elecrician will perorm elecrical

repairs and mainenance.

3.Elecrician will wear adequaed raed rubber hand glves while working

wih elecriciy.

4.Only use power cables wih good qualiy and adequae raed capaciy.

5.Workers,sa and visiors are alered on

sie supervisor, elecrician

Worker, Sa accidens relaed o elecriciry and precautonary measures.

Elecriciy Elecrocuton 5 4 20 Exreme risk and 3 2 6 Moderae risk

and visior 6.Danger sign borads/demarcatons shall provided

on elecrical appliances and near he aeced areas. Sie inhcarge.

Conaminaed Moderae 1.Do no ea or smoke w earing pain soaked coverall / gloves. sie supervisor,

Healh issues Worker 2 3 6 1 2 2 Low risk

Clohing risk 2.Wash hands properly beore consuming any ood. sie incharge

Unsae Sorage o Healh

Moderae 1. Pains & hinners o be sored in sae & designaed locaton away rom

Pain & Thinner and issues,Environmenal Worker and Sa 3 2 6 saey ocer 1 1 1 Low risk

risk source o igniton.

Pain spillage issues

AD Download to read ad-free.

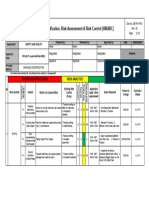

Doc. No. : DEPL/HIRA/BLASTING & PAINTING/01

DEEPA ERECTORS PRIVATE LIMITED REV. NO. : 01

Dae : 11/18/2022

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA) SHEET

Inital Risk Ratng Residual Risk Ratng

Sl

Actviy Hazard Risk Whom a Risk Risk Ratng Conrol Measures Responsibiliy Risk Ratng Risk

No. Probabiliy (P) Severiy (S) Risk Classifcaton Probabiliy (P) Severiy (S)

R= PXS R= PXS Classifcaton

1.Tools and ackles should have

calibraed by compenen person

2.Tool and ackles should mainain

Deectve properly.

moderae

ools & major injury Rigger 2 4 8 3.Beore inisiae he work, he w orkmen supervisor 1 4 4 low risk

risk

ackles and supervisor o ensure he good

conditon o ool and ackles

4.Training should provided o he rigger

regarding ool and ackles handling

1.A rigger should have wise k nowledge

in maerial handling.

Unskilled 2.supervisor should only well sie incharge,

Personal Injury Rigger 1 4 4 low risk 1 2 2 low risk

labour experience or loading and unloading supervisor

o plaes.

3.Training should provide or he workmen.

1.Beore sacking plae in he rame or

Uneven moderae blastng and pain, ooring should done sie incharge,

Plae shiing or serious injury Rigger 2 3 6 1 2 2 low risk

1 surace risk properly. supervisor

blastng and paintng 2.Adequae design o rame suiable o hold shells.

1.A rame should have capaciy o hold

Poor rame moderae he plae under he blastng pressure

serious injury rigger 1 3 3 supervisor 1 2 2 low risk

design risk 2. plae holding poin should be welded properly

periodic inspecton should be done.

1.A movemen or hydra o clear and

pre-deermined.

2.proper ooring/leveling o be done

or hydra movemen.

Insucien hydra moderae 3.In case o monsoon climae, additonal supervisor,

major injury rigger 2 4 8 1 4 4 low risk

movemen risk care should aken hydra movemen. sie Incharge

4.rame and shed o be prepared based on hydra

boom approach.

5.experiensed and rained person should be operae

hydra.

AD Download to read ad-free.

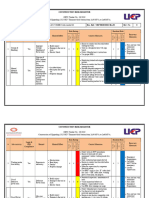

1.Every 3 phase equipmens should

grounded properly wih sandard,

capable earhing wire.

2.Only compeen person are allow o

used he heavy equipmens(compressor)

3.Rubber gloves o be used in case o

estng o supplied sysem.

4.All he powe cables are roued hrough 30mA RCC B.

Shock rom aaliy, 5. Proper Working o RCCB o be supervisor,

Elecrican, Exreme

elecrical permanen 3 5 15 ensure and estng Records should elecrician & 2 2 4 low risk

Workmen Risk

Equipmen disabiliy mainain Saey

6.No joins are permied in he power

cables.

7.Elecrical equipmens should proeced or rainall

and sagnaed rain waer.

8.Periodically Every Elecrical Equipmen should

mainain

9. No power cables o be laid on open

ground wihou sand.

2 Blastng

1.The Equipmens should periodically

calibraed.

2.An air reciever should have he nominal

design wall hickness o operae under

pressure and ensure o have valid TC.

3.For every pressure handling Equipmens

should have Saey pressure relie valve.

supervisor,

Unf Permanen disabiliy, Grid Blaser, High 4.Superior should have wise knownledge on all he low

2 5 10 elecrician & 1 3 3

equipmens aaliy supervisor Risk equipmens. risk

Saey

5.periodic Mainainance o be done

or all he Equipmens.

6. Pressure handle hose should be clamp properly,

beore sartng work, a

supervisor is o ensure hose hings.

7.Dead man swich should be provided near he

blastng gun.

AD Download to read ad-free.

1.Processed Copper slag should be use.

2.To ensure he qualiy o gri, a chemical

composion es o be done or copper

slag.

3. The es resul should no exceed he permied.

componen valves and especially is should no

coinain more han 0.5% o ree silica.

4. A blastng shed should have capaciy o

Respiraory

Grid Blaser, hold he dus wihin i, dus should no expose o

Abrasive Grid disease(silicosis)/ High Supervisor,

supervisor, 3 3 9 exernal amosphere. 2 2 4 low risk

Exposure disorder, risk Saey ocer

workmens 5.In additon o General medical check ups, blasers

environmenal Issue

should ake Pulmanory fness es.

6.workmens should use proper PPE's like blastng

goggles, Blastng sho wih Hood and Oxygen supply is

provided air line mask wih fler.

7. I i is Required, adequae saey raining

Blastng o be conduced o he Blaser/workmens

8.Wased Copper slag should dispose

properly by considering he Environmenal issue.

1.A copper should be in a fne grain size,

which should ree ow hough he hopper

and hoses.

2.A copper slag should no be we and

Chocking on Equipmen damage,

helper, mess o be provided o fler he larger

hopper and permanen 2 5 10 high risk supervisor 1 2 2 low risk

Supervisor size partcles ino Hopper.

hose disabiliy

3.A pressure Relie valve should be

work in proper conditon, in case chocking a pressure

will be release.

AD Download to read ad-free.

1.A buery spary nozzle should be ree

rom deecs.

2.Air less Spray Machine should Work

Unf moderae properly.

serious injury Painer, Helper 2 3 6 supervisor 1 2 2 low risk

equipmens risk 3.Equipmens mus be calibraed by a

compeen person.

4. The equipmens should mouned on

a surace.

1.While handling pain, one should use

proper PPE's.

2.Additonal Care o aken while paintng

a srong pain which posses high odour.

3.Paintng wases o be colleced in a

proper separae bin and i should no

Respiraory mix wih he oher wases.

Chemicals in disease/ disorder, 4.Disposal o hose wase should be supervisor,saey

Painer, Helper 3 3 9 high risk 2 2 4 low risk

a pain skin allergy handle wih care. ocer

environmenal Issue 5.A supervisor should ensure he pains have a valid

3 Paintng shel lie.

6.Mixing Rato o base, caalys and hinner should be

aken care.

7.Bach certfcaes o he pains and hinner o be

veriy beore paintng.

8. Proper ventlaton should be provided

1.Pains and hinner should sore in a

proper ventlaed area and is should no kep in a

direc sunligh.

2.Flammable iem should no carries near .

he pain and hinner.

Maerial damage, 3.Smoking is srickly prohibied.

Fire & supervisor,saey

aaliy and workmens 2 5 10 high risk 4.Only auhorised persons are allow o 1 4 4 low risk

Explosion ocer

Environmenal Issue ener he sore and working area.

5.Dry chemical fre Extnguisher are o kep

in sorage area as well as working area.

6.Window opening should be provided o ventlae

he pain umes.

7.Periodically checking he LEL level by gas deecor.

AD Download to read ad-free.

AD Download to read ad-free.

AD Download to read ad-free.

Read this document in other languages

Español

Share this document

You might also like

Document 7 pages

Jsa For Scaffolding Erection &

Dismentling

sanath adhikary

100% (5)

Document 5 pages

HIRA For Stores Activity

Rohit Singh

100% (22)

Document 5 pages

Risk Assessment - Grouting

Works

abhinav dj

100% (6)

Magazines Podcasts

Sheet music

Document 3 pages

JSA-017 Li"ing With Forkli"

Moaatazz Nouisri

67% (6)

Document 4 pages

HIRA For Loading or Unloading

Activity

MD Abdullah

100% (3)

Document 5 pages

Risk Assess

Anonymous iI88Lt

0% (1)

Document 2 pages

Job Safety Analysis (Jsa) : Title

of Activity / Work: Excavation…

Trenching

Jayendra Patel

89% (9)

Document 4 pages

Risk Assessment For Snake Bite

VIKASH KUMAR

100% (1)

Document 4 pages

Risk Assessment Of-

Shuttering-Deshuttering

Abdul Mujeeb

75% (4)

Document 13 pages

Risk Assessment of Concrete

Pouring

Abdul Mujeeb

No ratings yet

Document 11 pages

SWMS - Glass Partition

Paras

No ratings yet

Document 1 page

Height Work - HIRA

Ruchin Jain

91% (11)

Show more

About Support

About Scribd Help / FAQ

Everand: Ebooks & Accessibility

Audiobooks

Purchase help

SlideShare

AdChoices

Press

Join our team! Social

Contact us Instagram

Invite friends Twitter

Facebook

Legal

Pinterest

Terms

Privacy

Copyright

Cookie Preferences

Do not sell or share my

personal information

Get our free apps

Documents

Language: English

Copyright © 2024 Scribd Inc.

Download

Sponsored

You might also like

- Risk Assessment For ScaffoldingDocument6 pagesRisk Assessment For Scaffoldingطارق رضوان100% (2)

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (3)

- Audit Checklist For Purified Water SystemDocument2 pagesAudit Checklist For Purified Water Systempradeep28100171% (7)

- Risk Assessment of Flag PolesDocument5 pagesRisk Assessment of Flag Polesطارق رضوانNo ratings yet

- #Hiradec - DeaeratorDocument6 pages#Hiradec - DeaeratorPankaj PandeyNo ratings yet

- Risk Assessment SK GraphiteDocument8 pagesRisk Assessment SK GraphiteWasim KhanNo ratings yet

- 24.# Hiradec EH Oil PumpDocument5 pages24.# Hiradec EH Oil PumpPankaj PandeyNo ratings yet

- 14 Risk Assessment of CleaningDocument12 pages14 Risk Assessment of Cleaningطارق رضوان100% (1)

- 23.# Hiradec CEP PumpDocument7 pages23.# Hiradec CEP PumpPankaj PandeyNo ratings yet

- Department: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJDocument12 pagesDepartment: List of Workcentre: S.No Workcentre Name Process Involved No. of Employees VLJabhrrajjit SANo ratings yet

- Appendix 5. ALDAR Projects OSH Risk Assessment ModelDocument2 pagesAppendix 5. ALDAR Projects OSH Risk Assessment Modelerwin.tamayo1982No ratings yet

- Concrete Repair RISK ASSESSMENTDocument5 pagesConcrete Repair RISK ASSESSMENTVimal ViswanathNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- Aldar Risk Assessment ModelDocument2 pagesAldar Risk Assessment ModelSam AzzNo ratings yet

- #Hiradec - Cooling TowerDocument8 pages#Hiradec - Cooling TowerPankaj PandeyNo ratings yet

- Hira For DemolitionDocument3 pagesHira For DemolitionMokka SamaiyalNo ratings yet

- Iosh Risk Assessment Project v2000867 PDF Fires Personal Protective EquipmentDocument1 pageIosh Risk Assessment Project v2000867 PDF Fires Personal Protective EquipmentMohammed A MarzaniNo ratings yet

- Manhole Construction - ExcavationDocument1 pageManhole Construction - Excavationasr.engineering2023No ratings yet

- Risk - Draft 02Document3 pagesRisk - Draft 02ThabaneNo ratings yet

- Hirardc 1Document4 pagesHirardc 1Dwi Windi AjiNo ratings yet

- HIRAC-Erection of Aerodynamics or Other Small StructuresDocument6 pagesHIRAC-Erection of Aerodynamics or Other Small StructuresPinaki BhattacharjeeNo ratings yet

- C3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Document1 pageC3.Hiradec - ONLINE BOLT TIGHTENING (FLANGES & UNION JOINTS-GLANDS OF MOV-MCV-MIV-PCV)Pankaj PandeyNo ratings yet

- RA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)Document3 pagesRA For Firefighting (CS Pipe Prefabrication-Sprinklers - Pressure Test and Flashing Painting-001)RAMY ABOU AL DAHABNo ratings yet

- HIRA 4r Utility Identification CMRL 09.05.17Document3 pagesHIRA 4r Utility Identification CMRL 09.05.17mahesh naikNo ratings yet

- Risk Assessment of Confined SpaceDocument29 pagesRisk Assessment of Confined Spaceطارق رضوانNo ratings yet

- Soil Protection - Risk AssessmentDocument2 pagesSoil Protection - Risk AssessmentLeoniv Arviz LiboroNo ratings yet

- Risk Assessment For Installation of Fire Fighting SystemDocument12 pagesRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

- Risk Assessment of Indoor Plants PlantingDocument5 pagesRisk Assessment of Indoor Plants Plantingطارق رضوانNo ratings yet

- Risk Assessment For Ms Installation of Precast BoundrywallDocument11 pagesRisk Assessment For Ms Installation of Precast BoundrywallSajid ShahNo ratings yet

- 24.DG Hiradec CDocument2 pages24.DG Hiradec CPankaj PandeyNo ratings yet

- Blasting and Painting of Fire Fighting PipingDocument3 pagesBlasting and Painting of Fire Fighting PipingRAMY ABOU AL DAHABNo ratings yet

- 5.#hiradec - CWPDocument7 pages5.#hiradec - CWPPankaj PandeyNo ratings yet

- Risk Matrix: Project: ID: Start Date: End DateDocument2 pagesRisk Matrix: Project: ID: Start Date: End Dateketac100% (1)

- Annexure3 HIRA 2Document5 pagesAnnexure3 HIRA 2kanna gNo ratings yet

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Risk Assessment RA-FormatDocument5 pagesRisk Assessment RA-FormatImran ZamanNo ratings yet

- 4.oetc Hse o CRR F 000 FormatDocument2 pages4.oetc Hse o CRR F 000 FormatTATI HSENo ratings yet

- Important Risk Assessment of Wind FarmDocument3 pagesImportant Risk Assessment of Wind FarmRaza Muhammad SoomroNo ratings yet

- Royal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesDocument2 pagesRoyal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesLenaj Ebron100% (3)

- AMB 172-016 LiftingDocument3 pagesAMB 172-016 LiftingRues AgNo ratings yet

- RA - EIA ErgonomicsDocument2 pagesRA - EIA ErgonomicsعمروNo ratings yet

- 5.2.2.9 Laydown Drill Pipes1Document2 pages5.2.2.9 Laydown Drill Pipes1khrayzie bhone100% (1)

- C4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachineDocument2 pagesC4. Hiradec - Oil Top Up, Replacement, Sampling & Filtration MachinePankaj PandeyNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- 31.# Hiradec-CSTDocument2 pages31.# Hiradec-CSTPankaj PandeyNo ratings yet

- C6. #Hiradec For Vibration AnalysisDocument1 pageC6. #Hiradec For Vibration AnalysisPankaj PandeyNo ratings yet

- Manhole Construction - ShoringDocument1 pageManhole Construction - Shoringasr.engineering2023No ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- Al Qooz Contracting LLC: Hazard Identification and Risk AssesmentDocument8 pagesAl Qooz Contracting LLC: Hazard Identification and Risk Assesmentشاز إياس100% (1)

- RA - EIA Neon LampsDocument2 pagesRA - EIA Neon Lampsعمرو100% (1)

- Hirac Man Trasnfer BasketDocument4 pagesHirac Man Trasnfer BasketPinaki BhattacharjeeNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- Hira Interior Activities - RevisedDocument148 pagesHira Interior Activities - Revisedassac5741No ratings yet

- Risk Assessment: CCTV Inspection - Al MerifDocument9 pagesRisk Assessment: CCTV Inspection - Al MerifSaim AliNo ratings yet

- UEP-HSE-DISC-RA-02 - 30V DC System Shifting & Installation of LV ESDB Works Inside GS - Rev-0Document5 pagesUEP-HSE-DISC-RA-02 - 30V DC System Shifting & Installation of LV ESDB Works Inside GS - Rev-0balaNo ratings yet

- Health and Safety Risk Assessment FormDocument4 pagesHealth and Safety Risk Assessment Formbasil aliNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- Chapter 4 PLANTDocument3 pagesChapter 4 PLANTSedsed QuematonNo ratings yet

- WB P500L ManualDocument158 pagesWB P500L ManualsunhuynhNo ratings yet

- Pronoun and Preposition ExerciseDocument4 pagesPronoun and Preposition Exerciselena meldianaNo ratings yet

- Prometheus PDFDocument12 pagesPrometheus PDFFernán OteroNo ratings yet

- Nama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071Document11 pagesNama: Zaimah Shalsabilla Kelas: Alpha NIM: 04011181520071shalsaNo ratings yet

- A Three Phase Induction Motor Is Basically A Constant Speed Motor So ItDocument39 pagesA Three Phase Induction Motor Is Basically A Constant Speed Motor So ItManish MakwanaNo ratings yet

- STS Finals ReviewerDocument11 pagesSTS Finals Reviewerjulian.cuyaNo ratings yet

- Chapter 2 JFET AC AnalysisDocument47 pagesChapter 2 JFET AC AnalysisRazman RamedanNo ratings yet

- The Hot Air Balloon HistoryDocument3 pagesThe Hot Air Balloon HistoryRonnel ManrezaNo ratings yet

- Region III Tourism MasterPlanDocument34 pagesRegion III Tourism MasterPlanVenus Leilani Villanueva-GranadoNo ratings yet

- Extrusion and Drawing PDFDocument16 pagesExtrusion and Drawing PDFAravindhan AnbalaganNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gNo ratings yet

- 18222Document392 pages18222Lias JayNo ratings yet

- WWW - Swrs.ap - Gov.in: of 1753 Vacant Posts of Teachers, Special Teachers & Staff NursesDocument14 pagesWWW - Swrs.ap - Gov.in: of 1753 Vacant Posts of Teachers, Special Teachers & Staff NursesVijay KsheresagarNo ratings yet

- Drummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkaDocument18 pagesDrummond - Conceptualizing The Efficacy of Vipassana Meditation As Taught by SN GoenkamikeXF100% (1)

- SANY CRM TrainingDocument9 pagesSANY CRM Traininggirish_patkiNo ratings yet

- Questions - 7th EASA AD WorkshopDocument4 pagesQuestions - 7th EASA AD WorkshopFrank MasonNo ratings yet

- نسخة 12- Lecture Hematological DisordersDocument12 pagesنسخة 12- Lecture Hematological DisordersRoxe BroNo ratings yet

- Polymers in Sensor ApplicationsDocument68 pagesPolymers in Sensor ApplicationsAbc_scribdNo ratings yet

- Image Processing and Pattern Recoginition Lab ManualDocument38 pagesImage Processing and Pattern Recoginition Lab ManualDeepa SNo ratings yet

- Nice Classification For TrademarksDocument4 pagesNice Classification For Trademarkskagootukile80No ratings yet

- Jurnal Pruritus SenilisDocument19 pagesJurnal Pruritus Seniliszubair zainalNo ratings yet

- LO WEEK 6 IPHP Q1 W7 8 The Human Person and The Environment Gualdo Benguet DeletedDocument10 pagesLO WEEK 6 IPHP Q1 W7 8 The Human Person and The Environment Gualdo Benguet Deletedgordon boswayNo ratings yet

- Structural Organisation by Rakshita SinghDocument68 pagesStructural Organisation by Rakshita SinghS MUHAMMAD RAAHILNo ratings yet

- Columbia University College of Physicians and SurgeonsDocument12 pagesColumbia University College of Physicians and SurgeonsMichael SellersNo ratings yet

- Designing A Modern ICU - From An Architect PerspectiveDocument23 pagesDesigning A Modern ICU - From An Architect PerspectiveMuneeb Haider AbidiNo ratings yet

- Objective 4Document8 pagesObjective 4api-662676619No ratings yet

- API Chemical Synthesis Trends in Reactor Heat Transfer DesignDocument9 pagesAPI Chemical Synthesis Trends in Reactor Heat Transfer DesignDHAVALESH AMNo ratings yet

- GeographyDocument13 pagesGeographyRao RaasNo ratings yet