Professional Documents

Culture Documents

Service Life RATO DS DS Web

Service Life RATO DS DS Web

Uploaded by

Mohamed Ashraf SolimanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Life RATO DS DS Web

Service Life RATO DS DS Web

Uploaded by

Mohamed Ashraf SolimanCopyright:

Available Formats

RATO DS / RATO DS+

SERVICE LIFE OF HIGHLY FLEXIBLE COUPLINGS

THEORETICAL EXPECTED LIFETIME

VULKAN couplings are produced and tested under the most stringent

quality controls. As a result, apart from a high level of functional

safety across several hours of operation, they even offer the user

a long service life of several years. The expected service life of the

flexible elements is depending on the individual operating or storage

conditions. Even with optimal operating or storing condition, the

elastomer of the coupling ages and wears out. This results in changes

in the dynamic characteristic and functional performance of the

coupling over the lifetime.

Impermissible or excessively high element stresses caused by the

Coupling Natural Rubber Silicon

connected machinery reduces the expected service life. The alignment

of the connected parts has also an influence on the total lifetime. Hence, RATO DS 50,000 h 10 years – –

we recommend that you regularly inspect the elements at least twice a

year. The inspection procedure should include the operating hours, the RATO DS+ 50,000 h 10 years – –

visual shape, permanent set, cracks and other signs of damage and wear.

This inspection can be completed on-site by the crew referring to the

data on the attached tables or by a VULKAN Technician. Additionally, we

recommend to check the alignment between the connected machinery,

especially with elastic mounted systems in regular terms.

10 50k

years hours

Normal ageing of natural rubber causes a certain hardening and

changing of dynamic properties. After 10 years, the stiffness and

10 years service life 50,000 operation hours

damping of highly flexible rubber couplings has changed significantly.

In case of changes in dynamic properties of the rubber elements we

recommend, to replace them in order to ensure the function and the

dynamic behavior of the drive line.

In case of impermissible cracks, the flexible elements have to be

replaced. Permissible lengths and depths of cracks, permissible

permanent set and the theoretical expected lifetime may be selected

Dynamic characteristic Static twist angle

from the tables enclosed. For cracks in the bonding zone between

rubber and metal parts the same values in the tables are valid.

VULKAN Service is also pleased to provide support in the inspection

and assessment of couplings that have been installed.

Tearing

SERVICE LIFE – RATO DS / DS+

11/2022

RATO DS / RATO DS+

SERVICE LIFE OF HIGHLY FLEXIBLE COUPLINGS

Checking the permissible permanent set of a RATO DS / RATO DS+ PERMISSIBLE PERMANENT SET

element takes place by obtaining S measurement of the distance from

inner to the outer metal part as shown in the Figure 1 and Figure 2. Size S [mm] Size S [mm]

In case the maximum value is reached, the flexible element has to be

A21 34 A2B 34

replaced.

A23 38 A2D 38

A25 40 A2F 40

Figure 1

S A27 44 A2H 44

A29 48 A2K 48

A31 50 A3B 50

A33 56 A3D 56

A34 60 A3E 60

A39 68 A3K 68

Figure 2

S

SERVICE LIFE – RATO DS / DS+

11/2022

RATO DS / RATO DS+

SERVICE LIFE OF HIGHLY FLEXIBLE COUPLINGS

As a result of the deformation, aging and load of the flexible element PERMISSIBLE DEPTHS OF CRACKS

during normal operation, cracks may get formed that are permissible in

our natural rubber elements up to a certain limit (Figure 3 and Figure 4). Size X [mm] Y [mm] Size X [mm] Y [mm]

Surface cracks in the flexible element of a RATO DS / RATO DS+ coupling

A21 4 2 A2B 4 2

are permissible, if these cracks occur on both sides of the entire rubber

A23 4 2 A2D 4 2

surface up to a depth as mentioned (Figure 4, depth Y ). With defined

cracks predominantly on one side of the entire rubber surface up to a A25 6 3 A2F 6 3

depth as mentioned (Figure 3 X ). If the permissible influenced area as A27 6 3 A2H 6 3

a combination of the mentioned cracks is exceeded, it is recommended to A29 6 3 A2K 6 3

replace the flexible element as soon as possible.

A31 6 3 A3B 6 3

A33 6 3 A3D 6 3

A34 8 4 A3E 8 4

A39 8 4 A3K 8 4

X Y

Figure 3 Figure 4

SERVICE LIFE – RATO DS / DS+

11/2022

RATO DS / RATO DS+

ELEMENT INSPECTION SHEET

Vessel: Coupling: Size:

Date: Location: Comm-Nr.: Permanent set:

Running Hours: Engine: Engine < > Gearbox < > Shaft Generator

Power: Speed: Row 1 Row 2 Row 3 Row 4

FRONT SIDE

Please make a sketch of the cracks on the shown segments. Use one sheet for one element side. Mark the cracks with “length / depth” if possible.

SERVICE LIFE – RATO DG / DG+

11/2022

RATO DS / RATO DS+

ELEMENT INSPECTION SHEET

Vessel: Coupling: Size:

Date: Location: Comm-Nr.: Permanent set:

Running Hours: Engine: Engine < > Gearbox < > Shaft Generator

Power: Speed: Row 1 Row 2 Row 3 Row 4

BACK SIDE

Please make a sketch of the cracks on the shown segments. Use one sheet for one element side. Mark the cracks with “length / depth” if possible.

SERVICE LIFE – RATO DG / DG+

11/2022

You might also like

- Credit Card Tracking SheetDocument2 pagesCredit Card Tracking SheetMohamed Ashraf SolimanNo ratings yet

- MiniRail V2Document6 pagesMiniRail V2hepcomotionNo ratings yet

- QueryDocument2 pagesQueryTu PhamNo ratings yet

- TERA Joint BrochureDocument16 pagesTERA Joint BrochureraigoukiNo ratings yet

- 10i131648 - Fco2Document3 pages10i131648 - Fco2Lis RincónNo ratings yet

- Conical - Type Strainers: (Digitare Il Testo)Document3 pagesConical - Type Strainers: (Digitare Il Testo)blu.zac649gmail.comNo ratings yet

- Sma 2005finalDocument10 pagesSma 2005finalibrahim tanko abeNo ratings yet

- Bell Amphibious Excavators April2018 WebDocument12 pagesBell Amphibious Excavators April2018 Webparaia01No ratings yet

- PA44 Lycoming Ovehaul Manual 76 Series 60294-9 Rev Jun 1996Document91 pagesPA44 Lycoming Ovehaul Manual 76 Series 60294-9 Rev Jun 1996aditya nugrahaNo ratings yet

- Manual Ar Condicionado 60000 BtusDocument4 pagesManual Ar Condicionado 60000 BtusBruno SoaresNo ratings yet

- Arvis Brochure Plain BearingsDocument28 pagesArvis Brochure Plain BearingsJavierNo ratings yet

- Barmac Orange Series Application Guide 3124 - LowresDocument16 pagesBarmac Orange Series Application Guide 3124 - LowresRafaelDevNo ratings yet

- TDS BOPP Clear LSA47 TaghleefDocument2 pagesTDS BOPP Clear LSA47 TaghleefEmmanuel Alvarez100% (1)

- D SanderDocument5 pagesD SanderreshadshukurovNo ratings yet

- 2011 Traffic Sign Retroreflective Sheeting Identification GuidDocument2 pages2011 Traffic Sign Retroreflective Sheeting Identification GuidThai Wu TitaniumNo ratings yet

- Trelleborg VA ACME Calamity Gasket Kuminen Liikuntasaumanauha Tekninen Käyttöohje (Eng)Document17 pagesTrelleborg VA ACME Calamity Gasket Kuminen Liikuntasaumanauha Tekninen Käyttöohje (Eng)Dan MarkNo ratings yet

- Bolts - LRFDDocument6 pagesBolts - LRFDalexortiz83No ratings yet

- RedutorDocument4 pagesRedutormarcelo rojasNo ratings yet

- 01 r34 A RidicareDocument16 pages01 r34 A RidicareVagany7No ratings yet

- Accord Catalog 2.0 - Hoses and Couplings - 2005 (ENG)Document237 pagesAccord Catalog 2.0 - Hoses and Couplings - 2005 (ENG)EduardNo ratings yet

- MisiaDocument1 pageMisiaDante WilliamsNo ratings yet

- TRASCO CouplingsDocument21 pagesTRASCO CouplingsCarlosNo ratings yet

- DTX SKFDocument4 pagesDTX SKFFendyNo ratings yet

- Catalgue Bom Chim Dong Grey Model DRGDocument4 pagesCatalgue Bom Chim Dong Grey Model DRGthuytd8211No ratings yet

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- R-Kex Ii - StudsDocument20 pagesR-Kex Ii - StudsMarvinNo ratings yet

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryNo ratings yet

- Conti General OTRDocument100 pagesConti General OTRJamal HabbasNo ratings yet

- Technical Data Sheets of BIDIM GEOTEXTILESDocument2 pagesTechnical Data Sheets of BIDIM GEOTEXTILESDean Ryann SubaranNo ratings yet

- Proportioning of A Concrete MixDocument11 pagesProportioning of A Concrete MixSude FilizNo ratings yet

- Dim ReducersDocument7 pagesDim Reducersoscarapaza_00No ratings yet

- Manual AcumuladoresDocument12 pagesManual AcumuladoresHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Wave Solder Pallet Design GuidelinesDocument11 pagesWave Solder Pallet Design GuidelinesThe HoangNo ratings yet

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- CHECK VALVE S RE20375logoDocument4 pagesCHECK VALVE S RE20375logoThan NaingNo ratings yet

- Isolator ValvesDocument134 pagesIsolator ValvesZoran JankovNo ratings yet

- Bosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveDocument4 pagesBosch Rexroth S 6 S 10 S 20 S 30 Inline Check ValveOARIASCONo ratings yet

- Boss dd3 TDocument10 pagesBoss dd3 TVictor AriizNo ratings yet

- 05-32 SLRSOC2 50mm Seismic Series 1-9 - AusDocument1 page05-32 SLRSOC2 50mm Seismic Series 1-9 - Ausjonathan watsonNo ratings yet

- 5 Subcontract Agreement - 5D Bend Pipe Trimming Wor - 240312 - 085349Document17 pages5 Subcontract Agreement - 5D Bend Pipe Trimming Wor - 240312 - 085349Muhammad ZakiNo ratings yet

- Pebax Product Range and PropertiesDocument2 pagesPebax Product Range and Propertiesabhishek_negi_41No ratings yet

- PSK GET 9th v2Document827 pagesPSK GET 9th v2Luis PozoNo ratings yet

- 3453 Brochure Amphibious Excavator Mrt2019 LR DEF MinDocument12 pages3453 Brochure Amphibious Excavator Mrt2019 LR DEF MinDarkedgeNo ratings yet

- Recommended Performance Guideline For Chip Seal: NoticeDocument9 pagesRecommended Performance Guideline For Chip Seal: NoticeAnna KLNo ratings yet

- Gantrex Mk90 Raillok Pad Data Sheet MetricDocument2 pagesGantrex Mk90 Raillok Pad Data Sheet MetricZar Ka ZiNo ratings yet

- HPFRCC6 - Parra Et Al - FinalDocument8 pagesHPFRCC6 - Parra Et Al - Finalaksh007No ratings yet

- Section 703. - AGGREGATE: Include The Following When Section 301 Is RequiredDocument3 pagesSection 703. - AGGREGATE: Include The Following When Section 301 Is RequiredPrisscy ChimarroNo ratings yet

- Material List SummaryDocument2 pagesMaterial List SummaryNenad GajicNo ratings yet

- Portals Raybestos Files PM 1340 2017.08.30 APC Catalog Without ImagesDocument349 pagesPortals Raybestos Files PM 1340 2017.08.30 APC Catalog Without ImagesJose Huanca100% (2)

- PC 1357Document332 pagesPC 1357Jaime OchoaNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- ArcelorMittal Cofrastra 40 Brochure enDocument12 pagesArcelorMittal Cofrastra 40 Brochure endinoNo ratings yet

- Koehring and Bantam Excavators 6633l Parts Book SupplementDocument1 pageKoehring and Bantam Excavators 6633l Parts Book Supplementjoyce100% (52)

- HDS-1303NT (Exp)Document169 pagesHDS-1303NT (Exp)faisalmamat1997No ratings yet

- Condensate and Sediment TrapDocument3 pagesCondensate and Sediment TrapRahul PillaiNo ratings yet

- HCD Series: High Capacity Drum LouversDocument8 pagesHCD Series: High Capacity Drum LouversElvis Ruben Piza MerchanNo ratings yet

- O Rings CatalogueDocument87 pagesO Rings CatalogueVictor A. Claure ManzoniNo ratings yet

- Castel Globe ValveDocument17 pagesCastel Globe Valveroy fadliNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khan100% (1)

- 25stg 862-18000-XA Shell Units New Curve 50HZ 100psiDocument2 pages25stg 862-18000-XA Shell Units New Curve 50HZ 100psiMohamed Ashraf SolimanNo ratings yet

- RF-AVG Assembly InstructionsDocument1 pageRF-AVG Assembly InstructionsMohamed Ashraf SolimanNo ratings yet

- Guardian Anytime App InstructionsDocument1 pageGuardian Anytime App InstructionsMohamed Ashraf SolimanNo ratings yet

- Bloodborne Pathogen PolicyDocument13 pagesBloodborne Pathogen PolicyMohamed Ashraf SolimanNo ratings yet

- AJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBDocument2 pagesAJI20021 Ajax Integral Engine Compressor DPC 2801 r0 WEBMohamed Ashraf SolimanNo ratings yet

- AJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebDocument2 pagesAJI20020 Ajax Integral Engine Compressor DPC 2202 r0 WebMohamed Ashraf SolimanNo ratings yet

- Ajax Product Overview PT (Apr2024)Document1 pageAjax Product Overview PT (Apr2024)Mohamed Ashraf SolimanNo ratings yet

- Sample COI Template - US Enercorp Ltd/Ageron Energy LLC Certificate of InsuranceDocument1 pageSample COI Template - US Enercorp Ltd/Ageron Energy LLC Certificate of InsuranceMohamed Ashraf SolimanNo ratings yet

- Night School 12 Session 7Document113 pagesNight School 12 Session 7LCSNo ratings yet

- Quantum Mechanics II - Homework 6Document6 pagesQuantum Mechanics II - Homework 6Ale GomezNo ratings yet

- Band Theroy of Solids 1Document157 pagesBand Theroy of Solids 1Kakileti RupasriNo ratings yet

- 2023 CatalogDocument40 pages2023 Catalogmas agung chandraNo ratings yet

- Nano Select - 2023 - Mekuye - Nanomaterials An Overview of Synthesis Classification Characterization and ApplicationsDocument16 pagesNano Select - 2023 - Mekuye - Nanomaterials An Overview of Synthesis Classification Characterization and ApplicationsAmeer HamzaNo ratings yet

- Modelling of The Spray Drying Process For Particle Design PDFDocument41 pagesModelling of The Spray Drying Process For Particle Design PDFmarmaduke32No ratings yet

- Ee 502 1Document3 pagesEe 502 1Suresh NaiduNo ratings yet

- Code-A: Aakash Tower, 8, Pusa Road, New Delhi-110005, Ph. 011-47623456Document48 pagesCode-A: Aakash Tower, 8, Pusa Road, New Delhi-110005, Ph. 011-47623456Sujit LawareNo ratings yet

- Polyacetal (POM) : PropertiesDocument4 pagesPolyacetal (POM) : PropertiesnaninoNo ratings yet

- Fabrication Solar Refrigeration System by Peltier Effect Ijariie8926Document6 pagesFabrication Solar Refrigeration System by Peltier Effect Ijariie8926Prachurjya BaruahNo ratings yet

- Lateral Cyclic Behavior of Bridge Columns Confined With Pre Stressed Shape Memory Alloy WiresDocument15 pagesLateral Cyclic Behavior of Bridge Columns Confined With Pre Stressed Shape Memory Alloy WiresRani HendrikusNo ratings yet

- Ovako 280Document2 pagesOvako 280Ejang GutNo ratings yet

- Chapter 10-4Document14 pagesChapter 10-4AlbertoNo ratings yet

- Thermo 1 Exam 4Document1 pageThermo 1 Exam 4Juan KakakaNo ratings yet

- Module 3 Compression Members Lec #1Document5 pagesModule 3 Compression Members Lec #1k. NotujNo ratings yet

- Extrusion of AlMgSi AlloysDocument15 pagesExtrusion of AlMgSi Alloyscargetoianu2357No ratings yet

- (Revised) MIMOS 2-Sep - SFAM Endorsement On Wafer Fabrication Front - Back End Process For Manufacturing SpecialistDocument58 pages(Revised) MIMOS 2-Sep - SFAM Endorsement On Wafer Fabrication Front - Back End Process For Manufacturing Specialistmahadzir72No ratings yet

- Data Sheet 152uk Hardox 500 20180212 184 371857150 enDocument2 pagesData Sheet 152uk Hardox 500 20180212 184 371857150 enszystNo ratings yet

- IBCASTDocument10 pagesIBCASTKhalil ShadNo ratings yet

- Hints ABAQUS PDFDocument14 pagesHints ABAQUS PDFAndres CarphioNo ratings yet

- Performance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsDocument14 pagesPerformance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsMilmxmenNo ratings yet

- Thermo Lab ReportDocument8 pagesThermo Lab ReportHassan W. ZubairNo ratings yet

- Raman PDFDocument3 pagesRaman PDFAla TulleNo ratings yet

- Voestalpine Heavy Plate Datasheet Durostat en 20170904Document3 pagesVoestalpine Heavy Plate Datasheet Durostat en 20170904Kristy HillNo ratings yet

- NEBB Psych Chart Sea Level 11x17Document1 pageNEBB Psych Chart Sea Level 11x17JojolasNo ratings yet

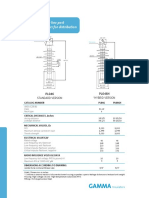

- Aislador Polimerico Poste Gamma 46KVDocument1 pageAislador Polimerico Poste Gamma 46KVEDGAR HALLNo ratings yet

- Tutorial 1 EG501LDocument3 pagesTutorial 1 EG501LderianzacharyNo ratings yet

- Physics Investigatory by SumitDocument16 pagesPhysics Investigatory by Sumitndnashudebnath94No ratings yet

- Theoretical Backround Oct18 PDFDocument134 pagesTheoretical Backround Oct18 PDFDavid MankoNo ratings yet