Professional Documents

Culture Documents

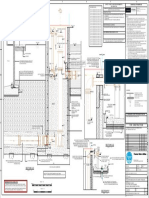

COMMENT ON MAWARI VIKASH TRUST,M50,DESIGN_edited

COMMENT ON MAWARI VIKASH TRUST,M50,DESIGN_edited

Uploaded by

Ashif AkhtarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COMMENT ON MAWARI VIKASH TRUST,M50,DESIGN_edited

COMMENT ON MAWARI VIKASH TRUST,M50,DESIGN_edited

Uploaded by

Ashif AkhtarCopyright:

Available Formats

Mix Design Report

Date : 09.04.2024

Submitted to : MAWARI VIKASH TRUST

Site Address : RAJGANJ

Ref. No. : FCR / DNB / 2024 / 027

Design Data :

1. Grade of Concrete : M50

SLUMP: ON ACCOUNT OF THE LONG DISTANCES OVER WHICH CONCRETE

2. Type of Concrete : R.C.C 0 ] NEEDS TO BE CARRIED FROM BATCHING PLANT/RMC PLANT, THE

3. Maximum Size of Aggregates : 20 mm CONCRETE MIX IS GENERALLY DESIGNED FOR A HIGHER SLUMP INITIALLY

THAN THE SLUMP REQUIRED AT THE TIME OF PLACING. THE INITIAL SLUMP

4. Degree of Quality Control : Very Good VALUE SHALL DEPEND ON THE DISTANCE OF TRANSPORT AND LOSS OF

SLUMP WITH TIME.

5. Exposure Condition : Moderate

RETENTION TIME: MAY BE ALLOWED FROM THE TIME OF WATER MIXING

6. Slump of Concrete ( mm ) : 125 + 25 After 3:00 hrs TILL THE PLACING OF CONCRETE. BUT IN NO CASE THE RETENTION TIME

SHOULD BE DESIGNED FOR MORE THAN 3 HOURS.

7. Concrete confirms to : IS 456 : 2000 & IS 10262 : 2019

8. Minimum cementitious content : 300 Kg [ As per Table No 5, IS 456 : 2000 ]

THIS REFERS FOR M25 ONLY !

9. Maximum w/cm ratio : 0.50 [ As per Table No 5, IS 456 : 2000 ]

10. Method of placement : PUMP / MANUAL

TYPE OF CEMENT SHOULD

Test Data for Materials : BE MENTIONED.

1. Brand & Type of Cement : NUVOCO / AMBUJA / ULTRATECH OPC

[ Confirming

53 to IS 269 : 2015 ] IS 269:2015 REFERS OPC.

2. Specific Gravity of Cement : 3.15 Source : [ ]

3. Specific Gravity of Aggregate ( SSD Condition )

Coarse Aggregate ( 20 mm ) : 2.82 Source : [ GOLABARI ]

Coarse Aggregate ( 10 mm ) : 2.82

Fine Aggregate ( River Sand ) : 2.66 Source : [ BARAKAR ]

4. Water Absorption of Aggregate

Coarse Aggregate ( 20 mm ) : 0.92%

Coarse Aggregate ( 10 mm ) : 0.92%

Fine Aggregate ( River Sand ) : 1.16%

5. Brand of Admixture : FC ESTEEMA 2001 Source : [ West Bengal ]

Type of Admixture : Superplasticizer [ Confirms to IS 9103 : 2007 and ASTM C-494 : 1981 ( Type – G ) ]

Dosage of Admixture : 0.90% by weight of cementitious content .

6. Specific Gravity of Fly Ash : 2.20 Source : [ CHANDRAPURA DVC]

7. Sieve Annalysis :

A ) Coarse Aggregate :

Analysis of Coarse Aggregate IS Limit as

IS Sieve Size Percentage of Different Fractions

Fraction per Table

I II I II Remarks

(mm) Total 7 , IS 383 :

20 mm 10 mm 60% 40% 100% 2016

20 85.7 100 51.4 40.0 91.4 90 - 100

1.6 89.8 1.0 35.9 36.9 25 - 55 Confirming to

10

Table 7 of IS

4.75 0.4 4.4 0.2 1.8 2.0 0 - 10 383:2016

2.36 0 0.7 0 0.3 0.3 -

B ) Fine Aggregate : Confirming to grading ZONE II of Table 9 of IS 383 : 2016

RABI SANKAR NATH

QC Incharge

Mix Design Report

Date : 09.04.2024

Target Mean Strength of Concrete :

Target Mean Strength of Concrete

f ' ck = f ck + 1.65 S

or

f ' ck = f ck + X , Whichever is higher .

f ' ck = Target avgerage compressive strength at 28 days ,

f ck = Characteristic compressive strength at 28 days ,

S = Standard Deviation

X = Factor based on grade of concrete .

From Table 1 of IS 10262 : 2019 , Value of factor X = 6.5 N/mm2

From Table 2 of IS 10262 : 2019 , standard deviation , S = 5.0 N/mm2

Therefore , Target mean using both equations , that is

f ' ck = f ck + 1.65 S = 50 + 1.65 X 5.0 = 58.25 N/mm2

Where f ' ck = f ck + X = 50 + 6.5 = 56.50 N/mm2

The higher value is to be adopted . Therefore , target average compressive strength is , f ' ck = 58.25 N/mm2

Selection of Water Cementitious Ratio ( w/cm ):

As per Table 5 , IS 456 : 2000 , maximum water cementitious ratio permisible = 0.50

Based on Experience we adopt water cementitious ratio as = 0.30 OKAY. LOWER THE W/C HIGHER THE

DURABILITY. BUT THE COARSE

0.30 < 0.50 , Hence O.K AGGREGATE MUST BE ANGULAR AS PER

CLAUSE 5.3 FROM IS 10262-2019. HOPE THE

EXPERIENCE ALSO CONSIDERED THE

Selection of Water Content : LOCAL ATMOSPHERIC TEMPARATURE!

As per Table 4 ,IS 10262 : 2019 Maximum water content for MSA 20 mm = 186 Kg ( for 50 mm Slump )

Hence , Estimated water content for 175 mm Slump = 214 Kg

As super plasticizer is used, the water content can be reduced up to 26 % and above .

Based on Lab Trials , corrected free water content for the mix is = 168 Kg

Calculation of Cementitious Content :

Water Cementitious ratio = 0.30

Cementitios content = 560 Kg/m3 > 300 Kg/m3 , Hence , O.K

Cement content = 450 Kg/m3

ACCEPTED.

Fly Ash content = 110 Kg/m3

From Table 5 of IS 456 : 2000 , minimum cementitious content for Moderate Exposure condition = 300 kg/m3

RABI SANKAR NATH

QC Incharge

Mix Design Report

Date : 09.04.2024

Proportion of volume of Coarse Aggregate and Fine Aggregate Content :

From Table 5, IS 10262 :2019 ,volume of coarse aggregate corresponding to 20 mm size aggregate and fine aggregate of ZONE II

For water cementitious ratio of 0.50 = 0.62 , Adopted water – cementitious ratio is = 0.30

Therefore corrected proportion of volume of coarse aggregate for w/cm ratio of 0.30 = 0.66

Considering higher workability, coarse aggregate volume need to reduce by 10% [ Based on Experience ]

Therefore , volume of Coarse aggregate = 0.594

Volume of Fine aggregate = 0.406

Mix Calculation as per IS 10262 : 2019 :

The mix Calculation per unit Volume of concrete shall be follows :

A ) Volume of Concrete = 1 m 3

B ) Volume of entrapped air in wet concrete = 0.010 m3

Mass of Cement 1

C ) Absolute volume of Cement = X

Specific Gravity of Cement 1000

450 1

= X = 0.143 m3

3.15 1000

Mass of Fly Ash 1

D ) Absolute volume of Fly Ash = X

Specific Gravity of Water 1000

110 1

= X = 0.050 m3

2.20 1000

Mass of Water 1

E ) Absolute volume of Water = X

Specific Gravity of Water 1000

168 1

= X = 0.168 m3

1.00 1000

F ) Absolute volume of Chemical Mass of Chemical Admixture 1

= X

Admixture Specific Gravity of Chemical Admixture 1000

5.04 1

= X = 0.0048 m3

1.05 1000

G ) Volume of All in Aggregate = [ A – ( B+C+D+E+F )]

= [ 1- ( 0.010 + 0.143 + 0.050 + 0.168 + 0.0048 )]

= 0.624 m3

H ) Weighted Average Specific Gravity of Coarse Aggregate

= ( % of 20mm Aggregate X Specific Gravity of 20mm Aggregate + % of 10mm Aggregate X Specific Gravity of 10mm Aggregate )

= ( 60% X 2.820 + 40% X 2.820 ) = 2.820

I ) Mass of Coarse Aggregate = G X Volume of Coarse Aggregate X Wt. Average Specific Gravity of Coarse Aggregate X 1000

= 0.6243 X 0.594 X 2.82 X 1000

= 1045.8 Kg

# Mass of 20 mm Aggregate = [ 1046 X 60% ] = 627.5 Kg

# Mass of 10 mm Aggregate = [ 1046 X 40% ] = 418.3 Kg

RABI SANKAR NATH

QC Incharge

Mix Design Report

Date : 09.04.2024

J ) Mass of Fine Aggregate = G X Volume of Fine Aggregate X Specific Gravity of Fine Aggregate X 1000

( River Sand )

= 0.624 X 0.406 X 2.66 X 1000

= 674.3 Kg

Adjustment for absorption by aggregates:

Coarse Aggregate 20 mm = 627.5 X 0.92% = 5.77

Coarse Aggregate 10 mm = 418.3 X 0.92% = 3.85

Fine Aggregate River Sand = 674.3 X 1.16% = 7.82

Total Water for Absorption of Aggregates = 17.4 Kg/ m3

Total water to be used including absorbed water = 168 + 17.4 = 185 Kg/ m3

Mix Proportion for 1 CuM: SSD Mix Dry Mix Design ( Trial Mix 1 )

Cement = 450 = 450 Kg/ m3

OKAY, BUT THE RATIO OF

Fly Ash = 110 = 110 Kg/ m3

FINE : COARSE IS 1:1.55, IT MAY

Coarse aggregate 20 mm = 627 - 5.8 = 622 Kg/ m3 BE REDUCED TO 1.5 ONLY

Coarse aggregate 10 mm = 418 - 3.8 = 414 Kg/ m3 ENSURING LESS ENTRAPPED AIR

Fine aggregate River Sand = 674 - 7.8 = 666 Kg/ m3 HENCE BUG HOLE APPEARANCE.

Total Water = 168 + 17.4 = 185 Kg/m3

Admixture = 5.04 = 5.04 Kg/ m3 SILICA FUMES? ISN'T IT IS

Total wt = 2453 Kg/ m3

MISSING IN THE CONCRETE MIX

WHICH MAY BE ASSUMED AS A

NECESSARY INGREDIENT FOR

Two More trials were carried out having variation of + 10 % of water cement ratio in the laboratory. HIGHER GRADES OF CONCRETE.

Results of Trial Mix

Average 7 days Cube Average 28 days Cube Slump

Trial Mix No. W/C Ratio compressive strength compressive strength (

After 3:00 hrs

( Mpa ) Mpa )

1 0.3 47.5 59.2 130

- - - - -

- - - - -

Remarks : Based on result obtain regarding Slump & the compressive strength at 7 days and 28 days.

The observations & test results mentioned above are based on a Lab trial conducted at firstchoice readymix Plant Lab.

The results may vary in actual situation. However the test results of actual concrete will conform to the requirements of IS

or as specified.

Note : Necessary moisture correction needs to be taken during production at batching plant.

Note -The per cum content mentioned in Kg may vary during production , for Cement upto (+/- 2%) and for other

materials upto (+/- 3%) as per IS 4926 : 2003 (Annex E , Clause no 9.1.2 & 9.1.3 )without prior information to the

customer and without effecting the actual character of the product. Redosing of admixture up to 0.25% can be done at site

if workability is found lower than requirement. Design Mix specified by customer. REDOSING OF EITHER ADMIXTURE

OR WATER IS NOT PERMISSIBLE AT

THE SITE AS IT MAY LEAD

THE PROPOSED MIX DESIGN MUST BE VETTED BY ANY WELL SIGNIFICANT CHARECTERISTIC

CHANGE AND ALSO THE CONTROL

RECOGNISED GOVERNMENT INSTITUTE LIKE IIT ON THE RETENTION TIME AS PER

CLAUSE NO 5.2.2 IS 4926.2003.

EVERYTHING MUST BE MADE AT

THE PLANT ONLY.

RABI SANKAR NATH

QC Incharge

You might also like

- Ubc 1973Document700 pagesUbc 1973adfadNo ratings yet

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- C40 Concrete Mix DesignDocument2 pagesC40 Concrete Mix DesignIsaiahogeda50% (2)

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument6 pagesTest Report: M/S Abhi Engg Corporation PVT LTDImran Khan100% (1)

- Tm-22 m35 RCCDocument19 pagesTm-22 m35 RCCVeera ManiNo ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- Mix Design M-35 MCDocument15 pagesMix Design M-35 MCRana MahatoNo ratings yet

- M35 Bhole ConstructionDocument6 pagesM35 Bhole ConstructionBIPL REPORT100% (1)

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument10 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- Design of Concrete Mix of M30 Grade: Report Prepared ForDocument5 pagesDesign of Concrete Mix of M30 Grade: Report Prepared ForGuru PrasathNo ratings yet

- S.E.C M35 PIle Birla Gold Cement 1042 UDocument5 pagesS.E.C M35 PIle Birla Gold Cement 1042 UBIPL REPORTNo ratings yet

- Client National Highways Authority of India Authority Engineer Epc ContractorDocument9 pagesClient National Highways Authority of India Authority Engineer Epc ContractorDeepakNo ratings yet

- TM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Document9 pagesTM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Gopinath kNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- CF 1000Document4 pagesCF 1000Anonymous 3eHGEDbxNo ratings yet

- m25 Mix DesignDocument7 pagesm25 Mix Design98675No ratings yet

- Design Mix m40Document4 pagesDesign Mix m40SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- IVS Industries M35 50% Crushed Sand GGBSDocument8 pagesIVS Industries M35 50% Crushed Sand GGBSImran KhanNo ratings yet

- Trail Mix M37-AccropodeDocument36 pagesTrail Mix M37-AccropodeKeerti Bongu50% (2)

- Mix Design FormatDocument18 pagesMix Design FormatChandan MondalNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- 3 Concrete Mix DesignDocument28 pages3 Concrete Mix DesignPraveen BhandariNo ratings yet

- Laboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)Document8 pagesLaboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)SubhadipNo ratings yet

- Laboratory Test Report: Faculty of Engineering & TechnologyDocument6 pagesLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- Principles of Concrete Mix Design ACCDocument8 pagesPrinciples of Concrete Mix Design ACCSunil ReddyNo ratings yet

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- Mix Designs PFADocument8 pagesMix Designs PFAasif razaNo ratings yet

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- Mix Design - New Code Format 2019 - M-25Document7 pagesMix Design - New Code Format 2019 - M-25Snehashish BasuNo ratings yet

- Kampli MVS Material Test 11.12.2021Document18 pagesKampli MVS Material Test 11.12.2021I'm AJNo ratings yet

- Korugud MVS Material Test 11.12.2021Document18 pagesKorugud MVS Material Test 11.12.2021I'm AJNo ratings yet

- Designed Concrete MixDocument6 pagesDesigned Concrete MixniceseshaNo ratings yet

- Test Report: M/S Abhi Engg Corporation PVT LTDDocument61 pagesTest Report: M/S Abhi Engg Corporation PVT LTDimran khanNo ratings yet

- Mix Design M - 30 NEWDocument6 pagesMix Design M - 30 NEWRajeev ReddyNo ratings yet

- Test Report of BricksDocument1 pageTest Report of BricksKumar Abhishek67% (3)

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- Teletech M20 Design MixDocument4 pagesTeletech M20 Design MixATC SurveyNo ratings yet

- RCC M-25, Ultratech, OPC43Document5 pagesRCC M-25, Ultratech, OPC43Sanjoy RoyNo ratings yet

- 7.AppNote 3.2 CementDocument4 pages7.AppNote 3.2 CementlehuylapNo ratings yet

- M10 PDFDocument3 pagesM10 PDFranjeet Chikane50% (2)

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Mix Designm30str wc-.43 Cem-360kgDocument10 pagesMix Designm30str wc-.43 Cem-360kgBscpl Repalle to EeppurpalemNo ratings yet

- Sanjog Chhetri Sapkota CVP441Document15 pagesSanjog Chhetri Sapkota CVP441sanjog chhetriNo ratings yet

- Asphalt Mix Design, WadriboDocument85 pagesAsphalt Mix Design, WadriboAbuBakerNo ratings yet

- TWT M50 Mix DesignDocument6 pagesTWT M50 Mix DesignStupidity TalksNo ratings yet

- Mix Design of Semi Dense Bituminous ConcreteDocument18 pagesMix Design of Semi Dense Bituminous ConcreteRahul GoyalNo ratings yet

- Project ReportDocument7 pagesProject ReportAnimesh JainNo ratings yet

- Emsu0138Document2 pagesEmsu0138Mohanned KhalidNo ratings yet

- Mix DesignDocument71 pagesMix DesignManikyaMayankNo ratings yet

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDocument84 pagesConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- Report Materials of SDII WDVI 464Document2 pagesReport Materials of SDII WDVI 464PARVEEN DUBEYNo ratings yet

- HASODocument1 pageHASOOkello StevenNo ratings yet

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Design Mix M 30Document4 pagesDesign Mix M 30SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Wit-Vm 250 MDocument24 pagesWit-Vm 250 MQCNo ratings yet

- Recommended Sheet: Authorised Signatory Pg. No. 1 of 5Document5 pagesRecommended Sheet: Authorised Signatory Pg. No. 1 of 5KA25 ConsultantNo ratings yet

- Analysis of Raft Pile Raft Foundation Using Safe Software IJERTV9IS070032 PDFDocument5 pagesAnalysis of Raft Pile Raft Foundation Using Safe Software IJERTV9IS070032 PDFKousalya MkNo ratings yet

- Estimation and Costing I.S 1200 Part 19Document14 pagesEstimation and Costing I.S 1200 Part 19nitinNo ratings yet

- Am2540 - Applied Mechanics Lab Solid Mechanics Lab ReportDocument13 pagesAm2540 - Applied Mechanics Lab Solid Mechanics Lab ReportAditya KoutharapuNo ratings yet

- of Final Year Project (2882) FinallDocument30 pagesof Final Year Project (2882) Finallbhattaraidipak101No ratings yet

- Civil Engineering Research PapersDocument6 pagesCivil Engineering Research Papersdwqdxttlg100% (1)

- CE New - FSTDocument1 pageCE New - FSTPavanNo ratings yet

- MR DampersDocument6 pagesMR DampersAnupam SonarNo ratings yet

- Maintenance ManualDocument20 pagesMaintenance ManualAbdulmuqtadetr AhmadiNo ratings yet

- Strength of Materials A Concise Textbook (2022)Document151 pagesStrength of Materials A Concise Textbook (2022)dian antiqueNo ratings yet

- LAKUSIC - Rail Traffic Noise and Vibration Mitigation Measures in Urban Areas - AhacDocument10 pagesLAKUSIC - Rail Traffic Noise and Vibration Mitigation Measures in Urban Areas - AhacGabriel BlancoNo ratings yet

- Types of Cement-1Document15 pagesTypes of Cement-1M.IDREES KhanNo ratings yet

- ConclusionDocument1 pageConclusionmacs_smac100% (3)

- Company OIL Saudi Arabian: Fine Sand or MarshDocument1 pageCompany OIL Saudi Arabian: Fine Sand or MarshMuhammad Fahmi MahmudNo ratings yet

- Level 1. EngineerDocument5 pagesLevel 1. EngineerDaniel mekete100% (1)

- Attachment PDFDocument19 pagesAttachment PDFjeroldscd0% (1)

- Cisc Handbook of Steel Construction 11 Edition, 3 Revised Printing 2017 Revisions List No. 2 - 4 October 2017Document6 pagesCisc Handbook of Steel Construction 11 Edition, 3 Revised Printing 2017 Revisions List No. 2 - 4 October 2017hetpinNo ratings yet

- Conversion of Diffusivity Equation Into Dimensionless Variable Form 1Document9 pagesConversion of Diffusivity Equation Into Dimensionless Variable Form 1Hasan AbidNo ratings yet

- Water - Dynamic and Kinematic ViscosityDocument3 pagesWater - Dynamic and Kinematic ViscosityManik KandanNo ratings yet

- Summary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoDocument32 pagesSummary of Cost For Ibef, Upcoming Office at 20Th Floor, STC Building Janpath, C.P. S.No Description of Item Page NoHEMANTNo ratings yet

- Soil Mechanics and Calculating Hydraulic Fracture Risk: June 2020Document8 pagesSoil Mechanics and Calculating Hydraulic Fracture Risk: June 2020stephenbttanNo ratings yet

- Project Report-8 JulyDocument300 pagesProject Report-8 JulyRoshan KejariwalNo ratings yet

- 1.boq - RC Work For Office (Part 3) - LattanavongDocument2 pages1.boq - RC Work For Office (Part 3) - LattanavongKu BờmNo ratings yet

- Pen-Channel Flow: When You Finish Reading This Chapter, You Should Be Able ToDocument68 pagesPen-Channel Flow: When You Finish Reading This Chapter, You Should Be Able To李建道No ratings yet

- 137-18 Appendix A - Project DrawingsDocument33 pages137-18 Appendix A - Project DrawingsDiego Martínez FernándezNo ratings yet

- Chapter 7: Serviceability Requirements: 7.2.1 Deflection ControlDocument21 pagesChapter 7: Serviceability Requirements: 7.2.1 Deflection ControlMohammed Ansar A MNo ratings yet

- Mme M1: Lesson 8Document17 pagesMme M1: Lesson 8r005w3ltNo ratings yet

- Fracture Mechanics Studies in Concrete Compounds - Hillemeier (1977) 2Document13 pagesFracture Mechanics Studies in Concrete Compounds - Hillemeier (1977) 2Dušan VajagićNo ratings yet

- Roofing and Waterproofing: Standard Terminology Relating ToDocument9 pagesRoofing and Waterproofing: Standard Terminology Relating ToRONALD MUELLERNo ratings yet

- Problem1 - Solution 1 - Design of SRCBDocument5 pagesProblem1 - Solution 1 - Design of SRCBRey Joseph IglesiaNo ratings yet