Professional Documents

Culture Documents

P1-Part-A-Preparation of wascator fom 71S for stability washes

P1-Part-A-Preparation of wascator fom 71S for stability washes

Uploaded by

shafiulmmlabCopyright:

Available Formats

You might also like

- Answer - Keys-New International Business English PDFDocument2 pagesAnswer - Keys-New International Business English PDFĐặng Thị Thu Nga81% (21)

- 500 Professional Chords Application Book by JohnsonkeyzDocument34 pages500 Professional Chords Application Book by JohnsonkeyzDaniel83% (6)

- Integrated Science Form 4 Final ExamDocument14 pagesIntegrated Science Form 4 Final ExamCHRISTOPHER SCALE100% (1)

- Brazilian Percussion Drumset For BeatBuddy-drum MapDocument3 pagesBrazilian Percussion Drumset For BeatBuddy-drum MapFernando MonteiroNo ratings yet

- Segak p1 2018Document57 pagesSegak p1 2018Joseph JacksonNo ratings yet

- Les Notes: Dec Hexdec Note GM-Roland YamahaDocument1 pageLes Notes: Dec Hexdec Note GM-Roland YamahaMercier Palmer MarcNo ratings yet

- All 12 Major ScalesDocument6 pagesAll 12 Major ScaleslestatmeNo ratings yet

- Pursuit DrillDocument3 pagesPursuit DrillMikeNo ratings yet

- S11-H1 RespuestasDocument6 pagesS11-H1 RespuestasHellen Martinez86% (7)

- Yangqin TuningDocument1 pageYangqin TuningFelix WongNo ratings yet

- Mackie Control MIDI MapDocument6 pagesMackie Control MIDI MaplipemixsomNo ratings yet

- Viol Chords PDFDocument4 pagesViol Chords PDFVVittiNo ratings yet

- 2001 Idea Prokom Open - Men's Singles: SeedsDocument7 pages2001 Idea Prokom Open - Men's Singles: SeedsFabian MuresanNo ratings yet

- 5 6073135403525734836Document49 pages5 6073135403525734836Larry CollectionsNo ratings yet

- Ukulele Chord Melody Solos Book 4 - Mike LynchDocument99 pagesUkulele Chord Melody Solos Book 4 - Mike LynchLucky StrikeNo ratings yet

- Scale Fingerings: Major ScalesDocument2 pagesScale Fingerings: Major ScalesLuis AngelNo ratings yet

- Scale & Arps-PianoDocument62 pagesScale & Arps-Pianorajulio77No ratings yet

- MP Grower CikampekDocument16 pagesMP Grower CikampekIvan BudimanNo ratings yet

- PESANDocument10 pagesPESANMuhammad ZackyNo ratings yet

- Major Scale FingeringsDocument2 pagesMajor Scale Fingeringsbellamilo100% (3)

- Grade I Scales RIAMDocument3 pagesGrade I Scales RIAMniamhkinsellaNo ratings yet

- Learn To Crochet: CraftsDocument6 pagesLearn To Crochet: CraftspatyminaNo ratings yet

- Lampiran Data Shear GashDocument6 pagesLampiran Data Shear Gashmuhammad alqori b.No ratings yet

- Learn To Solo in 5 Minutes Tab Book OnlineDocument6 pagesLearn To Solo in 5 Minutes Tab Book OnlineLugrinder100% (1)

- 01 Ensemble Rehearsal Plan TemplateDocument1 page01 Ensemble Rehearsal Plan Templateypxk76sknhNo ratings yet

- Teoría MusicalDocument12 pagesTeoría MusicalTute AlvarezNo ratings yet

- La Villa de Las TelasDocument38 pagesLa Villa de Las TelasCristina Merino100% (1)

- Major Scale Fingerings PDFDocument1 pageMajor Scale Fingerings PDFMarkDoyleNo ratings yet

- Libraje Bridas Asme B16.5-2013 R02Document69 pagesLibraje Bridas Asme B16.5-2013 R02MinaLitaNo ratings yet

- 24 Note NumbersDocument4 pages24 Note NumbersCorey ScottNo ratings yet

- Jadwal Shift 2020Document2 pagesJadwal Shift 2020Ahmad Zulkarnain ArikoNo ratings yet

- SNIDER (Version 1)Document77 pagesSNIDER (Version 1)TrentNo ratings yet

- Recorder Tuning Adjustments - Philippe BoltonDocument6 pagesRecorder Tuning Adjustments - Philippe BoltonClown e GregorianoNo ratings yet

- Fingering On Piano For Major and Minor ChordsDocument3 pagesFingering On Piano For Major and Minor ChordsChandan Mundhra100% (1)

- Chain8designs - Christmas Unicorn HeadbandDocument6 pagesChain8designs - Christmas Unicorn HeadbandRegina MartínezNo ratings yet

- Rencana Dinasan LebaranDocument45 pagesRencana Dinasan LebaranIgnas Getsema Agasi SuryaNo ratings yet

- CPT MATH Score Sheet - FinalDocument3 pagesCPT MATH Score Sheet - FinalDoc Albert Nito LopezNo ratings yet

- Top 5 DiagramDocument1 pageTop 5 DiagramNicolás EduardoNo ratings yet

- 8 TriadDocument49 pages8 TriadEry Setyo78% (9)

- Viola Grade 2 ScalesDocument1 pageViola Grade 2 ScalesjimmmusicNo ratings yet

- Basic Lefty Guitar Chords PDFDocument4 pagesBasic Lefty Guitar Chords PDFjaviriverNo ratings yet

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionjaviriverNo ratings yet

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionRobstter Rod100% (1)

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionKurt FlorescaNo ratings yet

- Absensi Apel Februari 2016Document5 pagesAbsensi Apel Februari 2016Ruth MillionNo ratings yet

- Ukuran Wallpanel SambasDocument1 pageUkuran Wallpanel SambasagusNo ratings yet

- Scales, Chords & Arpeggios - Bastien, James W - San Diego, CA, 1988 - San Diego, Calif. - Niel A. Kjos Music Co. - 9780849793516 - Anna's ArchiveDocument44 pagesScales, Chords & Arpeggios - Bastien, James W - San Diego, CA, 1988 - San Diego, Calif. - Niel A. Kjos Music Co. - 9780849793516 - Anna's Archivecraftycow62No ratings yet

- Benny Davis Trumpet Studio Trumpet Mouthpiece Brand Comparison ChartDocument6 pagesBenny Davis Trumpet Studio Trumpet Mouthpiece Brand Comparison ChartnaweNo ratings yet

- Manual Robot TefalDocument82 pagesManual Robot TefalPerfectreviewNo ratings yet

- 2018 ScheduleDocument1 page2018 ScheduleAndrian YtomNo ratings yet

- BS EN 1092 PN16 Flange Dimensions - Roy MechDocument4 pagesBS EN 1092 PN16 Flange Dimensions - Roy MechpriyankaNo ratings yet

- AntichristDocument3 pagesAntichristDAVID IKENNANo ratings yet

- Remon Juni TerataiDocument6 pagesRemon Juni TerataionetzzzNo ratings yet

- Absensi Apel Januari 2016Document3 pagesAbsensi Apel Januari 2016Ruth MillionNo ratings yet

- # Sorteo: Número: Fecha: 1ER# 2DO# 3ER# 4TO# 1 2 3 4 5 6 7Document10 pages# Sorteo: Número: Fecha: 1ER# 2DO# 3ER# 4TO# 1 2 3 4 5 6 7ingoscarportillahNo ratings yet

- Wktta League ResultsDocument1 pageWktta League Resultsapi-253238145No ratings yet

- TR Grade 3 ScalesDocument1 pageTR Grade 3 Scalesnewtonfogg123No ratings yet

- Thesis Sample, EUROCODEDocument151 pagesThesis Sample, EUROCODEelias workuNo ratings yet

- Fortified Relaxor Ferroelectricity of Rare Earth Substituted 4 Layered Babi Re Ti O (Re La, PR, ND, and SM) Aurivillius CompoundsDocument19 pagesFortified Relaxor Ferroelectricity of Rare Earth Substituted 4 Layered Babi Re Ti O (Re La, PR, ND, and SM) Aurivillius CompoundsTio Putra WendariNo ratings yet

- Problem Set in Power System 2Document3 pagesProblem Set in Power System 2Andrew AlterNo ratings yet

- Soil and Its PropertiesDocument20 pagesSoil and Its PropertiesHarsha HarapanahalliNo ratings yet

- RC Design (Outlet Section)Document36 pagesRC Design (Outlet Section)PRAVEEN CHAUDHARYNo ratings yet

- Motion in A Circle Updated 11Document3 pagesMotion in A Circle Updated 11Yahya Salman GamingNo ratings yet

- Transformer ProblemsDocument3 pagesTransformer ProblemsVaralakshmi SeerapuNo ratings yet

- Cswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductDocument40 pagesCswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductMohsen Keramati100% (1)

- PHY112 Lecture1Document131 pagesPHY112 Lecture18wc9sncvpwNo ratings yet

- G150 Option and SelectionDocument4 pagesG150 Option and SelectionJack SparrowNo ratings yet

- Bearing Arragements For Cement Industry FansDocument6 pagesBearing Arragements For Cement Industry FansAnonymous H3I29yjNo ratings yet

- Fme10 q2 w1 Em-WavesDocument6 pagesFme10 q2 w1 Em-WavesLouis Fetilo FabunanNo ratings yet

- HPH103 - Waves and Optics 1 - Lecture # 7-1Document16 pagesHPH103 - Waves and Optics 1 - Lecture # 7-1Praise NehumambiNo ratings yet

- 3 FlywheelDocument14 pages3 FlywheelAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Abett REF & MetrosilDocument6 pagesAbett REF & MetrosilNeeraj SinghNo ratings yet

- STRUCTUREDocument9 pagesSTRUCTUREFaria TahsinNo ratings yet

- 3 FL 5545tbabDocument51 pages3 FL 5545tbabjuan estebanNo ratings yet

- Flashcards - Topic 5.1 Nuclear Atoms - CAIE Physics IGCSEDocument25 pagesFlashcards - Topic 5.1 Nuclear Atoms - CAIE Physics IGCSEAHNAF AJMAINNo ratings yet

- Installation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNDocument112 pagesInstallation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNdarrel gimoteaNo ratings yet

- Material Data Sheet: Casting Material: Leaded Red Brass C83600Document2 pagesMaterial Data Sheet: Casting Material: Leaded Red Brass C83600Kamal ThummarNo ratings yet

- Phase2 Analysis Information Tajeo Esperanza NV 920: Project SummaryDocument5 pagesPhase2 Analysis Information Tajeo Esperanza NV 920: Project SummarysanchezmendozaaNo ratings yet

- Thesis Marco RiveraDocument159 pagesThesis Marco RiveraMarco RiveraNo ratings yet

- Circuit Lab Introduction I ECE - Partial NotesDocument27 pagesCircuit Lab Introduction I ECE - Partial NotesDr.P. RAJASEKARNo ratings yet

- 2018 ENG HSC Questions-1Document38 pages2018 ENG HSC Questions-1TripsZeeNo ratings yet

- Science Quarter 2 Module 8Document28 pagesScience Quarter 2 Module 8SHEENA MAE DALGUNTAS60% (5)

- Megator Oil Water Separator Operational Theory: Rate of Rise TheoryDocument2 pagesMegator Oil Water Separator Operational Theory: Rate of Rise TheoryAhmedRamadanNo ratings yet

- Binders For TextilesDocument9 pagesBinders For Textiles950 911No ratings yet

- Concrete CalculationDocument10 pagesConcrete CalculationKaye Ibañez CastilloNo ratings yet

- Real Analysis Lecture 4newDocument15 pagesReal Analysis Lecture 4newJohn Michael Ochea NatadNo ratings yet

P1-Part-A-Preparation of wascator fom 71S for stability washes

P1-Part-A-Preparation of wascator fom 71S for stability washes

Uploaded by

shafiulmmlabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P1-Part-A-Preparation of wascator fom 71S for stability washes

P1-Part-A-Preparation of wascator fom 71S for stability washes

Uploaded by

shafiulmmlabCopyright:

Available Formats

Marks & Spencer P1 PART A

METHOD OF TEST

PREPARATION OF WASCATOR FOM 71S FOR

STABILITY WASHES

PURPOSE To prepare the Wascator FOM 71S and its programme

cards for Marks and Spencer stability washes.

APPARATUS Wascator FOM 71S washing machine fitted with one

minute cam.

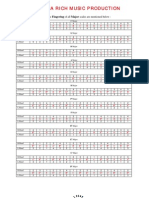

PROCEDURE 1. Cutting the programme card

A card consists of columns of pips, each controlling

a specific function.

A. Fabric softener

B. High level

C. Spin

D. Drain

E. Cool down valve

F. Gentle/normal drum action

G. Detergent

H. Heating - blue pointer control unit

I. Cold water input

K. Heating - yellow pointer control unit

L. Hot water input

M. Machine stops - buzzer sounds

The cards for the Marks and Spencer stability washes can

be cut out by reference to the tables below. Where

indicated, pips should be removed with the special tools

provided with the Wascator.

THE INSTRUCTIONS INDICATE THE ACTUAL

NUMBER OF PIPS REMOVED. THESE DO NOT

RELATE DIRECTLY TO THE ROW NUMBERS ON

THE CARDS.

IDENTIFY EACH CARD WITH APPROXIMATE

TIME OF WASH, TEMPERATURE AND WASH

TITLE.

P1 PART A P1 of 6 SEPTEMBER 2004

P1 PART A Marks & Spencer

Column MSA (Knobs 1, 3 & 4 out) Column MSB (Knobs 1, 3 & 4 out)

A None cut A Non cut

B Leave 17; cut 5; leave 1; B Leave 32; cut 5; leave 1; cut 5;

cut 5; leave 1; cut 5 leave 1; cut 5

C Leave 35; cut 1 C Leave 50; cut 1

D Leave 16; cut 1; leave 5; cut 1; D Leave 31; cut 1; leave 5; cut 1;

leave 5; cut 1; leave 5; cut 2 leave 5; cut 1; leave 5; cut 2

E None cut E None cut

F None cut F None cut

G Cut 2 G Cut 2

H Cut 16 H Cut 31

I Cut 16; leave 1; cut 5; leave 1; I Cut 31; leave 1; cut 5; leave 1;

cut 5; leave 1; cut 5 cut 5; leave 1; cut 5

K None cut K None cut

L Cut 5 L Cut 5

M Leave 35; cut 1 M Leave 50; cut 1

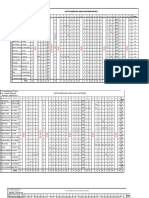

Column MSTD (Knobs 3 & 8 out) Column MSE (Knobs 1, 3 & 4 out)

A None cut A None cut

B Leave 61; cut 2; leave 1; cut 3; leave 1; B None cut

cut 3; leave 2; cut 2; leave 2; cut 2 C Leave 17; cut 1

C Leave 72; cut 1; leave 3; cut 1; D Leave 16; cut 2

leave 3; cut 6 E None cut

D Leave 63; cut 1; leave 3; cut 1; leave 3; F Cut 16

cut 2; leave 2; cut 2; leave 2; cut 7 G None cut

E None cut H Cut 16

F None cut I Cut 16

G None cut K None cut

H Leave 1, cut 60 L Cut 2

I Leave 1; cut 62; leave 1; cut 3; leave 1; M Leave 17; cut 1

cut 3; leave 2; cut 2; leave 2; cut 2

K None cut

L None cut

M Leave 85; cut 1

SEPTEMBER 2004 P1 PART A P2 of 6

Marks & Spencer P1 PART A

Column MSG (Knobs 1, 3 & 4 out) Column MSH (Knobs 1, 3 & 4 out)

A None cut A None cut

B Leave 17; cut 2; leave 1; B Leave 18; cut 5; leave 2; cut 5;

cut 2; leave 1; cut 2 leave 2; cut 5

C Leave 26; cut 1 C Leave 39; cut 6

D Leave 16; cut 1; leave 2; cut 1; D Leave 16; cut 2; leave 5; cut 2;

leave 2; cut 1; leave 2; cut 2 leave 5; cut 2; leave 5; cut 8

E None cut E None cut

F Cut 16; leave 1; cut 2; leave 1; F None cut

cut 2; leave 1; cut 2

G Cut 2 G Cut 2

H Cut 16 H Cut 16

I Cut 16; leave 1; cut 2; leave 1; I Cut 2; leave 16; cut 1; leave 6;

cut 2; leave 1; cut 2 cut 1; leave 6; cut 1

K None cut K None cut

L Cut 2 L Cut 2

M Leave 44; cut 1 M Leave 44; cut 1

Column MSK (Knobs 1, 3 & 4 out) Column MSS (Knobs 1, 3 & 4 out)

A None cut A None cut

B Leave 32; cut 5; leave 2; cut 5; B None cut

leave 2; cut 5 C Leave 62; cut 6

C Leave 53; cut 6 D Leave 61; cut 7

D Leave 31; cut 1; leave 5; cut 2; E None cut

leave 5; cut 2; leave 5; cut 8 F None cut

E None cut G None cut

F None cut H Cut 61

G Cut 2 I Cut 61

H Cut 31 K None cut

I Cut 2; leave 30; cut 1; leave 6 L Cut 5

cut 1; leave 6; cut 1 M Leave 67; cut 1

K None cut

L Cut 2

M Leave 58; cut 1

Column MSW i.e BS EN ISO 6330: 2001 (knobs 1 and 3 out)

A None cut

B Leave 32; cut 3; leave 1; cut 2; leave 1: cut 2.

C Leave 42; cut 2

D Leave 31; cut 1; leave 3; cut 1; leave 2; cut 1; leave 2; cut 3

E None cut

F Leave 31; cut 1; leave 3; cut 1; leave 2; cut 1; leave 2; cut 3

G None cut

H Cut 16

I Cut 31; leave 1; cut 3; leave 1: cut 2; leave 1; cut 2

K Leave 16: cut 15

L None cut

M Leave 43; cut 1

Set blue pointer to 40ºC

and yellow pointer to 50ºC

P1 PART A P3 of 6 SEPTEMBER 2004

P1 PART A Marks & Spencer

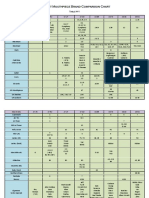

2. Summary of washes

CHECK THE TIMINGS OF NEWLY PUNCHED CARDS

MSA MSB MSE MSG MSH MSK MSS MSTD MSW*3

Detergent Yes Yes No Yes Yes No No No *2 Yes

Wash Water 160 160 160 160 160 160 100 100 100

Level (mm)

Wash time 15 30 15 15 15 30 60 60 15

(mins)

Cage N N G G N N N N N

Agitation*1

Temperature 40 60 40 40 60 40 40 40 50

(˚C) or 60

Rinse Water 200 200 - 200 200 200 - 130 130

Level (mm)

Rinses x 3x5 3x5 - 3x2 3x5 3x5 - 2x3 1x3

Time (mins) 2x2 2x2

Spin Time 1 1 1 1 6 6 6 6 2

(mins)

Approximate 50 75 35 45 65 70 90 100 70

Total Time mins

(mins)

*1 N = Normal Action: Cage revolving 12 seconds, stationary 3 seconds

G = Gentle Action: Cage revolving 3 seconds, stationary 12 seconds

*2 See MSTD test method for adjustment of pH.

*3 The wash programme is the same as BS EN ISO 6330: 2001 wash procedure 4A@50ºC

containing static drum during filling, gentle action during draining and 15 minute agitation at

40ºC before heating to 50ºC for the wash. See P1A test method for detergent quantity.

THIS IS NOT THE SAME WASH PROGRAMME AS BS EN 26330: 1994.

SEPTEMBER 2004 P1 PART A P4 of 6

Marks & Spencer P1 PART A

3. Setting the Wash and Rinse Water Levels (see

diagrams) Put into the control unit any MS card

(except MSE and MSS). Pull out knobs 1, 3 and 4

ONLY. Do not start the machine. Do not put

makeweights into the machine. Set the blue pointer

(F) on the control unit to the minimum temperature.

Move the high and low level float units to the top of

the tubes. Close the door.

Manually fill the machine by pressing the cold water

button (11) on the control unit until the water

reaches the first holes at the bottom of the cage (A).

If the water is over the holes, drain a small amount of

water by pressing the drain button (9) on the control

unit. Once the correct level is reached mark the cage

bottom level on the front tube.

To monitor the water level fix a metric scale to this

tube, such that the scale starts at 0.0mm from the

cage bottom level.

(a) Wash Level

i) Switch on the machine and allow the

water to fill automatically to the specified

height from the cage bottom level of

100mm ± 5mm. (MSS, MSW and

MSTD) or 160 ± 5mm. (All other

washes).

ii) Quickly move the wash level float down

until the agitation begins.

iii) Switch off the machine. Allow the water

to settle. Check that the water level is

correct as appropriate.

P1 PART A P5 of 6 SEPTEMBER 2004

P1 PART A Marks & Spencer

iv) If the water is above the specified level

drain until approximately 20mm below

the float.

v) Repeat steps (i), (iii) and (iv) re-adjusting

the float as many times as necessary to

establish the correct level.

vi) Mark the FLOAT DISC position on the

wash level tube.

(b) Rinse Level

i) Advance the card to the first rinse cycle.

ii) Start the machine and allow it to

automatically fill to the specified height

from the cage bottom level of 130mm

±5mm (MSTD and MSW) or 200mm

±5mm (all other washes).

iii) Quickly move the rinse level float down

until agitation begins.

iv) Carry out steps (iii), (iv) and (v) of the

wash level procedure to achieve the

correct level.

(v) Mark the FLOAT DISC position on the

rinse level tube.

IF THE SIGHT TUBES ARE REMOVED, FOR EXAMPLE FOR ROUTINE

SERVICING, IT IS IMPORTANT TO COMPLETELY RECALIBRATE

THE WATER LEVELS.

DO NOT TOUCH THE SPACING WASHERS ABOVE AND BELOW THE

CORKS. ENSURE THAT THE COMPLETE FLOAT ASSEMBLY DOES

NOT TOUCH THE TUBE SIDES WHICH MAY IMPEDE THEIR FREE

MOVEMENT.

Routine cleaning of float switches and sight tubes is important. It is not

necessary to remove the sight tubes during routine cleaning which can be done

using a long brush.

Labelling of sight tubes and float supports is advisable to ensure returning them

to the correct tubes and positions.

It is recommended that the filter is cleaned at least daily.

SEPTEMBER 2004 P1 PART A P6 of 6

You might also like

- Answer - Keys-New International Business English PDFDocument2 pagesAnswer - Keys-New International Business English PDFĐặng Thị Thu Nga81% (21)

- 500 Professional Chords Application Book by JohnsonkeyzDocument34 pages500 Professional Chords Application Book by JohnsonkeyzDaniel83% (6)

- Integrated Science Form 4 Final ExamDocument14 pagesIntegrated Science Form 4 Final ExamCHRISTOPHER SCALE100% (1)

- Brazilian Percussion Drumset For BeatBuddy-drum MapDocument3 pagesBrazilian Percussion Drumset For BeatBuddy-drum MapFernando MonteiroNo ratings yet

- Segak p1 2018Document57 pagesSegak p1 2018Joseph JacksonNo ratings yet

- Les Notes: Dec Hexdec Note GM-Roland YamahaDocument1 pageLes Notes: Dec Hexdec Note GM-Roland YamahaMercier Palmer MarcNo ratings yet

- All 12 Major ScalesDocument6 pagesAll 12 Major ScaleslestatmeNo ratings yet

- Pursuit DrillDocument3 pagesPursuit DrillMikeNo ratings yet

- S11-H1 RespuestasDocument6 pagesS11-H1 RespuestasHellen Martinez86% (7)

- Yangqin TuningDocument1 pageYangqin TuningFelix WongNo ratings yet

- Mackie Control MIDI MapDocument6 pagesMackie Control MIDI MaplipemixsomNo ratings yet

- Viol Chords PDFDocument4 pagesViol Chords PDFVVittiNo ratings yet

- 2001 Idea Prokom Open - Men's Singles: SeedsDocument7 pages2001 Idea Prokom Open - Men's Singles: SeedsFabian MuresanNo ratings yet

- 5 6073135403525734836Document49 pages5 6073135403525734836Larry CollectionsNo ratings yet

- Ukulele Chord Melody Solos Book 4 - Mike LynchDocument99 pagesUkulele Chord Melody Solos Book 4 - Mike LynchLucky StrikeNo ratings yet

- Scale Fingerings: Major ScalesDocument2 pagesScale Fingerings: Major ScalesLuis AngelNo ratings yet

- Scale & Arps-PianoDocument62 pagesScale & Arps-Pianorajulio77No ratings yet

- MP Grower CikampekDocument16 pagesMP Grower CikampekIvan BudimanNo ratings yet

- PESANDocument10 pagesPESANMuhammad ZackyNo ratings yet

- Major Scale FingeringsDocument2 pagesMajor Scale Fingeringsbellamilo100% (3)

- Grade I Scales RIAMDocument3 pagesGrade I Scales RIAMniamhkinsellaNo ratings yet

- Learn To Crochet: CraftsDocument6 pagesLearn To Crochet: CraftspatyminaNo ratings yet

- Lampiran Data Shear GashDocument6 pagesLampiran Data Shear Gashmuhammad alqori b.No ratings yet

- Learn To Solo in 5 Minutes Tab Book OnlineDocument6 pagesLearn To Solo in 5 Minutes Tab Book OnlineLugrinder100% (1)

- 01 Ensemble Rehearsal Plan TemplateDocument1 page01 Ensemble Rehearsal Plan Templateypxk76sknhNo ratings yet

- Teoría MusicalDocument12 pagesTeoría MusicalTute AlvarezNo ratings yet

- La Villa de Las TelasDocument38 pagesLa Villa de Las TelasCristina Merino100% (1)

- Major Scale Fingerings PDFDocument1 pageMajor Scale Fingerings PDFMarkDoyleNo ratings yet

- Libraje Bridas Asme B16.5-2013 R02Document69 pagesLibraje Bridas Asme B16.5-2013 R02MinaLitaNo ratings yet

- 24 Note NumbersDocument4 pages24 Note NumbersCorey ScottNo ratings yet

- Jadwal Shift 2020Document2 pagesJadwal Shift 2020Ahmad Zulkarnain ArikoNo ratings yet

- SNIDER (Version 1)Document77 pagesSNIDER (Version 1)TrentNo ratings yet

- Recorder Tuning Adjustments - Philippe BoltonDocument6 pagesRecorder Tuning Adjustments - Philippe BoltonClown e GregorianoNo ratings yet

- Fingering On Piano For Major and Minor ChordsDocument3 pagesFingering On Piano For Major and Minor ChordsChandan Mundhra100% (1)

- Chain8designs - Christmas Unicorn HeadbandDocument6 pagesChain8designs - Christmas Unicorn HeadbandRegina MartínezNo ratings yet

- Rencana Dinasan LebaranDocument45 pagesRencana Dinasan LebaranIgnas Getsema Agasi SuryaNo ratings yet

- CPT MATH Score Sheet - FinalDocument3 pagesCPT MATH Score Sheet - FinalDoc Albert Nito LopezNo ratings yet

- Top 5 DiagramDocument1 pageTop 5 DiagramNicolás EduardoNo ratings yet

- 8 TriadDocument49 pages8 TriadEry Setyo78% (9)

- Viola Grade 2 ScalesDocument1 pageViola Grade 2 ScalesjimmmusicNo ratings yet

- Basic Lefty Guitar Chords PDFDocument4 pagesBasic Lefty Guitar Chords PDFjaviriverNo ratings yet

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionjaviriverNo ratings yet

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionRobstter Rod100% (1)

- E Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionDocument4 pagesE Major E Minor E Major 7 E Major 6 E Minor 7 E Dom 7: Beginners Guitar Chords - Lefty EditionKurt FlorescaNo ratings yet

- Absensi Apel Februari 2016Document5 pagesAbsensi Apel Februari 2016Ruth MillionNo ratings yet

- Ukuran Wallpanel SambasDocument1 pageUkuran Wallpanel SambasagusNo ratings yet

- Scales, Chords & Arpeggios - Bastien, James W - San Diego, CA, 1988 - San Diego, Calif. - Niel A. Kjos Music Co. - 9780849793516 - Anna's ArchiveDocument44 pagesScales, Chords & Arpeggios - Bastien, James W - San Diego, CA, 1988 - San Diego, Calif. - Niel A. Kjos Music Co. - 9780849793516 - Anna's Archivecraftycow62No ratings yet

- Benny Davis Trumpet Studio Trumpet Mouthpiece Brand Comparison ChartDocument6 pagesBenny Davis Trumpet Studio Trumpet Mouthpiece Brand Comparison ChartnaweNo ratings yet

- Manual Robot TefalDocument82 pagesManual Robot TefalPerfectreviewNo ratings yet

- 2018 ScheduleDocument1 page2018 ScheduleAndrian YtomNo ratings yet

- BS EN 1092 PN16 Flange Dimensions - Roy MechDocument4 pagesBS EN 1092 PN16 Flange Dimensions - Roy MechpriyankaNo ratings yet

- AntichristDocument3 pagesAntichristDAVID IKENNANo ratings yet

- Remon Juni TerataiDocument6 pagesRemon Juni TerataionetzzzNo ratings yet

- Absensi Apel Januari 2016Document3 pagesAbsensi Apel Januari 2016Ruth MillionNo ratings yet

- # Sorteo: Número: Fecha: 1ER# 2DO# 3ER# 4TO# 1 2 3 4 5 6 7Document10 pages# Sorteo: Número: Fecha: 1ER# 2DO# 3ER# 4TO# 1 2 3 4 5 6 7ingoscarportillahNo ratings yet

- Wktta League ResultsDocument1 pageWktta League Resultsapi-253238145No ratings yet

- TR Grade 3 ScalesDocument1 pageTR Grade 3 Scalesnewtonfogg123No ratings yet

- Thesis Sample, EUROCODEDocument151 pagesThesis Sample, EUROCODEelias workuNo ratings yet

- Fortified Relaxor Ferroelectricity of Rare Earth Substituted 4 Layered Babi Re Ti O (Re La, PR, ND, and SM) Aurivillius CompoundsDocument19 pagesFortified Relaxor Ferroelectricity of Rare Earth Substituted 4 Layered Babi Re Ti O (Re La, PR, ND, and SM) Aurivillius CompoundsTio Putra WendariNo ratings yet

- Problem Set in Power System 2Document3 pagesProblem Set in Power System 2Andrew AlterNo ratings yet

- Soil and Its PropertiesDocument20 pagesSoil and Its PropertiesHarsha HarapanahalliNo ratings yet

- RC Design (Outlet Section)Document36 pagesRC Design (Outlet Section)PRAVEEN CHAUDHARYNo ratings yet

- Motion in A Circle Updated 11Document3 pagesMotion in A Circle Updated 11Yahya Salman GamingNo ratings yet

- Transformer ProblemsDocument3 pagesTransformer ProblemsVaralakshmi SeerapuNo ratings yet

- Cswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductDocument40 pagesCswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductMohsen Keramati100% (1)

- PHY112 Lecture1Document131 pagesPHY112 Lecture18wc9sncvpwNo ratings yet

- G150 Option and SelectionDocument4 pagesG150 Option and SelectionJack SparrowNo ratings yet

- Bearing Arragements For Cement Industry FansDocument6 pagesBearing Arragements For Cement Industry FansAnonymous H3I29yjNo ratings yet

- Fme10 q2 w1 Em-WavesDocument6 pagesFme10 q2 w1 Em-WavesLouis Fetilo FabunanNo ratings yet

- HPH103 - Waves and Optics 1 - Lecture # 7-1Document16 pagesHPH103 - Waves and Optics 1 - Lecture # 7-1Praise NehumambiNo ratings yet

- 3 FlywheelDocument14 pages3 FlywheelAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Abett REF & MetrosilDocument6 pagesAbett REF & MetrosilNeeraj SinghNo ratings yet

- STRUCTUREDocument9 pagesSTRUCTUREFaria TahsinNo ratings yet

- 3 FL 5545tbabDocument51 pages3 FL 5545tbabjuan estebanNo ratings yet

- Flashcards - Topic 5.1 Nuclear Atoms - CAIE Physics IGCSEDocument25 pagesFlashcards - Topic 5.1 Nuclear Atoms - CAIE Physics IGCSEAHNAF AJMAINNo ratings yet

- Installation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNDocument112 pagesInstallation and Operating Instruction: Gas Burner WG10 /1-D ZM-LNdarrel gimoteaNo ratings yet

- Material Data Sheet: Casting Material: Leaded Red Brass C83600Document2 pagesMaterial Data Sheet: Casting Material: Leaded Red Brass C83600Kamal ThummarNo ratings yet

- Phase2 Analysis Information Tajeo Esperanza NV 920: Project SummaryDocument5 pagesPhase2 Analysis Information Tajeo Esperanza NV 920: Project SummarysanchezmendozaaNo ratings yet

- Thesis Marco RiveraDocument159 pagesThesis Marco RiveraMarco RiveraNo ratings yet

- Circuit Lab Introduction I ECE - Partial NotesDocument27 pagesCircuit Lab Introduction I ECE - Partial NotesDr.P. RAJASEKARNo ratings yet

- 2018 ENG HSC Questions-1Document38 pages2018 ENG HSC Questions-1TripsZeeNo ratings yet

- Science Quarter 2 Module 8Document28 pagesScience Quarter 2 Module 8SHEENA MAE DALGUNTAS60% (5)

- Megator Oil Water Separator Operational Theory: Rate of Rise TheoryDocument2 pagesMegator Oil Water Separator Operational Theory: Rate of Rise TheoryAhmedRamadanNo ratings yet

- Binders For TextilesDocument9 pagesBinders For Textiles950 911No ratings yet

- Concrete CalculationDocument10 pagesConcrete CalculationKaye Ibañez CastilloNo ratings yet

- Real Analysis Lecture 4newDocument15 pagesReal Analysis Lecture 4newJohn Michael Ochea NatadNo ratings yet