Professional Documents

Culture Documents

Lincoln E6010 Fleetweld 5P - Root and Hot Pass -Test Certificate

Lincoln E6010 Fleetweld 5P - Root and Hot Pass -Test Certificate

Uploaded by

vipan0 ratings0% found this document useful (0 votes)

0 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views1 pageLincoln E6010 Fleetweld 5P - Root and Hot Pass -Test Certificate

Lincoln E6010 Fleetweld 5P - Root and Hot Pass -Test Certificate

Uploaded by

vipanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

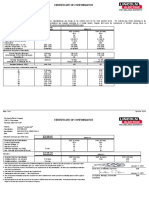

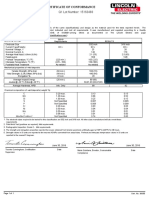

The Lincoln Electric Company

22801 St. Clair Avenue CERTIFICATE OF CONFORMANCE

Cleveland, Ohio 44117-1199

Q1 Lot Number: 17509094

Product: Fleetweld® 5P®

Classification: E6010

Specification: AWS A5.1:2012, ASME SFA-5.1

Date July 01, 2021

This is to certify that the product named above is of the same classification(s) and design as the material used for the tests reported herein. The material was tested according to the

specification(s) indicated and met all requirements. It was manufactured and supplied according to a Quality System Program that meets the requirements of ISO9001 among others as

documented on The Lincoln Electric web page (http://www.lincolnelectric.com/en-us/company/Pages/certifications.aspx).

E6010

Operating Settings Requirements RESULTS

Required Size for Classification 1

Not Specified 1 mm)

5/32" (4.0 2 mm)

3/16" (4.8 3 mm)

7/32" (5.6

Current Type/Polarity DC+ DC+ DC+ DC+

Nominal Voltage, V 27 27 28

Nominal Current, A 140 170 215

Average Heat Input, kJ/mm (kJ/in) 2.1 (52.2) 2.3 (58) 3.1 (79.9)

Travel Speed, cm/min (in/min) 11 (4.4) 12 (4.8) 11 (4.5)

Pass/Layers 16/8 16/8 16/8

Preheat Temperature, °C (°F) (225 min.) 105 (225) 105 (225) 105 (225)

Interpass Temperature, °C (°F) (225 - 350) 150 (300) 150 (300) 150 (300)

Postweld Heat Treatment - As-welded As-welded As-welded

Mechanical Properties of Weld Metal

Tensile Strength, MPa (ksi) (60 min.) 500 (73) 500 (72) 510 (74)

Yield Strength, 0.2% Offset, MPa (ksi) (48 min.) 410 (59) 400 (59) 410 (60)

Elongation % 22 min. 28 29 28

Average Impact Energy (20 min.) 66 (48) 73 (54) 47 (35)

Joules @ -29 °C (ft-lbs @ -20 °F) 61,63,73 (45,46,54) 54,78,85 (40,58,63) 41,48,53 (30,36,39)

Average Hardness, HRB Info. Only 83 82 83

Chemical Composition of Weld Metal (weight %)

C 0.20 max. 0.10 0.11 0.06

Mn 1.20 max. 0.53 0.43 0.45

Si 1.00 max. 0.37 0.23 0.12

S Not Specified 0.007 0.009 0.005

P Not Specified 0.005 0.006 0.007

Cr 0.20 max. 0.02 0.02 0.02

Ni 0.30 max. 0.01 0.01 0.01

Mo 0.30 max. <0.00 <0.00 <0.00

V 0.08 max. 0.00 0.00 0.00

Mn+Ni+Cr+Mo+V Not Specified 0.56 0.46 0.49

1. This document meets the requirements of AWS A5.01M/A5.01 Schedule G. When a specific lot number is referenced it

also meets the requirements of EN10204, type 2.2. It does not meet the requirements of type 3.1. July 01, 2021

2. The size(s) of electrode tested is determined by the requirements for this classification. All other sizes manufactured will

also meet these requirements. Daniel Gaul, Certification Supervisor Date

3. Fillet Weld Test (positions as required): Met requirements.

4. Radiographic Inspection: Grade 2 - Met requirements. July 02, 2021

5. The strength and elongation properties reported here were obtained from tensile specimens artificially aged at 105°C Jon Ogborn, Manager, Consumable Compliance Date

(220°F) for 48 hours.

6. Strength values in SI units are reported to the nearest 10 MPa converted from actual data. Preheat and interpass

temperature values in SI units are reported to the nearest 5 degrees.

Page 1 of 1 Cert. No. 30050

You might also like

- Small Clear Specimens of Timber: Standard Test Methods ForDocument31 pagesSmall Clear Specimens of Timber: Standard Test Methods ForCaro ChasipantaNo ratings yet

- Q1Display 15843280Document3 pagesQ1Display 15843280Oscar BasantesNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- Excalibur 11018M MR CertDocument2 pagesExcalibur 11018M MR CertAminNo ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- Q1 Lot Number: 14997588: Certificate of ConformanceDocument3 pagesQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesNo ratings yet

- .072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232Document1 page.072" (1.8 MM) AWS D1.8:2016 March 01, 2022: Innershield® NR®-232yousab creator2No ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Document2 pagesPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazNo ratings yet

- PORON 4701-50 Firm Global Standards Data Sheet-1Document2 pagesPORON 4701-50 Firm Global Standards Data Sheet-1Layeeq AhmedNo ratings yet

- L-50 Lincolnweld 980Document1 pageL-50 Lincolnweld 980geloram66No ratings yet

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazNo ratings yet

- Technical Data: 02014W104KATDocument9 pagesTechnical Data: 02014W104KATndfgdfs oishdfNo ratings yet

- Certificate of ConformanceDocument1 pageCertificate of ConformanceedwinNo ratings yet

- Coslight GFM-200ZDocument1 pageCoslight GFM-200ZLê Hữu Ái100% (1)

- Fike Rupture Disc-DatasheetDocument3 pagesFike Rupture Disc-DatasheetathulyaNo ratings yet

- Certificate of Conformance: Superarc® L-50®Document2 pagesCertificate of Conformance: Superarc® L-50®edwinNo ratings yet

- Coslight GFM-300ZDocument1 pageCoslight GFM-300ZUCTT BLU MONo ratings yet

- B DPCS CharPropCVandCA DATA v024-WEBDocument2 pagesB DPCS CharPropCVandCA DATA v024-WEBguivc.ethernet.32No ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Fta12 200HTDocument2 pagesFta12 200HTMohammedAbdulfattahNo ratings yet

- TroubleshootingDocument6 pagesTroubleshootingKolo BenduNo ratings yet

- Certificado Lote Er70s-6Document1 pageCertificado Lote Er70s-6willariasNo ratings yet

- Data Sheet: Rd520 Axius® Rupture DiscDocument3 pagesData Sheet: Rd520 Axius® Rupture DiscbondsivamaniNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Grinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyDocument4 pagesGrinnell Mechanical Products Mechanical Outlet Coupling General Description Technical Data Installation / AssemblyСергей КолесниковNo ratings yet

- Datasheet For GFM-400Z Battery: Specifications Discharging Characteristics Curves (25 C)Document1 pageDatasheet For GFM-400Z Battery: Specifications Discharging Characteristics Curves (25 C)UCTT BLU MONo ratings yet

- GBU10A GBU10K Data SheetDocument2 pagesGBU10A GBU10K Data Sheetmarcelo giussaniNo ratings yet

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- FT Series: FTA12-200 12V200Ah FTA12-200 12V200AhDocument2 pagesFT Series: FTA12-200 12V200Ah FTA12-200 12V200AhALEX ALEXNo ratings yet

- Qmot Qsh6018 ManualDocument14 pagesQmot Qsh6018 ManualleftoverchopsNo ratings yet

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankNo ratings yet

- RDamper CatalogDocument12 pagesRDamper CatalogEvandro MoreiraNo ratings yet

- MG CatalogDocument21 pagesMG CatalogSanket IchakeNo ratings yet

- Physical: .100" and .100" × .100" Straight, Solder Tails 929 SeriesDocument3 pagesPhysical: .100" and .100" × .100" Straight, Solder Tails 929 Seriesyamaha640No ratings yet

- 1 - Primacore LW71 1.2 E208038900Document1 page1 - Primacore LW71 1.2 E208038900Suli HartoNo ratings yet

- Datasheet Nema23Document1 pageDatasheet Nema23Juan De La TorreNo ratings yet

- V90D6412Document1 pageV90D6412ardalanxoshnawNo ratings yet

- VRLA Rechargeable Battery: Application FeaturesDocument1 pageVRLA Rechargeable Battery: Application FeaturesbrobataNo ratings yet

- FT Series: FTB12-150 12V150AhDocument2 pagesFT Series: FTB12-150 12V150AhJohn Edwin MuñozNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- PT Paver Strength CalculationsDocument3 pagesPT Paver Strength CalculationsEr Narayan ApawatNo ratings yet

- 04012XT3E364TDocument24 pages04012XT3E364TSKataNo ratings yet

- 04012XT3E364TDocument24 pages04012XT3E364TSKataNo ratings yet

- 005 - Fuel+SystemDocument92 pages005 - Fuel+Systemeduan laraNo ratings yet

- Sacred Sun Fta 12-200Document2 pagesSacred Sun Fta 12-200ALEX ALEXNo ratings yet

- 17PS M001VvvDocument1 page17PS M001VvvBen sayari Mohamed AmineNo ratings yet

- Jacketed Tubing (MS-02-188) R1Document6 pagesJacketed Tubing (MS-02-188) R1herysyam1980No ratings yet

- AWS D1.8 Certificate-Primacore LW71Document1 pageAWS D1.8 Certificate-Primacore LW71edwinNo ratings yet

- Certificates-50l O2 CylinderDocument6 pagesCertificates-50l O2 CylinderClaudia TiradoNo ratings yet

- COILBXDocument1 pageCOILBXMUKESHNo ratings yet

- Power Unit (85A Models) : Maintenance SpecificationDocument1 pagePower Unit (85A Models) : Maintenance SpecificationPHUONG NGUYENNo ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Wts AEM Automotive SMD Fuses 2016.12Document22 pagesWts AEM Automotive SMD Fuses 2016.12AlexNo ratings yet

- MBRF2035 - MBRF20150: FeaturesDocument2 pagesMBRF2035 - MBRF20150: FeaturesY. Leonel MolinaNo ratings yet

- Surface-Mount Fuses: 2410 Very Fast-Acting Chip FusesDocument4 pagesSurface-Mount Fuses: 2410 Very Fast-Acting Chip Fusesreza yousefiNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlNo ratings yet

- OMI 2 Pole PDFDocument2 pagesOMI 2 Pole PDFedgartepe4324No ratings yet

- PowerPact J-Frame Moulded Case Circuit Breakers - JJA36250Document4 pagesPowerPact J-Frame Moulded Case Circuit Breakers - JJA36250techtricNo ratings yet

- Crane2 GL4524 4028-2S PDFDocument370 pagesCrane2 GL4524 4028-2S PDFnguyenvanhai19031981100% (1)

- 422 01 F12Document4 pages422 01 F12Burime GrajqevciNo ratings yet

- American Public University MATH 110 Complete CourseDocument29 pagesAmerican Public University MATH 110 Complete CoursejustquestionanswerNo ratings yet

- Assay of Calcium CarbonateDocument11 pagesAssay of Calcium CarbonateMawen Anuncio100% (1)

- Skinny 'Scrapers: Publications CE MagazineDocument17 pagesSkinny 'Scrapers: Publications CE MagazineAamirShabbirNo ratings yet

- Introduction of Modern Physics by Nurul Amin SirDocument13 pagesIntroduction of Modern Physics by Nurul Amin SirFardeen KhanNo ratings yet

- Example The Surface IntegralDocument5 pagesExample The Surface IntegralsondhaniNo ratings yet

- Guidelines For Performance Based Seismic Design of Tall Building (PEER, 2017) )Document148 pagesGuidelines For Performance Based Seismic Design of Tall Building (PEER, 2017) )Subash Bastola100% (1)

- XI Maths QP 161Document4 pagesXI Maths QP 161RichurajanNo ratings yet

- Sci20 Unitb 2 RDocument3 pagesSci20 Unitb 2 Rapi-207957230No ratings yet

- Mathematical Modeling and Transient Analysis of DC-DC Buck-Boost Converter in CCMDocument6 pagesMathematical Modeling and Transient Analysis of DC-DC Buck-Boost Converter in CCMmabrouk1998No ratings yet

- Chemical Periodicity (REVISED)Document3 pagesChemical Periodicity (REVISED)Annie Valerie OgedeNo ratings yet

- Field IoDocument74 pagesField IoKellie RamosNo ratings yet

- Tangent GalvanometerDocument4 pagesTangent GalvanometerParikshit DurgamNo ratings yet

- The Bacterial FlagellumDocument1 pageThe Bacterial Flagellummferra100% (1)

- Mitm11590 1Document1 pageMitm11590 1fredymademydayNo ratings yet

- ch03 PDFDocument11 pagesch03 PDFFarhan KhanNo ratings yet

- Lecture 17 - Signalized Intersection DelayDocument34 pagesLecture 17 - Signalized Intersection DelayBasoz Arif AhmadNo ratings yet

- Preamble and Syllabus MSC ChemistryDocument34 pagesPreamble and Syllabus MSC ChemistrycomgmailNo ratings yet

- Non-Calculus Graphing HSC QuestionsDocument8 pagesNon-Calculus Graphing HSC QuestionsNathan HaNo ratings yet

- Chapter 8 (Complex Numbers)Document8 pagesChapter 8 (Complex Numbers)Naledi MashishiNo ratings yet

- CORDE Cosserat Rod Elements For The Dynamic Simulation of One Dimensional Elastic ObjectsDocument11 pagesCORDE Cosserat Rod Elements For The Dynamic Simulation of One Dimensional Elastic ObjectsCFNo ratings yet

- Gravitational Forces 5E Lesson Template Legends of LearningDocument5 pagesGravitational Forces 5E Lesson Template Legends of LearningNeha YadavNo ratings yet

- Topic 5 HeatDocument26 pagesTopic 5 HeatAnthonyDomNo ratings yet

- Chapter 6 PID ControlDocument56 pagesChapter 6 PID ControlHana Muhammad100% (1)

- Linear AlgebraDocument3 pagesLinear AlgebraMuhammad SaimNo ratings yet

- HELM Workbook26 Functions of A Complex VariableDocument62 pagesHELM Workbook26 Functions of A Complex VariableCristina RiosNo ratings yet

- Chapter 5 Analysis of StructureDocument20 pagesChapter 5 Analysis of StructureRenu SekaranNo ratings yet

- Hron 2012Document15 pagesHron 2012Maica SantosNo ratings yet