Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsAandrijftechniek 3 V5

Aandrijftechniek 3 V5

Uploaded by

Mark GeesinkCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Samenvatting Kerst Fysica Quark 6.2Document4 pagesSamenvatting Kerst Fysica Quark 6.2Flore DebruyneNo ratings yet

- Overal Natuurkunde 3 H H05 UitwerkingenDocument12 pagesOveral Natuurkunde 3 H H05 UitwerkingenEva PelNo ratings yet

- 2324 Formuleblad ThermoDocument2 pages2324 Formuleblad ThermoguytorcqueNo ratings yet

- Formuleblad 2021Document10 pagesFormuleblad 2021Mira de VoogdNo ratings yet

- Formuleblad Reactorkunde Versie Feb 22Document3 pagesFormuleblad Reactorkunde Versie Feb 22guytorcqueNo ratings yet

- FormulebladDocument4 pagesFormulebladguytorcqueNo ratings yet

- Wiu 1Document4 pagesWiu 1Miguel PandoNo ratings yet

- Oefententamen 2Document18 pagesOefententamen 2nattehond5No ratings yet

- Oefeningen Online 12 JanuariDocument10 pagesOefeningen Online 12 JanuariPeggy BothaNo ratings yet

- Opsomming en FormulesDocument5 pagesOpsomming en FormulesMegan BerrNo ratings yet

- TM Aflevering Uge 37Document8 pagesTM Aflevering Uge 37Mo AzzamNo ratings yet

- Natuurkunde Samenvatting H2,3,7,8Document3 pagesNatuurkunde Samenvatting H2,3,7,8Josephine nellensteijnNo ratings yet

- Les 1 NotasDocument23 pagesLes 1 NotasTes Van der MerweNo ratings yet

- RL SerieketenDocument13 pagesRL SerieketenJurgen NijsNo ratings yet

- College 5 (NL)Document8 pagesCollege 5 (NL)Julian PostmaNo ratings yet

- Formularium Technisch Wiskunde 2Document10 pagesFormularium Technisch Wiskunde 2JarisNo ratings yet

- BK1TE1 Formuleblad Klimaatontwerp v1.4Document4 pagesBK1TE1 Formuleblad Klimaatontwerp v1.4Steven van HaaftenNo ratings yet

- 2023-11-20 Hoofdstelling Integraalrekening en GevolgDocument6 pages2023-11-20 Hoofdstelling Integraalrekening en GevolgYannick BruwierNo ratings yet

- Oefenopgaven - Stromingsleer - UitwerkingenDocument5 pagesOefenopgaven - Stromingsleer - UitwerkingenV GoNo ratings yet

- Formularium 2020Document6 pagesFormularium 2020Zombie BossNo ratings yet

- Formularium 2024Document6 pagesFormularium 2024Zombie BossNo ratings yet

- Hogeschool VIVES Formuleblad Mechanica 2Document3 pagesHogeschool VIVES Formuleblad Mechanica 2Mr GoodmanNo ratings yet

- Formuleblad BCH11T 22-23Document1 pageFormuleblad BCH11T 22-23Ray BruinsNo ratings yet

- Blz. 147 171 Buigen Traagheidsmomenten Groenendijk 1Document30 pagesBlz. 147 171 Buigen Traagheidsmomenten Groenendijk 1kwatta 16No ratings yet

- Oefentoets Dynamica 2018-2019Document3 pagesOefentoets Dynamica 2018-2019mayank pratap mishraNo ratings yet

- WS H2 EnkelvoudigeDocument27 pagesWS H2 Enkelvoudigediel.deweerdt4No ratings yet

- Samenvatting Regels Wib HavoDocument2 pagesSamenvatting Regels Wib HavoJoost SPNo ratings yet

- 3A HST 08 + Verg v301 UitwDocument6 pages3A HST 08 + Verg v301 Uitwtygo van den heuvelNo ratings yet

- 1âºc1av1212c Aritmetica (Sol)Document2 pages1âºc1av1212c Aritmetica (Sol)bbyggrllNo ratings yet

- ZIn Spanning in GeleiderDocument39 pagesZIn Spanning in GeleiderPeggy BothaNo ratings yet

- Proef2 UitwerkingDocument4 pagesProef2 UitwerkingHugo BurggraaffNo ratings yet

- Wiskunde 1 BewijzenDocument15 pagesWiskunde 1 BewijzenOmid AlzNo ratings yet

- Trigonometriese Grafieke Breinkaart 1 TemplaatDocument1 pageTrigonometriese Grafieke Breinkaart 1 Templaatannemelouw11No ratings yet

- MachtenDocument5 pagesMachtenadpas8No ratings yet

- 1-Chemie Les 10 ThermodynamicaDocument48 pages1-Chemie Les 10 ThermodynamicaMichiel Van de VeldeNo ratings yet

- Wisk 4Document5 pagesWisk 4fxwg4vx2m7No ratings yet

- Theorie Wiskunde Lineaire Algebra 1Document8 pagesTheorie Wiskunde Lineaire Algebra 19m66z7vbbxNo ratings yet

- ANA3-51-a-theorie-ik Bestudeer de Afvlakking (Condensator)Document8 pagesANA3-51-a-theorie-ik Bestudeer de Afvlakking (Condensator)Seppe MoensNo ratings yet

- Slides Dag 1 RCC WiskundeBE-EBE-FEDocument57 pagesSlides Dag 1 RCC WiskundeBE-EBE-FEf.dualeNo ratings yet

- Formuleblad LuchtbehandelingenDocument7 pagesFormuleblad LuchtbehandelingenMatthijs BoomNo ratings yet

- Oefenopg Analyse 2Document1 pageOefenopg Analyse 2Kiren P.No ratings yet

- Elektriciteit Samenvatting KerstDocument26 pagesElektriciteit Samenvatting Kerstrobbedecuyper20No ratings yet

- Formularium Financiã Le Algebra Uitgebreid PDFDocument3 pagesFormularium Financiã Le Algebra Uitgebreid PDFCisse BexNo ratings yet

- Les 4 Eerste BeginselsDocument27 pagesLes 4 Eerste BeginselsCiara ChimangaNo ratings yet

- KrimpenDocument3 pagesKrimpenNiek MasselinkNo ratings yet

- Leerstofoverzicht Fysica Kerst 4HWEWDocument6 pagesLeerstofoverzicht Fysica Kerst 4HWEWImane MaroufNo ratings yet

- Complexe Getallen Uitgewerkte Oefeningen en Extra UitlegDocument57 pagesComplexe Getallen Uitgewerkte Oefeningen en Extra UitlegYannick BruwierNo ratings yet

- 6.8 - A - Binome MaalDocument11 pages6.8 - A - Binome MaalnorthcliffmmNo ratings yet

- ELEWIS10 Week 2 1Document23 pagesELEWIS10 Week 2 1CharmillaNo ratings yet

- 23 EM-TR2 Transformatoren OefeningenDocument22 pages23 EM-TR2 Transformatoren Oefeningendiel.deweerdt4No ratings yet

- Aula 2e3 VIDocument18 pagesAula 2e3 VI92966818thNo ratings yet

- Xx-Xxxx-Buckling CalculationDocument5 pagesXx-Xxxx-Buckling CalculationNafees ShaikhNo ratings yet

- 2023-11-20 de Bepaalde Integraal Van X 2 AlgemeenDocument4 pages2023-11-20 de Bepaalde Integraal Van X 2 AlgemeenYannick BruwierNo ratings yet

- ZIn Spanning in Geleider (Automatisch Opgeslagen)Document34 pagesZIn Spanning in Geleider (Automatisch Opgeslagen)Peggy BothaNo ratings yet

- WiskundeDocument12 pagesWiskundeselma.ouladNo ratings yet

- H5 Antwoorden 3HDocument21 pagesH5 Antwoorden 3Hjessika.wieczorek02No ratings yet

- Practica 5Document4 pagesPractica 5MARIANA VALENCIA SANCHEZNo ratings yet

- 1-Chemie Les 9Document37 pages1-Chemie Les 9Michiel Van de VeldeNo ratings yet

- Formules - 3-Bedrijfseconomie - UA FTI - 2018-2019Document3 pagesFormules - 3-Bedrijfseconomie - UA FTI - 2018-2019AmberNo ratings yet

Aandrijftechniek 3 V5

Aandrijftechniek 3 V5

Uploaded by

Mark Geesink0 ratings0% found this document useful (0 votes)

2 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesAandrijftechniek 3 V5

Aandrijftechniek 3 V5

Uploaded by

Mark GeesinkCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

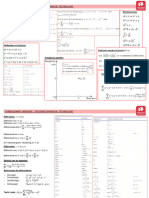

Formule Opmerking 𝑎𝑐𝑜𝑛𝑡.

= ∆𝑣/∆𝑡 Bij niet constante versnellingen de Hydropompen

𝑊 = 𝐹 ∙ 𝑠 of 𝑊 = 𝑀 ∙ 𝜃 Mechanisch koppel/moment gevonden functie integreren met ɳ𝑚ℎ = Mechanisch hydraulisch

2∙𝜋∙𝑛

𝑃 = 𝐹 ∙ 𝑣 of 𝑃 = 𝑀 ∙ 𝜔 Mechanisch vermogen 𝛼𝑐𝑜𝑛𝑡. = ∆𝜔/∆𝑡 na omvormen; 𝑃𝑖𝑛 = 𝑇𝑖𝑛 ∙ 𝜔𝑖𝑛 = 𝑇𝑖𝑛 ∙ ( ) rendement

𝑊 = ∆𝑝 ∙ 𝑉 Hydraulisch arbeid ∫ 𝑑𝜃 = ∫ 𝜔(𝑡) 𝑑𝑡 60

𝑃𝑖𝑛 = (𝑄̇𝑣(𝑡ℎ.) ∙ ∆𝑝)/ɳ𝑚ℎ ɳ𝑣𝑜𝑙 = Volumetrisch

𝑃 = ∆𝑝 ∙ 𝑄 = ∆𝑝 ∙ 𝑉̇ = ∆𝑝 ∙ 𝑣𝑞 Hydraulisch vermogen 1 1 rendement(lekkage verliezen)

𝐸𝑘 = ∙ 𝑚 ∙ 𝑣2 → ∙ 𝜌 ∙ 𝑣2 𝑃𝑖𝑛 = (𝑄̇𝑣(𝑤.) ∙ ∆𝑝)/(ɳ𝑚ℎ ∙ ɳ𝑣𝑜𝑙 )

𝐹 Statische druk 2 2 𝑛=RPM

𝑝 = → 𝐹 =𝐴∙𝑝|𝐹 𝐹 Dynamische viscositeit

𝐴 ( ) 𝑃𝑢𝑖𝑡 = ∆𝑝 ∙ 𝑄̇𝑣(𝑤) = ∆𝑝 ∙ 𝑄̇𝑣(𝑡ℎ) ∙ ɳ𝑣𝑜𝑙

𝑝 =𝜌∙𝑔∙ℎ Potentiële druk, h= kolom hoogte in 𝜂= 𝐴 𝑣

𝐷 = laagdikte of afstand vlakken 𝑇𝑖𝑛 = (∆𝑝 ∙ 𝑉𝑠 )/(ɳ𝑚ℎ ∙ 2 ∙ 𝜋)

[𝑚] ( ) in[m]

𝐷 𝑃𝑢𝑖𝑡 = 𝑃𝑖𝑛 ∙ ɳ𝑣𝑜𝑙 ∙ ɳ𝑚ℎ

𝑘𝑔 ∙ 𝑚 𝑣 = 𝑆𝑛𝑒𝑙ℎ𝑒𝑖𝑑 𝑖𝑛 [𝑚/𝑠]

g=[𝑚/𝑠 2 ] 𝑜𝑓 [𝑁/𝑘𝑔], [𝑁] = [ 2 ] 𝑄̇ 𝑣(𝑤.) 𝑝𝑜𝑚𝑝 = 𝑛 ∙ 𝑉𝑠 ∙ ɳ𝑣𝑜𝑙(𝑝𝑜𝑚𝑝)

𝑠

𝜂 = [𝑁𝑠/𝑚2 ]

1 Dynamische druk →kinetische energie 𝑃𝑛𝑢𝑡𝑡𝑖𝑔 𝑃𝑢𝑖𝑡

𝑝= ∙ 𝜌 ∙ 𝑣2 𝑣 = (𝜂/𝜌) Kinematische viscositeit = = ɳ𝑡𝑜𝑡 ISO VG ref. temp. 40°C

2 𝜐 = [𝑚2 /𝑠] 𝑃𝑡𝑜𝑒𝑔𝑒𝑣𝑜𝑒𝑟𝑑 𝑃𝑖𝑛

1 Wet van Bernoulli 𝑃 ≥ 200[𝑏𝑎𝑟] → (𝑠𝑡𝑖𝑗𝑔𝑡)𝜐𝑑𝑦𝑛. ↑

𝑝1 + 𝜌 ∙ 𝑔 ∙ ℎ1 + ∙ 𝜌 ∙ 𝑣12 = 𝜐 = [𝑚𝑚2 /𝑠] = 𝑐𝑆𝑡 = ɳ𝑣𝑜𝑙 ∙ ɳ𝑚ℎ

2 (Wet van behoud van energie) 𝑃 = 400[𝑏𝑎𝑟] → 2 ∙ 𝜐𝑑𝑦𝑛.(𝑃=0)

1

𝑛𝑡𝑜𝑒𝑣𝑜𝑒𝑟 Afscheidingsvermogen 𝑄̇𝑣(𝑤.)

𝑝2 + 𝜌 ∙ 𝑔 ∙ ℎ2 + ∙ 𝜌 ∙ 𝑣22

𝛽𝑥 = ɳ𝑣𝑜𝑙 = 𝜐𝑑𝑦𝑛.𝑖𝑑𝑒𝑎𝑎𝑙 = 36[𝑚𝑚2 /𝑠]

𝑛𝑎𝑓𝑣𝑜𝑒𝑟 filterelementen 𝑄̇𝑣(𝑡ℎ.)

2

∆𝑝 = 𝑝1 − 𝑝2 Drukverlies 𝛽𝑥 = 2 → 50% Hydromotoren

𝐹1 𝐹2 Krachtoverbrenging(autokrik principe) 𝛽𝑥 = 20 → 95% 𝑃𝑢𝑖𝑡 = 𝑇𝑢𝑖𝑡 ∙ 𝜔𝑢𝑖𝑡

𝑝= = 𝛽𝑥 = 75 → 98,6% 2∙𝜋∙𝑛

𝐴1 𝐴2 𝑃𝑢𝑖𝑡 = 𝑇𝑢𝑖𝑡 ∙ ( )

𝑝1 𝐴2 𝛽𝑥 = 100 → 99% 60

Druktransformatie

= 𝑥 = 𝑔𝑟𝑜𝑜𝑡𝑡𝑒 𝑣/𝑑 𝑑𝑒𝑒𝑙𝑡𝑗𝑒𝑠 𝑖𝑛 [𝜇𝑚] ̇

𝑃𝑢𝑖𝑡 = ∆𝑝 ∙ 𝑄𝑣(𝑤.) ∙ ɳ𝑚ℎ

𝑝2 𝐴1

𝑉𝑚𝑎𝑥 = 2 ∙ 𝑉𝑔𝑒𝑚 Laminaire stroming 𝑃𝑢𝑖𝑡 = ∆𝑝 ∙ 𝑄̇𝑣(𝑡ℎ.) ∙ ɳ𝑚ℎ ∙ ɳ𝑣𝑜𝑙

𝑄 = 𝐴 ∙ 𝑣 → 𝑄1 = 𝑄2 → 𝑉1̇ = 𝑉̇2 Volumestroom & continuïteitsprincipe

𝑉𝑚𝑎𝑥 = 1,1 … 1,2 ∙ 𝑉𝑔𝑒𝑚 Turbulente stroming 𝑇𝑢𝑖𝑡 = (∆𝑝 ∙ 𝑉𝑠 ∙ ɳ𝑚ℎ )/(2 ∙ 𝜋)

𝐴1 ∙ 𝑣1 = 𝐴2 ∙ 𝑣2 → 𝐴1 ∙ 𝑠1 = 𝐴2 ∙ 𝑠2

𝑄 = 𝑉̇ = 𝑞𝑣 Cilinders 𝑃𝑖𝑛 = ∆𝑝 ∙ 𝑄̇𝑣(𝑡ℎ.) *let op!!

𝑣𝑘.𝑣𝑖𝑠𝑐𝑜 = 𝑘𝑖𝑛𝑒𝑚𝑎𝑡𝑖𝑠𝑐ℎ𝑒 𝑣𝑖𝑠𝑐𝑜𝑠𝑖𝑡𝑒𝑖𝑡 ɳ𝑚ℎ = Mechanisch hydraulisch 𝑃𝑢𝑖𝑡 = 𝑃𝑖𝑛 ∙ ɳ𝑣𝑜𝑙 ∙ ɳ𝑚ℎ

𝑑ℎ 𝑟𝑜𝑛𝑑𝑒 𝑙𝑒𝑖𝑑𝑖𝑛𝑔 = Ø𝑙𝑒𝑖𝑑𝑖𝑛𝑔 𝑖𝑛[𝑚] 𝐹𝑢𝑖𝑡𝑔𝑎𝑎𝑛𝑑 = 𝑝 ∙ ɳ𝑚ℎ ∙ 𝐴𝑧𝑔𝑟

rendement (𝑛𝑚𝑎𝑥 ∙ 𝑉𝑠 )

𝐴 𝜋 2 2 ) 𝑄̇𝑣 max 𝑚𝑜𝑡𝑜𝑟 =

𝑑ℎ 𝑣𝑜𝑟𝑚 = 4 ∙ 𝐹𝑖𝑛𝑔𝑎𝑎𝑛𝑑 = 𝑝 ∙ ɳ𝑚ℎ ∙ 𝐴𝑟𝑖𝑛𝑔 𝐴𝑟𝑖𝑛𝑔 = ∙ (𝑑𝑏𝑢 − 𝑑𝑏𝑖 ɳ𝑣𝑜𝑙

𝑣 ∙ 𝑑ℎ 𝑈 4

𝑅𝑒 = Knikberekening 𝑄̇ 𝑣 (𝑡ℎ.)(𝑚𝑜𝑡𝑜𝑟) = (𝑛 ∙ 𝑉𝑠 )/ɳ𝑣𝑜𝑙(𝑚𝑜𝑡𝑜𝑟) 𝑄̇ 𝑣 (𝑤.)(𝑚𝑜𝑡𝑜𝑟) = 𝑛 ∙ 𝑉𝑠

𝑣𝑘.𝑣𝑖𝑠𝑐𝑜 𝐴 = 𝑑𝑜𝑜𝑟𝑠𝑛𝑒𝑑𝑒 𝑜𝑝𝑝. 𝑖𝑛[𝑚2 ]

𝑈 = 𝑜𝑚𝑡𝑟𝑒𝑘 𝑖𝑛 [𝑚] 𝑠𝑘2 =tabel 7.4 blz.128 𝐹𝑚𝑎𝑥.𝑡𝑎𝑛𝑔. = 𝑇𝑚𝑎𝑥. /𝑟𝑠𝑡𝑟𝑎𝑎𝑙

𝐾 = (𝜋 2 ∙ 𝐸𝑠𝑡 ∙ hydrauliekboek

𝑅𝑒 𝑐𝑟𝑖𝑡. ≥ 2300

𝐽𝑡𝑟𝑎𝑎𝑔ℎ𝑒𝑖𝑑𝑠𝑚𝑜𝑚𝑒𝑛𝑡 𝑎𝑠𝑠𝑒𝑛 )/𝑠𝑘2 𝜋

𝑣𝑘.𝑣𝑖𝑠𝑐𝑜 = [𝑚2 /𝑠] 𝐽𝑡𝑟𝑎𝑎𝑔ℎ𝑒𝑖𝑑𝑠𝑚𝑜𝑚𝑒𝑛𝑡 𝑎𝑠𝑠𝑒𝑛 = ( ) ∙

64

64 Laminaire stroming 4 4

ʎ= (𝑑𝑏𝑢 − 𝑑𝑏𝑖 )

𝑅𝑒 ʎ=Weerstandscoëfficiënt 𝑆𝑎 =Veiligheidsfactor 3,5 volgens

0,316 Turbulente stroming 𝐹𝑚𝑎𝑥.𝑏𝑒𝑙𝑎𝑠𝑡𝑖𝑛𝑔 = 𝐾𝑘𝑛𝑖𝑘 /𝑆𝑎

ʎ= boek

𝑅𝑒 ʎ=Weerstandscoëfficiënt Remkracht uitgaande horizontaal

ʎ ∙ 𝑙 ∙ 𝜌 ∙ 𝑣2 Leidingweerstand 𝐹𝑟𝑒𝑚 𝑢𝑖𝑡 = 𝑚𝑡𝑜𝑡 ∙ 𝑎 + 𝐴𝑧𝑔𝑟 ∙ 𝑝

∆𝑝 = georiënteerd

2∙𝑑 𝑙 = 𝑙𝑒𝑛𝑔𝑡𝑒 𝑖𝑛 [𝑚] Remkracht ingaand horizontaal

𝜌 = 𝑑𝑖𝑐ℎ𝑡ℎ𝑒𝑖𝑑 𝑖𝑛 [𝑘𝑔/𝑚3 ] 𝐹𝑟𝑒𝑚 𝑖𝑛 = 𝑚𝑡𝑜𝑡 ∙ 𝑎 + 𝐴𝑟𝑖𝑛𝑔 ∙ 𝑝

georiënteerd

𝑣 = 𝑠𝑛𝑒𝑙ℎ𝑒𝑖𝑑 𝑖𝑛 [𝑚/𝑠]

𝐴𝑑 =nuttig buffer oppervlakte

𝑑 = Ø𝑏𝑢𝑖𝑠 𝑖𝑛 [𝑚]

𝑃𝑑.𝑏𝑢𝑓𝑓𝑒𝑟 =Druk die binnen buffer

1 𝜁 = 𝑤𝑒𝑒𝑟𝑠𝑡𝑎𝑛𝑑𝑤𝑎𝑎𝑟𝑑𝑒 𝑎𝑝𝑝𝑒𝑛𝑑𝑎𝑔𝑒𝑠 𝑃𝑑.𝑏𝑢𝑓𝑓𝑒𝑟 = 𝐹𝐵 /𝐴𝑑

∆𝑝 = 𝜁 ∙ ∙ 𝜌 ∙ 𝑣 2 kamer ontstaat, controle op

2

𝜌𝑣2 Compensatie drukverlies door andere 𝑃𝑑 ≤ 𝑃𝑛𝑜𝑚.

∆𝑝𝑣2 = ∙ ∆𝑝𝑣1 ∆𝑙 = 𝛼𝑡 ∙ 𝑙𝑜 ∙ ∆𝑇1−2

𝜌𝑣1 dichtheid

𝐹∙𝑙 𝐹

𝑣2 𝑥 Compensatie drukverlies voor andere (∆)𝜎 = 𝐸 ∙ 𝜀 = 𝜀 = ∆𝑙/𝑙 & 𝜎 =

∆𝑝𝑣2 = ( ) ∙ ∆𝑝1 𝐴

𝑣1 viscositeit 𝐸∙𝐴

∆𝑝 = 𝐸 ∙ (∆𝑉/𝑉) → ∆𝑝 = 𝐸 ∙ (∆𝑙/𝑙) ∆𝑉

Exponent x= 1 voor laminaire stroming ∆𝑝 = 𝐸 ∙ ( ) → (∆)𝜎 = 𝐸 ∙ 𝜀 →

Exponent x= 0,25 voor turbulente 𝑉

𝐺 = 𝐸 ∙ (∆𝑙/𝑙)

stroming (∆)𝜎 = ∆𝑝 = 𝛼𝑡 ∙ 𝐸(𝑜𝑙𝑖𝑒) ∙ ∆𝑇1−2 Drukverschil door

∆𝑝𝑡𝑜𝑡𝑎𝑎𝑙 = ∆𝑝1 + ∆𝑝2 + ∆𝑝3 + ∆𝑝𝑛 SERIE temperatuurverschil

𝑄̇𝑡𝑜𝑡𝑎𝑎𝑙 = 𝑄̇1 + 𝑄̇2 + 𝑄̇3 + 𝑄̇𝑛 PARALLEL 𝐹 𝐹 Vergelijkingsformules voor het

𝑄̇𝑣 1 = 𝐴1 ∙ 𝑣1 Inwendige diameter a.d.v. snelheid 𝑝= →𝐺=

𝐴 𝐴 berekenen van elasticiteitseffecten

𝜋

𝐴1 = ∙ 𝑑𝑖2

4

(𝑄̇𝑣 ∙ 4)

𝑑𝑖 = √( )

(𝑣𝑚𝑎𝑥. ∙ 𝜋)

Formule Opmerking

𝑃0 𝑃1 Isochoor, V =constant (c=cv, n=∞)

= Leeg VOL ‘LEEG’

𝑇0 𝑇1

𝑝0 ∙ 𝑉0 = 𝑃1 ∙ 𝑉1 Isotherm, T= constant, (n=1, c=∞)

𝑝0 ∙ 𝑉0𝑘 = 𝑝1 ∙ 𝑉1𝑘 Adiabaat, energie uitwisseling=0

𝑉0 𝑉1 Isobaar, p=constant

=

𝑇0 𝑇1 ΔV

𝑛 𝑛

𝑝0 ∙ 𝑉0 = 𝑝1 ∙ 𝑉1 Polytrope (tussen adiabaat & Isotherm

𝐶𝑝 𝑐 − 𝑐𝑝 𝑝0 𝑣𝑜𝑜𝑟𝑠𝑝𝑎𝑛𝑑𝑟𝑢𝑘 = 0,7 − 0,9 ∙ 𝑝𝑤𝑒𝑟𝑘(min)

𝑘= ,𝑛 =

𝐶𝑣 𝑐 − 𝑐𝑣

𝑝

ln 1 𝑡𝑐𝑦𝑐𝑙𝑢𝑠 < 1 [𝑚𝑖𝑛] → 𝐴𝑑𝑖𝑎𝑏𝑎𝑡𝑖𝑠𝑐ℎ

𝑝2

𝑛= 𝑡𝑐𝑦𝑐𝑙𝑢𝑠 > 1 & < 3[𝑚𝑖𝑛] → 𝑃𝑜𝑙𝑦𝑡𝑟𝑜𝑝𝑒

𝑉

ln 1 𝑡𝑐𝑦𝑐𝑙𝑢𝑠 > 3 [𝑚𝑖𝑛] → 𝐼𝑠𝑜𝑡ℎ𝑒𝑟𝑚e

𝑉2

Indicatie persleiding snelheden; Elasticiteitsmodules hydraulische

Tot 2,5 MPa (=25 bar) 2,5 – 3 [m/s] vloeistof;

2,5 tot 5 MPa (=50 bar)3,5 – 4 [m/s] Normale lucht E = 1,0 [𝐺𝑃𝑎]

5 tot 10 MPa (=100 bar)4,5 – 5 [m/s] Veel lucht E = 0,5 [𝐺𝑃𝑎]

10 tot 20 MPa(=200 bar)5,0 – 6 [m/s] Geen lucht ca. E = 1,5 [𝐺𝑃𝑎]

Boven 20 MPa(=200 bar)6 [m/s]

You might also like

- Samenvatting Kerst Fysica Quark 6.2Document4 pagesSamenvatting Kerst Fysica Quark 6.2Flore DebruyneNo ratings yet

- Overal Natuurkunde 3 H H05 UitwerkingenDocument12 pagesOveral Natuurkunde 3 H H05 UitwerkingenEva PelNo ratings yet

- 2324 Formuleblad ThermoDocument2 pages2324 Formuleblad ThermoguytorcqueNo ratings yet

- Formuleblad 2021Document10 pagesFormuleblad 2021Mira de VoogdNo ratings yet

- Formuleblad Reactorkunde Versie Feb 22Document3 pagesFormuleblad Reactorkunde Versie Feb 22guytorcqueNo ratings yet

- FormulebladDocument4 pagesFormulebladguytorcqueNo ratings yet

- Wiu 1Document4 pagesWiu 1Miguel PandoNo ratings yet

- Oefententamen 2Document18 pagesOefententamen 2nattehond5No ratings yet

- Oefeningen Online 12 JanuariDocument10 pagesOefeningen Online 12 JanuariPeggy BothaNo ratings yet

- Opsomming en FormulesDocument5 pagesOpsomming en FormulesMegan BerrNo ratings yet

- TM Aflevering Uge 37Document8 pagesTM Aflevering Uge 37Mo AzzamNo ratings yet

- Natuurkunde Samenvatting H2,3,7,8Document3 pagesNatuurkunde Samenvatting H2,3,7,8Josephine nellensteijnNo ratings yet

- Les 1 NotasDocument23 pagesLes 1 NotasTes Van der MerweNo ratings yet

- RL SerieketenDocument13 pagesRL SerieketenJurgen NijsNo ratings yet

- College 5 (NL)Document8 pagesCollege 5 (NL)Julian PostmaNo ratings yet

- Formularium Technisch Wiskunde 2Document10 pagesFormularium Technisch Wiskunde 2JarisNo ratings yet

- BK1TE1 Formuleblad Klimaatontwerp v1.4Document4 pagesBK1TE1 Formuleblad Klimaatontwerp v1.4Steven van HaaftenNo ratings yet

- 2023-11-20 Hoofdstelling Integraalrekening en GevolgDocument6 pages2023-11-20 Hoofdstelling Integraalrekening en GevolgYannick BruwierNo ratings yet

- Oefenopgaven - Stromingsleer - UitwerkingenDocument5 pagesOefenopgaven - Stromingsleer - UitwerkingenV GoNo ratings yet

- Formularium 2020Document6 pagesFormularium 2020Zombie BossNo ratings yet

- Formularium 2024Document6 pagesFormularium 2024Zombie BossNo ratings yet

- Hogeschool VIVES Formuleblad Mechanica 2Document3 pagesHogeschool VIVES Formuleblad Mechanica 2Mr GoodmanNo ratings yet

- Formuleblad BCH11T 22-23Document1 pageFormuleblad BCH11T 22-23Ray BruinsNo ratings yet

- Blz. 147 171 Buigen Traagheidsmomenten Groenendijk 1Document30 pagesBlz. 147 171 Buigen Traagheidsmomenten Groenendijk 1kwatta 16No ratings yet

- Oefentoets Dynamica 2018-2019Document3 pagesOefentoets Dynamica 2018-2019mayank pratap mishraNo ratings yet

- WS H2 EnkelvoudigeDocument27 pagesWS H2 Enkelvoudigediel.deweerdt4No ratings yet

- Samenvatting Regels Wib HavoDocument2 pagesSamenvatting Regels Wib HavoJoost SPNo ratings yet

- 3A HST 08 + Verg v301 UitwDocument6 pages3A HST 08 + Verg v301 Uitwtygo van den heuvelNo ratings yet

- 1âºc1av1212c Aritmetica (Sol)Document2 pages1âºc1av1212c Aritmetica (Sol)bbyggrllNo ratings yet

- ZIn Spanning in GeleiderDocument39 pagesZIn Spanning in GeleiderPeggy BothaNo ratings yet

- Proef2 UitwerkingDocument4 pagesProef2 UitwerkingHugo BurggraaffNo ratings yet

- Wiskunde 1 BewijzenDocument15 pagesWiskunde 1 BewijzenOmid AlzNo ratings yet

- Trigonometriese Grafieke Breinkaart 1 TemplaatDocument1 pageTrigonometriese Grafieke Breinkaart 1 Templaatannemelouw11No ratings yet

- MachtenDocument5 pagesMachtenadpas8No ratings yet

- 1-Chemie Les 10 ThermodynamicaDocument48 pages1-Chemie Les 10 ThermodynamicaMichiel Van de VeldeNo ratings yet

- Wisk 4Document5 pagesWisk 4fxwg4vx2m7No ratings yet

- Theorie Wiskunde Lineaire Algebra 1Document8 pagesTheorie Wiskunde Lineaire Algebra 19m66z7vbbxNo ratings yet

- ANA3-51-a-theorie-ik Bestudeer de Afvlakking (Condensator)Document8 pagesANA3-51-a-theorie-ik Bestudeer de Afvlakking (Condensator)Seppe MoensNo ratings yet

- Slides Dag 1 RCC WiskundeBE-EBE-FEDocument57 pagesSlides Dag 1 RCC WiskundeBE-EBE-FEf.dualeNo ratings yet

- Formuleblad LuchtbehandelingenDocument7 pagesFormuleblad LuchtbehandelingenMatthijs BoomNo ratings yet

- Oefenopg Analyse 2Document1 pageOefenopg Analyse 2Kiren P.No ratings yet

- Elektriciteit Samenvatting KerstDocument26 pagesElektriciteit Samenvatting Kerstrobbedecuyper20No ratings yet

- Formularium Financiã Le Algebra Uitgebreid PDFDocument3 pagesFormularium Financiã Le Algebra Uitgebreid PDFCisse BexNo ratings yet

- Les 4 Eerste BeginselsDocument27 pagesLes 4 Eerste BeginselsCiara ChimangaNo ratings yet

- KrimpenDocument3 pagesKrimpenNiek MasselinkNo ratings yet

- Leerstofoverzicht Fysica Kerst 4HWEWDocument6 pagesLeerstofoverzicht Fysica Kerst 4HWEWImane MaroufNo ratings yet

- Complexe Getallen Uitgewerkte Oefeningen en Extra UitlegDocument57 pagesComplexe Getallen Uitgewerkte Oefeningen en Extra UitlegYannick BruwierNo ratings yet

- 6.8 - A - Binome MaalDocument11 pages6.8 - A - Binome MaalnorthcliffmmNo ratings yet

- ELEWIS10 Week 2 1Document23 pagesELEWIS10 Week 2 1CharmillaNo ratings yet

- 23 EM-TR2 Transformatoren OefeningenDocument22 pages23 EM-TR2 Transformatoren Oefeningendiel.deweerdt4No ratings yet

- Aula 2e3 VIDocument18 pagesAula 2e3 VI92966818thNo ratings yet

- Xx-Xxxx-Buckling CalculationDocument5 pagesXx-Xxxx-Buckling CalculationNafees ShaikhNo ratings yet

- 2023-11-20 de Bepaalde Integraal Van X 2 AlgemeenDocument4 pages2023-11-20 de Bepaalde Integraal Van X 2 AlgemeenYannick BruwierNo ratings yet

- ZIn Spanning in Geleider (Automatisch Opgeslagen)Document34 pagesZIn Spanning in Geleider (Automatisch Opgeslagen)Peggy BothaNo ratings yet

- WiskundeDocument12 pagesWiskundeselma.ouladNo ratings yet

- H5 Antwoorden 3HDocument21 pagesH5 Antwoorden 3Hjessika.wieczorek02No ratings yet

- Practica 5Document4 pagesPractica 5MARIANA VALENCIA SANCHEZNo ratings yet

- 1-Chemie Les 9Document37 pages1-Chemie Les 9Michiel Van de VeldeNo ratings yet

- Formules - 3-Bedrijfseconomie - UA FTI - 2018-2019Document3 pagesFormules - 3-Bedrijfseconomie - UA FTI - 2018-2019AmberNo ratings yet