Professional Documents

Culture Documents

A Programmable Batch Mixing System

A Programmable Batch Mixing System

Uploaded by

kalabCopyright:

Available Formats

You might also like

- PLC ExercisesDocument28 pagesPLC ExercisesMohamed Amine100% (1)

- Large Batching Control Application: Workshop#3: Design of HMI Applications For Process MonitoringDocument6 pagesLarge Batching Control Application: Workshop#3: Design of HMI Applications For Process MonitoringAdriancito Aguilar100% (3)

- Reference Control PhilosophyDocument22 pagesReference Control PhilosophyReno MurdaNo ratings yet

- PLC Programming ExampleDocument26 pagesPLC Programming ExampleManu R Krishnan50% (2)

- SOP For PotentiometerDocument25 pagesSOP For PotentiometerPawan KumarNo ratings yet

- Advanced BatchDocument2 pagesAdvanced BatchYerko Reyes CaamañoNo ratings yet

- LogixPro Labs Batch MixingDocument4 pagesLogixPro Labs Batch MixingSyedNadeemAhmed100% (1)

- PLC Problems PDFDocument5 pagesPLC Problems PDFNyan Linn HtunNo ratings yet

- Lab Mezcla Por Lotes - ContadoresDocument1 pageLab Mezcla Por Lotes - ContadoresjackvjcaNo ratings yet

- SFC Exercises EnonceDocument12 pagesSFC Exercises EnonceLuc Auster0% (1)

- IA ActivityDocument5 pagesIA Activityshanmuganandabr1982No ratings yet

- PLC Exercises PDFDocument28 pagesPLC Exercises PDFzoulouweNo ratings yet

- PH / ORP Controller: Programming and Operations ManualDocument13 pagesPH / ORP Controller: Programming and Operations ManualHECTOR IBARRANo ratings yet

- Model 370 PH/MV Meter Operating Manual: 370 350/REV A/10-03Document19 pagesModel 370 PH/MV Meter Operating Manual: 370 350/REV A/10-03Malik Mehboob Ali LakhaniNo ratings yet

- Training Concepts UpdatedDocument2 pagesTraining Concepts Updatedmech SuryaNo ratings yet

- Instrumentation Assignment Part 2Document4 pagesInstrumentation Assignment Part 2Perez LiberNo ratings yet

- Logixpro Traffic Control Lab Utilizing Word ComparisonDocument22 pagesLogixpro Traffic Control Lab Utilizing Word ComparisonLuis Angel Medina MejiaNo ratings yet

- Tutorials On PLCs - NAHPIDocument7 pagesTutorials On PLCs - NAHPImarshal galilee djitsa0% (2)

- Experiment 7 Silo SimulationDocument7 pagesExperiment 7 Silo SimulationAvinash Umesh SarmaNo ratings yet

- PLC Applications Level-1: First Second ThirdDocument5 pagesPLC Applications Level-1: First Second ThirdnaveenNo ratings yet

- Automation Mini ProjectsDocument3 pagesAutomation Mini ProjectsAhmed Samy El GoharyNo ratings yet

- User Manual: Front Panel & Display Technical DataDocument2 pagesUser Manual: Front Panel & Display Technical Datapromeo56No ratings yet

- Manual IMW50Document30 pagesManual IMW50Diseño Enefenco100% (1)

- Curing Oven Operation ManualDocument16 pagesCuring Oven Operation ManualWONG TS0% (1)

- Huong Dan Su Dung ph56Document2 pagesHuong Dan Su Dung ph56Đinh Văn KiênNo ratings yet

- PLC Ladder LogicDocument5 pagesPLC Ladder LogicJean-nette BarlisanNo ratings yet

- BatchMix-02 CLKDocument2 pagesBatchMix-02 CLKHafiez Angpau RayaNo ratings yet

- SOP For Sree Bhagwati Mixing MachineDocument1 pageSOP For Sree Bhagwati Mixing MachinePrasad KasettiNo ratings yet

- Users' Manual: Model HRDK24-D Electric Control Box For Grease Lubrication SystemDocument6 pagesUsers' Manual: Model HRDK24-D Electric Control Box For Grease Lubrication SystemVanesa Soledad AvilaNo ratings yet

- EU07 ManualDocument9 pagesEU07 Manualdziobale dziobaleNo ratings yet

- SOP of Calibration of PH MeterDocument6 pagesSOP of Calibration of PH MeterIlham NurNo ratings yet

- Minor AnswersDocument30 pagesMinor AnswersLinux ThingsNo ratings yet

- Water Level Indicator and ControllerDocument3 pagesWater Level Indicator and Controllermr_zirNo ratings yet

- DPH 503 ManualDocument35 pagesDPH 503 ManualKrishnaraj DhavalaNo ratings yet

- Mechatronic Lab 9 StudyofLinearConveyorControlSystem 20008Document3 pagesMechatronic Lab 9 StudyofLinearConveyorControlSystem 20008Kannan MuthusamyNo ratings yet

- PLC ActivityDocument2 pagesPLC ActivityHarsha KotuwegedaraNo ratings yet

- PLC Lecture7Document7 pagesPLC Lecture7Mohamed MNo ratings yet

- LogixPro - Lab 4 - Control of SiloDocument2 pagesLogixPro - Lab 4 - Control of SiloShah HussainNo ratings yet

- PLC Program For Heating and Mixing of ProductsDocument3 pagesPLC Program For Heating and Mixing of ProductsSivaNo ratings yet

- Ph100 Ph110 ManualDocument8 pagesPh100 Ph110 Manualbala sonyNo ratings yet

- Assignment - 1Document5 pagesAssignment - 1spppppNo ratings yet

- Exstik Fl700: User GuideDocument11 pagesExstik Fl700: User GuideTogoYouredNo ratings yet

- Lube Oil Purifier Operation PDFDocument1 pageLube Oil Purifier Operation PDFMARAWANNo ratings yet

- Key Task EO 2.9 Demonstrates An Ability To Prepare and Operate The SewageDocument2 pagesKey Task EO 2.9 Demonstrates An Ability To Prepare and Operate The SewageApolLLloNNo ratings yet

- Operation ManualDocument19 pagesOperation ManualM Abdullah QureshiNo ratings yet

- SPX-100/150/250B-Z Biochemical Incubator Instruction Manual First, The Instructions For UseDocument3 pagesSPX-100/150/250B-Z Biochemical Incubator Instruction Manual First, The Instructions For Usescribd birdNo ratings yet

- Orligno 500: Instruction Manual & Service ManualDocument28 pagesOrligno 500: Instruction Manual & Service ManualAraNo ratings yet

- Manual Ad11 - Ad12Document2 pagesManual Ad11 - Ad12adwainstNo ratings yet

- Detecting The Standing Bottles On The Conveyor and Pushing Falling Bottles in TrayDocument26 pagesDetecting The Standing Bottles On The Conveyor and Pushing Falling Bottles in TrayManu R KrishnanNo ratings yet

- STI Camden 5 (Automat)Document8 pagesSTI Camden 5 (Automat)somod95239No ratings yet

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemEhsan Ul HaqueNo ratings yet

- Mewp Operating InstrDocument4 pagesMewp Operating InstrPrimelift Safety Resources LimitedNo ratings yet

- PLC Automation ExamplesDocument6 pagesPLC Automation ExamplesAbhishek PachlegaonkarNo ratings yet

- 57737Document27 pages57737Mohamed RamadanNo ratings yet

- Exstik Waterproof PH Meters: User GuideDocument8 pagesExstik Waterproof PH Meters: User GuidestarprofiNo ratings yet

- Lube Oil System ReportDocument9 pagesLube Oil System ReportSatyaKrishna Palla100% (2)

- Iss 7 BM350 MultilingualDocument124 pagesIss 7 BM350 MultilingualThe Baby BossNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

A Programmable Batch Mixing System

A Programmable Batch Mixing System

Uploaded by

kalabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Programmable Batch Mixing System

A Programmable Batch Mixing System

Uploaded by

kalabCopyright:

Available Formats

A Programmable Batch Mixing System

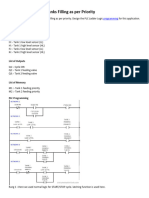

Exercise #1 -- Single Batch Mode of Operation

Using your knowledge of PLCs, design a program to meet the following criteria:

When the 3 position Selector Switch is in position "A". the batch

mixing process will run in a single batch mode. The operator may start the

batch mix sequence by momentarily pressing the Start Switch.

Once a batch sequence has begun, the sequence may be stopped and

resumed at any time using the Stop and Start switches.

The tank is to be filled with a mixture obtained from the separate fill lines

utilizing fill pumps P1 and P2. A counter will track the quantity of product

obtained from Line 1 (P1) while the remainder will come from Line 2 (P2).

The mixture ratio of the product will be controllable by adjusting the

counter's preset. The tank is to be filled to the point where the Hi-Level

sensor goes true.

When filling is complete, the Full light will turn On. Heater O:2/04 and

Mixer O:2/00 will be started allowing the mixture to begin heating.

Thermostat I:1/02 will be employed to control the temperature.

The mixer will continue to run for 4 seconds after the mixture reaches the

desired temperature. When the mixer stops, pump P3 will be used to drain

the product from the tank. The tank will be drained to the point where the

Lo-Level sensor trips.

Once emptied, a new single batch sequence may again be started by

pressing the Start Switch while the Selector switch is in position "A".

You might also like

- PLC ExercisesDocument28 pagesPLC ExercisesMohamed Amine100% (1)

- Large Batching Control Application: Workshop#3: Design of HMI Applications For Process MonitoringDocument6 pagesLarge Batching Control Application: Workshop#3: Design of HMI Applications For Process MonitoringAdriancito Aguilar100% (3)

- Reference Control PhilosophyDocument22 pagesReference Control PhilosophyReno MurdaNo ratings yet

- PLC Programming ExampleDocument26 pagesPLC Programming ExampleManu R Krishnan50% (2)

- SOP For PotentiometerDocument25 pagesSOP For PotentiometerPawan KumarNo ratings yet

- Advanced BatchDocument2 pagesAdvanced BatchYerko Reyes CaamañoNo ratings yet

- LogixPro Labs Batch MixingDocument4 pagesLogixPro Labs Batch MixingSyedNadeemAhmed100% (1)

- PLC Problems PDFDocument5 pagesPLC Problems PDFNyan Linn HtunNo ratings yet

- Lab Mezcla Por Lotes - ContadoresDocument1 pageLab Mezcla Por Lotes - ContadoresjackvjcaNo ratings yet

- SFC Exercises EnonceDocument12 pagesSFC Exercises EnonceLuc Auster0% (1)

- IA ActivityDocument5 pagesIA Activityshanmuganandabr1982No ratings yet

- PLC Exercises PDFDocument28 pagesPLC Exercises PDFzoulouweNo ratings yet

- PH / ORP Controller: Programming and Operations ManualDocument13 pagesPH / ORP Controller: Programming and Operations ManualHECTOR IBARRANo ratings yet

- Model 370 PH/MV Meter Operating Manual: 370 350/REV A/10-03Document19 pagesModel 370 PH/MV Meter Operating Manual: 370 350/REV A/10-03Malik Mehboob Ali LakhaniNo ratings yet

- Training Concepts UpdatedDocument2 pagesTraining Concepts Updatedmech SuryaNo ratings yet

- Instrumentation Assignment Part 2Document4 pagesInstrumentation Assignment Part 2Perez LiberNo ratings yet

- Logixpro Traffic Control Lab Utilizing Word ComparisonDocument22 pagesLogixpro Traffic Control Lab Utilizing Word ComparisonLuis Angel Medina MejiaNo ratings yet

- Tutorials On PLCs - NAHPIDocument7 pagesTutorials On PLCs - NAHPImarshal galilee djitsa0% (2)

- Experiment 7 Silo SimulationDocument7 pagesExperiment 7 Silo SimulationAvinash Umesh SarmaNo ratings yet

- PLC Applications Level-1: First Second ThirdDocument5 pagesPLC Applications Level-1: First Second ThirdnaveenNo ratings yet

- Automation Mini ProjectsDocument3 pagesAutomation Mini ProjectsAhmed Samy El GoharyNo ratings yet

- User Manual: Front Panel & Display Technical DataDocument2 pagesUser Manual: Front Panel & Display Technical Datapromeo56No ratings yet

- Manual IMW50Document30 pagesManual IMW50Diseño Enefenco100% (1)

- Curing Oven Operation ManualDocument16 pagesCuring Oven Operation ManualWONG TS0% (1)

- Huong Dan Su Dung ph56Document2 pagesHuong Dan Su Dung ph56Đinh Văn KiênNo ratings yet

- PLC Ladder LogicDocument5 pagesPLC Ladder LogicJean-nette BarlisanNo ratings yet

- BatchMix-02 CLKDocument2 pagesBatchMix-02 CLKHafiez Angpau RayaNo ratings yet

- SOP For Sree Bhagwati Mixing MachineDocument1 pageSOP For Sree Bhagwati Mixing MachinePrasad KasettiNo ratings yet

- Users' Manual: Model HRDK24-D Electric Control Box For Grease Lubrication SystemDocument6 pagesUsers' Manual: Model HRDK24-D Electric Control Box For Grease Lubrication SystemVanesa Soledad AvilaNo ratings yet

- EU07 ManualDocument9 pagesEU07 Manualdziobale dziobaleNo ratings yet

- SOP of Calibration of PH MeterDocument6 pagesSOP of Calibration of PH MeterIlham NurNo ratings yet

- Minor AnswersDocument30 pagesMinor AnswersLinux ThingsNo ratings yet

- Water Level Indicator and ControllerDocument3 pagesWater Level Indicator and Controllermr_zirNo ratings yet

- DPH 503 ManualDocument35 pagesDPH 503 ManualKrishnaraj DhavalaNo ratings yet

- Mechatronic Lab 9 StudyofLinearConveyorControlSystem 20008Document3 pagesMechatronic Lab 9 StudyofLinearConveyorControlSystem 20008Kannan MuthusamyNo ratings yet

- PLC ActivityDocument2 pagesPLC ActivityHarsha KotuwegedaraNo ratings yet

- PLC Lecture7Document7 pagesPLC Lecture7Mohamed MNo ratings yet

- LogixPro - Lab 4 - Control of SiloDocument2 pagesLogixPro - Lab 4 - Control of SiloShah HussainNo ratings yet

- PLC Program For Heating and Mixing of ProductsDocument3 pagesPLC Program For Heating and Mixing of ProductsSivaNo ratings yet

- Ph100 Ph110 ManualDocument8 pagesPh100 Ph110 Manualbala sonyNo ratings yet

- Assignment - 1Document5 pagesAssignment - 1spppppNo ratings yet

- Exstik Fl700: User GuideDocument11 pagesExstik Fl700: User GuideTogoYouredNo ratings yet

- Lube Oil Purifier Operation PDFDocument1 pageLube Oil Purifier Operation PDFMARAWANNo ratings yet

- Key Task EO 2.9 Demonstrates An Ability To Prepare and Operate The SewageDocument2 pagesKey Task EO 2.9 Demonstrates An Ability To Prepare and Operate The SewageApolLLloNNo ratings yet

- Operation ManualDocument19 pagesOperation ManualM Abdullah QureshiNo ratings yet

- SPX-100/150/250B-Z Biochemical Incubator Instruction Manual First, The Instructions For UseDocument3 pagesSPX-100/150/250B-Z Biochemical Incubator Instruction Manual First, The Instructions For Usescribd birdNo ratings yet

- Orligno 500: Instruction Manual & Service ManualDocument28 pagesOrligno 500: Instruction Manual & Service ManualAraNo ratings yet

- Manual Ad11 - Ad12Document2 pagesManual Ad11 - Ad12adwainstNo ratings yet

- Detecting The Standing Bottles On The Conveyor and Pushing Falling Bottles in TrayDocument26 pagesDetecting The Standing Bottles On The Conveyor and Pushing Falling Bottles in TrayManu R KrishnanNo ratings yet

- STI Camden 5 (Automat)Document8 pagesSTI Camden 5 (Automat)somod95239No ratings yet

- McDonnell Douglas DC 10 40 Fuel SystemDocument9 pagesMcDonnell Douglas DC 10 40 Fuel SystemEhsan Ul HaqueNo ratings yet

- Mewp Operating InstrDocument4 pagesMewp Operating InstrPrimelift Safety Resources LimitedNo ratings yet

- PLC Automation ExamplesDocument6 pagesPLC Automation ExamplesAbhishek PachlegaonkarNo ratings yet

- 57737Document27 pages57737Mohamed RamadanNo ratings yet

- Exstik Waterproof PH Meters: User GuideDocument8 pagesExstik Waterproof PH Meters: User GuidestarprofiNo ratings yet

- Lube Oil System ReportDocument9 pagesLube Oil System ReportSatyaKrishna Palla100% (2)

- Iss 7 BM350 MultilingualDocument124 pagesIss 7 BM350 MultilingualThe Baby BossNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet