Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsdrawworks Lubrication Schedule

drawworks Lubrication Schedule

Uploaded by

learningzabatCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- RB211 Lube System (Ssloc) DescriptionDocument6 pagesRB211 Lube System (Ssloc) DescriptionmuazmaslanNo ratings yet

- Plan de Maintenance Atlas Copco ORX12 - GEMEXDocument3 pagesPlan de Maintenance Atlas Copco ORX12 - GEMEXPhilippe Dumont100% (1)

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Engine Oil (Checking The Level) : WarningDocument4 pagesEngine Oil (Checking The Level) : WarningPhạm Hoài MinhNo ratings yet

- Checking The Engine Coolant LevelDocument6 pagesChecking The Engine Coolant LevelPhạm Hoài MinhNo ratings yet

- Top Drive Lubrication and Maintenance ChecklistDocument1 pageTop Drive Lubrication and Maintenance ChecklistAlessandra FloresfarNo ratings yet

- 保养Document48 pages保养jackNo ratings yet

- SRT95 OffHighway Truck Maintenance OverviewDocument11 pagesSRT95 OffHighway Truck Maintenance OverviewoktopusNo ratings yet

- 3 JAC006-2 MaintenanceDocument12 pages3 JAC006-2 MaintenancejuanNo ratings yet

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- 1 Standard Parts, ServiceDocument128 pages1 Standard Parts, ServiceJulio Gaston Castellanos DuranNo ratings yet

- 1-Lubricating Systems For B&C p24Document24 pages1-Lubricating Systems For B&C p24Jonathan RiveraNo ratings yet

- Operation Manual For Wp4g95e221 EngineDocument28 pagesOperation Manual For Wp4g95e221 EngineCarlos Astudillo VargasNo ratings yet

- Lubricacion Sistema Grua Zoomlion Manual Mantenimiento Grua Zoomlion Qy70v532Document9 pagesLubricacion Sistema Grua Zoomlion Manual Mantenimiento Grua Zoomlion Qy70v532Alejandro LealNo ratings yet

- Pages 30-37 From 9852 1639 01f Maintenance Instructions ML2 DSDocument8 pagesPages 30-37 From 9852 1639 01f Maintenance Instructions ML2 DSpedriscoNo ratings yet

- 1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532Document25 pages1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532IAN GRUPNo ratings yet

- Unit 5.oil System 16112019Document45 pagesUnit 5.oil System 16112019motores4297100% (1)

- MaintenanceDocument24 pagesMaintenanceRodolfo AlmeidaNo ratings yet

- C5000SL инструкция по ремонту-01Document33 pagesC5000SL инструкция по ремонту-01Евгений ГубаревNo ratings yet

- معلومات الزيوت للمعداتDocument6 pagesمعلومات الزيوت للمعداتApo ghasan Al shargapiNo ratings yet

- 1d. MANUAL BOOK For LubricantsDocument8 pages1d. MANUAL BOOK For LubricantsFerinoviardiNo ratings yet

- LubricationDocument25 pagesLubricationf_mo_meNo ratings yet

- ESB - 515 - 5!1!08 Bombas VikingDocument1 pageESB - 515 - 5!1!08 Bombas VikingjosedureNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- Kbu KBZ8Document9 pagesKbu KBZ8Andrew VNo ratings yet

- Ariel J. Lubrication System-03 04 04Document43 pagesAriel J. Lubrication System-03 04 04Manuel LiñeiroNo ratings yet

- O&M FD40-7T KomatsuDocument35 pagesO&M FD40-7T Komatsujheison valencia100% (2)

- 17-30 Lubrication System Components CheckingDocument3 pages17-30 Lubrication System Components Checkingmefisto06cNo ratings yet

- Mixing Plant Maintenance Operation ManualDocument22 pagesMixing Plant Maintenance Operation ManualGuillermo HerreraNo ratings yet

- Turbine Lube Oil System AND GENERATOR SealingDocument32 pagesTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNo ratings yet

- Oil Mist LubricationDocument22 pagesOil Mist LubricationPitipong SunkhongNo ratings yet

- RASYIDDocument25 pagesRASYIDAbdur RasyidNo ratings yet

- FD35 Lubricant ListDocument2 pagesFD35 Lubricant ListErsa RahmandaNo ratings yet

- TDS 11saDocument1 pageTDS 11saMohamedAbdel-Rahman100% (1)

- 420 Maintenance ScheduleDocument4 pages420 Maintenance Scheduleicyan.ahmad.tiNo ratings yet

- Atlas Copco Xrvs 476 Manual (054 058) PDFDocument5 pagesAtlas Copco Xrvs 476 Manual (054 058) PDFjoseNo ratings yet

- Turbine Lube Oil OperationDocument34 pagesTurbine Lube Oil OperationNIHAR BEHERANo ratings yet

- NNNDocument127 pagesNNNNeeraj maurya100% (2)

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- F004-P006-Gfpi Guia de ApreDocument165 pagesF004-P006-Gfpi Guia de Aprejuan perezNo ratings yet

- 14 LubricationDocument27 pages14 Lubricationr2jnqrzr72No ratings yet

- 3 XS122D润滑、保养与维护Document45 pages3 XS122D润滑、保养与维护Antonio MedeirosNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet

- Fluids, Lubricants and CapacitiesDocument2 pagesFluids, Lubricants and CapacitiesYeny CatzinNo ratings yet

- Guide To Interchangeable LubricantsDocument12 pagesGuide To Interchangeable LubricantsJavier Jesus Gonzalez QuinaNo ratings yet

- Seal Oil SysDocument32 pagesSeal Oil SysASHIT KUMAR100% (2)

- Lube Oil System Instruction 141A.000.2SM (B) - 5Document32 pagesLube Oil System Instruction 141A.000.2SM (B) - 5anbarasan50% (2)

- Bomba Hidraulica SKFDocument84 pagesBomba Hidraulica SKFJůan LópežNo ratings yet

- Epiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Document12 pagesEpiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Bontor TuaNo ratings yet

- AIMIX SLM Maintenance ManualDocument21 pagesAIMIX SLM Maintenance Manualtonoh4678No ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- Diesel Oil Purifier GeaDocument16 pagesDiesel Oil Purifier GeaaymangamalsmeNo ratings yet

- Er 56 06Document26 pagesEr 56 06Faisal Naeem100% (1)

- Apu Eng Oil SysDocument21 pagesApu Eng Oil SysSamares DasNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Size 12.4 Mesur-Fil Fluid Couplings: Installation InstructionsDocument14 pagesSize 12.4 Mesur-Fil Fluid Couplings: Installation InstructionslearningzabatNo ratings yet

- M3G Drilling Choke Manual 1Document17 pagesM3G Drilling Choke Manual 1learningzabatNo ratings yet

- KDC Rig 45 Check ListDocument1 pageKDC Rig 45 Check ListlearningzabatNo ratings yet

- Well Control Equipment Inspection & Maintenance - Course ContentsDocument3 pagesWell Control Equipment Inspection & Maintenance - Course ContentslearningzabatNo ratings yet

- Wash PipeDocument21 pagesWash PipelearningzabatNo ratings yet

- DocumentDocument133 pagesDocumentlearningzabatNo ratings yet

- Zabat Daily Check ListDocument2 pagesZabat Daily Check ListlearningzabatNo ratings yet

- MCB S200 Technical Catalog - ENDocument33 pagesMCB S200 Technical Catalog - ENlearningzabatNo ratings yet

- Hydraulics For AllDocument187 pagesHydraulics For AlllearningzabatNo ratings yet

- National 110UE: Stationary Diesel - Electric SCR System RigDocument1 pageNational 110UE: Stationary Diesel - Electric SCR System RiglearningzabatNo ratings yet

- Equipment Serial NumberDocument3 pagesEquipment Serial NumberlearningzabatNo ratings yet

- CCTV Client Monitor ThinkVersionDocument1 pageCCTV Client Monitor ThinkVersionlearningzabatNo ratings yet

- BookDocument1 pageBooklearningzabatNo ratings yet

- 0-1air TheoryDocument132 pages0-1air TheorylearningzabatNo ratings yet

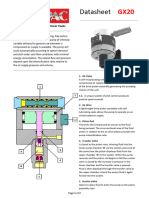

- Dat Gx20 Rev2Document2 pagesDat Gx20 Rev2learningzabatNo ratings yet

- OKcon KR40Document1 pageOKcon KR40learningzabatNo ratings yet

drawworks Lubrication Schedule

drawworks Lubrication Schedule

Uploaded by

learningzabat0 ratings0% found this document useful (0 votes)

2 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views1 pagedrawworks Lubrication Schedule

drawworks Lubrication Schedule

Uploaded by

learningzabatCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Document No.

D231000984-MAN-001

Page 31

Perform the following checks while the lubrication system is operating:

A. Check the oil pressure gauge. It should indicate 10 to 30 psi (69 to 207 kPa).

1. If pressure is too high:

a. Check chain oil spray nozzles and tubes for blockage

b. Adjust flow control valve at inlet end of spray pipe header and open further.

c. Check for flow at the bearing housings.

d. Adjust pump bypass relief valve.

2. If gauge shows no pressure:

a. Check oil level in reservoir and add oil if necessary.

b. Check the pump suction strainer and clean if necessary by washing in a

suitable cleaning solution.

c. If all spray nozzles and bearings are receiving adequate oil, check pressure

transducer tubing for damages or blockages.

d. Check lube system relief valve. Turn the valve inwards to adjust pressure.

B. Check all spray nozzles to ensure oil holes are open and delivering oil. Spray nozzles

are located in all drive chain cases.

NOTE: National Oilwell Varco recommends the use of ISO 150 gear oil for warmer

climates and an ISO all season gear oil for colder climates.

Shaft bearings Fittings EP2 Grease 50 to 75 g Daily

5,10 (1.8 to 2.6 oz)

Water Union 4 zerks EP2 Grease 50 g (1.8 oz) Weekly

Wireline Apply as Wireline Lubricant Application Monthly

required

Oil Sump Access SAE 30 Oil 60 US Gal

from rear of non-detergent or (227 L) 6 Months

drawworks ISO 150 EP Gear Oil

Air Valves -- Silicone-base grease Lightly coat

moving parts

Air Cylinders -- NLGI Grease Lightly coat

(where applicable) graphite lime moving parts

Use premium all-purpose grease such as NLGI EP2 Lithium based grease where grease

is required unless another type is specifically recommended. All-purpose EP2 Lithium-

based grease is recommended because of its excellent water resistance and operating

temperature range.

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- RB211 Lube System (Ssloc) DescriptionDocument6 pagesRB211 Lube System (Ssloc) DescriptionmuazmaslanNo ratings yet

- Plan de Maintenance Atlas Copco ORX12 - GEMEXDocument3 pagesPlan de Maintenance Atlas Copco ORX12 - GEMEXPhilippe Dumont100% (1)

- Manual Motor WC30D Tier-3 SM PDFDocument105 pagesManual Motor WC30D Tier-3 SM PDFAndres Abril100% (1)

- Engine Oil (Checking The Level) : WarningDocument4 pagesEngine Oil (Checking The Level) : WarningPhạm Hoài MinhNo ratings yet

- Checking The Engine Coolant LevelDocument6 pagesChecking The Engine Coolant LevelPhạm Hoài MinhNo ratings yet

- Top Drive Lubrication and Maintenance ChecklistDocument1 pageTop Drive Lubrication and Maintenance ChecklistAlessandra FloresfarNo ratings yet

- 保养Document48 pages保养jackNo ratings yet

- SRT95 OffHighway Truck Maintenance OverviewDocument11 pagesSRT95 OffHighway Truck Maintenance OverviewoktopusNo ratings yet

- 3 JAC006-2 MaintenanceDocument12 pages3 JAC006-2 MaintenancejuanNo ratings yet

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- 1 Standard Parts, ServiceDocument128 pages1 Standard Parts, ServiceJulio Gaston Castellanos DuranNo ratings yet

- 1-Lubricating Systems For B&C p24Document24 pages1-Lubricating Systems For B&C p24Jonathan RiveraNo ratings yet

- Operation Manual For Wp4g95e221 EngineDocument28 pagesOperation Manual For Wp4g95e221 EngineCarlos Astudillo VargasNo ratings yet

- Lubricacion Sistema Grua Zoomlion Manual Mantenimiento Grua Zoomlion Qy70v532Document9 pagesLubricacion Sistema Grua Zoomlion Manual Mantenimiento Grua Zoomlion Qy70v532Alejandro LealNo ratings yet

- Pages 30-37 From 9852 1639 01f Maintenance Instructions ML2 DSDocument8 pagesPages 30-37 From 9852 1639 01f Maintenance Instructions ML2 DSpedriscoNo ratings yet

- 1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532Document25 pages1125-003-07Y Cap 7 Mantenimiento Grua QY70V 532IAN GRUPNo ratings yet

- Unit 5.oil System 16112019Document45 pagesUnit 5.oil System 16112019motores4297100% (1)

- MaintenanceDocument24 pagesMaintenanceRodolfo AlmeidaNo ratings yet

- C5000SL инструкция по ремонту-01Document33 pagesC5000SL инструкция по ремонту-01Евгений ГубаревNo ratings yet

- معلومات الزيوت للمعداتDocument6 pagesمعلومات الزيوت للمعداتApo ghasan Al shargapiNo ratings yet

- 1d. MANUAL BOOK For LubricantsDocument8 pages1d. MANUAL BOOK For LubricantsFerinoviardiNo ratings yet

- LubricationDocument25 pagesLubricationf_mo_meNo ratings yet

- ESB - 515 - 5!1!08 Bombas VikingDocument1 pageESB - 515 - 5!1!08 Bombas VikingjosedureNo ratings yet

- Lubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingDocument159 pagesLubrication System: Lubrication System Diagram OIL Pressure Check Service Information Oil Pump Trouble ShootingpoiufdsapuroiqNo ratings yet

- Kbu KBZ8Document9 pagesKbu KBZ8Andrew VNo ratings yet

- Ariel J. Lubrication System-03 04 04Document43 pagesAriel J. Lubrication System-03 04 04Manuel LiñeiroNo ratings yet

- O&M FD40-7T KomatsuDocument35 pagesO&M FD40-7T Komatsujheison valencia100% (2)

- 17-30 Lubrication System Components CheckingDocument3 pages17-30 Lubrication System Components Checkingmefisto06cNo ratings yet

- Mixing Plant Maintenance Operation ManualDocument22 pagesMixing Plant Maintenance Operation ManualGuillermo HerreraNo ratings yet

- Turbine Lube Oil System AND GENERATOR SealingDocument32 pagesTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNo ratings yet

- Oil Mist LubricationDocument22 pagesOil Mist LubricationPitipong SunkhongNo ratings yet

- RASYIDDocument25 pagesRASYIDAbdur RasyidNo ratings yet

- FD35 Lubricant ListDocument2 pagesFD35 Lubricant ListErsa RahmandaNo ratings yet

- TDS 11saDocument1 pageTDS 11saMohamedAbdel-Rahman100% (1)

- 420 Maintenance ScheduleDocument4 pages420 Maintenance Scheduleicyan.ahmad.tiNo ratings yet

- Atlas Copco Xrvs 476 Manual (054 058) PDFDocument5 pagesAtlas Copco Xrvs 476 Manual (054 058) PDFjoseNo ratings yet

- Turbine Lube Oil OperationDocument34 pagesTurbine Lube Oil OperationNIHAR BEHERANo ratings yet

- NNNDocument127 pagesNNNNeeraj maurya100% (2)

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- F004-P006-Gfpi Guia de ApreDocument165 pagesF004-P006-Gfpi Guia de Aprejuan perezNo ratings yet

- 14 LubricationDocument27 pages14 Lubricationr2jnqrzr72No ratings yet

- 3 XS122D润滑、保养与维护Document45 pages3 XS122D润滑、保养与维护Antonio MedeirosNo ratings yet

- GW491QE Petrol Engine Service Manual Lubrication+systemDocument7 pagesGW491QE Petrol Engine Service Manual Lubrication+systemAlbert BriceñoNo ratings yet

- Fluids, Lubricants and CapacitiesDocument2 pagesFluids, Lubricants and CapacitiesYeny CatzinNo ratings yet

- Guide To Interchangeable LubricantsDocument12 pagesGuide To Interchangeable LubricantsJavier Jesus Gonzalez QuinaNo ratings yet

- Seal Oil SysDocument32 pagesSeal Oil SysASHIT KUMAR100% (2)

- Lube Oil System Instruction 141A.000.2SM (B) - 5Document32 pagesLube Oil System Instruction 141A.000.2SM (B) - 5anbarasan50% (2)

- Bomba Hidraulica SKFDocument84 pagesBomba Hidraulica SKFJůan LópežNo ratings yet

- Epiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Document12 pagesEpiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Bontor TuaNo ratings yet

- AIMIX SLM Maintenance ManualDocument21 pagesAIMIX SLM Maintenance Manualtonoh4678No ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- Diesel Oil Purifier GeaDocument16 pagesDiesel Oil Purifier GeaaymangamalsmeNo ratings yet

- Er 56 06Document26 pagesEr 56 06Faisal Naeem100% (1)

- Apu Eng Oil SysDocument21 pagesApu Eng Oil SysSamares DasNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Size 12.4 Mesur-Fil Fluid Couplings: Installation InstructionsDocument14 pagesSize 12.4 Mesur-Fil Fluid Couplings: Installation InstructionslearningzabatNo ratings yet

- M3G Drilling Choke Manual 1Document17 pagesM3G Drilling Choke Manual 1learningzabatNo ratings yet

- KDC Rig 45 Check ListDocument1 pageKDC Rig 45 Check ListlearningzabatNo ratings yet

- Well Control Equipment Inspection & Maintenance - Course ContentsDocument3 pagesWell Control Equipment Inspection & Maintenance - Course ContentslearningzabatNo ratings yet

- Wash PipeDocument21 pagesWash PipelearningzabatNo ratings yet

- DocumentDocument133 pagesDocumentlearningzabatNo ratings yet

- Zabat Daily Check ListDocument2 pagesZabat Daily Check ListlearningzabatNo ratings yet

- MCB S200 Technical Catalog - ENDocument33 pagesMCB S200 Technical Catalog - ENlearningzabatNo ratings yet

- Hydraulics For AllDocument187 pagesHydraulics For AlllearningzabatNo ratings yet

- National 110UE: Stationary Diesel - Electric SCR System RigDocument1 pageNational 110UE: Stationary Diesel - Electric SCR System RiglearningzabatNo ratings yet

- Equipment Serial NumberDocument3 pagesEquipment Serial NumberlearningzabatNo ratings yet

- CCTV Client Monitor ThinkVersionDocument1 pageCCTV Client Monitor ThinkVersionlearningzabatNo ratings yet

- BookDocument1 pageBooklearningzabatNo ratings yet

- 0-1air TheoryDocument132 pages0-1air TheorylearningzabatNo ratings yet

- Dat Gx20 Rev2Document2 pagesDat Gx20 Rev2learningzabatNo ratings yet

- OKcon KR40Document1 pageOKcon KR40learningzabatNo ratings yet