Professional Documents

Culture Documents

energija pr 4

energija pr 4

Uploaded by

Predrag RaskovicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

energija pr 4

energija pr 4

Uploaded by

Predrag RaskovicCopyright:

Available Formats

1 Introduction

Many process industries are energy-intensive. A large amount of heat energy applied to process

streams is normally dissipated through cooling utilities. It is possible to reuse the heat energy

of hot process streams for heating cold process streams by means of additional heat exchangers.

Such a system is called heat recovery system. The heat recovery system consists of a set of heat

exchangers including heaters, coolers, condensers, reboilers, or other equipment and

attachments for heat transfer between process streams. It can be treated as a heat exchanger

network with different kinds of exchangers in which hot process streams can be cooled by the

cold streams to be heated, and vice versa. In this way, the heating and cooling loads from

external sources (hot and cold utilities) can be dramatically reduced. However, the reduction in

utility costs is often accompanied by the increase in investment costs. Therefore, a balance

between utility costs and investment costs should be established.

The optimal design of a heat exchanger network is to structure a system capable of performing

the prescribed tasks at the minimum total annual costs, which is the sum of the utility costs and

investment costs [1]. Because of its structural characteristics, it is also named the synthesis of

heat exchanger networks. A further extension of the network synthesis is the optimal retrofit

design of existing networks. Principally, the methodologies of optimal design of heat exchanger

networks do not focus on the determination of detailed parameters of heat exchangers of a

network. It takes the network as a system and determines the network configuration and heat

loads of the exchangers used in the network for the further detailed unit design. The well-known

synthesis methodologies are the Pinch design method [2], mathematical programming [3], and

stochastic or heuristic algorithms such as genetic algorithm [4], simulated annealing algorithm

[5] and Tabu search procedure [6]. The genetic algorithm was also combined with simulated

annealing algorithm for the synthesis of multistream heat exchanger networks [7, 8]. This

chapter introduces only the fundamental theories of the design of heat exchanger networks.

2 Temperature Calculation of Heat Exchanger Networks

2.1 Temperature Calculation of a Single Heat Exchanger

For a single heat exchanger, the heat load can be determined by

Q= (M c p )h (h − h) = (M c p )c (c − c ) = F k A LM (1)

where the subscripts „h“ and „c“ denote hot stream and cold stream, and are inlet and

outlet temperatures, k is the overall heat transfer coefficient, A the heat transfer area, M the

mass flow rate, and c p the specific heat capacity at constant pressure. The product term (M c p )

is also named heat capacity flow rate. The correction factor F is the ratio of the real mean

temperature difference to the logarithmic mean temperature difference of the counterflow heat

exchanger LM (see also >Chap. C1),

(h − c) − (h − c )

LM =

ln (h − c) (h − c ) (2)

If (h − c) (h − c ) , the arithmetic mean can be used,

(h − c) + (h − c )

1

LM (3)

2

Equation (1) is used to determine the exchanger size according to known stream temperatures.

In >Chap. C1 the two flow streams are denoted with indexes „1“ and „2,“ as defined for the

channels of each flow arrangement. For heat exchanger networks the notations „h“ and „c“ is

more appropriate.

For an existing heat exchanger, the outlet stream temperatures are given by

h vhh vhc h

= v

vcc c (4)

c ch

or in the matrix form

= V (5)

in which and are the inlet and outlet temperature vectors of the exchanger, respectively,

and

(1 − Rh ) e − NTU h (1− Rh ) 1 − e − NTU h (1− Rh )

* *

v vhc 1 − Rh e − NTU h (1− Rh ) 1 − Rh e − NTU h (1− Rh )

* *

V = hh

vch

=

vcc Rh 1 − e − NTU h (1− Rh )

*

1 − Rh

(6)

− NTU h* (1− Rh )

1 − Rh e − NTU h (1− Rh )

*

1 − Rh e

Rh = 1 Rc = (M c p )h (M c p )c (7)

NTU h* = Rc NTU c* = F k A (M c p )h (8)

Special cases:

e − NTU h 1 − e − NTU h

* *

Rh → 0 : V = (9)

0 1

1 0

Rh → : V = − NTU c − NTU c* (10)

−

*

1 e e

(F k A) → 0 : V =

1 0

(11)

0 1

orks. Chem Eng Proc, 48:1506–1516

You might also like

- Sample - Solution Manual For Heat Exchangers 3rd Edition by Sadik Kakac and Hongtan Liu PDFDocument15 pagesSample - Solution Manual For Heat Exchangers 3rd Edition by Sadik Kakac and Hongtan Liu PDFPolkmnjhhg Polkmjnbhgyt100% (1)

- Heat Balance of Kilns and Coolers and Related TopicsDocument62 pagesHeat Balance of Kilns and Coolers and Related TopicsAde Oktaviani Chaniago100% (2)

- Thermal Analysis of Thrust Chambers: RPA: Tool For Rocket Propulsion AnalysisDocument26 pagesThermal Analysis of Thrust Chambers: RPA: Tool For Rocket Propulsion AnalysisBill M. SpragueNo ratings yet

- BASF-Catalog - North-America - Product Selection Guide EfkaDocument84 pagesBASF-Catalog - North-America - Product Selection Guide Efkatrường phạm100% (1)

- In-Class Worksheet AnswersDocument6 pagesIn-Class Worksheet AnswersalgonzNo ratings yet

- Rating Calculation For Plate Heat Exchanger Effectiveness and Pressure Drop Using Existing Performance DataDocument10 pagesRating Calculation For Plate Heat Exchanger Effectiveness and Pressure Drop Using Existing Performance DataFrandhoni UtomoNo ratings yet

- Rating Calculation For Plate Heat Exchanger Effectiveness and Pressure Drop Using Existing Performance Data PDFDocument10 pagesRating Calculation For Plate Heat Exchanger Effectiveness and Pressure Drop Using Existing Performance Data PDFFrandhoni UtomoNo ratings yet

- Cooling A Pipe Filled With WaterDocument78 pagesCooling A Pipe Filled With WatervyrgoNo ratings yet

- Trajectory Analysis of Nonisothermal Tubular Reactor Nonlinear ModelsDocument16 pagesTrajectory Analysis of Nonisothermal Tubular Reactor Nonlinear ModelsMuhammad HassanNo ratings yet

- University of TripoliDocument16 pagesUniversity of TripoliSrewaBenshebilNo ratings yet

- Derivation of The LMTD and E-NTUDocument3 pagesDerivation of The LMTD and E-NTUmezacoeNo ratings yet

- CD Ch06BMembraneReactorDocument6 pagesCD Ch06BMembraneReactorJorge Eduardo CamposNo ratings yet

- List of Equations Samenvatting Fundamentals of Wind Energy IDocument2 pagesList of Equations Samenvatting Fundamentals of Wind Energy Isy.buitienNo ratings yet

- M M T T U A: Heat Exchanger PerformanceDocument6 pagesM M T T U A: Heat Exchanger PerformanceYonas AddamNo ratings yet

- 4-2-Partial Fugacity in Gas MixturesDocument31 pages4-2-Partial Fugacity in Gas MixturesIkNo ratings yet

- Trade-Wind Inversion: Tropical Meteorology Lecture Notes, Page 69Document8 pagesTrade-Wind Inversion: Tropical Meteorology Lecture Notes, Page 69Karen CondaNo ratings yet

- Mathematical Modeling of Hydraulic SystemsDocument4 pagesMathematical Modeling of Hydraulic SystemsScribdTranslationsNo ratings yet

- Study of Ballistic Parameters For Projectile Range ExtensionDocument7 pagesStudy of Ballistic Parameters For Projectile Range ExtensionMohamed MohamedNo ratings yet

- CH 1. Mathematical Formulation of Physicochemical Problems PDFDocument23 pagesCH 1. Mathematical Formulation of Physicochemical Problems PDFDea Puspa Karinda 02211940000031No ratings yet

- Shell and Tube Heat ExchangerDocument12 pagesShell and Tube Heat ExchangerHassanal HarisNo ratings yet

- 18 A3Document3 pages18 A3kkdbiggyNo ratings yet

- ECRE 2011S Chap4Document176 pagesECRE 2011S Chap4llolliiNo ratings yet

- Day 3Document114 pagesDay 3ramnareshretneniNo ratings yet

- NMPC For Runaway-Safe Fed-Batch ReactorsDocument8 pagesNMPC For Runaway-Safe Fed-Batch ReactorsKarima ChakerNo ratings yet

- Thrust Vector Control by Flexible Nozzle and Secondary Fluid InjectionDocument10 pagesThrust Vector Control by Flexible Nozzle and Secondary Fluid InjectionPurushothamanNo ratings yet

- Tutorial 4Document9 pagesTutorial 4Jabin XingNo ratings yet

- The Modeling of Chemical Reactors Chapter 8Document44 pagesThe Modeling of Chemical Reactors Chapter 8Manoaki100% (1)

- RPA ThermalAnalysisDocument26 pagesRPA ThermalAnalysisAnonymous 7XKvxZNo ratings yet

- CLL261-Theoretical Models of Chemical Process: Hariprasad Kodamana Iit DelhiDocument18 pagesCLL261-Theoretical Models of Chemical Process: Hariprasad Kodamana Iit DelhiGARGI SHARMANo ratings yet

- Computer Simulation of Opposing Reaction Kinetics: Chemical EngineeringDocument6 pagesComputer Simulation of Opposing Reaction Kinetics: Chemical EngineeringRamesh Mishra0% (1)

- Dynamic Analysis of Liquid Storage Cylindrical Tanks Due To EarthquakeDocument7 pagesDynamic Analysis of Liquid Storage Cylindrical Tanks Due To EarthquakeRAKSHITH NNo ratings yet

- Simulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreDocument11 pagesSimulation and Identification of Drum - Boiler Dynamics: Msc. Thesis by Giambattista PistoreAlfredo ToyosNo ratings yet

- Design of Natural Circulation BoilerDocument12 pagesDesign of Natural Circulation BoilerALIyilmazNo ratings yet

- LMECA2854 HEXLab GroupU PrérapportDocument7 pagesLMECA2854 HEXLab GroupU PrérapportLissa BerloNo ratings yet

- SS4201 Fluid and MagnetohydrodynamicsDocument3 pagesSS4201 Fluid and MagnetohydrodynamicsSayantan DuttaNo ratings yet

- Sanchez LacombeDocument8 pagesSanchez LacombeFisicoquimica ULSNo ratings yet

- Saleem Bahi Software SimulationDocument5 pagesSaleem Bahi Software SimulationUsama ArifNo ratings yet

- Che 471: Lecture 4 Fall 2003: Ideal ReactorsDocument18 pagesChe 471: Lecture 4 Fall 2003: Ideal ReactorsMuhammad BilalNo ratings yet

- CN2116-Unit 8-2022Document21 pagesCN2116-Unit 8-2022Carmen ChanNo ratings yet

- Differences FiniesDocument6 pagesDifferences FiniesKawtar KabbiNo ratings yet

- Kcontrol PDFDocument8 pagesKcontrol PDFVaibhav SharmaNo ratings yet

- Process Motion and Control PDFDocument8 pagesProcess Motion and Control PDFVaibhav SharmaNo ratings yet

- Compressible Flow Through Nozzles and Diffusers: V DT V D V VDocument14 pagesCompressible Flow Through Nozzles and Diffusers: V DT V D V VCamilo SantacruzNo ratings yet

- Observability and Sliding Mode Observer Design For Multi-Cell Series ConverterDocument6 pagesObservability and Sliding Mode Observer Design For Multi-Cell Series ConverterSana OthmanNo ratings yet

- Comsol Nonisothermal Plug Flow ReactorDocument14 pagesComsol Nonisothermal Plug Flow ReactorArjun TomerNo ratings yet

- King Fahd University of Petroleum and Minerals: Combined Convection and Radiation Heat Transfer (H2)Document17 pagesKing Fahd University of Petroleum and Minerals: Combined Convection and Radiation Heat Transfer (H2)hutime44No ratings yet

- Analytical Solutions To The Navier-Stokes EquationsDocument13 pagesAnalytical Solutions To The Navier-Stokes Equationssidiabdelli_83761508No ratings yet

- Models - Chem.nonisothermal Plug FlowDocument20 pagesModels - Chem.nonisothermal Plug FlowNavid AhadiNo ratings yet

- 1.0 Test Objectives: 436-351 Thermofluids 2, Unit 2: Thermodynamics Laboratory T2 - Heat ExcangersDocument4 pages1.0 Test Objectives: 436-351 Thermofluids 2, Unit 2: Thermodynamics Laboratory T2 - Heat Excangersنزار الدهاميNo ratings yet

- Program For Simulation of A Continuous Stirred Tank Reactor in Matlab'S GuiDocument6 pagesProgram For Simulation of A Continuous Stirred Tank Reactor in Matlab'S GuiFathurRahmanNo ratings yet

- chm305 Lecture2 PDFDocument6 pageschm305 Lecture2 PDFJan Harry EstuyeNo ratings yet

- DryingDocument5 pagesDryingnabeelbirdNo ratings yet

- Helical Flow of Power-Law Fluids: Dostal, Zitnf, and J. SestakDocument4 pagesHelical Flow of Power-Law Fluids: Dostal, Zitnf, and J. SestakHicham HichamNo ratings yet

- Vol-1, Issue-5Document6 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- On Significance of Second-Order Dynamics For Coupled Tanks SystemsDocument6 pagesOn Significance of Second-Order Dynamics For Coupled Tanks SystemsJuan Felipe HernandezNo ratings yet

- Gear Analysis 11Document22 pagesGear Analysis 11premnathgopinathanNo ratings yet

- Molecular Dynamics Calculations of Insb Nanowires Thermal ConductivityDocument10 pagesMolecular Dynamics Calculations of Insb Nanowires Thermal ConductivityolicardNo ratings yet

- Individual Equipment Design: Ammonia ConverterDocument26 pagesIndividual Equipment Design: Ammonia ConverterMohaiminNo ratings yet

- Report 7Document20 pagesReport 7Mariam DalloulNo ratings yet

- Numerical Solution On Transient Heat Transfer For Forced Convection Flow of Helium Gas Over A Twisted Plate With Different Helical PitchDocument9 pagesNumerical Solution On Transient Heat Transfer For Forced Convection Flow of Helium Gas Over A Twisted Plate With Different Helical PitchKwanchai ChoicharoenNo ratings yet

- Vortex Lattice MethodsDocument12 pagesVortex Lattice MethodsLam Trinh NguyenNo ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- The Equidistribution Theory of Holomorphic Curves. (AM-64), Volume 64From EverandThe Equidistribution Theory of Holomorphic Curves. (AM-64), Volume 64No ratings yet

- Constants of PhysicsDocument1 pageConstants of PhysicsPredrag RaskovicNo ratings yet

- International Conference On Engineering DesignDocument14 pagesInternational Conference On Engineering DesignPredrag RaskovicNo ratings yet

- Conversion FactorsDocument2 pagesConversion FactorsPredrag RaskovicNo ratings yet

- Astronomical DataDocument1 pageAstronomical DataPredrag RaskovicNo ratings yet

- Review of Design MethodologyDocument10 pagesReview of Design MethodologyPredrag RaskovicNo ratings yet

- An Analysis of Design Process Models Across Disciplines: K. Gericke and L. BlessingDocument10 pagesAn Analysis of Design Process Models Across Disciplines: K. Gericke and L. BlessingPredrag RaskovicNo ratings yet

- A Brief Review of Methods For The Design and SynthDocument11 pagesA Brief Review of Methods For The Design and SynthPredrag RaskovicNo ratings yet

- Journal of Loss Prevention in The Process IndustriesDocument12 pagesJournal of Loss Prevention in The Process IndustriesPredrag RaskovicNo ratings yet

- Basic Revision NotesDocument55 pagesBasic Revision Noteshabiba ulanNo ratings yet

- 06-Measurement of TemperatureDocument16 pages06-Measurement of TemperatureChidiebere Samuel OkogwuNo ratings yet

- Hall Heroult Process and Hooper ProcessDocument9 pagesHall Heroult Process and Hooper ProcesssaadNo ratings yet

- Chapter 3 What Is MatterDocument35 pagesChapter 3 What Is MatterarifzaidialwiNo ratings yet

- KCES'S College of Engineering & Management, Jalgaon Department of Mechanical Engineering. B.Tech - Second Year Academic Year 2020-21Document3 pagesKCES'S College of Engineering & Management, Jalgaon Department of Mechanical Engineering. B.Tech - Second Year Academic Year 2020-21dspNo ratings yet

- Liquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidDocument10 pagesLiquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidAleska Guzman SantamariaNo ratings yet

- The Temperature of The Solar Corona: G. NociDocument9 pagesThe Temperature of The Solar Corona: G. NociAllan Maximiliano Jil TorresNo ratings yet

- Gases & The Kinetic-Molecular TheoryDocument20 pagesGases & The Kinetic-Molecular TheoryAshley Marie ChildersNo ratings yet

- Unit 8B AP Chem - ElectrochemistryDocument11 pagesUnit 8B AP Chem - ElectrochemistryAnivia12100% (1)

- Science-10 Q4 Mod1.2 Charles-LawDocument21 pagesScience-10 Q4 Mod1.2 Charles-Lawmarkdoro387No ratings yet

- Electro Engineering MaterialDocument0 pagesElectro Engineering Materialwww.bhawesh.com.npNo ratings yet

- Steam Consumption: Example For A Single-Corrugator Work Width 2200mmDocument2 pagesSteam Consumption: Example For A Single-Corrugator Work Width 2200mmV U P RaoNo ratings yet

- Design Project ReportDocument4 pagesDesign Project Reporttheodor1988No ratings yet

- Exergy Analysis of Rankine Cycle & STPPDocument18 pagesExergy Analysis of Rankine Cycle & STPPSaAhRaNo ratings yet

- Oxidative Dehydrogenation of ButaneDocument13 pagesOxidative Dehydrogenation of ButaneblackelfvampireNo ratings yet

- Medical Gas Cylinder Valves For PinDocument11 pagesMedical Gas Cylinder Valves For PinRICHIHOTS2No ratings yet

- Stochiometry ExerciseDocument35 pagesStochiometry ExerciseVarun JishnuNo ratings yet

- Report On Chloro Caustic GroupDocument79 pagesReport On Chloro Caustic Grouppankaj verma100% (2)

- Fermann J.T. - Hartree-Fock Approximate Molecular Orbital Theory (1997)Document21 pagesFermann J.T. - Hartree-Fock Approximate Molecular Orbital Theory (1997)Anonymous AzXah9n0YNo ratings yet

- 01 - Properties of Fluids PDFDocument11 pages01 - Properties of Fluids PDFHyvemperorNo ratings yet

- Chemistry Paper 3 TZ1 HL MarkschemeDocument29 pagesChemistry Paper 3 TZ1 HL MarkschemeDhruv BhallaNo ratings yet

- Kandhal Lecture 1 On Bitumen: Refining, Types and Conventional Properties (Handouts)Document8 pagesKandhal Lecture 1 On Bitumen: Refining, Types and Conventional Properties (Handouts)Prof. Prithvi Singh Kandhal100% (4)

- Science 7 q1 Module 4Document20 pagesScience 7 q1 Module 4Buena Fe chavezNo ratings yet

- Nitrogen Services For Pipeline and Process ApplicationsDocument2 pagesNitrogen Services For Pipeline and Process ApplicationsgobiNo ratings yet

- Anion and Cation TestsDocument2 pagesAnion and Cation TestsTanvir Ahmed MazumderNo ratings yet

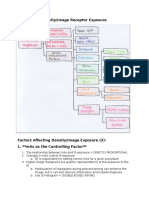

- Chapter 26: Density/Image Receptor Exposure: Notebook #7Document8 pagesChapter 26: Density/Image Receptor Exposure: Notebook #7api-338781568No ratings yet

- MLL242 Lab ManualDocument26 pagesMLL242 Lab Manualyadavtstsy07No ratings yet