Professional Documents

Culture Documents

1-4 AquaMist ULF G-Press piping systems

1-4 AquaMist ULF G-Press piping systems

Uploaded by

thebrilliantmistakescribdCopyright:

Available Formats

You might also like

- Diagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)Document1,605 pagesDiagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)javier borrego0% (1)

- Support Items: Panasonic Factory Solutions Co., LTDDocument48 pagesSupport Items: Panasonic Factory Solutions Co., LTDMelchiades OliveiraNo ratings yet

- Hitachi Seal KitDocument2 pagesHitachi Seal Kitlabeddu0% (1)

- Topworx DXP - Installation and ConfigurationDocument52 pagesTopworx DXP - Installation and ConfigurationJames Dawe100% (1)

- Unisab III Industrial Refrigeration Package Controller: Ultimate FlexibilityDocument7 pagesUnisab III Industrial Refrigeration Package Controller: Ultimate Flexibilityandrew.golovanNo ratings yet

- Ipac Drop TestDocument7 pagesIpac Drop TestSUNIL KUMARNo ratings yet

- SVP Brochure 106 PDFDocument4 pagesSVP Brochure 106 PDFLuis CarlosNo ratings yet

- Hose, Tube & Connection Fittings Catalogue: JSG Industrial SystemsDocument20 pagesHose, Tube & Connection Fittings Catalogue: JSG Industrial Systemsagung wijayaNo ratings yet

- MKT Product Catalog 2019Document64 pagesMKT Product Catalog 2019Üstün Onur BaktırNo ratings yet

- Sumner WeldingDocument48 pagesSumner WeldingfELIPENo ratings yet

- Ficha Tecnica FlujometroDocument2 pagesFicha Tecnica FlujometroTatiana Mejías SeguraNo ratings yet

- 1-3 FM AquaMist ULF Machinery Spaces (JCI 11-2019)Document20 pages1-3 FM AquaMist ULF Machinery Spaces (JCI 11-2019)thebrilliantmistakescribdNo ratings yet

- Lifting Clamps - Camlok (2012) PDFDocument16 pagesLifting Clamps - Camlok (2012) PDFPernando SagaNo ratings yet

- Datasheet A480Document2 pagesDatasheet A480Mustafa Lagha100% (1)

- NN - 2142 - A - Lid - Opener - System Manual Nido ShenandoahDocument12 pagesNN - 2142 - A - Lid - Opener - System Manual Nido ShenandoahWill MolinaNo ratings yet

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- 1-2 Introduction Machinery SpacesDocument18 pages1-2 Introduction Machinery SpacesthebrilliantmistakescribdNo ratings yet

- Safety Valve - 118CSS SpecificationDocument2 pagesSafety Valve - 118CSS SpecificationManuel Pimentel Del Campo100% (1)

- 귀하면접 기출문제Document15 pages귀하면접 기출문제Suzane HormilladaNo ratings yet

- Laminated Veneer Lumber: Kerto® LVL Beams, Headers, Rafters and Columns For Floor and Roof Applications. Usa VersionDocument16 pagesLaminated Veneer Lumber: Kerto® LVL Beams, Headers, Rafters and Columns For Floor and Roof Applications. Usa VersionJuan Manuel JorqueraNo ratings yet

- Slim WS BNT65 Valve Operation ManualDocument18 pagesSlim WS BNT65 Valve Operation ManualSamanthaNo ratings yet

- Light Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesDocument3 pagesLight Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesMuchamad Fajar NugrohoNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- PB 2461Document3 pagesPB 2461M Aamir AsgharNo ratings yet

- 2-2021 SierraMoeller NewProductFocus-1Document32 pages2-2021 SierraMoeller NewProductFocus-1Anonymous 6LI4fyjjNo ratings yet

- Bonfix Compression FittingsDocument8 pagesBonfix Compression FittingsmsiarovNo ratings yet

- INTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bDocument45 pagesINTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bMehdi Soltani0% (1)

- Montabert Blue LineDocument4 pagesMontabert Blue LineGeorge Kwamina Anaman0% (1)

- Netbow 1Document10 pagesNetbow 1Cindy ClarkNo ratings yet

- Netbow Installation ManualDocument10 pagesNetbow Installation ManualIgnacio RinaldiNo ratings yet

- Valley Dealer Customer: Agrolmos S.A. Agrolmos S.ADocument31 pagesValley Dealer Customer: Agrolmos S.A. Agrolmos S.AJesús Albert Leyva MarínNo ratings yet

- Wilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08Document7 pagesWilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08donsterthemonsterNo ratings yet

- Garbage Disposer FD3-125Document4 pagesGarbage Disposer FD3-125carlosorizabaNo ratings yet

- Catalago Hydraulic PDFDocument684 pagesCatalago Hydraulic PDFMarca ChristianNo ratings yet

- Binotto BrochureDocument2 pagesBinotto BrochureDony WijayaNo ratings yet

- PilotSystem Gas15Gal 1BBL - V5Document21 pagesPilotSystem Gas15Gal 1BBL - V5antonio alberto gutierrez suarezNo ratings yet

- Anti Vibration PadsDocument5 pagesAnti Vibration PadsNikhil RajanNo ratings yet

- Spreader BrommaDocument414 pagesSpreader BrommamaloxNo ratings yet

- MTC Attach A Puller SpecsDocument4 pagesMTC Attach A Puller SpecsCarlos MurilloNo ratings yet

- Drinking Systems For Broilers: Climate Housing Drinking FeedingDocument8 pagesDrinking Systems For Broilers: Climate Housing Drinking FeedingZama SinkalaNo ratings yet

- NSB enDocument28 pagesNSB enPablo GonzalezNo ratings yet

- User Instruction Manual Horizontal Lifeline System: Model Numbers: (See Inside Back Cover.)Document20 pagesUser Instruction Manual Horizontal Lifeline System: Model Numbers: (See Inside Back Cover.)arockiajijinsNo ratings yet

- VIBRATORY FEEDER & PERMANENT PLATE MAGNET (Apex)Document1 pageVIBRATORY FEEDER & PERMANENT PLATE MAGNET (Apex)kh lowNo ratings yet

- CC4 50 ACT Controller ManualDocument29 pagesCC4 50 ACT Controller ManualAyub SetiawanNo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Blue Line Hydraulic Breakers: Product RangeDocument6 pagesBlue Line Hydraulic Breakers: Product RangeChandra prakash Jangid0% (1)

- CBS-880 Instruction Manual 2013 DougCareDocument39 pagesCBS-880 Instruction Manual 2013 DougCareMike PandeyNo ratings yet

- Fittings BookDocument26 pagesFittings Bookmotrenko123No ratings yet

- 1384 3942 00 en General Arrangement Drawing Omega 50 HZDocument32 pages1384 3942 00 en General Arrangement Drawing Omega 50 HZmohamed ghareebNo ratings yet

- PD-1250 Pressure Relief BackdraftDocument4 pagesPD-1250 Pressure Relief BackdraftDo MinhNo ratings yet

- XR3C 6 Element Triband Yagi 20-15-10MDocument18 pagesXR3C 6 Element Triband Yagi 20-15-10Msboonuy331No ratings yet

- Redsail C Series Cutting Plotter User ManualDocument28 pagesRedsail C Series Cutting Plotter User ManualjydproduccionNo ratings yet

- Comparison - Yoco Vs Brausse-1Document9 pagesComparison - Yoco Vs Brausse-1Catherine MahaNo ratings yet

- Spanco Freestanding Jib Cranes ManualDocument40 pagesSpanco Freestanding Jib Cranes ManualMarceloPolicastro100% (1)

- Body Point CatalogoDocument28 pagesBody Point Catalogojosuevargas17No ratings yet

- Redsail Cutting Plotter User Manual ADocument41 pagesRedsail Cutting Plotter User Manual AMindy Marshall100% (3)

- CBC in LHB CoachesDocument45 pagesCBC in LHB Coacheskaustav royNo ratings yet

- Aso Abf Series A4dm 20210624 SDocument2 pagesAso Abf Series A4dm 20210624 Sdroessaert_stijnNo ratings yet

- 4ZD34 1Document12 pages4ZD34 1Edwin Patricio Taco ChuseteNo ratings yet

- Semua Online Assesment Mira Sem 4Document6 pagesSemua Online Assesment Mira Sem 4Hamierul MohamadNo ratings yet

- Toy World CaseDocument9 pagesToy World Casesaurabhsaurs100% (1)

- Psychology and Economics: Evidence From The Field: Stefano DellavignaDocument58 pagesPsychology and Economics: Evidence From The Field: Stefano DellavignaRoberto PaezNo ratings yet

- Vip Voyager-Pro Strolly 79 360 JBK Check-In Suitcase - 31 InchDocument1 pageVip Voyager-Pro Strolly 79 360 JBK Check-In Suitcase - 31 InchPLUG - INNo ratings yet

- Tuga 2 Pengantar Akuntansi 1Document25 pagesTuga 2 Pengantar Akuntansi 1Akbar MansyNo ratings yet

- Tourism Traning Centre Politeknik Negeri Bali (TTC-PNB) : Executive SummaryDocument8 pagesTourism Traning Centre Politeknik Negeri Bali (TTC-PNB) : Executive SummaryBowoNo ratings yet

- Estimation and Professional Practices-Ca2Document3 pagesEstimation and Professional Practices-Ca2Rajen KoleyNo ratings yet

- DOS CabuniagDocument2 pagesDOS CabuniagAlex MolinyaweNo ratings yet

- CSS Preparatory ClassesDocument2 pagesCSS Preparatory Classeswaleedmirani37No ratings yet

- Water Efficiency ManagerDocument4 pagesWater Efficiency ManagerNigel AngNo ratings yet

- Lbs/hrs/units Peso: Fill Up Details (ENCODE) Encoding Area Standard CostDocument5 pagesLbs/hrs/units Peso: Fill Up Details (ENCODE) Encoding Area Standard CostBetchang AquinoNo ratings yet

- BT4 4Document1 pageBT4 4JasNo ratings yet

- Columbia County Property Transfers April 5-11Document2 pagesColumbia County Property Transfers April 5-11augustapressNo ratings yet

- Test Bank For Essentials of Economics 6th Edition by MankiwDocument24 pagesTest Bank For Essentials of Economics 6th Edition by MankiwKatieSanchezikpq100% (44)

- BSE Member (Jaipur)Document40 pagesBSE Member (Jaipur)Prayank JainNo ratings yet

- Weighted Index Numbers Are Also of Two TypesDocument4 pagesWeighted Index Numbers Are Also of Two TypesSumit BainNo ratings yet

- E StatementpdfDocument3 pagesE StatementpdfgarrettloehrNo ratings yet

- Column Buckling - Inelastic: A Long TopicDocument43 pagesColumn Buckling - Inelastic: A Long TopicKishore BhatNo ratings yet

- Struktur Organisasi RHBDocument1 pageStruktur Organisasi RHBiksan rmdnNo ratings yet

- Multiple Choice Questions and Answers On Globalisation and The Indian EconomyDocument3 pagesMultiple Choice Questions and Answers On Globalisation and The Indian EconomyAbhilash100% (1)

- LED For HighmastsDocument19 pagesLED For HighmastsMichael BenhuraNo ratings yet

- HDMANN Project ReferenceDocument50 pagesHDMANN Project Referenceandy limNo ratings yet

- Lowara VM TD en LDocument40 pagesLowara VM TD en LSagar ParmarNo ratings yet

- Math Question Bank (Bank Math Bible 3rd Edition) ADD (Part-5)Document63 pagesMath Question Bank (Bank Math Bible 3rd Edition) ADD (Part-5)mirajrahmancu100No ratings yet

- Hemchand Yadav Vishwavidyalaya, Durg (C.G.)Document1 pageHemchand Yadav Vishwavidyalaya, Durg (C.G.)G AaruNo ratings yet

- Deposit Slip-Examinations SectionDocument2 pagesDeposit Slip-Examinations SectionAhmad TaimurNo ratings yet

- LienTu, GioiTuDocument3 pagesLienTu, GioiTutgstestloginNo ratings yet

- PUT Question Paper - EAMDocument2 pagesPUT Question Paper - EAMMahesh ShendeNo ratings yet

- Vendor - Payment ReceiptDocument125 pagesVendor - Payment ReceiptdamithssNo ratings yet

1-4 AquaMist ULF G-Press piping systems

1-4 AquaMist ULF G-Press piping systems

Uploaded by

thebrilliantmistakescribdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-4 AquaMist ULF G-Press piping systems

1-4 AquaMist ULF G-Press piping systems

Uploaded by

thebrilliantmistakescribdCopyright:

Available Formats

If the you can read If the you can read

this Click on the this Click on the

icon to choose a icon to choose a

picture or picture or

Reset the slide. Reset the slide.

To Reset: Right click on the To Reset: Right click on the

slide thumbnail and select slide thumbnail and select

‘reset slide’ or choose the ‘reset slide’ or choose the

‘Reset’ button on the ‘Home’ ‘Reset’ button on the ‘Home’

ribbon (next to the font ribbon (next to the font

choice box) choice box)

AquaMist ULF, G-Press Piping Systems

Water Mist Piping Systems

© Copyright Johnson Controls. All rights reserved.

1 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Tyco AquaMist G-Press Piping Systems

© Copyright Johnson Controls. All rights reserved.

2 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited. 2

AquaMist ULF (Low Pressure)

System Supply

Pumps Valves G-Press Nozzles

© Copyright Johnson Controls. All rights reserved.

3 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

General, G-Press Piping System

Tyco Fire Suppression & Building Products is proud to offer our valued customers

a complete piping system for a Sprinkler Fire Protection installation.

The Grinnell® G-PressTM Piping System offers a broad piping system solution for

all kind of sprinkler (water mist) installations.

The G-Press Fittings and Tubes are backed by a 10 years limited

warranty after delivery date. Products replaced according the terms of guarantee

will have the same period of warranty as the original supplied products.

Damage as a result of wrong assembly or improper use of G-Press will not be

compensated!

G-Press fittings and Tubes are FM, VdS and LPCB approved and specific

assembly tools should be used accordingly.

If other products or tools are used the warranty will not be valid anymore

© Copyright Johnson Controls. All rights reserved.

4 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Piping system

• 316 Stainless Steel

• Quick Installation

• Clean Installation

• Light weight

• No heat

• 10 year warranty

• One tool Installation

• ISO 9001 QA

• C-Factor 140

© Copyright Johnson Controls. All rights reserved.

5 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Working principle of the G-Press-fitting

The connection between the tube and fitting is created by pressure

using a pressing tool.

The packing sleeve is deformed and adapts to the surface of the

tube, which is then pressed in turn against the sealing rings on the

surface of the fitting. This ensures the sealing effect and prevents

the tube from slipping out.

All G-PressTM fittings are produced with the "M“ pressing contour.

© Copyright Johnson Controls. All rights reserved.

6 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

“M” Pressing Profile

M-Profile (G-press)

Impressing on:

3 points on O-ring bead

1 side next to the bead on the fitting

© Copyright Johnson Controls. All rights reserved.

7 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Identification Pipes

Stainless steel 1.4401:

G-Press stainless steel 1.4401, DN../

diam x wall thickness mm,

16.0 bar, VdS <FM>, batch number,

production date

G-Press™ stainless steel 1.4401, DN50/54 x 1.5 mm, 16.0 bar, VdS G4090002, <FM>, batch number, production date

G-Press™ stainless steel 1.4521, DN50/54 x 1.5 mm, 16.0 bar, <FM>, batch number, production date

© Copyright Johnson Controls. All rights reserved.

8 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Piping Systems

© Copyright Johnson Controls. All rights reserved.

9 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Nozzle Fittings

• Fixed Nozzle fitting options

• Adjustable Nozzle fitting.

40 mm installation flexibility! (L)

An alternative to flexible hoses

© Copyright Johnson Controls. All rights reserved.

10 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Fast-Flex hoses

Flexible hose assemblies (TFP 720)

• YB281500

© Copyright Johnson Controls. All rights reserved.

11 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

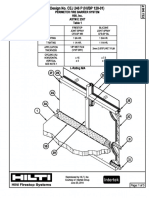

Support types

Stainless Steel piping systems

• UNI-S03 (28mm pipe)

• UNI-S08 (54mm pipe)

Note: no approval

© Copyright Johnson Controls. All rights reserved.

12 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

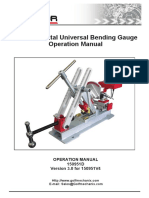

G-Press Tooling oct 2019

NOVOPRESS ACO 203BT

NOVOPRESS ACO 203BT

ACO203BT NOVOPRESS ACO 203BT battery operated

BATT03 G-Press™ Battery for use with ACO 203BT & 403BT (18 V / 3,0 Ah)

P28-203 ACO203 Press jaw for 28mm

P54-203 ACO203 Snap On HP Press Collar for 54mm

ZB203 ZB203 ACO203 adapter for 35 - 54mm

MARKER1554 Pipe marker for sizes 15-54mm

DEBUR1554 Hand deburr tool for sizes 15-54mm

© Copyright Johnson Controls. All rights reserved.

13 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Tooling oct 2019

ACO 203BT

Dimensions Up to to 54mm

Power Supply 18 V / 3.0 Ah

Power Consumption 450 W

Piston Force 32 kN

Piston Stroke 40mm

Dimensions (L x W x H) 387 x 75 x 111mm

Weight 2.8 KG

80 / 160 pressing cycles (depending

Battery Capacity

on dimension and material)

Approx. 30 min / 60 min depending

Charging time

on battery capacity

© Copyright Johnson Controls. All rights reserved.

14 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Tooling oct 2019

NOVOPRESS ACO 403BT

NOVOPRESS ACO 403BT

ACO403BT NOVOPRESS ACO 403BT battery operated (76.1 - 88.9 - 108MM)

BATT03 G-Press™ Battery for use with ACO 203BT & 403BT (18 V / 3,0 Ah)

P76-403 ACO403 Snap On HP Press Collar for 76.1mm

P89-403 ACO403 Snap On HP Press Collar for 89mm

P108-403 ACO403 Snap On HP Press Collar for 108mm

© Copyright Johnson Controls. All rights reserved.

15 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Tooling oct 2019

ACO 403BT

Dimensions Up to 108mm

Power Supply 18 V / 3.0 Ah / 5.0 Ah

Power Consumption 450 W

Piston Force 120 kN

Piston Stroke 60mm

Dimensions (L x W x H) 650 x 95 x 320mm

Weight 13 KG

20 / 30 pressing cycles (depending

Battery Capacity

on dimension and material)

Approx. 60 min / 120 min depending

Charging time

on battery capacity

© Copyright Johnson Controls. All rights reserved.

16 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Installation Instructions

© Copyright Johnson Controls. All rights reserved.

17 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited. Safer. Smarter. Tyco.TM 17

Installation instructions

After the measurements have been taken the G-

Press tube can be cut to size with a tube cutter,

fine-toothed handsaw or electric saw, suitable for

the pipe material. Cut at right angle.

The pipe has to be cut right through properly rather

than breaking it before it has been completely cut, to

avoid risk of corrosion.

Please check if pipe ends are smooth.

Do not use oil cooled saws, abrasive wheels or flame cutting

© Copyright Johnson Controls. All rights reserved.

18 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Installation instructions

Carefully deburr the pipe ends, both internally and

externally using a manual or electric deburring tool,

to avoid the O-ring being damaged during the pipe

insertion into the G-Press fitting.

It must be ensured at all times that the tube ends

are radial and even rounded.

To ensure a reliable and properly made connection

the pipe must be inserted at a certain depth into the

press fitting. This insertion depth must be marked

using a suitable marking tool and must remain

visible on the pipe after the connection is pressed to

identify any movement before or after pressing.

© Copyright Johnson Controls. All rights reserved.

19 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Installation instructions

Before assembly, the press fitting must be checked

to ensure that it has a proper functioning & correctly

positioned sealing ring. The tube, press fitting and

O-ring should be examined for foreign matter (e.g.

dirt,burrs), which should be removed if necessary.

Before the pressing operation the fitting or the tube

is inserted as far as the marked insertion depth

while being rotated slightly and pressed in an axial

direction at the same time. Water or soap may be

used as lubricant but never use oil or grease.

© Copyright Johnson Controls. All rights reserved.

20 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Installation instructions

Select the right tool for the intended application. For sizes 22 and 28 mm, use jaws.

For sizes 35 mm and up, use the intended collars.

The slot of the pressing jaw/collar must be positioned exactly around the press

fitting’s formed end. Pressing must be carried out only once and the press process

should not be interrupted.

To optimise installation time, first assemble several fittings with the

pipes and then G-Press them.

© Copyright Johnson Controls. All rights reserved.

21 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Installation instructions

© Copyright Johnson Controls. All rights reserved.

22 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Minimum distances and insertion depth

Marking the distance A is necessary in order to insure

that the tube has not been pushed out of the fitting

during the pressing procedure for the different

connections. dmin

Check the minimum clearances before pressing. A

© Copyright Johnson Controls. All rights reserved.

23 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Minimum distances when handling tools

© Copyright Johnson Controls. All rights reserved.

24 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Bending

Depending on the system, it may be necessary to bend the tube during

installation. For this, commercially available manual, hydraulic or electric

bending tools with the corresponding bending segments are used. The

suitability of the bending tool is defined by the manufacturer.

Due to the danger of corrosion the pipe must not be bent in combination

with a heat source!

Minimum Bending radius:

Stainless Steel : Rmin = 3½ x D (for OD max. 28 mm)

© Copyright Johnson Controls. All rights reserved.

26 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Threaded connections

For Stainless Steel threads hemp or other sealing materials

not containing chlorides can be used. Teflon® may not be

used.

For threaded connections we recommend that the pressed connections

should not be subjected to a load. Tightening of threaded connections

should preferably be performed before pressing (with an exception for

Tees when mounting the sprinkler)

© Copyright Johnson Controls. All rights reserved.

27 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Fixed Sprinkler Systems

When the G-PressTM Piping System is used it should also be ensured

that no loads can fall on to the tube network under normal conditions or

in the case of a fire;

for example ventilation ducts and cable trays must not be installed above

the sprinkler tubes.

© Copyright Johnson Controls. All rights reserved.

28 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Pressure Testing

The pipelines belonging to the sprinkler system must be subjected to a

pressure test according to valid guidelines, for example EN 12845 lasting

at least two hours.

During the test a pressure (measured at the alarm valves) corresponding

to 1.5 times the permitted positive operating pressure- but at least 15 bar

- must be maintained. This pressure test is a check of both the strength

and tightness of the system.

© Copyright Johnson Controls. All rights reserved.

29 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Pressure Testing

G-PRESS™ PASSIVE LEAK MONITORING (PLM) SEALING RING

The G-Press™ fittings up to 54 mm are supplied with an EPDM Passive

Leak Monitoring (PLM) O-ring. This O-ring ensures leakages during

pressurization of the system of all un-pressed connections.

Technical data of the PLM EPDM sealing ring:

Material: EPDM

Colour: Black

Coating: Silicone-free

Min./max. temperature: -35ºC till +130ºC

Max. operating pressure: 16 bar

© Copyright Johnson Controls. All rights reserved.

30 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Pressure Testing

Leak detection for non pressed fittings

• Non pressed connections will leak during pressure test

• Forgotten pressing easy to recognize

• Prevents installation mistakes

Reliability

• No leaking fittings in a press system

• After pressing guaranteed water- and air tight

• Strong and lasting solution

© Copyright Johnson Controls. All rights reserved.

31 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

G-Press Piping Systems

• G-Press piping systems should be installed by technicians

who are trained and certified by Tyco.

• Pipe and fitting quantity are the installers / distributor’s

responsibility.

© Copyright Johnson Controls. All rights reserved.

32 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

Questions?

© Copyright Johnson Controls. All rights reserved.

33 Johnson Controls—Public. Any unauthorized use, copying or distribution is strictly prohibited.

You might also like

- Diagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)Document1,605 pagesDiagramas Electricos Audi A4 B9 8W - EWD (Desde Julio de 2015)javier borrego0% (1)

- Support Items: Panasonic Factory Solutions Co., LTDDocument48 pagesSupport Items: Panasonic Factory Solutions Co., LTDMelchiades OliveiraNo ratings yet

- Hitachi Seal KitDocument2 pagesHitachi Seal Kitlabeddu0% (1)

- Topworx DXP - Installation and ConfigurationDocument52 pagesTopworx DXP - Installation and ConfigurationJames Dawe100% (1)

- Unisab III Industrial Refrigeration Package Controller: Ultimate FlexibilityDocument7 pagesUnisab III Industrial Refrigeration Package Controller: Ultimate Flexibilityandrew.golovanNo ratings yet

- Ipac Drop TestDocument7 pagesIpac Drop TestSUNIL KUMARNo ratings yet

- SVP Brochure 106 PDFDocument4 pagesSVP Brochure 106 PDFLuis CarlosNo ratings yet

- Hose, Tube & Connection Fittings Catalogue: JSG Industrial SystemsDocument20 pagesHose, Tube & Connection Fittings Catalogue: JSG Industrial Systemsagung wijayaNo ratings yet

- MKT Product Catalog 2019Document64 pagesMKT Product Catalog 2019Üstün Onur BaktırNo ratings yet

- Sumner WeldingDocument48 pagesSumner WeldingfELIPENo ratings yet

- Ficha Tecnica FlujometroDocument2 pagesFicha Tecnica FlujometroTatiana Mejías SeguraNo ratings yet

- 1-3 FM AquaMist ULF Machinery Spaces (JCI 11-2019)Document20 pages1-3 FM AquaMist ULF Machinery Spaces (JCI 11-2019)thebrilliantmistakescribdNo ratings yet

- Lifting Clamps - Camlok (2012) PDFDocument16 pagesLifting Clamps - Camlok (2012) PDFPernando SagaNo ratings yet

- Datasheet A480Document2 pagesDatasheet A480Mustafa Lagha100% (1)

- NN - 2142 - A - Lid - Opener - System Manual Nido ShenandoahDocument12 pagesNN - 2142 - A - Lid - Opener - System Manual Nido ShenandoahWill MolinaNo ratings yet

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- 1-2 Introduction Machinery SpacesDocument18 pages1-2 Introduction Machinery SpacesthebrilliantmistakescribdNo ratings yet

- Safety Valve - 118CSS SpecificationDocument2 pagesSafety Valve - 118CSS SpecificationManuel Pimentel Del Campo100% (1)

- 귀하면접 기출문제Document15 pages귀하면접 기출문제Suzane HormilladaNo ratings yet

- Laminated Veneer Lumber: Kerto® LVL Beams, Headers, Rafters and Columns For Floor and Roof Applications. Usa VersionDocument16 pagesLaminated Veneer Lumber: Kerto® LVL Beams, Headers, Rafters and Columns For Floor and Roof Applications. Usa VersionJuan Manuel JorqueraNo ratings yet

- Slim WS BNT65 Valve Operation ManualDocument18 pagesSlim WS BNT65 Valve Operation ManualSamanthaNo ratings yet

- Light Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesDocument3 pagesLight Conveyor Belts SAG-8E 07: Main Industry Segments Applications Special FeaturesMuchamad Fajar NugrohoNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- PB 2461Document3 pagesPB 2461M Aamir AsgharNo ratings yet

- 2-2021 SierraMoeller NewProductFocus-1Document32 pages2-2021 SierraMoeller NewProductFocus-1Anonymous 6LI4fyjjNo ratings yet

- Bonfix Compression FittingsDocument8 pagesBonfix Compression FittingsmsiarovNo ratings yet

- INTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bDocument45 pagesINTEGRATED OEM GENERAL ELASTOMER CATALOG - 1 2020bMehdi Soltani0% (1)

- Montabert Blue LineDocument4 pagesMontabert Blue LineGeorge Kwamina Anaman0% (1)

- Netbow 1Document10 pagesNetbow 1Cindy ClarkNo ratings yet

- Netbow Installation ManualDocument10 pagesNetbow Installation ManualIgnacio RinaldiNo ratings yet

- Valley Dealer Customer: Agrolmos S.A. Agrolmos S.ADocument31 pagesValley Dealer Customer: Agrolmos S.A. Agrolmos S.AJesús Albert Leyva MarínNo ratings yet

- Wilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08Document7 pagesWilkerson Filter Model B08-02-FKG0 Spec Sheet 9EM-B08donsterthemonsterNo ratings yet

- Garbage Disposer FD3-125Document4 pagesGarbage Disposer FD3-125carlosorizabaNo ratings yet

- Catalago Hydraulic PDFDocument684 pagesCatalago Hydraulic PDFMarca ChristianNo ratings yet

- Binotto BrochureDocument2 pagesBinotto BrochureDony WijayaNo ratings yet

- PilotSystem Gas15Gal 1BBL - V5Document21 pagesPilotSystem Gas15Gal 1BBL - V5antonio alberto gutierrez suarezNo ratings yet

- Anti Vibration PadsDocument5 pagesAnti Vibration PadsNikhil RajanNo ratings yet

- Spreader BrommaDocument414 pagesSpreader BrommamaloxNo ratings yet

- MTC Attach A Puller SpecsDocument4 pagesMTC Attach A Puller SpecsCarlos MurilloNo ratings yet

- Drinking Systems For Broilers: Climate Housing Drinking FeedingDocument8 pagesDrinking Systems For Broilers: Climate Housing Drinking FeedingZama SinkalaNo ratings yet

- NSB enDocument28 pagesNSB enPablo GonzalezNo ratings yet

- User Instruction Manual Horizontal Lifeline System: Model Numbers: (See Inside Back Cover.)Document20 pagesUser Instruction Manual Horizontal Lifeline System: Model Numbers: (See Inside Back Cover.)arockiajijinsNo ratings yet

- VIBRATORY FEEDER & PERMANENT PLATE MAGNET (Apex)Document1 pageVIBRATORY FEEDER & PERMANENT PLATE MAGNET (Apex)kh lowNo ratings yet

- CC4 50 ACT Controller ManualDocument29 pagesCC4 50 ACT Controller ManualAyub SetiawanNo ratings yet

- 4LA SB Longitudinal Sway Brace AttachmentDocument3 pages4LA SB Longitudinal Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Blue Line Hydraulic Breakers: Product RangeDocument6 pagesBlue Line Hydraulic Breakers: Product RangeChandra prakash Jangid0% (1)

- CBS-880 Instruction Manual 2013 DougCareDocument39 pagesCBS-880 Instruction Manual 2013 DougCareMike PandeyNo ratings yet

- Fittings BookDocument26 pagesFittings Bookmotrenko123No ratings yet

- 1384 3942 00 en General Arrangement Drawing Omega 50 HZDocument32 pages1384 3942 00 en General Arrangement Drawing Omega 50 HZmohamed ghareebNo ratings yet

- PD-1250 Pressure Relief BackdraftDocument4 pagesPD-1250 Pressure Relief BackdraftDo MinhNo ratings yet

- XR3C 6 Element Triband Yagi 20-15-10MDocument18 pagesXR3C 6 Element Triband Yagi 20-15-10Msboonuy331No ratings yet

- Redsail C Series Cutting Plotter User ManualDocument28 pagesRedsail C Series Cutting Plotter User ManualjydproduccionNo ratings yet

- Comparison - Yoco Vs Brausse-1Document9 pagesComparison - Yoco Vs Brausse-1Catherine MahaNo ratings yet

- Spanco Freestanding Jib Cranes ManualDocument40 pagesSpanco Freestanding Jib Cranes ManualMarceloPolicastro100% (1)

- Body Point CatalogoDocument28 pagesBody Point Catalogojosuevargas17No ratings yet

- Redsail Cutting Plotter User Manual ADocument41 pagesRedsail Cutting Plotter User Manual AMindy Marshall100% (3)

- CBC in LHB CoachesDocument45 pagesCBC in LHB Coacheskaustav royNo ratings yet

- Aso Abf Series A4dm 20210624 SDocument2 pagesAso Abf Series A4dm 20210624 Sdroessaert_stijnNo ratings yet

- 4ZD34 1Document12 pages4ZD34 1Edwin Patricio Taco ChuseteNo ratings yet

- Semua Online Assesment Mira Sem 4Document6 pagesSemua Online Assesment Mira Sem 4Hamierul MohamadNo ratings yet

- Toy World CaseDocument9 pagesToy World Casesaurabhsaurs100% (1)

- Psychology and Economics: Evidence From The Field: Stefano DellavignaDocument58 pagesPsychology and Economics: Evidence From The Field: Stefano DellavignaRoberto PaezNo ratings yet

- Vip Voyager-Pro Strolly 79 360 JBK Check-In Suitcase - 31 InchDocument1 pageVip Voyager-Pro Strolly 79 360 JBK Check-In Suitcase - 31 InchPLUG - INNo ratings yet

- Tuga 2 Pengantar Akuntansi 1Document25 pagesTuga 2 Pengantar Akuntansi 1Akbar MansyNo ratings yet

- Tourism Traning Centre Politeknik Negeri Bali (TTC-PNB) : Executive SummaryDocument8 pagesTourism Traning Centre Politeknik Negeri Bali (TTC-PNB) : Executive SummaryBowoNo ratings yet

- Estimation and Professional Practices-Ca2Document3 pagesEstimation and Professional Practices-Ca2Rajen KoleyNo ratings yet

- DOS CabuniagDocument2 pagesDOS CabuniagAlex MolinyaweNo ratings yet

- CSS Preparatory ClassesDocument2 pagesCSS Preparatory Classeswaleedmirani37No ratings yet

- Water Efficiency ManagerDocument4 pagesWater Efficiency ManagerNigel AngNo ratings yet

- Lbs/hrs/units Peso: Fill Up Details (ENCODE) Encoding Area Standard CostDocument5 pagesLbs/hrs/units Peso: Fill Up Details (ENCODE) Encoding Area Standard CostBetchang AquinoNo ratings yet

- BT4 4Document1 pageBT4 4JasNo ratings yet

- Columbia County Property Transfers April 5-11Document2 pagesColumbia County Property Transfers April 5-11augustapressNo ratings yet

- Test Bank For Essentials of Economics 6th Edition by MankiwDocument24 pagesTest Bank For Essentials of Economics 6th Edition by MankiwKatieSanchezikpq100% (44)

- BSE Member (Jaipur)Document40 pagesBSE Member (Jaipur)Prayank JainNo ratings yet

- Weighted Index Numbers Are Also of Two TypesDocument4 pagesWeighted Index Numbers Are Also of Two TypesSumit BainNo ratings yet

- E StatementpdfDocument3 pagesE StatementpdfgarrettloehrNo ratings yet

- Column Buckling - Inelastic: A Long TopicDocument43 pagesColumn Buckling - Inelastic: A Long TopicKishore BhatNo ratings yet

- Struktur Organisasi RHBDocument1 pageStruktur Organisasi RHBiksan rmdnNo ratings yet

- Multiple Choice Questions and Answers On Globalisation and The Indian EconomyDocument3 pagesMultiple Choice Questions and Answers On Globalisation and The Indian EconomyAbhilash100% (1)

- LED For HighmastsDocument19 pagesLED For HighmastsMichael BenhuraNo ratings yet

- HDMANN Project ReferenceDocument50 pagesHDMANN Project Referenceandy limNo ratings yet

- Lowara VM TD en LDocument40 pagesLowara VM TD en LSagar ParmarNo ratings yet

- Math Question Bank (Bank Math Bible 3rd Edition) ADD (Part-5)Document63 pagesMath Question Bank (Bank Math Bible 3rd Edition) ADD (Part-5)mirajrahmancu100No ratings yet

- Hemchand Yadav Vishwavidyalaya, Durg (C.G.)Document1 pageHemchand Yadav Vishwavidyalaya, Durg (C.G.)G AaruNo ratings yet

- Deposit Slip-Examinations SectionDocument2 pagesDeposit Slip-Examinations SectionAhmad TaimurNo ratings yet

- LienTu, GioiTuDocument3 pagesLienTu, GioiTutgstestloginNo ratings yet

- PUT Question Paper - EAMDocument2 pagesPUT Question Paper - EAMMahesh ShendeNo ratings yet

- Vendor - Payment ReceiptDocument125 pagesVendor - Payment ReceiptdamithssNo ratings yet