Professional Documents

Culture Documents

3M Marine Adhesive Sealant 5200

3M Marine Adhesive Sealant 5200

Uploaded by

夏斌Copyright:

Available Formats

You might also like

- Sikagard - 62Document4 pagesSikagard - 62bassem kooliNo ratings yet

- Concrete Finishing and Coating Procedure, Rev.1Document10 pagesConcrete Finishing and Coating Procedure, Rev.1moytabura96100% (1)

- GIFT - Gabion Slope Protection BOQ and Cost EstimateDocument11 pagesGIFT - Gabion Slope Protection BOQ and Cost EstimateshahqazwsxNo ratings yet

- 3M Scotch Weld Epoxy Adhesive DP125 TranslucentDocument6 pages3M Scotch Weld Epoxy Adhesive DP125 TranslucentasinghNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- 3M Neoprene High Performance Rubber & Gasket Adhesive 1300LDocument6 pages3M Neoprene High Performance Rubber & Gasket Adhesive 1300LIventNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- 3M VHB Tape GPH 160GFDocument6 pages3M VHB Tape GPH 160GFasinghNo ratings yet

- Jotamastic 87 PDFDocument6 pagesJotamastic 87 PDFGurdeep Sungh AroraNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- TDS - Jotamastic 80 PrimerDocument6 pagesTDS - Jotamastic 80 PrimershahoorhussainNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Jotamastic 80 Technical Data SheetDocument6 pagesJotamastic 80 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Thermal Transfer Polyester Label Material: Technical Data May 2017Document5 pagesThermal Transfer Polyester Label Material: Technical Data May 2017Sebastian BaenaNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- TDS 24100 Penguard WF Euk GBDocument6 pagesTDS 24100 Penguard WF Euk GBpradnyeyNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- LLDPE Exxon 1001BUDocument2 pagesLLDPE Exxon 1001BULily LiNo ratings yet

- BL4 - HM 8255Document1 pageBL4 - HM 8255ShahryarNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Computer Imprintable Polyester Label MaterialDocument4 pagesComputer Imprintable Polyester Label MaterialyoganandvNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Belzona 1821: Product Specification SheetDocument2 pagesBelzona 1821: Product Specification SheetAlex BravoNo ratings yet

- Exceed™ 1018KB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 1018KB: Metallocene Polyethylene ResinHafiani HichamNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Jimmys GothiqueNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- TDS 525 Jotamastic 87 GF Euk GBDocument5 pagesTDS 525 Jotamastic 87 GF Euk GBhidayatNo ratings yet

- Exceed S 9243MLDocument2 pagesExceed S 9243MLzhen liuNo ratings yet

- 323+ Data SheetDocument5 pages323+ Data SheetSergioNo ratings yet

- Exxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene Resinabdelmoumene djafer beyNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Total 2287 HDPE Bimodal Film ResinDocument2 pagesTotal 2287 HDPE Bimodal Film ResinshuvoNo ratings yet

- Technical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinPaul TsaiNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- TDS Lldpe 1001buDocument2 pagesTDS Lldpe 1001buAmirun AeimanzzNo ratings yet

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- Technical Data Sheet: ApplicationsDocument2 pagesTechnical Data Sheet: ApplicationsJuan Sebastián Fernández RamírezNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBManuel LópezNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Exceed™ XP 8784 Series: Performance PolymerDocument2 pagesExceed™ XP 8784 Series: Performance PolymerMaram YasserNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- TDS 523 Jotamastic 87 Aluminium Euk GBDocument6 pagesTDS 523 Jotamastic 87 Aluminium Euk GBBarathan RajandranNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Exxon LD 100 BWDocument2 pagesExxon LD 100 BWAli KüçükNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Environmental Analysis and Technology for the Refining IndustryFrom EverandEnvironmental Analysis and Technology for the Refining IndustryNo ratings yet

- X4C35J1-03GDocument6 pagesX4C35J1-03G夏斌No ratings yet

- electronics-11-02660-v2Document9 pageselectronics-11-02660-v2夏斌No ratings yet

- 5200FCDocument5 pages5200FC夏斌No ratings yet

- RF Signal Analysis With - App Bro - en - 3609 9057 92 - v0100Document12 pagesRF Signal Analysis With - App Bro - en - 3609 9057 92 - v0100夏斌No ratings yet

- Obsolete Product(s) - Obsolete Product(s) : RF Power Amplifier Using 1 X Pd54003LDocument11 pagesObsolete Product(s) - Obsolete Product(s) : RF Power Amplifier Using 1 X Pd54003L夏斌No ratings yet

- 11 Foldable Bridge 2017 PrintDocument48 pages11 Foldable Bridge 2017 PrintChockalingam AthilingamNo ratings yet

- Decorative Exterior Paints: Performance & Binder Design Trends in Asia PacificDocument27 pagesDecorative Exterior Paints: Performance & Binder Design Trends in Asia PacificAPEX SONNo ratings yet

- How To Put Up CovingDocument7 pagesHow To Put Up CovingBob KowalskiNo ratings yet

- IRC 16-2008 Prime Coat Tack Coat SpecificationDocument7 pagesIRC 16-2008 Prime Coat Tack Coat SpecificationVenkat Talupula100% (1)

- Nason Industrial Brochure 2015 Singles PDFDocument4 pagesNason Industrial Brochure 2015 Singles PDFsidneidecarvalhoNo ratings yet

- Objectra SE Website InfoDocument4 pagesObjectra SE Website Infotroyel99No ratings yet

- Aac Spec 377003Document25 pagesAac Spec 377003JakesNo ratings yet

- TDS Grip A310 ProjectDocument2 pagesTDS Grip A310 Projecteng.abdullrahmanNo ratings yet

- Metal Roof and Wall SystemDocument44 pagesMetal Roof and Wall SystemMihaela SurduNo ratings yet

- DPLF Epoxy Primer: Features Compatible SurfacesDocument4 pagesDPLF Epoxy Primer: Features Compatible SurfacesRobert StarkNo ratings yet

- WarehouseDocument51 pagesWarehouseAnonymous q0irDXlWAm100% (2)

- Installation Procedure Ceilcote 25 LiningDocument5 pagesInstallation Procedure Ceilcote 25 LiningNadia AgdikaNo ratings yet

- PRESENTATIONDocument23 pagesPRESENTATIONIyad Abu-FirasNo ratings yet

- Motorised Drift TrikeDocument52 pagesMotorised Drift TrikeDylan ChysykNo ratings yet

- Sigmaweld™ 120: Product Data SheetDocument4 pagesSigmaweld™ 120: Product Data Sheetjaime San Martin PulgarNo ratings yet

- Exposed Steel: ArchitecturallyDocument16 pagesExposed Steel: Architecturallykip099No ratings yet

- PRC-9002 - Rev - HDocument20 pagesPRC-9002 - Rev - HHenryNo ratings yet

- Intercare 123Document4 pagesIntercare 123Trịnh Minh KhoaNo ratings yet

- Sikaflex Construction: 1-C Polyurethane Sealant For Building JointsDocument4 pagesSikaflex Construction: 1-C Polyurethane Sealant For Building JointsJay PadamaNo ratings yet

- Seajet 015 Underwater PrimerDocument2 pagesSeajet 015 Underwater PrimerAleš NovakNo ratings yet

- End Closure Location: Technical Data Series Industry Alert SDIDocument14 pagesEnd Closure Location: Technical Data Series Industry Alert SDIAdlanAbushibaNo ratings yet

- Vol. IIDocument61 pagesVol. IIkarimNo ratings yet

- BAL Micromax SealantDocument3 pagesBAL Micromax Sealantannayya.chandrashekar Civil EngineerNo ratings yet

- E 9114 - Sika Unitherm 7854Document3 pagesE 9114 - Sika Unitherm 7854didapopescuNo ratings yet

- Waterproofing SystemsDocument24 pagesWaterproofing SystemsKC OcumenNo ratings yet

- Junbond High Quality Acetic Silicone Sealant Technical Data Sheet!Document3 pagesJunbond High Quality Acetic Silicone Sealant Technical Data Sheet!Junbond silicone sealantNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- NY2.NV ZZ FIB ZZ ZZ XX MT LA 00006 - 00 Material Submittal For EPDM Rubber External Surfacing - CompressedDocument226 pagesNY2.NV ZZ FIB ZZ ZZ XX MT LA 00006 - 00 Material Submittal For EPDM Rubber External Surfacing - CompressedKenneth Paul FulmaranNo ratings yet

3M Marine Adhesive Sealant 5200

3M Marine Adhesive Sealant 5200

Uploaded by

夏斌Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3M Marine Adhesive Sealant 5200

3M Marine Adhesive Sealant 5200

Uploaded by

夏斌Copyright:

Available Formats

English

Last Revision Date: May, 2022

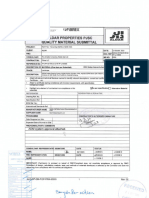

Technical Data Sheet

3M™ Marine Adhesive Sealant 5200

Product Details Regulatory Info/SDS

Product Description

3M™ Marine Adhesive Sealant 5200 is a one-part polyurethane that chemically reacts with moisture to deliver strong,

flexible bonds. It has excellent adhesion to wood, gelcoat, and fiberglass. It forms a watertight, weather-resistant seal on

joints and boat hardware, above and below the waterline. In addition, its flexibility allows for dissipation of stress caused

by shock, vibration, swelling or shrinking.

Product Features

• Tough/flexible polyurethane polymer

• One component, moisture curing

• Long working time

• Bonds dissimilar materials

• Non-shrinking

• Adheres to a wide variety of substrates

Technical Information Note

The following technical information and data should be considered representative or typical only and should not be used

for specification purposes.

Typical Uncured Physical Properties

Attribute Name Value

Density 11.3 lb/gal

Consistency Caulkable, non-sag paste

Typical Mixed Physical Properties

Temperature: 22 °C (72 °F)

Attribute Name Environmental Condition Value

Tack Free Time 12 h

Tack Free Time 90%RH 4h

Rate of Cure 3 mm/5 d (1 to 8 in/5 d)

Typical Physical Properties

Attribute Name Value

White

Color Black

Mahogany

Solids Content by Weight 97 %

3M™ Marine Adhesive Sealant 5200 | English-US 1/4

Typical Cured Characteristics

Attribute Name Test Method Value

Shore A Hardness ASTM C661 68

Typical Performance Characteristics

Overlap Shear Strength

Temperature: 22 °C (72 °F)

Substrate Value

Teak 35 kg/cm² (500 lb/in²) ¹

Pine 48 kg/cm² (680 lb/in²) ¹

Oak 39 kg/cm² (545 lb/in²) ¹

Maple 46 kg/cm² (655 lb/in²) ¹

Fir 49 kg/cm² (700 lb/in²) ¹

Mahogany 40 kg/cm² (560 lb/in²) ¹

Stainless Steel 25 kg/cm² (350 lb/in²) ¹

Aluminum 28 kg/cm² (390 lb/in²) ¹

Brass 33 kg/cm² (470 lb/in²) ¹

Bronze 18 kg/cm² (250 lb/in²) ¹

Copper 14 kg/cm² (200 lb/in²) ¹

Lead 7.5 kg/cm² (100 lb/in²) ¹

Zinc (Galvanized) 34 kg/cm² (480 lb/in²) ¹

Acrylic (PMMA) 15 kg/cm² (215 lb/in²) ¹

Nylon 12 kg/cm² (175 lb/in²) ¹

ABS 16 kg/cm² (230 lb/in²) ¹

Cold Rolled Steel 38 kg/cm² (530 lb/in²) ¹

Polycarbonate (PC) 27 kg/cm² (380 lb/in²) ¹

Fiber-Reinforced Plastic 26 kg/cm² (360 lb/in²) ¹

¹ 1in overlap specimens 0.093in thick.

Cohesive – Adhesive/Sealant fails before adhesive/sealant releases from substrate. Desired failure mode.

Adhesive Failure – Adhesive/Sealant releases from substrate.

Attribute Name Test Method Value

Long Term Temperature Resistance 90 °C (190 °F) ¹

Minimum Long Term Temperature

-40 °C (-40 °F) ¹

Resistance

Tensile Strength ASTM D412 4.8 MPa (700 lb/in²)

¹ Long Term (day, weeks)

Handling/Application Information

Directions for Use

Surface Preparation:

There are waxes, coatings, sealers, greases, oils and other contaminants used in the marine industry, making it very

important to clean all surfaces to be bonded before applying 3MTM Adhesive Sealant 5200. Recommended procedures

include cleaning with 3MTM General Purpose Adhesive Cleaner* 08984. Abrading the surface with 180- to 200-grit

abrasive before cleaning will enhance the bond strength.

Cut the plastic nozzle tip to the desired bead size. Puncture the seal in nozzle end of the cartridge and screw the plastic

nozzle in place. Remove the bottom end seal of cartridge and place the cartridge in a caulk gun dispenser. Apply 5200

to the seam or part to be bonded. Position parts and tool material to desired appearance. Tooling of adhesive can be

accomplished by using a tongue depressor. If a finger is used, rubber gloves are recommended. Remove excess with

General Purpose Adhesive Cleaner 08984 or suitable solvent.

3M™ Marine Adhesive Sealant 5200 | English-US 2/4

*When using solvents, use in a well ventilated area. Extinguish all sources of ignition in the work area and observe

product directions for use and precautionary measures. Refer to product label and MSDS for further precautions. Always

pre-test solvent to ensure it is compatible with substrates.

Local and federal air quality regulations may regulate or prohibit the use of these products or surface preparation and

cleanup materials. Consult local and federal air quality regulations before using these products.

Note: Alcohol will interfere with the curing process and extra care must be taken when using alcohol as a cleaning

solvent to prevent any contact with the sealant.

Primer:

Use of a primer is an extra step and cost and will depend on the final end use. Using primer can improve the corrosion

resistance of certain metals as well as improve the durability of the bond when exposed to high humidity conditions.

Pre-testing for adhesion is suggested to determine if a primer is needed. Contact your 3M Technical Service

representative for primer recommendation and application advice.

Applications:

Applications:

3MTM Adhesive Sealant 5200 is for permanent assembly of wood and fiberglass parts bonded together. If a

non-permanent bond is desired, use 3MTM Marine Adhesive Sealant 4200.

Typical bonding applications include:

- Fiberglass deck to fiberglass hull

- Wood to fiberglass

- Portholes

- Deck fittings

- Moldings

- Trunk joints

- Between struts and planking

- Stern joints

Typical sealing applications include:

- Some plastics (test before assembly)

- Glass

- Metals (priming may be required)

Limitations :

- Alcohol should not be used in preparation for bonding as it will interfere with the curing process, causing the adhesive

to fail.

- Due to the decreased value in bond strength at elevated temperatures, use of this product is not recommended above

190°F (88°C).

- Do not apply at temperatures below 40°F (4°C) or on frost covered surfaces. Do not apply at surface temperatures

above 100°F (38°C).

- Sealant should be used within 24 hours after inner seal is punctured, as product will start to cure in the cartridge and

nozzle.

- At 90o F (32o C) and 90% relative humidity, bonds should be made within 15 minutes.

- Some one-part solvent-based Marine paints may not cure on top of cured 5200. It is strongly recommended to test all

desired paints for suitability.

- 5200 has an elongation much greater than most paints. Most paints will not elongate to this extent before cracking or

losing adhesion to the sealant. If the sealant is used in an application where it will elongate or flex to a high degree, it is

best not to paint.

- 5200 is not recommended for use as a teak deck seam sealer. Extended exposure to chemicals (teak cleaners, oxalic

acid, gasoline, strong solvents and other harsh chemicals) may cause permanent softening of the sealant.

- 5200 is not recommended for the installation of glass, polycarbonate, or acrylic windows that are not also mechanically

fastened. Inconsistent adhesion of these unprimed substrates, specific design of the window and movement due to

thermal expansion and flexing may cause application failure. Contact a Technical Service Engineer for help with these

applications.

- When using 3MTM Marine Adhesive Sealant 5200 with metals it may be necessary to prime the surface to achieve

adequate adhesion and durability of the bond. 3M Metal Primer P592 may be used for priming of most metals.

Cleanup:

For cleaning 3MTM Marine Adhesive Sealant 5200 before it is cured, use a dry cloth to remove the majority of sealant,

followed by a cloth damp with 3MTM General Purpose Adhesive Cleaner 08984. Cured material can be removed

mechanically with a knife, razor blade, piano wire, or sanding device.

Storage and Shelf Life

Polyurethane sealants and adhesive sealants must be stored in a controlled environment to maximize shelf life. Store

the products in the original unopened containers below 77°F (25C).

When stored at the recommended conditions in the original, unopened container this product has a shelf life of 24

months from date of manufacture.

3M™ Marine Adhesive Sealant 5200 | English-US 3/4

Precautionary Information

Refer to Product Label and Material Safety Data Sheet for health and safety information before using this product. For

additional health and safety information, call 1-800-364-3577 or (651) 737-6501.

Automotive Disclaimer

Select Automotive Applications: This product is an industrial product and has not been designed or tested for use in certain automotive applications,

such as automotive electric powertrain battery or high voltage applications, which may require the product to be manufactured in a IATF certified facility,

meet a Ppk of 1.33 for all properties, undergo an automotive production part approval process (PPAP), or fully adhere to automotive design or quality

system requirements (e.g., IATF 16949 or VDA 6.3). Customer assumes all responsibility and risk if customer chooses to use this product in these

applications.

Information

Technical Information: The technical information, guidance, and other statements contained in this document or otherwise provided by 3M are based

upon records, tests, or experience that 3M believes to be reliable, but the accuracy, completeness, and representative nature of such information is not

guaranteed. Such information is intended for people with knowledge and technical skills sufficient to assess and apply their own informed judgment to the

information. No license under any 3M or third party intellectual property rights is granted or implied with this information.

Product Selection and Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of

a 3M product in a particular application. As a result, customer is solely responsible for evaluating the product and determining whether it is appropriate

and suitable for customer’s application, including conducting a workplace hazard assessment and reviewing all applicable regulations and standards (e.g.,

OSHA, ANSI, etc.). Failure to properly evaluate, select, and use a 3M product and appropriate safety products, or to meet all applicable safety regulations,

may result in injury, sickness, death, and/or harm to property.

Warranty, Limited Remedy, and Disclaimer: Unless a different warranty is specifically stated on the applicable 3M product packaging or product

literature (in which case such warranty governs), 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M ships the

product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR

CONDITION OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR ARISING OUT OF A COURSE OF DEALING, CUSTOM, OR USAGE OF TRADE. If a

3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the

purchase price.

Limitation of Liability: Except for the limited remedy stated above, and except to the extent prohibited by law, 3M will not be liable for any loss or

damage arising from or related to the 3M product, whether direct, indirect, special, incidental, or consequential (including, but not limited to, lost profits or

business opportunity), regardless of the legal or equitable theory asserted, including, but not limited to, warranty, contract, negligence, or strict liability.

Disclaimer: 3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for

workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or

packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the

applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards

(e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and limitations, and the user must take any action required under any

recall, field action or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, or death. For help with

product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert. For additional product information,

visit www.3M.com.

ISO Statement

This Industrial Adhesives and Tapes Division product was manufactured under a 3M quality system registered to ISO 9001 standards.

3M 3M and Scotch-Brite are trademarks of 3M Company.

Industrial Adhesives and Tapes Division ©3M 2022 (5/22)

3M Center, Building 225-3S-06

St. Paul, MN 55144-1000

800-362-3550

3M™ Marine Adhesive Sealant 5200 | English-US 4/4

You might also like

- Sikagard - 62Document4 pagesSikagard - 62bassem kooliNo ratings yet

- Concrete Finishing and Coating Procedure, Rev.1Document10 pagesConcrete Finishing and Coating Procedure, Rev.1moytabura96100% (1)

- GIFT - Gabion Slope Protection BOQ and Cost EstimateDocument11 pagesGIFT - Gabion Slope Protection BOQ and Cost EstimateshahqazwsxNo ratings yet

- 3M Scotch Weld Epoxy Adhesive DP125 TranslucentDocument6 pages3M Scotch Weld Epoxy Adhesive DP125 TranslucentasinghNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- 3M Neoprene High Performance Rubber & Gasket Adhesive 1300LDocument6 pages3M Neoprene High Performance Rubber & Gasket Adhesive 1300LIventNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- 3M VHB Tape GPH 160GFDocument6 pages3M VHB Tape GPH 160GFasinghNo ratings yet

- Jotamastic 87 PDFDocument6 pagesJotamastic 87 PDFGurdeep Sungh AroraNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- TDS - Jotamastic 80 PrimerDocument6 pagesTDS - Jotamastic 80 PrimershahoorhussainNo ratings yet

- Product Specification Sheet Belzona 1111Document2 pagesProduct Specification Sheet Belzona 1111Quy RomNo ratings yet

- Jotamastic 80 Technical Data SheetDocument6 pagesJotamastic 80 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Thermal Transfer Polyester Label Material: Technical Data May 2017Document5 pagesThermal Transfer Polyester Label Material: Technical Data May 2017Sebastian BaenaNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- TDS 24100 Penguard WF Euk GBDocument6 pagesTDS 24100 Penguard WF Euk GBpradnyeyNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- LLDPE Exxon 1001BUDocument2 pagesLLDPE Exxon 1001BULily LiNo ratings yet

- BL4 - HM 8255Document1 pageBL4 - HM 8255ShahryarNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Computer Imprintable Polyester Label MaterialDocument4 pagesComputer Imprintable Polyester Label MaterialyoganandvNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Belzona 1821: Product Specification SheetDocument2 pagesBelzona 1821: Product Specification SheetAlex BravoNo ratings yet

- Exceed™ 1018KB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 1018KB: Metallocene Polyethylene ResinHafiani HichamNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Exceed 3518Document2 pagesExceed 3518Jimmys GothiqueNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- TDS 525 Jotamastic 87 GF Euk GBDocument5 pagesTDS 525 Jotamastic 87 GF Euk GBhidayatNo ratings yet

- Exceed S 9243MLDocument2 pagesExceed S 9243MLzhen liuNo ratings yet

- 323+ Data SheetDocument5 pages323+ Data SheetSergioNo ratings yet

- Exxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene ResinDocument2 pagesExxonmobil™ Ldpe Eva Copolymers LD 362 Series: Low Density Polyethylene Resinabdelmoumene djafer beyNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Total 2287 HDPE Bimodal Film ResinDocument2 pagesTotal 2287 HDPE Bimodal Film ResinshuvoNo ratings yet

- Technical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinDocument2 pagesTechnical Data Sheet: Regalrez™ 1094 Hydrocarbon ResinPaul TsaiNo ratings yet

- Exceed XP 8784 SeriesDocument2 pagesExceed XP 8784 SeriesAli RazuNo ratings yet

- TDS Lldpe 1001buDocument2 pagesTDS Lldpe 1001buAmirun AeimanzzNo ratings yet

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- Technical Data Sheet: ApplicationsDocument2 pagesTechnical Data Sheet: ApplicationsJuan Sebastián Fernández RamírezNo ratings yet

- TDS 515 Jotamastic 87 Euk GBDocument6 pagesTDS 515 Jotamastic 87 Euk GBManuel LópezNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- Exceed™ XP 8784 Series: Performance PolymerDocument2 pagesExceed™ XP 8784 Series: Performance PolymerMaram YasserNo ratings yet

- Exceed™ XP 6026 Series: Performance PolymerDocument2 pagesExceed™ XP 6026 Series: Performance PolymerMaram YasserNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- TDS 523 Jotamastic 87 Aluminium Euk GBDocument6 pagesTDS 523 Jotamastic 87 Aluminium Euk GBBarathan RajandranNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Exxon LD 100 BWDocument2 pagesExxon LD 100 BWAli KüçükNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Environmental Analysis and Technology for the Refining IndustryFrom EverandEnvironmental Analysis and Technology for the Refining IndustryNo ratings yet

- X4C35J1-03GDocument6 pagesX4C35J1-03G夏斌No ratings yet

- electronics-11-02660-v2Document9 pageselectronics-11-02660-v2夏斌No ratings yet

- 5200FCDocument5 pages5200FC夏斌No ratings yet

- RF Signal Analysis With - App Bro - en - 3609 9057 92 - v0100Document12 pagesRF Signal Analysis With - App Bro - en - 3609 9057 92 - v0100夏斌No ratings yet

- Obsolete Product(s) - Obsolete Product(s) : RF Power Amplifier Using 1 X Pd54003LDocument11 pagesObsolete Product(s) - Obsolete Product(s) : RF Power Amplifier Using 1 X Pd54003L夏斌No ratings yet

- 11 Foldable Bridge 2017 PrintDocument48 pages11 Foldable Bridge 2017 PrintChockalingam AthilingamNo ratings yet

- Decorative Exterior Paints: Performance & Binder Design Trends in Asia PacificDocument27 pagesDecorative Exterior Paints: Performance & Binder Design Trends in Asia PacificAPEX SONNo ratings yet

- How To Put Up CovingDocument7 pagesHow To Put Up CovingBob KowalskiNo ratings yet

- IRC 16-2008 Prime Coat Tack Coat SpecificationDocument7 pagesIRC 16-2008 Prime Coat Tack Coat SpecificationVenkat Talupula100% (1)

- Nason Industrial Brochure 2015 Singles PDFDocument4 pagesNason Industrial Brochure 2015 Singles PDFsidneidecarvalhoNo ratings yet

- Objectra SE Website InfoDocument4 pagesObjectra SE Website Infotroyel99No ratings yet

- Aac Spec 377003Document25 pagesAac Spec 377003JakesNo ratings yet

- TDS Grip A310 ProjectDocument2 pagesTDS Grip A310 Projecteng.abdullrahmanNo ratings yet

- Metal Roof and Wall SystemDocument44 pagesMetal Roof and Wall SystemMihaela SurduNo ratings yet

- DPLF Epoxy Primer: Features Compatible SurfacesDocument4 pagesDPLF Epoxy Primer: Features Compatible SurfacesRobert StarkNo ratings yet

- WarehouseDocument51 pagesWarehouseAnonymous q0irDXlWAm100% (2)

- Installation Procedure Ceilcote 25 LiningDocument5 pagesInstallation Procedure Ceilcote 25 LiningNadia AgdikaNo ratings yet

- PRESENTATIONDocument23 pagesPRESENTATIONIyad Abu-FirasNo ratings yet

- Motorised Drift TrikeDocument52 pagesMotorised Drift TrikeDylan ChysykNo ratings yet

- Sigmaweld™ 120: Product Data SheetDocument4 pagesSigmaweld™ 120: Product Data Sheetjaime San Martin PulgarNo ratings yet

- Exposed Steel: ArchitecturallyDocument16 pagesExposed Steel: Architecturallykip099No ratings yet

- PRC-9002 - Rev - HDocument20 pagesPRC-9002 - Rev - HHenryNo ratings yet

- Intercare 123Document4 pagesIntercare 123Trịnh Minh KhoaNo ratings yet

- Sikaflex Construction: 1-C Polyurethane Sealant For Building JointsDocument4 pagesSikaflex Construction: 1-C Polyurethane Sealant For Building JointsJay PadamaNo ratings yet

- Seajet 015 Underwater PrimerDocument2 pagesSeajet 015 Underwater PrimerAleš NovakNo ratings yet

- End Closure Location: Technical Data Series Industry Alert SDIDocument14 pagesEnd Closure Location: Technical Data Series Industry Alert SDIAdlanAbushibaNo ratings yet

- Vol. IIDocument61 pagesVol. IIkarimNo ratings yet

- BAL Micromax SealantDocument3 pagesBAL Micromax Sealantannayya.chandrashekar Civil EngineerNo ratings yet

- E 9114 - Sika Unitherm 7854Document3 pagesE 9114 - Sika Unitherm 7854didapopescuNo ratings yet

- Waterproofing SystemsDocument24 pagesWaterproofing SystemsKC OcumenNo ratings yet

- Junbond High Quality Acetic Silicone Sealant Technical Data Sheet!Document3 pagesJunbond High Quality Acetic Silicone Sealant Technical Data Sheet!Junbond silicone sealantNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- NY2.NV ZZ FIB ZZ ZZ XX MT LA 00006 - 00 Material Submittal For EPDM Rubber External Surfacing - CompressedDocument226 pagesNY2.NV ZZ FIB ZZ ZZ XX MT LA 00006 - 00 Material Submittal For EPDM Rubber External Surfacing - CompressedKenneth Paul FulmaranNo ratings yet