Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsKAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

KAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

Uploaded by

lionelkapopo6Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Refrigeration Study Guide IIDocument10 pagesRefrigeration Study Guide IICesar Bl83% (6)

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoNo ratings yet

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

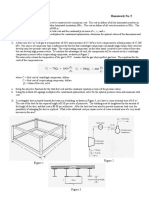

- HW 5Document6 pagesHW 5Snigdha YadavNo ratings yet

- Manual Starting and Desludging of PurifierDocument2 pagesManual Starting and Desludging of PurifierAnupGautam50% (2)

- Boiler CommissioningDocument29 pagesBoiler Commissioningbratishkaity100% (8)

- Contact Equilibrium ProcessesDocument13 pagesContact Equilibrium ProcessesDavid Aremania100% (1)

- Aerodynamics Lab 3 - Direct Measurements of Airfoil Lift and DragDocument18 pagesAerodynamics Lab 3 - Direct Measurements of Airfoil Lift and DragDavid Clark83% (12)

- Template of Weekly summary for Kamoa Trainees(1)Document2 pagesTemplate of Weekly summary for Kamoa Trainees(1)lionelkapopo6No ratings yet

- Cleaning Pin Tubes Procedure PDFDocument3 pagesCleaning Pin Tubes Procedure PDFAarón Díaz100% (1)

- Boiler Lab Safety Precaution 1Document12 pagesBoiler Lab Safety Precaution 1Muhammad UsmanNo ratings yet

- SOP Cleaup With HPH Blow ProcessDocument2 pagesSOP Cleaup With HPH Blow Processsarojdubey0107No ratings yet

- Alkali Boil Out - ProcedureDocument4 pagesAlkali Boil Out - ProcedureMourya DevuNo ratings yet

- Start/stop of The Boiler: 1 GeneralDocument4 pagesStart/stop of The Boiler: 1 GeneralphuocNo ratings yet

- Boiler MaintenanceDocument14 pagesBoiler MaintenanceEzam WisnuNo ratings yet

- Commissioning & OperationDocument55 pagesCommissioning & OperationHarjith Vaibav100% (1)

- Operation of BoilerDocument13 pagesOperation of BoilermenishaNo ratings yet

- Philipp Loos GMBHDocument21 pagesPhilipp Loos GMBHfakhirkz37100% (1)

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument35 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Week 9Document7 pagesWeek 9Mariel PernitoNo ratings yet

- Steam Boiler Operation Part 1 Week 10Document46 pagesSteam Boiler Operation Part 1 Week 10cadaxeshpatelNo ratings yet

- CEP PresentatioDocument14 pagesCEP PresentatioVinod Mahajan100% (2)

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Blow DownDocument94 pagesBlow DownManit Siriworasilp100% (1)

- Climbing Film Evaporation Data (2016) - All GroupsDocument12 pagesClimbing Film Evaporation Data (2016) - All GroupsJuwon Jeremiah MakuNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- Lab Report 5Document12 pagesLab Report 5Norhanisah Zamri Rcsu100% (1)

- Compressors OperationDocument35 pagesCompressors OperationSalim Chohan100% (1)

- KAPOPO LUMBWE LIONEL WEEKLY REPORT FOR 18 to 23 JUNE 2024(1)Document1 pageKAPOPO LUMBWE LIONEL WEEKLY REPORT FOR 18 to 23 JUNE 2024(1)lionelkapopo6No ratings yet

- Blow Down Boiler and Soot BlowingDocument6 pagesBlow Down Boiler and Soot BlowingSahil MishraNo ratings yet

- Operation and Maintenance: Start/stop of BoilerDocument24 pagesOperation and Maintenance: Start/stop of BoilerAlexander BaziotisNo ratings yet

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocument3 pagesHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890No ratings yet

- CONDENSEr GLDocument37 pagesCONDENSEr GLharisankar100% (1)

- Boiler Maintenance On ShipsDocument7 pagesBoiler Maintenance On ShipsRobert LuuNo ratings yet

- Vacuum Leakage TestDocument11 pagesVacuum Leakage Testsambhu100% (1)

- Ammonia Plant SopsDocument31 pagesAmmonia Plant SopsKarthik Manjunath100% (1)

- Guidance For Lab: Part A. Beginning of The ExperimentDocument4 pagesGuidance For Lab: Part A. Beginning of The ExperimentlemizeNo ratings yet

- Lab 3-2 - Venturi and Splits F20Document2 pagesLab 3-2 - Venturi and Splits F20hamzaNo ratings yet

- Iceland Operating ProceduresDocument14 pagesIceland Operating ProceduresYudha ArtikaNo ratings yet

- Power Plant BoilersDocument24 pagesPower Plant BoilerstabishkhanaligNo ratings yet

- Phase II Boiler QuestionsDocument12 pagesPhase II Boiler Questionsabbutalibb5407No ratings yet

- Print MeDocument10 pagesPrint MeBryan TanNo ratings yet

- Progressive Development of Power Generation Through Steam GenerationDocument8 pagesProgressive Development of Power Generation Through Steam GenerationAshish GauravNo ratings yet

- Loeffler BoilerDocument22 pagesLoeffler BoilerDr. BIBIN CHIDAMBARANATHAN0% (1)

- Steam DrumDocument9 pagesSteam DrumMECHANICAL KRCENo ratings yet

- Turn Over by Bunan MV Ariso WiperDocument6 pagesTurn Over by Bunan MV Ariso WiperJoren PalminNo ratings yet

- Boiler OperationDocument14 pagesBoiler OperationjmayurrNo ratings yet

- BoilerDocument65 pagesBoilermangal SinghNo ratings yet

- Ppe Exp.3 ROLLNO 1Document9 pagesPpe Exp.3 ROLLNO 1Aniket SinghNo ratings yet

- Aeration Commisioning - STPDocument7 pagesAeration Commisioning - STPdexterNo ratings yet

- Boiler CommissioningDocument7 pagesBoiler CommissioningDevanshu SinghNo ratings yet

- Basic Civil and Mechanical-Unit-4-Boilers-Support Notes-Studyhaunters PDFDocument11 pagesBasic Civil and Mechanical-Unit-4-Boilers-Support Notes-Studyhaunters PDFSriram J100% (1)

- 5 - Hand Over THENAILLER - VLADYCHENKO Sept 2017Document3 pages5 - Hand Over THENAILLER - VLADYCHENKO Sept 2017alex.verdzadze98No ratings yet

- Power Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1Document43 pagesPower Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1rohit_0123100% (2)

- Training Material of Boiler Operation: Drum and Internal DevicesDocument8 pagesTraining Material of Boiler Operation: Drum and Internal DevicesandreNo ratings yet

- The Traveling Engineers' Association to Improve the Locomotive Engine Service of American Railroads Examination Questions and Answers for Firemen for Promotion and New Men for EmploymentFrom EverandThe Traveling Engineers' Association to Improve the Locomotive Engine Service of American Railroads Examination Questions and Answers for Firemen for Promotion and New Men for EmploymentNo ratings yet

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingFrom EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- AAR Newsletter August2015 006 PDFDocument24 pagesAAR Newsletter August2015 006 PDFAnil KumarNo ratings yet

- Selected SELO AnnouncementsDocument7 pagesSelected SELO AnnouncementsSalvatore CannataNo ratings yet

- Oem - High Performance Screw Compressor Lubricants: OEM Oem Description Oem Part NoDocument23 pagesOem - High Performance Screw Compressor Lubricants: OEM Oem Description Oem Part Nomeet dodhiwalaNo ratings yet

- Water Handbook - Boiler Blowdown Control - VeoliaDocument8 pagesWater Handbook - Boiler Blowdown Control - Veoliaحسين مهديNo ratings yet

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocument7 pagesSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- Group1: Refrigeration and Air Conditioning Course ProjectDocument67 pagesGroup1: Refrigeration and Air Conditioning Course Projectdamola2realNo ratings yet

- Petrobras Marine Lubricating Oils Equivalent ListDocument10 pagesPetrobras Marine Lubricating Oils Equivalent Listelizbanfavio8008No ratings yet

- Study Guide For Module No. 3Document4 pagesStudy Guide For Module No. 3JanineEsmaoNo ratings yet

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- Thermodynamic Analysis of Advance Vapour Compression Refrigeration SystemDocument18 pagesThermodynamic Analysis of Advance Vapour Compression Refrigeration SystemSonakshi GoyalNo ratings yet

- 4 Centrifugal Pump Leakage FourDocument31 pages4 Centrifugal Pump Leakage FourAbdallah MansourNo ratings yet

- Agilent 490 Micro GC Natural Gas Analyzers: Data SheetDocument6 pagesAgilent 490 Micro GC Natural Gas Analyzers: Data SheetVaibhav AhujaNo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- Vessel Design SlidesDocument32 pagesVessel Design SlidesJay Lawson100% (1)

- ZEO Brochure Final 3 16Document5 pagesZEO Brochure Final 3 16Santiago Cabarcas L. de UrquizoNo ratings yet

- Distribiteur Cat 320C Mbarake 9Document16 pagesDistribiteur Cat 320C Mbarake 9مهدي شقرونNo ratings yet

- Internal FlowDocument6 pagesInternal FlowdenisarissetiajiNo ratings yet

- Empirical Relations of Convective Heat TansferDocument29 pagesEmpirical Relations of Convective Heat TansferArvin DalisayNo ratings yet

- Pump Fundamental Training Latest 2021Document153 pagesPump Fundamental Training Latest 2021nishanuddin zainal100% (1)

- Rising Main Design - SampleDocument8 pagesRising Main Design - Sampleprasadnn2001100% (1)

- A Burners PDFDocument37 pagesA Burners PDFaldoking202028No ratings yet

- Lecture 18 and 19 - Pressure Control Vavles: Self Evaluation Questions and AnswersDocument5 pagesLecture 18 and 19 - Pressure Control Vavles: Self Evaluation Questions and AnswersVivienAlagBatalNo ratings yet

- FM 5 Bernoulli and Energy EquationsDocument47 pagesFM 5 Bernoulli and Energy Equationsالياس يونس مرغلانيNo ratings yet

- Gree-44814 09K 12K (LCLH)Document87 pagesGree-44814 09K 12K (LCLH)MatyoJNo ratings yet

- 9 Gas Power PlantsDocument20 pages9 Gas Power PlantsSaif YounusNo ratings yet

- Operating Instructions: K S G 40/60-2 K S G 50/80-2Document38 pagesOperating Instructions: K S G 40/60-2 K S G 50/80-2Vlady Lopez CastroNo ratings yet

KAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

KAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

Uploaded by

lionelkapopo60 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesKAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

KAPOPO LUMBWE LIONEL MONTHLY REPORT FOR JUNE 2024(1)

Uploaded by

lionelkapopo6Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Monthly Summary of Kamoa Trainees

Department :FF Name:KAPOPO LUMBWE Lionel Post:BOILER Date:From june

Interpreter :Mr Quo QOXIANG

Class :D Supervisor : Mr HANSHENG FU Master:HUA FENG XIE

(Mr JIM)

Content of weekly training

Summary: For our June month we had to do our daily tasks such as the inspection of our boiler the sampling of liquid and

solid samples also spot inspection of steam drum, cylinder crusher and converter boiler.

We had to review the Operating standards for replacement of the dust tank of the first dust hopper for the boiler

in the flash furnace (FF) process. We have to respect 3 steps before, during and after the replacement of the ash

hopper such as:

• If an operation involves manual work and forklift operation simultaneously, the worker shall keep in contact with

the forklift driver and evacuate in time in case of emergency

• During operation, the operator must wear protective goggles, protective gloves, protective masks as specified.

• After the dust tank is forked out of the first dust hopper, the operator must be at least 4m above the first dust

hopper to conduct command operations. We have to replace the dust tank every 7hours after fulling

We had learned how to change the converter boiler for maintenance and for this operation we have some steps

to respect such as:

• Confirm that the heat surface inlet and outlet valves, and the inlet bypass valve, are fully closed.

• Ensure that the cleaning of large debris in the converter is completed, and there are no remaining tools or other

debris inside the boiler. The heat surface is now ready for warming.

• Slightly open the inlet bypass valve (about 1/3 open).

• Slightly open the return water valve (just until you hear water flowing).

• Monitor the temperature at the heat surface temperature measurement point. When the temperature rises to

60°C, proceed as follows:

➢ Open the inlet bypass valve one circle every hour until it is fully open.

➢ Once the inlet bypass valve is fully open, open the returning water valve one circle every hour until the central

control room detects a circulation flow rate of 30 cubic meters per hour, then stop opening the valve.

➢ When the heat surface temperature reaches 180°C, fully open the return water valve to complete the warming

process.

we have learned how to start a circulating pump for any inspection.

We have to respect some steps such as

• Open the inlet pipe valve for feeding water n circulating pump

• Close the outlet pipe valve from the circulating pump (slight open 10%)

• Open the blowdown of the pump.

• Switch to stop and ensure that the bearing is in good condition.

• Switch on manual and close the blowdown.

• Ensure that power supply is connecting into cabinet box of the pump

• Press green button for starting the pump

We have found leak at the circulating pump that’s why we have a dynamic maintenance after some times.

We had learned how do we determinate the leaks of pipe water inside of the boiler

If there is water pipe leakage inside of the boiler, we have noticed by:

• We gonna show the humidity in the dust samples

• We gonna have the wet dust in the scraper and this dust will be create impossibility scraper’s running

• It’ll be difficult to adjust the negative pressure

• We gonna have the low quantity of dust to ESP

• We gonna have the drip out inside the boiler

Master comments

Summary Score: Master's signature:

You might also like

- Refrigeration Study Guide IIDocument10 pagesRefrigeration Study Guide IICesar Bl83% (6)

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoNo ratings yet

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewRating: 5 out of 5 stars5/5 (1)

- HW 5Document6 pagesHW 5Snigdha YadavNo ratings yet

- Manual Starting and Desludging of PurifierDocument2 pagesManual Starting and Desludging of PurifierAnupGautam50% (2)

- Boiler CommissioningDocument29 pagesBoiler Commissioningbratishkaity100% (8)

- Contact Equilibrium ProcessesDocument13 pagesContact Equilibrium ProcessesDavid Aremania100% (1)

- Aerodynamics Lab 3 - Direct Measurements of Airfoil Lift and DragDocument18 pagesAerodynamics Lab 3 - Direct Measurements of Airfoil Lift and DragDavid Clark83% (12)

- Template of Weekly summary for Kamoa Trainees(1)Document2 pagesTemplate of Weekly summary for Kamoa Trainees(1)lionelkapopo6No ratings yet

- Cleaning Pin Tubes Procedure PDFDocument3 pagesCleaning Pin Tubes Procedure PDFAarón Díaz100% (1)

- Boiler Lab Safety Precaution 1Document12 pagesBoiler Lab Safety Precaution 1Muhammad UsmanNo ratings yet

- SOP Cleaup With HPH Blow ProcessDocument2 pagesSOP Cleaup With HPH Blow Processsarojdubey0107No ratings yet

- Alkali Boil Out - ProcedureDocument4 pagesAlkali Boil Out - ProcedureMourya DevuNo ratings yet

- Start/stop of The Boiler: 1 GeneralDocument4 pagesStart/stop of The Boiler: 1 GeneralphuocNo ratings yet

- Boiler MaintenanceDocument14 pagesBoiler MaintenanceEzam WisnuNo ratings yet

- Commissioning & OperationDocument55 pagesCommissioning & OperationHarjith Vaibav100% (1)

- Operation of BoilerDocument13 pagesOperation of BoilermenishaNo ratings yet

- Philipp Loos GMBHDocument21 pagesPhilipp Loos GMBHfakhirkz37100% (1)

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument35 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Week 9Document7 pagesWeek 9Mariel PernitoNo ratings yet

- Steam Boiler Operation Part 1 Week 10Document46 pagesSteam Boiler Operation Part 1 Week 10cadaxeshpatelNo ratings yet

- CEP PresentatioDocument14 pagesCEP PresentatioVinod Mahajan100% (2)

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Blow DownDocument94 pagesBlow DownManit Siriworasilp100% (1)

- Climbing Film Evaporation Data (2016) - All GroupsDocument12 pagesClimbing Film Evaporation Data (2016) - All GroupsJuwon Jeremiah MakuNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- Lab Report 5Document12 pagesLab Report 5Norhanisah Zamri Rcsu100% (1)

- Compressors OperationDocument35 pagesCompressors OperationSalim Chohan100% (1)

- KAPOPO LUMBWE LIONEL WEEKLY REPORT FOR 18 to 23 JUNE 2024(1)Document1 pageKAPOPO LUMBWE LIONEL WEEKLY REPORT FOR 18 to 23 JUNE 2024(1)lionelkapopo6No ratings yet

- Blow Down Boiler and Soot BlowingDocument6 pagesBlow Down Boiler and Soot BlowingSahil MishraNo ratings yet

- Operation and Maintenance: Start/stop of BoilerDocument24 pagesOperation and Maintenance: Start/stop of BoilerAlexander BaziotisNo ratings yet

- Handling of Turbine During Emergency: Emergencies in Turbine and AuxiliariesDocument3 pagesHandling of Turbine During Emergency: Emergencies in Turbine and Auxiliariesron1234567890No ratings yet

- CONDENSEr GLDocument37 pagesCONDENSEr GLharisankar100% (1)

- Boiler Maintenance On ShipsDocument7 pagesBoiler Maintenance On ShipsRobert LuuNo ratings yet

- Vacuum Leakage TestDocument11 pagesVacuum Leakage Testsambhu100% (1)

- Ammonia Plant SopsDocument31 pagesAmmonia Plant SopsKarthik Manjunath100% (1)

- Guidance For Lab: Part A. Beginning of The ExperimentDocument4 pagesGuidance For Lab: Part A. Beginning of The ExperimentlemizeNo ratings yet

- Lab 3-2 - Venturi and Splits F20Document2 pagesLab 3-2 - Venturi and Splits F20hamzaNo ratings yet

- Iceland Operating ProceduresDocument14 pagesIceland Operating ProceduresYudha ArtikaNo ratings yet

- Power Plant BoilersDocument24 pagesPower Plant BoilerstabishkhanaligNo ratings yet

- Phase II Boiler QuestionsDocument12 pagesPhase II Boiler Questionsabbutalibb5407No ratings yet

- Print MeDocument10 pagesPrint MeBryan TanNo ratings yet

- Progressive Development of Power Generation Through Steam GenerationDocument8 pagesProgressive Development of Power Generation Through Steam GenerationAshish GauravNo ratings yet

- Loeffler BoilerDocument22 pagesLoeffler BoilerDr. BIBIN CHIDAMBARANATHAN0% (1)

- Steam DrumDocument9 pagesSteam DrumMECHANICAL KRCENo ratings yet

- Turn Over by Bunan MV Ariso WiperDocument6 pagesTurn Over by Bunan MV Ariso WiperJoren PalminNo ratings yet

- Boiler OperationDocument14 pagesBoiler OperationjmayurrNo ratings yet

- BoilerDocument65 pagesBoilermangal SinghNo ratings yet

- Ppe Exp.3 ROLLNO 1Document9 pagesPpe Exp.3 ROLLNO 1Aniket SinghNo ratings yet

- Aeration Commisioning - STPDocument7 pagesAeration Commisioning - STPdexterNo ratings yet

- Boiler CommissioningDocument7 pagesBoiler CommissioningDevanshu SinghNo ratings yet

- Basic Civil and Mechanical-Unit-4-Boilers-Support Notes-Studyhaunters PDFDocument11 pagesBasic Civil and Mechanical-Unit-4-Boilers-Support Notes-Studyhaunters PDFSriram J100% (1)

- 5 - Hand Over THENAILLER - VLADYCHENKO Sept 2017Document3 pages5 - Hand Over THENAILLER - VLADYCHENKO Sept 2017alex.verdzadze98No ratings yet

- Power Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1Document43 pagesPower Plant Operation Turbine & Auxiliaries: 8 January 2013 H K Sethi 1rohit_0123100% (2)

- Training Material of Boiler Operation: Drum and Internal DevicesDocument8 pagesTraining Material of Boiler Operation: Drum and Internal DevicesandreNo ratings yet

- The Traveling Engineers' Association to Improve the Locomotive Engine Service of American Railroads Examination Questions and Answers for Firemen for Promotion and New Men for EmploymentFrom EverandThe Traveling Engineers' Association to Improve the Locomotive Engine Service of American Railroads Examination Questions and Answers for Firemen for Promotion and New Men for EmploymentNo ratings yet

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingFrom EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- AAR Newsletter August2015 006 PDFDocument24 pagesAAR Newsletter August2015 006 PDFAnil KumarNo ratings yet

- Selected SELO AnnouncementsDocument7 pagesSelected SELO AnnouncementsSalvatore CannataNo ratings yet

- Oem - High Performance Screw Compressor Lubricants: OEM Oem Description Oem Part NoDocument23 pagesOem - High Performance Screw Compressor Lubricants: OEM Oem Description Oem Part Nomeet dodhiwalaNo ratings yet

- Water Handbook - Boiler Blowdown Control - VeoliaDocument8 pagesWater Handbook - Boiler Blowdown Control - Veoliaحسين مهديNo ratings yet

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocument7 pagesSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- Group1: Refrigeration and Air Conditioning Course ProjectDocument67 pagesGroup1: Refrigeration and Air Conditioning Course Projectdamola2realNo ratings yet

- Petrobras Marine Lubricating Oils Equivalent ListDocument10 pagesPetrobras Marine Lubricating Oils Equivalent Listelizbanfavio8008No ratings yet

- Study Guide For Module No. 3Document4 pagesStudy Guide For Module No. 3JanineEsmaoNo ratings yet

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- Thermodynamic Analysis of Advance Vapour Compression Refrigeration SystemDocument18 pagesThermodynamic Analysis of Advance Vapour Compression Refrigeration SystemSonakshi GoyalNo ratings yet

- 4 Centrifugal Pump Leakage FourDocument31 pages4 Centrifugal Pump Leakage FourAbdallah MansourNo ratings yet

- Agilent 490 Micro GC Natural Gas Analyzers: Data SheetDocument6 pagesAgilent 490 Micro GC Natural Gas Analyzers: Data SheetVaibhav AhujaNo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- Vessel Design SlidesDocument32 pagesVessel Design SlidesJay Lawson100% (1)

- ZEO Brochure Final 3 16Document5 pagesZEO Brochure Final 3 16Santiago Cabarcas L. de UrquizoNo ratings yet

- Distribiteur Cat 320C Mbarake 9Document16 pagesDistribiteur Cat 320C Mbarake 9مهدي شقرونNo ratings yet

- Internal FlowDocument6 pagesInternal FlowdenisarissetiajiNo ratings yet

- Empirical Relations of Convective Heat TansferDocument29 pagesEmpirical Relations of Convective Heat TansferArvin DalisayNo ratings yet

- Pump Fundamental Training Latest 2021Document153 pagesPump Fundamental Training Latest 2021nishanuddin zainal100% (1)

- Rising Main Design - SampleDocument8 pagesRising Main Design - Sampleprasadnn2001100% (1)

- A Burners PDFDocument37 pagesA Burners PDFaldoking202028No ratings yet

- Lecture 18 and 19 - Pressure Control Vavles: Self Evaluation Questions and AnswersDocument5 pagesLecture 18 and 19 - Pressure Control Vavles: Self Evaluation Questions and AnswersVivienAlagBatalNo ratings yet

- FM 5 Bernoulli and Energy EquationsDocument47 pagesFM 5 Bernoulli and Energy Equationsالياس يونس مرغلانيNo ratings yet

- Gree-44814 09K 12K (LCLH)Document87 pagesGree-44814 09K 12K (LCLH)MatyoJNo ratings yet

- 9 Gas Power PlantsDocument20 pages9 Gas Power PlantsSaif YounusNo ratings yet

- Operating Instructions: K S G 40/60-2 K S G 50/80-2Document38 pagesOperating Instructions: K S G 40/60-2 K S G 50/80-2Vlady Lopez CastroNo ratings yet