Professional Documents

Culture Documents

bombas

bombas

Uploaded by

Wilki SantanderCopyright:

Available Formats

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- G4 Hydrocyclone ManualDocument21 pagesG4 Hydrocyclone ManualANo ratings yet

- Power Plant Operation Vol-VDocument133 pagesPower Plant Operation Vol-Vsenthil03127793% (15)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control Engineering SupportDocument2 pagesWell Control Engineering SupportJorge Vásquez CarreñoNo ratings yet

- Substations Switchgear - Thermal Image ManualDocument2 pagesSubstations Switchgear - Thermal Image ManualLucia NunezNo ratings yet

- Thermography Application NotesDocument95 pagesThermography Application NotesGabor100% (1)

- Thermographic Scanning Fact SheetDocument3 pagesThermographic Scanning Fact SheetDines zNo ratings yet

- Thermalapplication Edu-Series PDFDocument95 pagesThermalapplication Edu-Series PDFTomi GánnNo ratings yet

- Camara Termografica Flir Con Pantilt para Deteccion Temprada de Incendios en Almacen de CarbonDocument2 pagesCamara Termografica Flir Con Pantilt para Deteccion Temprada de Incendios en Almacen de Carbonugui81No ratings yet

- FLIR AutomationBrochure - ENDocument16 pagesFLIR AutomationBrochure - ENimman4468No ratings yet

- Improve Flaring OperationsDocument4 pagesImprove Flaring Operationsaa dd qqNo ratings yet

- cadenasDocument2 pagescadenasWilki SantanderNo ratings yet

- Infrared ThermographyDocument15 pagesInfrared ThermographyreurriNo ratings yet

- Commissioning of Large Vacuum Systems: K. ZapfeDocument10 pagesCommissioning of Large Vacuum Systems: K. ZapfeLê Văn Thế QuangNo ratings yet

- Cost of Applying I RDocument4 pagesCost of Applying I RMishkat Immaculate100% (1)

- TigerTech PredictiveMaintenance 1Document2 pagesTigerTech PredictiveMaintenance 1Música BNo ratings yet

- Safety Is Money in The BankDocument3 pagesSafety Is Money in The BankArun KumarNo ratings yet

- Automation: Putting Thermal Imaging To Work For Your ApplicationDocument16 pagesAutomation: Putting Thermal Imaging To Work For Your ApplicationfasdfsdNo ratings yet

- FlareVIEW For Flare Stack Monitoring Rev01Document7 pagesFlareVIEW For Flare Stack Monitoring Rev01smnizamNo ratings yet

- Applying Infrared ThermographyDocument4 pagesApplying Infrared ThermographyJaya DiNo ratings yet

- Thermographic Survey As Part of A Predictive Maintenance ProgramDocument2 pagesThermographic Survey As Part of A Predictive Maintenance ProgramA.YOGAGURUNo ratings yet

- FLIR - Substation MonitoringDocument2 pagesFLIR - Substation Monitoringrony silvaNo ratings yet

- Power Plant OperationDocument148 pagesPower Plant Operationkeerthi dayarathna100% (2)

- Control System AdvancementsDocument15 pagesControl System AdvancementstungluongNo ratings yet

- Control & Instrumentation-1Document123 pagesControl & Instrumentation-1Ashish Vashisth100% (11)

- 2012-06 TurboMach ThermalGrowthDocument2 pages2012-06 TurboMach ThermalGrowthGilberto PérezNo ratings yet

- 2005snellpaper 1 PDFDocument12 pages2005snellpaper 1 PDFblem_0075No ratings yet

- Improve Refinery Production and Efficiency With Asset MonitoringDocument11 pagesImprove Refinery Production and Efficiency With Asset MonitoringVishwarajNo ratings yet

- Troubleshooting Rotating MachineryDocument5 pagesTroubleshooting Rotating Machineryroberdani12No ratings yet

- Loose or Corroded Electrical Connections: ThermalDocument2 pagesLoose or Corroded Electrical Connections: Thermalmario gallardoNo ratings yet

- Thermography in The Service Center - Nyberg - 0607Document42 pagesThermography in The Service Center - Nyberg - 0607andres monederoNo ratings yet

- Design Installation & Maintenance Guide For Electric TracingDocument20 pagesDesign Installation & Maintenance Guide For Electric Tracinghon choong chongNo ratings yet

- Vibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryDocument8 pagesVibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryFajar HidayatNo ratings yet

- Thermal Predictive Maintenance at A Coal PlantDocument3 pagesThermal Predictive Maintenance at A Coal PlantYugandhara Chakravarthy KancherlaNo ratings yet

- Introduction To Predictive MaintenanceDocument5 pagesIntroduction To Predictive MaintenanceM Ilyas MarwatNo ratings yet

- The Expert GuidebookDocument16 pagesThe Expert Guidebookescuadrian9043No ratings yet

- Compressor Trouble ShootingDocument41 pagesCompressor Trouble ShootingsyammcNo ratings yet

- Steam Turbine Maintenance Inspections or Repairs: Turbine Restart After MajorDocument3 pagesSteam Turbine Maintenance Inspections or Repairs: Turbine Restart After Majordreamboy87No ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsJohn BeaconNo ratings yet

- 2005 06 Emerging Technologies - Damper Diagnostics - FengDocument3 pages2005 06 Emerging Technologies - Damper Diagnostics - FengmeomeportabNo ratings yet

- M300 Temp Measurement App NoteDocument4 pagesM300 Temp Measurement App NoteMauricio GuanellaNo ratings yet

- Infrared Cameras Application DetailsDocument8 pagesInfrared Cameras Application DetailsEagle BangaloreNo ratings yet

- IR Windows AppNote Transformer USDocument3 pagesIR Windows AppNote Transformer UShugo2890No ratings yet

- Control & Inst - V-IDocument180 pagesControl & Inst - V-ISiva Kumar TutikaNo ratings yet

- Monitoring Strategy of LNG Reciprocating CompressorsDocument4 pagesMonitoring Strategy of LNG Reciprocating Compressorsalhumaid28No ratings yet

- By CSADocument3 pagesBy CSAbudiartoeliyantoNo ratings yet

- DELTA Solution Series Part 4 - Thermal Inspection of Solar PanelsDocument5 pagesDELTA Solution Series Part 4 - Thermal Inspection of Solar PanelsEagle BangaloreNo ratings yet

- Tunnel DamperDocument8 pagesTunnel DamperIvanNo ratings yet

- Ventilation - Electrical Rooms PDFDocument4 pagesVentilation - Electrical Rooms PDFvalentinlupascu33No ratings yet

- Monitoring Transformers: Application NoteDocument2 pagesMonitoring Transformers: Application NotebertovalenNo ratings yet

- ThermoregulationDocument64 pagesThermoregulationapi-3703371No ratings yet

- 174Document24 pages174Janko ArtukovićNo ratings yet

- Condition Based MaintenaceDocument27 pagesCondition Based MaintenaceRitwik AravindNo ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemssuhasNo ratings yet

- Fachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enDocument6 pagesFachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enGiovanni EsguerraNo ratings yet

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANNo ratings yet

- Analyzing Mechanical Systems Using Infrared ThermographyDocument9 pagesAnalyzing Mechanical Systems Using Infrared ThermographyGOPINATHNo ratings yet

- Monitoring Equipment Performance With Thermal ImagingDocument4 pagesMonitoring Equipment Performance With Thermal ImagingRachit SharmaNo ratings yet

- Contents : Unit - 6Document28 pagesContents : Unit - 6amit singhNo ratings yet

- CPTG007 - EN (Web)Document30 pagesCPTG007 - EN (Web)Abdullah AzzamNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 2022 Meat Alternative Poultry Seafood Executive SummaryDocument12 pages2022 Meat Alternative Poultry Seafood Executive SummaryWilki SantanderNo ratings yet

- Vacuum Coater EnglishDocument8 pagesVacuum Coater EnglishWilki SantanderNo ratings yet

- Alloy Hammermills 2021 F1Document2 pagesAlloy Hammermills 2021 F1Wilki SantanderNo ratings yet

- Swine Handbook Swine Handbook Nutrition & Feeds Nutrition & FeedsDocument3 pagesSwine Handbook Swine Handbook Nutrition & Feeds Nutrition & FeedsWilki SantanderNo ratings yet

- FB Cooler CBK and PCF DataDocument4 pagesFB Cooler CBK and PCF DataWilki SantanderNo ratings yet

- FB GB Combi Zone Dryer DataDocument8 pagesFB GB Combi Zone Dryer DataWilki SantanderNo ratings yet

- The Sweet Life For Diabetics: (Sweeteners)Document3 pagesThe Sweet Life For Diabetics: (Sweeteners)Wilki SantanderNo ratings yet

- Foreign Qualification RecognitionDocument2 pagesForeign Qualification RecognitionWilki SantanderNo ratings yet

- Extrusion Technology in The Production of Aquatic Feed: Konrad Munz, Buhler AG, SwitzerlandDocument19 pagesExtrusion Technology in The Production of Aquatic Feed: Konrad Munz, Buhler AG, SwitzerlandWilki SantanderNo ratings yet

- Walmart Kmart English June 2021Document3 pagesWalmart Kmart English June 2021Wilki SantanderNo ratings yet

- Haus Santrifuj EngDocument28 pagesHaus Santrifuj EngWilki SantanderNo ratings yet

- Seminar IngleseDocument119 pagesSeminar IngleseWilki SantanderNo ratings yet

- Your Guide To The New Brunswick Skilled Worker StreamDocument29 pagesYour Guide To The New Brunswick Skilled Worker StreamWilki SantanderNo ratings yet

- A Key Ingredient To Your Success.: Candidate Handbook 2018Document22 pagesA Key Ingredient To Your Success.: Candidate Handbook 2018Wilki SantanderNo ratings yet

- Australian MB Meal Nutritional ReviewDocument48 pagesAustralian MB Meal Nutritional ReviewWilki SantanderNo ratings yet

- China Brasil Partnership AgricultureDocument431 pagesChina Brasil Partnership AgricultureWilki SantanderNo ratings yet

- Application Sheet New PlantDocument7 pagesApplication Sheet New PlantWilki SantanderNo ratings yet

- Meat and Bone Meal - 1997Document4 pagesMeat and Bone Meal - 1997Wilki SantanderNo ratings yet

- MF2298Document44 pagesMF2298Wilki SantanderNo ratings yet

- Performance Test of Francis TurbineDocument6 pagesPerformance Test of Francis TurbineAbelBayartNo ratings yet

- Common RailDocument30 pagesCommon RailrowanNo ratings yet

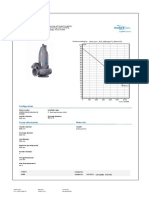

- Technical Specification: ConfigurationDocument7 pagesTechnical Specification: ConfigurationAhmedRamadanNo ratings yet

- GD755-5 FEN04876-01 PartbookDocument634 pagesGD755-5 FEN04876-01 Partbookdianrianto275No ratings yet

- Gea Hilge TP Centrifugal Pumps Us 170792Document6 pagesGea Hilge TP Centrifugal Pumps Us 170792German TchiliNo ratings yet

- Midterm Exam Answers 2-3-4Document7 pagesMidterm Exam Answers 2-3-4Aslıhan KayaNo ratings yet

- Uganda Standards Catalogue As of 30 June 2023-FinalDocument1,010 pagesUganda Standards Catalogue As of 30 June 2023-Finalchief.nytilNo ratings yet

- Influence of T-Shape Tip Clearance On Performance of A Mixed-Flow Pump.Document11 pagesInfluence of T-Shape Tip Clearance On Performance of A Mixed-Flow Pump.POOJA JAISWALNo ratings yet

- Jt8D Maintenance Advisory NoticeDocument4 pagesJt8D Maintenance Advisory Noticeamir ghaznaviNo ratings yet

- Safe and Efficient Flare Gas RecoveryDocument10 pagesSafe and Efficient Flare Gas RecoveryMike PowerNo ratings yet

- KITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFDocument16 pagesKITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFYulita Ika PawestriNo ratings yet

- 7100Document22 pages7100aniballllcNo ratings yet

- Pumps - Part B - 2019Document23 pagesPumps - Part B - 2019Sanda KinithiNo ratings yet

- 1 Open Loop Conrol: 1.1 Subgroup ControlDocument17 pages1 Open Loop Conrol: 1.1 Subgroup ControlMohammad Jahangir AlamNo ratings yet

- SERVICE WATER SYSTEM DESCRIPTION 服务水Document22 pagesSERVICE WATER SYSTEM DESCRIPTION 服务水کالرو تحریک اتحادNo ratings yet

- Repair Manual Gearbox: Doc. No. E4.08.16Document61 pagesRepair Manual Gearbox: Doc. No. E4.08.16Blaze123xNo ratings yet

- REDA Continuum LF Product Sheet - 7483196 - 01Document1 pageREDA Continuum LF Product Sheet - 7483196 - 01Andi PermanaNo ratings yet

- Sealing High-Speed Shafts in TurbomachineryDocument4 pagesSealing High-Speed Shafts in TurbomachineryimtiazNo ratings yet

- Aircooled Diesel Engine Above 20HPDocument8 pagesAircooled Diesel Engine Above 20HPMuthalaguNo ratings yet

- 2500C OP&SERV SN 665,680&upDocument130 pages2500C OP&SERV SN 665,680&upАлександр Романов100% (1)

- QSI Series: Instruction ManualDocument100 pagesQSI Series: Instruction ManualRAUL PEREZ NEGREIROSNo ratings yet

- FM Global Property Loss Prevention Data Sheets: 1.0 SCOPEDocument49 pagesFM Global Property Loss Prevention Data Sheets: 1.0 SCOPEBastián Leonardo Araneda HinojosaNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- Homogenization Is The: HomogenisationDocument5 pagesHomogenization Is The: Homogenisationabhi030689100% (5)

- EESIFLO International Pte LTDDocument30 pagesEESIFLO International Pte LTDAnish KarthikeyanNo ratings yet

- 4.ageing 01.01.21Document4,991 pages4.ageing 01.01.21Mukesh ManideepNo ratings yet

- 5 Liner Risk AssessmentDocument7 pages5 Liner Risk AssessmentAmr FathiNo ratings yet

- Kinetic PumpsDocument17 pagesKinetic Pumpsshady mohamedNo ratings yet

bombas

bombas

Uploaded by

Wilki SantanderCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

bombas

bombas

Uploaded by

Wilki SantanderCopyright:

Available Formats

Applications for Thermal Imagers

Pumps, fans and

compressors

Application Note

Pumps, fans, compressors and other motor-driven rotating

equipment are essential to manufacturing, commercial and

institutional enterprise, from fluid handling systems in petro-

chemical plants to large air comfort systems in shopping malls.

Thermography can also be

used together with other predic-

tive technologies such as oil

analysis, vibration monitoring

and ultrasound.

What to check?

While it is in operation and under

load, monitor rotating equipment

that is critical to your operations,

i.e., equipment whose failure

would threaten people, property

or production. Be sure to scan the

equipment’s drives—electric

motors and gearboxes (if any)—

and follow the guidelines for

monitoring these units spelled

out in earlier Fluke Application

Notes. Also, on pumps and fans,

get thermal profiles of the

housings— scans that are likely

Many facilities monitor this type Thermal imaging is especially to reveal any problems with

of equipment on a regular basis, useful for monitoring rotating bearings or seals —as well as

because often a simple problem equipment, since many impend- scans of shaft couplings or drive

like lubrication can be spotted ing failures are accompanied belts and sheaves. For a com-

and fixed inexpensively, before by overheating. This predictive pressor, use several images, if

the entire unit burns out. Such technique uses a handheld necessary, to get a thermal

strategies fall under the general thermal imager to capture profile of the entire unit.

heading of predictive mainte- two-dimensional images repre- *Apparent temperature can differ significantly

nance (PdM). senting the apparent* surface from actual temperature, due to the emissivity

of a material’s surface.

temperatures of equipment.

On compressors, belt slippage on cooler fans, shaft misalignment and bearing

problems will all appear as abnormal hot spots.

For more information on Thermal Imagers

go to your local Fluke web site.

What to look for? Vibration analysis and/or an What’s the potential

alignment check will confirm cost of failure?

In general, look for hot spots and the latter condition.

pay special attention to differ- Since a compressor is a “heat Because pumps, fans and com-

ences in temperature between machine”, a thermal imager can pressors are key to productivity

similar units operating under quite literally “see” a compressor in so many industries, it is diffi-

similar conditions. For example, work as compression produces cult to speak generally about

if a bearing in one fan in a bank heat while expansion cools2. To the cost to a company from the

of similar fans is running hotter check the efficiency of compres- failure of a critical unit. However,

than rest, the hotter one may be sors, look for belt slippage on a failed pump at one automotive

trending toward premature failure. cooler fans, shaft misalignment, facility cost more than €15,000

On a pump, a difference in bearing problems, and blocked to repair while lost labor costs

temperature along a seal or gas- or leaking valves. totaled €600 per minute and

ket is the “signature” of a failure. A good approach is to create lost production opportunities

A hot spot on the housing adja- a regular inspection route that amounted to €30,000 per

cent to a bearing may signal an includes all critical rotating minute3. Try developing similar

impending bearing failure, equipment. Then, save a thermal figures for a critical equipment

although the root cause probably image and associated data of failure in your operations. It may

will not be ascertainable from a each unit scanned on a computer help you justify thermal imaging

thermal image alone. Perhaps and track the measurements over to your managers.

there’s a lubrication problem or time. That way, you’ll have a

maybe misalignment in the drive. baseline for comparisons with Follow-up actions

An overheating bearing on a fan subsequent images. They will

Whenever you use a thermal

also signals a problem but a help you determine whether a imager and find a problem, use

thermal image of it alone is non- hot spot is unusual or not, and,

the associated software to

definitive. Again, the root cause following repairs, help you verify document your findings in a

could be lack of lubrication, the that the repairs were successful. report that includes a digital

wrong lubrication, drive mis-

photograph as well as a thermal

alignment or unbalance in the What represents a image. That’s the best way to

fan itself. Further investigation is

required.

“red alert?” communicate the problems you

Equipment conditions that pose a find and to suggest repairs. If a

Many industrial and most

safety risk should take the high- catastrophic failure appears

building-system fans are belt-

est repair priority. However, the imminent, the equipment must

driven, as are some pumps.

either be removed from service

According to one source1, a imminent failure of any critical

pump, fan or compressor repre- or repaired immediately.

belt-and-sheave drive that is

1From the Web site of John Snell &

designed and installed correctly sents a red alert. Consider using

Associates www.snellinfrared.com/tt/

generates very little heat, and key safety, maintenance and TT5_05%20Web%20Version.pdf.

the belt moving through the air operations personnel to quantify 2Go to www.gmrc.org/gmrc/2004finalpa-

tends to cool it to near ambient “warning” and “alarm” levels pers/Optimized%20Compressor%20Effi-

temperature. Overheating, for these assets. Then, you can ciency%20through%20Thermography.pdf.

3Source: the Web site of the Academy of

detected by thermography, set alarm levels for specific

Infrared Thermography, specifically at

reflects a problem with the equipment on your Fluke www.infraredmechanical.com/mechani-

drive’s design or installation, thermal imager 4. cal_5.html.

4Model depending.

perhaps mismatched belt and

sheaves or misalignment.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

An imaging tip: Fluke Europe B.V.

PO Box 1186, 5602 BD

Winds (or air currents inside) in excess of even a few miles per hour will Eindhoven, The Netherlands

reduce the surface temperatures you are seeing, causing real problems For more information call:

to seem less significant or even making them invisible. Inside plants air In the U.S.A. (800) 443-5853 or

currents are often 10-15MPH! Buy a good quality wind meter and record Fax (425) 446-5116

the wind speed when you record the apparent temperature. When you In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

must inspect in high convection situations, note all problems for a In Canada (800) 36-FLUKE or

follow-up inspection. Even those with small temperature increases may Fax (905) 890-6866

become critically hot when the airflow is reduced. From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2005 Fluke Corporation. All rights reserved.

Printed in U.S.A. 10/2005 2547428 Pub-ID 11063-eng

2 Fluke Corporation Thermal Applications: Pumps, fans and compressors

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- G4 Hydrocyclone ManualDocument21 pagesG4 Hydrocyclone ManualANo ratings yet

- Power Plant Operation Vol-VDocument133 pagesPower Plant Operation Vol-Vsenthil03127793% (15)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control Engineering SupportDocument2 pagesWell Control Engineering SupportJorge Vásquez CarreñoNo ratings yet

- Substations Switchgear - Thermal Image ManualDocument2 pagesSubstations Switchgear - Thermal Image ManualLucia NunezNo ratings yet

- Thermography Application NotesDocument95 pagesThermography Application NotesGabor100% (1)

- Thermographic Scanning Fact SheetDocument3 pagesThermographic Scanning Fact SheetDines zNo ratings yet

- Thermalapplication Edu-Series PDFDocument95 pagesThermalapplication Edu-Series PDFTomi GánnNo ratings yet

- Camara Termografica Flir Con Pantilt para Deteccion Temprada de Incendios en Almacen de CarbonDocument2 pagesCamara Termografica Flir Con Pantilt para Deteccion Temprada de Incendios en Almacen de Carbonugui81No ratings yet

- FLIR AutomationBrochure - ENDocument16 pagesFLIR AutomationBrochure - ENimman4468No ratings yet

- Improve Flaring OperationsDocument4 pagesImprove Flaring Operationsaa dd qqNo ratings yet

- cadenasDocument2 pagescadenasWilki SantanderNo ratings yet

- Infrared ThermographyDocument15 pagesInfrared ThermographyreurriNo ratings yet

- Commissioning of Large Vacuum Systems: K. ZapfeDocument10 pagesCommissioning of Large Vacuum Systems: K. ZapfeLê Văn Thế QuangNo ratings yet

- Cost of Applying I RDocument4 pagesCost of Applying I RMishkat Immaculate100% (1)

- TigerTech PredictiveMaintenance 1Document2 pagesTigerTech PredictiveMaintenance 1Música BNo ratings yet

- Safety Is Money in The BankDocument3 pagesSafety Is Money in The BankArun KumarNo ratings yet

- Automation: Putting Thermal Imaging To Work For Your ApplicationDocument16 pagesAutomation: Putting Thermal Imaging To Work For Your ApplicationfasdfsdNo ratings yet

- FlareVIEW For Flare Stack Monitoring Rev01Document7 pagesFlareVIEW For Flare Stack Monitoring Rev01smnizamNo ratings yet

- Applying Infrared ThermographyDocument4 pagesApplying Infrared ThermographyJaya DiNo ratings yet

- Thermographic Survey As Part of A Predictive Maintenance ProgramDocument2 pagesThermographic Survey As Part of A Predictive Maintenance ProgramA.YOGAGURUNo ratings yet

- FLIR - Substation MonitoringDocument2 pagesFLIR - Substation Monitoringrony silvaNo ratings yet

- Power Plant OperationDocument148 pagesPower Plant Operationkeerthi dayarathna100% (2)

- Control System AdvancementsDocument15 pagesControl System AdvancementstungluongNo ratings yet

- Control & Instrumentation-1Document123 pagesControl & Instrumentation-1Ashish Vashisth100% (11)

- 2012-06 TurboMach ThermalGrowthDocument2 pages2012-06 TurboMach ThermalGrowthGilberto PérezNo ratings yet

- 2005snellpaper 1 PDFDocument12 pages2005snellpaper 1 PDFblem_0075No ratings yet

- Improve Refinery Production and Efficiency With Asset MonitoringDocument11 pagesImprove Refinery Production and Efficiency With Asset MonitoringVishwarajNo ratings yet

- Troubleshooting Rotating MachineryDocument5 pagesTroubleshooting Rotating Machineryroberdani12No ratings yet

- Loose or Corroded Electrical Connections: ThermalDocument2 pagesLoose or Corroded Electrical Connections: Thermalmario gallardoNo ratings yet

- Thermography in The Service Center - Nyberg - 0607Document42 pagesThermography in The Service Center - Nyberg - 0607andres monederoNo ratings yet

- Design Installation & Maintenance Guide For Electric TracingDocument20 pagesDesign Installation & Maintenance Guide For Electric Tracinghon choong chongNo ratings yet

- Vibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryDocument8 pagesVibration Analysis of An Alstom Typhoon Gas Turbine Power Plant Related To Iran Oil IndustryFajar HidayatNo ratings yet

- Thermal Predictive Maintenance at A Coal PlantDocument3 pagesThermal Predictive Maintenance at A Coal PlantYugandhara Chakravarthy KancherlaNo ratings yet

- Introduction To Predictive MaintenanceDocument5 pagesIntroduction To Predictive MaintenanceM Ilyas MarwatNo ratings yet

- The Expert GuidebookDocument16 pagesThe Expert Guidebookescuadrian9043No ratings yet

- Compressor Trouble ShootingDocument41 pagesCompressor Trouble ShootingsyammcNo ratings yet

- Steam Turbine Maintenance Inspections or Repairs: Turbine Restart After MajorDocument3 pagesSteam Turbine Maintenance Inspections or Repairs: Turbine Restart After Majordreamboy87No ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsJohn BeaconNo ratings yet

- 2005 06 Emerging Technologies - Damper Diagnostics - FengDocument3 pages2005 06 Emerging Technologies - Damper Diagnostics - FengmeomeportabNo ratings yet

- M300 Temp Measurement App NoteDocument4 pagesM300 Temp Measurement App NoteMauricio GuanellaNo ratings yet

- Infrared Cameras Application DetailsDocument8 pagesInfrared Cameras Application DetailsEagle BangaloreNo ratings yet

- IR Windows AppNote Transformer USDocument3 pagesIR Windows AppNote Transformer UShugo2890No ratings yet

- Control & Inst - V-IDocument180 pagesControl & Inst - V-ISiva Kumar TutikaNo ratings yet

- Monitoring Strategy of LNG Reciprocating CompressorsDocument4 pagesMonitoring Strategy of LNG Reciprocating Compressorsalhumaid28No ratings yet

- By CSADocument3 pagesBy CSAbudiartoeliyantoNo ratings yet

- DELTA Solution Series Part 4 - Thermal Inspection of Solar PanelsDocument5 pagesDELTA Solution Series Part 4 - Thermal Inspection of Solar PanelsEagle BangaloreNo ratings yet

- Tunnel DamperDocument8 pagesTunnel DamperIvanNo ratings yet

- Ventilation - Electrical Rooms PDFDocument4 pagesVentilation - Electrical Rooms PDFvalentinlupascu33No ratings yet

- Monitoring Transformers: Application NoteDocument2 pagesMonitoring Transformers: Application NotebertovalenNo ratings yet

- ThermoregulationDocument64 pagesThermoregulationapi-3703371No ratings yet

- 174Document24 pages174Janko ArtukovićNo ratings yet

- Condition Based MaintenaceDocument27 pagesCondition Based MaintenaceRitwik AravindNo ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemssuhasNo ratings yet

- Fachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enDocument6 pagesFachartikel - Antriebstechnik - Belastungen Messen Und Bewerten - 16 07 2014 - enGiovanni EsguerraNo ratings yet

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANNo ratings yet

- Analyzing Mechanical Systems Using Infrared ThermographyDocument9 pagesAnalyzing Mechanical Systems Using Infrared ThermographyGOPINATHNo ratings yet

- Monitoring Equipment Performance With Thermal ImagingDocument4 pagesMonitoring Equipment Performance With Thermal ImagingRachit SharmaNo ratings yet

- Contents : Unit - 6Document28 pagesContents : Unit - 6amit singhNo ratings yet

- CPTG007 - EN (Web)Document30 pagesCPTG007 - EN (Web)Abdullah AzzamNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 2022 Meat Alternative Poultry Seafood Executive SummaryDocument12 pages2022 Meat Alternative Poultry Seafood Executive SummaryWilki SantanderNo ratings yet

- Vacuum Coater EnglishDocument8 pagesVacuum Coater EnglishWilki SantanderNo ratings yet

- Alloy Hammermills 2021 F1Document2 pagesAlloy Hammermills 2021 F1Wilki SantanderNo ratings yet

- Swine Handbook Swine Handbook Nutrition & Feeds Nutrition & FeedsDocument3 pagesSwine Handbook Swine Handbook Nutrition & Feeds Nutrition & FeedsWilki SantanderNo ratings yet

- FB Cooler CBK and PCF DataDocument4 pagesFB Cooler CBK and PCF DataWilki SantanderNo ratings yet

- FB GB Combi Zone Dryer DataDocument8 pagesFB GB Combi Zone Dryer DataWilki SantanderNo ratings yet

- The Sweet Life For Diabetics: (Sweeteners)Document3 pagesThe Sweet Life For Diabetics: (Sweeteners)Wilki SantanderNo ratings yet

- Foreign Qualification RecognitionDocument2 pagesForeign Qualification RecognitionWilki SantanderNo ratings yet

- Extrusion Technology in The Production of Aquatic Feed: Konrad Munz, Buhler AG, SwitzerlandDocument19 pagesExtrusion Technology in The Production of Aquatic Feed: Konrad Munz, Buhler AG, SwitzerlandWilki SantanderNo ratings yet

- Walmart Kmart English June 2021Document3 pagesWalmart Kmart English June 2021Wilki SantanderNo ratings yet

- Haus Santrifuj EngDocument28 pagesHaus Santrifuj EngWilki SantanderNo ratings yet

- Seminar IngleseDocument119 pagesSeminar IngleseWilki SantanderNo ratings yet

- Your Guide To The New Brunswick Skilled Worker StreamDocument29 pagesYour Guide To The New Brunswick Skilled Worker StreamWilki SantanderNo ratings yet

- A Key Ingredient To Your Success.: Candidate Handbook 2018Document22 pagesA Key Ingredient To Your Success.: Candidate Handbook 2018Wilki SantanderNo ratings yet

- Australian MB Meal Nutritional ReviewDocument48 pagesAustralian MB Meal Nutritional ReviewWilki SantanderNo ratings yet

- China Brasil Partnership AgricultureDocument431 pagesChina Brasil Partnership AgricultureWilki SantanderNo ratings yet

- Application Sheet New PlantDocument7 pagesApplication Sheet New PlantWilki SantanderNo ratings yet

- Meat and Bone Meal - 1997Document4 pagesMeat and Bone Meal - 1997Wilki SantanderNo ratings yet

- MF2298Document44 pagesMF2298Wilki SantanderNo ratings yet

- Performance Test of Francis TurbineDocument6 pagesPerformance Test of Francis TurbineAbelBayartNo ratings yet

- Common RailDocument30 pagesCommon RailrowanNo ratings yet

- Technical Specification: ConfigurationDocument7 pagesTechnical Specification: ConfigurationAhmedRamadanNo ratings yet

- GD755-5 FEN04876-01 PartbookDocument634 pagesGD755-5 FEN04876-01 Partbookdianrianto275No ratings yet

- Gea Hilge TP Centrifugal Pumps Us 170792Document6 pagesGea Hilge TP Centrifugal Pumps Us 170792German TchiliNo ratings yet

- Midterm Exam Answers 2-3-4Document7 pagesMidterm Exam Answers 2-3-4Aslıhan KayaNo ratings yet

- Uganda Standards Catalogue As of 30 June 2023-FinalDocument1,010 pagesUganda Standards Catalogue As of 30 June 2023-Finalchief.nytilNo ratings yet

- Influence of T-Shape Tip Clearance On Performance of A Mixed-Flow Pump.Document11 pagesInfluence of T-Shape Tip Clearance On Performance of A Mixed-Flow Pump.POOJA JAISWALNo ratings yet

- Jt8D Maintenance Advisory NoticeDocument4 pagesJt8D Maintenance Advisory Noticeamir ghaznaviNo ratings yet

- Safe and Efficient Flare Gas RecoveryDocument10 pagesSafe and Efficient Flare Gas RecoveryMike PowerNo ratings yet

- KITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFDocument16 pagesKITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFYulita Ika PawestriNo ratings yet

- 7100Document22 pages7100aniballllcNo ratings yet

- Pumps - Part B - 2019Document23 pagesPumps - Part B - 2019Sanda KinithiNo ratings yet

- 1 Open Loop Conrol: 1.1 Subgroup ControlDocument17 pages1 Open Loop Conrol: 1.1 Subgroup ControlMohammad Jahangir AlamNo ratings yet

- SERVICE WATER SYSTEM DESCRIPTION 服务水Document22 pagesSERVICE WATER SYSTEM DESCRIPTION 服务水کالرو تحریک اتحادNo ratings yet

- Repair Manual Gearbox: Doc. No. E4.08.16Document61 pagesRepair Manual Gearbox: Doc. No. E4.08.16Blaze123xNo ratings yet

- REDA Continuum LF Product Sheet - 7483196 - 01Document1 pageREDA Continuum LF Product Sheet - 7483196 - 01Andi PermanaNo ratings yet

- Sealing High-Speed Shafts in TurbomachineryDocument4 pagesSealing High-Speed Shafts in TurbomachineryimtiazNo ratings yet

- Aircooled Diesel Engine Above 20HPDocument8 pagesAircooled Diesel Engine Above 20HPMuthalaguNo ratings yet

- 2500C OP&SERV SN 665,680&upDocument130 pages2500C OP&SERV SN 665,680&upАлександр Романов100% (1)

- QSI Series: Instruction ManualDocument100 pagesQSI Series: Instruction ManualRAUL PEREZ NEGREIROSNo ratings yet

- FM Global Property Loss Prevention Data Sheets: 1.0 SCOPEDocument49 pagesFM Global Property Loss Prevention Data Sheets: 1.0 SCOPEBastián Leonardo Araneda HinojosaNo ratings yet

- The New Generation of Roto Drum Oil Skimmer 1995Document3 pagesThe New Generation of Roto Drum Oil Skimmer 1995arondaniel ocampoNo ratings yet

- Homogenization Is The: HomogenisationDocument5 pagesHomogenization Is The: Homogenisationabhi030689100% (5)

- EESIFLO International Pte LTDDocument30 pagesEESIFLO International Pte LTDAnish KarthikeyanNo ratings yet

- 4.ageing 01.01.21Document4,991 pages4.ageing 01.01.21Mukesh ManideepNo ratings yet

- 5 Liner Risk AssessmentDocument7 pages5 Liner Risk AssessmentAmr FathiNo ratings yet

- Kinetic PumpsDocument17 pagesKinetic Pumpsshady mohamedNo ratings yet