Professional Documents

Culture Documents

Calibration of SS Tanks

Calibration of SS Tanks

Uploaded by

Sanjay yadavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calibration of SS Tanks

Calibration of SS Tanks

Uploaded by

Sanjay yadavCopyright:

Available Formats

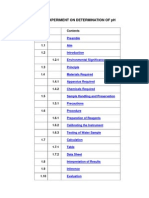

LOMUS Page No: 1 of 1

Pharmaceuticals

Standard Operating

Pvt. Ltd. Procedure SOP No: LPPL/P/SOP/415

Gothatar, Ktm;

Nepal TITLE : CALIBRATION OF STAINLESS Supersedes No. : New

STEEL MANUFACTURING AND

STORAGE TANKS

Prepared by : Checked by : Approved by : Effective Date : 01.01.2007

Date : Date : Date : Review Date : 01.01.2009

1. Purpose: To lay down a procedure for calibration of stainless steel manufacturing

and storage tanks.

2. Responsibility: Production Officer/ IPQC Officer/ Analyst

3. Accountability: QA Manager

4. Procedure:

4.1 Check the integrity of the calibrating instruments & Tanks. The tanks should be in

perfect condition (ie. Without leakage and other defects)

4.2 Check the level of the tank with spirit leveler.

4.3 Calibrate a bucket with the help of standard measuring cylinder.

4.4 Take 1 liter capacity measuring cylinder and fill water up to 1 liter mark. Pour into

the bucket to make 10 liters. Mark the 10 liter level with a permanent marker.

Continue the process for marking 20 liters.

4.5 Use the calibrated bucket to pour the water into the SS tank.

4.6 Consider the claim volume of the tank and pour the measured quantity of water to

2/3rd of the height with the calibrated bucket.

4.7 Dip the calibrated SS scale into five different places of the tank and record the

reading. Take the average of all measurement.

4.8 Pour more water and continue taking measurement. Note the respective measurement

of SS Sacle with the respective volume of water added.

4.9 Calculate the litre per centimeter as:

Litre/cm = Volume of water in the tank (Liters)

Scale Measurement (cm)

4.10 Measure the temperature and humidity of the area during calibration.

You might also like

- Operational Qualification GL ReactorDocument3 pagesOperational Qualification GL Reactorjokish100% (2)

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

- Testing of Marine Boiler WaterDocument10 pagesTesting of Marine Boiler WaterVishu SharmaNo ratings yet

- SOP For Sampling and Testing Schedule of Purified WaterDocument4 pagesSOP For Sampling and Testing Schedule of Purified WaterSolomonNo ratings yet

- SOP For Sampling and Testing Schedule of Water For Injection and Clean SteamDocument4 pagesSOP For Sampling and Testing Schedule of Water For Injection and Clean SteamSolomonNo ratings yet

- SOP Testing Nitrates-1Document5 pagesSOP Testing Nitrates-1joshuaNo ratings yet

- Sop For Testing IronDocument4 pagesSop For Testing IronjoshuaNo ratings yet

- TKN Determination in Water and Waste Water: Application Note No. 191/2015Document9 pagesTKN Determination in Water and Waste Water: Application Note No. 191/2015Alessandro BisbanoNo ratings yet

- PPS Boiler Feed Water AnalysisDocument6 pagesPPS Boiler Feed Water AnalysisAraNo ratings yet

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- Standard Operating Procedure No. 2 Sample Management: 1.0 Purpose and ScopeDocument9 pagesStandard Operating Procedure No. 2 Sample Management: 1.0 Purpose and ScopeRajendra ChoudharyNo ratings yet

- 1.3.1 Hemoglobin Estimation (CuSo4 Preparation)Document3 pages1.3.1 Hemoglobin Estimation (CuSo4 Preparation)Ross Navarro SupeñaNo ratings yet

- 6.distillation PlantDocument23 pages6.distillation PlantPaban BhattaraiNo ratings yet

- STP of Purified WaterDocument9 pagesSTP of Purified WaterBhawani singhNo ratings yet

- Saqlain Raza - TRB ChemistryDocument88 pagesSaqlain Raza - TRB ChemistryHasan AhmedNo ratings yet

- Nitttr Environmental Engineering and Public Health Lab ManualDocument215 pagesNitttr Environmental Engineering and Public Health Lab Manualkumsai7164% (11)

- Determination of TurbidityDocument12 pagesDetermination of TurbidityAkash SahuNo ratings yet

- Lab Quality Manual Rev 10 (031119)Document17 pagesLab Quality Manual Rev 10 (031119)paeg6512No ratings yet

- EXP7 WATER TANK-minDocument15 pagesEXP7 WATER TANK-mingoblinsbrideNo ratings yet

- Boiler Chemical Cleaning Procedure DT 19 12 2020 - For OfferDocument21 pagesBoiler Chemical Cleaning Procedure DT 19 12 2020 - For OfferNeeraj HegdeNo ratings yet

- NIST For Liquid Volume SP250-72 2014Document128 pagesNIST For Liquid Volume SP250-72 2014Hiba AlkhateebNo ratings yet

- Hydrotest ProcedureDocument9 pagesHydrotest ProcedurejeszzymenNo ratings yet

- Expt1.Basic Lab TechniquesDocument10 pagesExpt1.Basic Lab TechniquesAngela Dianne GarciaNo ratings yet

- V06.21 PH WP Water For Pharma Applications EN LRDocument14 pagesV06.21 PH WP Water For Pharma Applications EN LRboucifben42No ratings yet

- Sample Cleaning Validation ProtocolDocument9 pagesSample Cleaning Validation ProtocolOryza SativaNo ratings yet

- Performance Qualification of Pure Steam ProtocolDocument17 pagesPerformance Qualification of Pure Steam ProtocolHaythemOrabiNo ratings yet

- Occpl: Hydro & Pneumatic Test ProcedureDocument3 pagesOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNo ratings yet

- Work Instruction GalDocument31 pagesWork Instruction Galjasminnee100% (1)

- SOP For Testing Sulphates New.Document4 pagesSOP For Testing Sulphates New.joshuaNo ratings yet

- S.O.P 1Document7 pagesS.O.P 1vishvendanNo ratings yet

- MNT 008-03 Cleaning of Overhead Potable Water Storage TankDocument3 pagesMNT 008-03 Cleaning of Overhead Potable Water Storage TankAniket kopate100% (2)

- Gas ChromatographyDocument34 pagesGas ChromatographyReverse FlashNo ratings yet

- Well Testing ProcedureDocument7 pagesWell Testing ProceduremofiyinfoluNo ratings yet

- Amendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankDocument8 pagesAmendment 1: Replacement of 3Kl Uf Storage Tank & Installation of New 500 Ltr. Brine TankprakashNo ratings yet

- Engineer's Guide To Marine Boiler Water Treatment & TestingDocument11 pagesEngineer's Guide To Marine Boiler Water Treatment & TestingAhmed Bensalem BélarouciNo ratings yet

- HACCP PLAN APPROVED 11 26 2012 Páginas 5Document25 pagesHACCP PLAN APPROVED 11 26 2012 Páginas 5jerco27No ratings yet

- Boiler Water TestDocument4 pagesBoiler Water TestRavindar AnandanNo ratings yet

- Zymark TurboVapDocument5 pagesZymark TurboVapSrikanth IneediNo ratings yet

- PQ For Water Treatment PlantDocument29 pagesPQ For Water Treatment PlantDilawar Bakht100% (2)

- 08.53 Calcimeter: Operating InstructionsDocument6 pages08.53 Calcimeter: Operating InstructionsBogdanNo ratings yet

- Astmc1580 11250Document3 pagesAstmc1580 11250Pablo SaavedraNo ratings yet

- Operation and Calibration of HPLC SystemDocument12 pagesOperation and Calibration of HPLC SystemMubarak PatelNo ratings yet

- 23-phosphateDocument9 pages23-phosphatesala7mailNo ratings yet

- OQ For 10KL ReactorDocument8 pagesOQ For 10KL Reactorpinakinqc3No ratings yet

- 1 Well Testing PresentationDocument51 pages1 Well Testing PresentationPablo RomanosNo ratings yet

- Fouling and Scale Control 2009Document31 pagesFouling and Scale Control 2009kikokalazo50% (2)

- Determining Chloride Content in Concrete PDFDocument15 pagesDetermining Chloride Content in Concrete PDFaishwaryaNo ratings yet

- Calibration of Equipments: By: Shravan KumarDocument28 pagesCalibration of Equipments: By: Shravan KumarOula HatahetNo ratings yet

- Work Instruction For Galvanizing Plant (7 Tank Process) .: WI No.: HY/WI/01 Rev. No Eff. DateDocument34 pagesWork Instruction For Galvanizing Plant (7 Tank Process) .: WI No.: HY/WI/01 Rev. No Eff. DateScribdbahrainNo ratings yet

- Lab ReportDocument12 pagesLab Reportmadan praveenNo ratings yet

- Boiler Feed Water AnalysisDocument6 pagesBoiler Feed Water AnalysisMARISSA DINLASANNo ratings yet

- Hydo Test ProcedureDocument2 pagesHydo Test ProcedureAbdulMajidYousoffNo ratings yet

- DMP Operation SOWDocument12 pagesDMP Operation SOWBikash Kumar SahooNo ratings yet

- Performance Qualification of Autoclave Cum Bung ProcessorDocument17 pagesPerformance Qualification of Autoclave Cum Bung ProcessorĐức LinhNo ratings yet

- SOP For HPLC Column Receipt, Checking and Regeneration - PharmaguidelineDocument3 pagesSOP For HPLC Column Receipt, Checking and Regeneration - PharmaguidelineMahmoud MahmoudNo ratings yet

- Bucket Test Instructions-NEW PDFDocument1 pageBucket Test Instructions-NEW PDFA. JainNo ratings yet

- Bioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardFrom EverandBioprocessing Piping and Equipment Design: A Companion Guide for the ASME BPE StandardNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Handling of Returned Drug Products (1)Document2 pagesHandling of Returned Drug Products (1)Sanjay yadavNo ratings yet

- Sop for Batch Coding SystemDocument1 pageSop for Batch Coding SystemSanjay yadavNo ratings yet

- entry issue batch manufactirng record.Document2 pagesentry issue batch manufactirng record.Sanjay yadavNo ratings yet

- sop for cleainin of raw material storeDocument2 pagessop for cleainin of raw material storeSanjay yadavNo ratings yet

- ChangeOver procedureDocument2 pagesChangeOver procedureSanjay yadavNo ratings yet

- fIRST AIDDocument3 pagesfIRST AIDSanjay yadavNo ratings yet

- sop for handling linenDocument3 pagessop for handling linenSanjay yadavNo ratings yet

- Label Control (1)Document3 pagesLabel Control (1)Sanjay yadavNo ratings yet

- Product Recall SystemDocument3 pagesProduct Recall SystemSanjay yadavNo ratings yet