Professional Documents

Culture Documents

WFTI Editorial Calendar

WFTI Editorial Calendar

Uploaded by

Franco PuglieseCopyright:

Available Formats

You might also like

- SCJ v46n2 Web SecuredDocument56 pagesSCJ v46n2 Web SecuredRohan KulkarniNo ratings yet

- Standard Cable Color-Coding ReferenceDocument11 pagesStandard Cable Color-Coding ReferenceCarlo AccerNo ratings yet

- Welding and CuttingDocument64 pagesWelding and CuttingScott TrainorNo ratings yet

- Wfti Fall 2013Document76 pagesWfti Fall 2013Franco PuglieseNo ratings yet

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesDocument12 pagesMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokNo ratings yet

- Sektor Sub Sektor Nama Kode TahunDocument26 pagesSektor Sub Sektor Nama Kode TahunReiza FairruzNo ratings yet

- Wfti Fall 2014Document92 pagesWfti Fall 2014Franco PuglieseNo ratings yet

- 13-Ref List Phoceenne Rev.1 (2010-2017)Document25 pages13-Ref List Phoceenne Rev.1 (2010-2017)Jawad BasraNo ratings yet

- Roofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Document44 pagesRoofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Liondo PurbaNo ratings yet

- Boletín Residuos InglesDocument7 pagesBoletín Residuos InglesSandosHotelsNo ratings yet

- Monitoring of Codes and StandardsDocument2 pagesMonitoring of Codes and StandardsHkNo ratings yet

- Soldering Plating Stonesetting ENDocument16 pagesSoldering Plating Stonesetting ENAsia MarinoNo ratings yet

- Ssss SN&N Jun Sept 2010 IssueDocument68 pagesSsss SN&N Jun Sept 2010 IssueKTMONo ratings yet

- 6.2. Procurement PlanDocument27 pages6.2. Procurement PlanFahim AfrozeNo ratings yet

- International International: New Liebherr ATDocument68 pagesInternational International: New Liebherr ATrail32No ratings yet

- February2019 540611Document60 pagesFebruary2019 540611rail32No ratings yet

- Aug2019 PDFDocument70 pagesAug2019 PDFgv Sathishkumar KumarNo ratings yet

- HANSA 05 2018 Pod Drives 2018Document4 pagesHANSA 05 2018 Pod Drives 2018xeyranNo ratings yet

- IC Apr 2106Document100 pagesIC Apr 2106edsonbdasilvajuniorNo ratings yet

- Catalog 1353392054 PDFDocument6 pagesCatalog 1353392054 PDFNarendra Reddy BhumaNo ratings yet

- Report On The Kobe Steel Group's MisconductDocument7 pagesReport On The Kobe Steel Group's Misconduct205549No ratings yet

- Supply ChainDocument1 pageSupply Chainanil_munjalNo ratings yet

- CAMESE MSTA CatalogueDocument98 pagesCAMESE MSTA CatalogueAdalberto GomesNo ratings yet

- Fasteners Media Pack 2022 UKDocument2 pagesFasteners Media Pack 2022 UKsoni pravinNo ratings yet

- Asus Product Guide: Colors That InspireDocument31 pagesAsus Product Guide: Colors That Inspireit4728No ratings yet

- 15 - New Products - 20190920 PDFDocument35 pages15 - New Products - 20190920 PDFjamilNo ratings yet

- Display Design Solutions: WWW - Multipaneluk.co - UkDocument4 pagesDisplay Design Solutions: WWW - Multipaneluk.co - UkArdy WidyartaNo ratings yet

- Stainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Document6 pagesStainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Partagon PowNo ratings yet

- Nook Jack Catalog PDFDocument109 pagesNook Jack Catalog PDFHenrique MarquesNo ratings yet

- 22 Concertia CAT Ingles 01Document28 pages22 Concertia CAT Ingles 01Jair BerríoNo ratings yet

- Wa-0636860 0001 0001Document1 pageWa-0636860 0001 0001Bilal ChohanNo ratings yet

- Catalogue Yamawa 2016-17Document876 pagesCatalogue Yamawa 2016-17DenisNo ratings yet

- Corporate Presentation May2015 - enDocument19 pagesCorporate Presentation May2015 - enAnkit KumarNo ratings yet

- Slag Inclusion - Causes and Remedies PDFDocument1 pageSlag Inclusion - Causes and Remedies PDFkim lawNo ratings yet

- Axjo KatalogDocument6 pagesAxjo KatalogNicolasNo ratings yet

- Cartuchos y Filtros para Respidadores 3MDocument2 pagesCartuchos y Filtros para Respidadores 3MDean RojasNo ratings yet

- S60 Female Buttress Thread X Male Camlock - IBC Buttress Threaded Camlocks - Camlock Cam & Groove Couplings - Hose Couplings & Clamps - PAR GroupDocument1 pageS60 Female Buttress Thread X Male Camlock - IBC Buttress Threaded Camlocks - Camlock Cam & Groove Couplings - Hose Couplings & Clamps - PAR GroupkitofanecoNo ratings yet

- Starcke Catalog - GB - 01 - 2023Document100 pagesStarcke Catalog - GB - 01 - 2023jhscribdaccNo ratings yet

- NSSMC BrochureDocument12 pagesNSSMC BrochurePrasad MenonNo ratings yet

- Arch: Jan/Feb 2010Document68 pagesArch: Jan/Feb 2010promechmagsNo ratings yet

- Rondelle Inox Acton Ron Lfam1Document20 pagesRondelle Inox Acton Ron Lfam1Elie KhawandNo ratings yet

- Cat 3800 IND UKDocument68 pagesCat 3800 IND UKcaua0709No ratings yet

- Pipes and TubesDocument16 pagesPipes and TubesWer Tower ToNo ratings yet

- Ppt. Kel1 Fire ADocument42 pagesPpt. Kel1 Fire ARishad FadilahNo ratings yet

- ALPEMA Standard For Brazed Aluminium Plate-Fin Heat ExchangerDocument86 pagesALPEMA Standard For Brazed Aluminium Plate-Fin Heat ExchangerdgkmurtiNo ratings yet

- BIM IMPLEMENTATION High Speed Railway PT. Wijaya Karya 20 Mei 2020Document25 pagesBIM IMPLEMENTATION High Speed Railway PT. Wijaya Karya 20 Mei 2020Juliyus FajrinNo ratings yet

- Kiswire Group PresentationDocument21 pagesKiswire Group PresentationYeimi LaraNo ratings yet

- NS2 XF00 P0eaf 650001 AbDocument1 pageNS2 XF00 P0eaf 650001 AbLê ĐứcNo ratings yet

- Updated Price List 15 July 2020Document24 pagesUpdated Price List 15 July 2020SAGAR GUPTANo ratings yet

- Galvanized Pole Catalogue Version2.09Document20 pagesGalvanized Pole Catalogue Version2.09oprea.gheo17No ratings yet

- Quality Changes THE World: SYT80 (T6510-8)Document2 pagesQuality Changes THE World: SYT80 (T6510-8)Budiman Laveran SiraitNo ratings yet

- Kansal Industries - Tool Development Plan Model 'N': Assy T0 SampleDocument2 pagesKansal Industries - Tool Development Plan Model 'N': Assy T0 SampleajayNo ratings yet

- Askari Bank LTD Askari Bank LTD Askari Bank LTD Askari Bank LTDDocument1 pageAskari Bank LTD Askari Bank LTD Askari Bank LTD Askari Bank LTDAhmad Din ThaheemNo ratings yet

- Marafiq Approved Equipments Manufacturer ListDocument2 pagesMarafiq Approved Equipments Manufacturer ListkapsarcNo ratings yet

- WorldPipelines August 2016Document162 pagesWorldPipelines August 2016Integridad de Equipos y Gestión de Activos Nelcam100% (2)

- Komax - News - 2015 - 1 - EN - Copie - CopieDocument24 pagesKomax - News - 2015 - 1 - EN - Copie - CopieOmayma BoukatayaNo ratings yet

- March 2017Document105 pagesMarch 2017Pumper MagazineNo ratings yet

- Leviton PatchCord ReferenceGuideDocument1 pageLeviton PatchCord ReferenceGuideJMARMOLSNo ratings yet

- Markets and Commodity Figures: MetalsDocument1 pageMarkets and Commodity Figures: MetalsTiso Blackstar GroupNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- D6477Document4 pagesD6477Luana PalmaNo ratings yet

- Kelani Cu CablesDocument12 pagesKelani Cu CablesHansika Rajapaksha0% (1)

- BOQ Sample of Electrical DesignDocument2 pagesBOQ Sample of Electrical DesignAshik Rahman RifatNo ratings yet

- Designs For Brazil of Lightning Resistant OPGWDocument7 pagesDesigns For Brazil of Lightning Resistant OPGWJjjjpf100% (1)

- XLPE Insulated Power Cable - Garylion CableDocument60 pagesXLPE Insulated Power Cable - Garylion CableemmanskiNo ratings yet

- 132/76 KV XLPE Cable: Single-Core XLPE High Voltage Cable With Aluminium Laminated SheathDocument1 page132/76 KV XLPE Cable: Single-Core XLPE High Voltage Cable With Aluminium Laminated SheathBilal JavaidNo ratings yet

- NBR 14136 Plugs and Socket Outlets in BrazilDocument7 pagesNBR 14136 Plugs and Socket Outlets in BrazilCLOUD ALIGLOBALNo ratings yet

- 2017 NEC Code CH 2 Article 215 225 3Document20 pages2017 NEC Code CH 2 Article 215 225 3Roy Ferdy MassoloNo ratings yet

- Single Core & Multicore Flexible CablesDocument12 pagesSingle Core & Multicore Flexible Cablesdh24992499No ratings yet

- QCS-2010 Section 21 Part 10 Wiring Accessories and General PowerDocument8 pagesQCS-2010 Section 21 Part 10 Wiring Accessories and General Powerbryanpastor106No ratings yet

- Ancilliaryautopakcatvp PDFDocument56 pagesAncilliaryautopakcatvp PDFDaniel DumitruNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 10010Document1 pageR12 T07B24 Ifmi XX XX SDW El 10010Abrar DigitalNo ratings yet

- Lifting StandardsDocument17 pagesLifting Standardsanantharamakrishnan kNo ratings yet

- Rod Breakdown MachineDocument2 pagesRod Breakdown MachineMuhammad Nur CahyadiNo ratings yet

- OHMPRO CABLE GLANDS - LUGS CATALOG - BMPDocument36 pagesOHMPRO CABLE GLANDS - LUGS CATALOG - BMPVijai PrasathNo ratings yet

- Final Exam: Summer 2020: Please Write Your Answer in This GoogleDocument12 pagesFinal Exam: Summer 2020: Please Write Your Answer in This GoogleAjouwad Khandoker ÆdibNo ratings yet

- Tutorial, TB 531, B1-30 Cable System Electrical Characteristics PDFDocument27 pagesTutorial, TB 531, B1-30 Cable System Electrical Characteristics PDFgovindarulNo ratings yet

- Chapters 6 ExercisesDocument11 pagesChapters 6 ExercisesbibinbibinNo ratings yet

- Raychem Tubing Products: Selection GuideDocument12 pagesRaychem Tubing Products: Selection GuidetdjapyNo ratings yet

- Splicing Instructions For Flemish Eye TerminationsDocument9 pagesSplicing Instructions For Flemish Eye TerminationsGodfred Quarm0% (1)

- Research Proposal Samsom OwinoDocument15 pagesResearch Proposal Samsom OwinoDaniel Edward OmondiNo ratings yet

- Grounding and Its TypesDocument48 pagesGrounding and Its TypesAqeel � JZ Batch 22No ratings yet

- Proxxon Micromot New Products 2024Document6 pagesProxxon Micromot New Products 2024Vlad RoșoiNo ratings yet

- House Wiring Emf PDFDocument18 pagesHouse Wiring Emf PDFAbraham JyothimonNo ratings yet

- CPV Operating Manual 2011 95722Document28 pagesCPV Operating Manual 2011 95722Ana Goreti Sousa TorresNo ratings yet

- C-L-X Okoseal-N P-Os: Product DataDocument2 pagesC-L-X Okoseal-N P-Os: Product DatacubarturNo ratings yet

- Molylube Open Gear & Rope LubricantDocument2 pagesMolylube Open Gear & Rope LubricantdhowardjNo ratings yet

- Conductor and SuperconductorDocument12 pagesConductor and Superconductorankesh_ghoghariNo ratings yet

- Kata LogDocument54 pagesKata LogCatur EriyantoNo ratings yet

WFTI Editorial Calendar

WFTI Editorial Calendar

Uploaded by

Franco PuglieseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WFTI Editorial Calendar

WFTI Editorial Calendar

Uploaded by

Franco PuglieseCopyright:

Available Formats

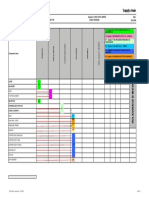

2016 EDITORIAL CALENDAR

Serving Worldwide Manufacturers of Springs,

Wire Formed Parts, Wire Mesh and Rebar Products

Written with industry experience and engineering knowledge, Wire Forming Technology International

brings its readers the technology, product and market information required to excel in the production

of springs, wire formed parts, wire mesh and rebar products.

ISSUE EMPHASIS ROUNDUPS SPOTLIGHT BONUS* AD CLOSING

WINTER Top Products Mesh Welding

of 2015 Rebar Processing wire 2016 February 19

Materials

wire 2016 Preview

Rebuild & Upgrade

SPRING Spring Coiling Straightening &

WIre Expo 2016 Wire Expo 2016 April 29

Preview Wire Handling Cutting

SPRING WORLD Preview

SUMMER wire China 2016 Preview Wire Forming & SPRING WORLD

Heat Treatment wire China 2016 August 12

WIre & Cable India 2016 Bending

Preview WIre & Cable India 2016

FALL Company Profiles Cleaning & Coating

Testing Company Profiles October 7

Fence Making Spring Grinding

* Bonus Distribution of the magazine at various wire forming and spring making industry trade shows (Winter, Spring and Summer issues).

Company Profiles posted online at www.wireformingtech.com (Fall issue).

Ultimation Machines Ltd.

Laundry Way Industrial Estate

Capel, Surrey, RH5 5LQ, U.K.

Tel: +44 1306 712205 • Fax: +44 1306 713182

COMPANY PRO- Spotlight On Spring Grinding

by Michael McNulty, Editor

SPOTLIGHT

FILES ARTICLES

Wire Forming Technology International

E-Mail: sales@ultimat.com • Web Site: www.ultimat.com

MISSION STATEMENT: Introduced in 2002, the ultimat range of kets used for the transplanting of trees and

Ultimation is committed to providing 2-axis, PC-controlled wire forming machines large shrubs. The ucw range of crosswire Some springs, like compression springs, require that

cost-effective solutions for their wire forming is comprised of 3 main types designed for welding machines for the automatic weld- their ends be ground to a flattened state in order to

and wire welding requirements. wire diameters from 2.00 mm (0.080") up ing of crosswires into frames. This machine facilitate their positioning when used in service. Spring

to 16.00 mm (0.629"). The versatile um / can be used as a stand alone model or fully Forming Systems, Inc. end grinding is carried out on spring grinding machines

Fall 2016 issue. Staff written articles on

HISTORY: umw series 2 axis machines are available integrated with the umw range for the fully P.O. Box 694 that are equipped with abrasive grinding wheels (also

Ultimation Machines was established in with/without automatic butt welding and are automatic production of filter frames and Schoolcraft, MI 49087 USA

1991 and manufactures a wide range of wire

called grinding stones). This operation is said to be one

suitable for the manufacture of 2D wire forms shelving used by manufactures of ovens and Contact: Tim Weber

forming and welding machines. used in POP displays, Supermarket Shelv- refrigerators. Tel: +1 877-727-FORM (3676) of the most expensive operations in the process of manu-

Ultimation’s staff has over 40 years of ing and Trolleys, Refrigerator shelving, and +1 269 679 3557 facturing compression springs. Because of this, spring

experience in the design and manufacture of many other wire products. The simpler ume Fax: +1 269 679 3567 grinding machine makers and suppliers of spring grind-

various machines for the wire industry. series incorporate many of the features of the SALES OFFICES/AGENTS: E-mail: info@formingsystemsinc.com ing wheels put a good amount of effort into improving

Internet: www.formingsystemsinc.com

um/umw but has a tilting tabletop. Ultimation Machines Ltd. the grinding operation by reducing the grinding time

Full and half page a selected product(s)

PRODUCTS: The ultimat range is perfect for the Laundry Way Industrial Estate and increasing the life of the grinding wheel.

Through the use of state of the art 3D manufacture of prototypes to high-volume Capel, Surrey, RH5 5LQ, UK

CAD software, Ultimation is capable of T: +44 1306 712205 • F: +44 1306 713182 Spring grinding is a unique process which aims to

production runs. Special versions can be

creating new models from initial concept to supplied for use with flat strip or profiled sales@ultimat.com • www.ultimat.com produce precision ground spring ends to certain toler-

completed designs in a very short amount of wire. Options include press and chamfer- ances. This is accomplished by removing some wire

time. Utilizing this technology together with ing stations, and secondary bend heads for Penn Machinery Company (Agent) stock from the end of the spring. Wire stock removal is

the latest in AC drives, machine controls and intricate forms. P.O. Box 226, Flourtown, PA 19031 USA dependant on wire diameter—the larger the diameter,

programming software, enables the company T: +1 215 233 0976 • F: +1 215 233 0977 the more wire stock that will need to come off. Typically,

advertisers receive or trade show(s).

Ultimation also design and manufacture

to be flexible in creating a diverse range of special purpose models to suit customer sales@pennbenders.com

the stock removal equals one-half of the wire diameter

machines engineered to suit specific cus- requirements. The ubw-24, a 3D jig welder www.pennbenders.com

tomer requirements.

at the very end of the coil.

for the fully automatic welding of wire bas-

The spring grinding process is usually a dry operation,

except in the case of very large springs—0.75” (19 mm)

xxxxxxxxxxxxxxxxxxxx diameter wire and larger—where wet grinding is uti-

WAFIOS

106 Ninth Street North

Brigantine, NJ 08203 USA

lized. Used in the industry for several years, dry grind-

a complimentary Each advertiser of

Contact: Jim Maguire ing allows manufacturers to avoid coolant costs which

North American Headquarters

Tel: +1 609 266 0200 include maintenance and disposal of the cooling media

WAFIOS Machinery Corporation Fax: +1 609 266 9079 as well as drying of the ground springs.

27 Northeast Industrial Road E-mail: info@MaguireMachinery.com

Branford, CT 06405 USA Internet: www.MaguireMachinery.com There are different types of machines and wheels used

for spring grinding, and there are two common, but

Tel: +1 203 481 5555 • Fax: +1 203 481 9854

different grinding methods that are used. First, there

E-Mail: sales@wafios.com • Web Site: www.wafios.com

is “crash/crush grinding” where two rotating grinding

Company Profile in a the selected topic will

wheels are set apart at a specific distance and a spring

COMPANY HISTORY: and tube bending machines to produce SALES OFFICES: carrier plate (also referred to as a spring loading plate)

WAFIOS Machinery Corporation of springs, wire and tube forms, cut wires,

chamfered wires, nails, screws, chains, North American Headquarters moves the un-ground springs in between to the grind-

Branford Connecticut is a subsidiary of

WAFIOS AG of Reutlingen Germany fence. WAFIOS Machinery Corporation ing wheels, and ground springs exit the machine. In this

(est. 1893). In addition to WAFIOS WAFIOS Machinery Corp. also rep- 27 Northeast Industrial Rd. process, the springs are “crushed” between the grinding

brand machinery, the WAFIOS Group resents STRECKER for buttwelding, Branford, CT 06405 USA wheels to achieve the desired end and ground length.

also includes: Hilgeland, Nutap and Rudolf Grauer for staples, paperclips Tel: +1 203 481 5555 The second method is “downfeed” grinding where the

special bound section receive a free Spotlight

Formatech companies. and coathangers, and Hezel, manual and Fax: +1 203 481 9854 plate of un-ground springs is rotating at a high speed,

powered shears for burr-free cutting. E-Mail: sales@wafios.com and the grinding wheels are progressively moved

CAPABILITIES: Web Site: www.wafios.com down onto the ends of all of the springs on the plate to

WAFIOS Machinery Corporation’s KEY PERSONNEL: xxxxxxxxxxxxxxxxxxxx remove the end material and achieve the desired length,

12,000 sq. foot Branford Connecticut fa- World Headquarters 106 Ninth Street North squareness, etc.

cility houses WAFIOS’ North American WAFIOS Machinery Corporation: Brigantine, NJ 08203 USA

Goetz Arndt, President WAFIOS Aktiengesellschaft In general, crash/crush grinding is the faster method

Sales, Spare Parts and Service headquar- Silberburgstrasse 5

Contact: Jim Maguire

of the Fall issue. Ad including contact

ters, maintaining more that 70,000 cubic Donald Fisher, VP, Sales Tel: +1 609 266 0200 when the grinder can remove the specified stock in

Reutlingen, 72764 Fax: +1 609 266 9079 one pass between the grinding wheels. If more than

feet of automated spare parts stores, for Bob Ackermann, VP, Engineering Germany E-mail: info@MaguireMachinery.com

WAFIOS customers in North America. Internet: www.MaguireMachinery.com

one pass is required, then downfeed grinding would

WAFIOS AG: Tel: +49 7127 1460 be more economical since the springs would only need

PRODUCTS: Thomas Hösle, CEO Fax: +49 7121 491209 to be loaded once. In some cases, downfeed grinding

WAFIOS manufactures more than Egon Reich, Manager, E-Mail: sales@wafios.de can give a higher quality of ground end, squareness

200 different models of wire working International Sales Web Site: www.wafios.de

or parallelism. Some grinding machines can perform

information and logo.

60 Wire Forming Technology International/Fall 2007 xx Wire Forming Technology International/Summer 2007

www.wireformingtech.com

You might also like

- SCJ v46n2 Web SecuredDocument56 pagesSCJ v46n2 Web SecuredRohan KulkarniNo ratings yet

- Standard Cable Color-Coding ReferenceDocument11 pagesStandard Cable Color-Coding ReferenceCarlo AccerNo ratings yet

- Welding and CuttingDocument64 pagesWelding and CuttingScott TrainorNo ratings yet

- Wfti Fall 2013Document76 pagesWfti Fall 2013Franco PuglieseNo ratings yet

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesDocument12 pagesMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokNo ratings yet

- Sektor Sub Sektor Nama Kode TahunDocument26 pagesSektor Sub Sektor Nama Kode TahunReiza FairruzNo ratings yet

- Wfti Fall 2014Document92 pagesWfti Fall 2014Franco PuglieseNo ratings yet

- 13-Ref List Phoceenne Rev.1 (2010-2017)Document25 pages13-Ref List Phoceenne Rev.1 (2010-2017)Jawad BasraNo ratings yet

- Roofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Document44 pagesRoofing and Waterproofing Product Catalog 2015 16 2014 - 11 - 04Liondo PurbaNo ratings yet

- Boletín Residuos InglesDocument7 pagesBoletín Residuos InglesSandosHotelsNo ratings yet

- Monitoring of Codes and StandardsDocument2 pagesMonitoring of Codes and StandardsHkNo ratings yet

- Soldering Plating Stonesetting ENDocument16 pagesSoldering Plating Stonesetting ENAsia MarinoNo ratings yet

- Ssss SN&N Jun Sept 2010 IssueDocument68 pagesSsss SN&N Jun Sept 2010 IssueKTMONo ratings yet

- 6.2. Procurement PlanDocument27 pages6.2. Procurement PlanFahim AfrozeNo ratings yet

- International International: New Liebherr ATDocument68 pagesInternational International: New Liebherr ATrail32No ratings yet

- February2019 540611Document60 pagesFebruary2019 540611rail32No ratings yet

- Aug2019 PDFDocument70 pagesAug2019 PDFgv Sathishkumar KumarNo ratings yet

- HANSA 05 2018 Pod Drives 2018Document4 pagesHANSA 05 2018 Pod Drives 2018xeyranNo ratings yet

- IC Apr 2106Document100 pagesIC Apr 2106edsonbdasilvajuniorNo ratings yet

- Catalog 1353392054 PDFDocument6 pagesCatalog 1353392054 PDFNarendra Reddy BhumaNo ratings yet

- Report On The Kobe Steel Group's MisconductDocument7 pagesReport On The Kobe Steel Group's Misconduct205549No ratings yet

- Supply ChainDocument1 pageSupply Chainanil_munjalNo ratings yet

- CAMESE MSTA CatalogueDocument98 pagesCAMESE MSTA CatalogueAdalberto GomesNo ratings yet

- Fasteners Media Pack 2022 UKDocument2 pagesFasteners Media Pack 2022 UKsoni pravinNo ratings yet

- Asus Product Guide: Colors That InspireDocument31 pagesAsus Product Guide: Colors That Inspireit4728No ratings yet

- 15 - New Products - 20190920 PDFDocument35 pages15 - New Products - 20190920 PDFjamilNo ratings yet

- Display Design Solutions: WWW - Multipaneluk.co - UkDocument4 pagesDisplay Design Solutions: WWW - Multipaneluk.co - UkArdy WidyartaNo ratings yet

- Stainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Document6 pagesStainless Steel Shapes Stainless Steel Shapes: Tel: +81-3-6867-4111 Tel: +81-3-6867-4111Partagon PowNo ratings yet

- Nook Jack Catalog PDFDocument109 pagesNook Jack Catalog PDFHenrique MarquesNo ratings yet

- 22 Concertia CAT Ingles 01Document28 pages22 Concertia CAT Ingles 01Jair BerríoNo ratings yet

- Wa-0636860 0001 0001Document1 pageWa-0636860 0001 0001Bilal ChohanNo ratings yet

- Catalogue Yamawa 2016-17Document876 pagesCatalogue Yamawa 2016-17DenisNo ratings yet

- Corporate Presentation May2015 - enDocument19 pagesCorporate Presentation May2015 - enAnkit KumarNo ratings yet

- Slag Inclusion - Causes and Remedies PDFDocument1 pageSlag Inclusion - Causes and Remedies PDFkim lawNo ratings yet

- Axjo KatalogDocument6 pagesAxjo KatalogNicolasNo ratings yet

- Cartuchos y Filtros para Respidadores 3MDocument2 pagesCartuchos y Filtros para Respidadores 3MDean RojasNo ratings yet

- S60 Female Buttress Thread X Male Camlock - IBC Buttress Threaded Camlocks - Camlock Cam & Groove Couplings - Hose Couplings & Clamps - PAR GroupDocument1 pageS60 Female Buttress Thread X Male Camlock - IBC Buttress Threaded Camlocks - Camlock Cam & Groove Couplings - Hose Couplings & Clamps - PAR GroupkitofanecoNo ratings yet

- Starcke Catalog - GB - 01 - 2023Document100 pagesStarcke Catalog - GB - 01 - 2023jhscribdaccNo ratings yet

- NSSMC BrochureDocument12 pagesNSSMC BrochurePrasad MenonNo ratings yet

- Arch: Jan/Feb 2010Document68 pagesArch: Jan/Feb 2010promechmagsNo ratings yet

- Rondelle Inox Acton Ron Lfam1Document20 pagesRondelle Inox Acton Ron Lfam1Elie KhawandNo ratings yet

- Cat 3800 IND UKDocument68 pagesCat 3800 IND UKcaua0709No ratings yet

- Pipes and TubesDocument16 pagesPipes and TubesWer Tower ToNo ratings yet

- Ppt. Kel1 Fire ADocument42 pagesPpt. Kel1 Fire ARishad FadilahNo ratings yet

- ALPEMA Standard For Brazed Aluminium Plate-Fin Heat ExchangerDocument86 pagesALPEMA Standard For Brazed Aluminium Plate-Fin Heat ExchangerdgkmurtiNo ratings yet

- BIM IMPLEMENTATION High Speed Railway PT. Wijaya Karya 20 Mei 2020Document25 pagesBIM IMPLEMENTATION High Speed Railway PT. Wijaya Karya 20 Mei 2020Juliyus FajrinNo ratings yet

- Kiswire Group PresentationDocument21 pagesKiswire Group PresentationYeimi LaraNo ratings yet

- NS2 XF00 P0eaf 650001 AbDocument1 pageNS2 XF00 P0eaf 650001 AbLê ĐứcNo ratings yet

- Updated Price List 15 July 2020Document24 pagesUpdated Price List 15 July 2020SAGAR GUPTANo ratings yet

- Galvanized Pole Catalogue Version2.09Document20 pagesGalvanized Pole Catalogue Version2.09oprea.gheo17No ratings yet

- Quality Changes THE World: SYT80 (T6510-8)Document2 pagesQuality Changes THE World: SYT80 (T6510-8)Budiman Laveran SiraitNo ratings yet

- Kansal Industries - Tool Development Plan Model 'N': Assy T0 SampleDocument2 pagesKansal Industries - Tool Development Plan Model 'N': Assy T0 SampleajayNo ratings yet

- Askari Bank LTD Askari Bank LTD Askari Bank LTD Askari Bank LTDDocument1 pageAskari Bank LTD Askari Bank LTD Askari Bank LTD Askari Bank LTDAhmad Din ThaheemNo ratings yet

- Marafiq Approved Equipments Manufacturer ListDocument2 pagesMarafiq Approved Equipments Manufacturer ListkapsarcNo ratings yet

- WorldPipelines August 2016Document162 pagesWorldPipelines August 2016Integridad de Equipos y Gestión de Activos Nelcam100% (2)

- Komax - News - 2015 - 1 - EN - Copie - CopieDocument24 pagesKomax - News - 2015 - 1 - EN - Copie - CopieOmayma BoukatayaNo ratings yet

- March 2017Document105 pagesMarch 2017Pumper MagazineNo ratings yet

- Leviton PatchCord ReferenceGuideDocument1 pageLeviton PatchCord ReferenceGuideJMARMOLSNo ratings yet

- Markets and Commodity Figures: MetalsDocument1 pageMarkets and Commodity Figures: MetalsTiso Blackstar GroupNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- D6477Document4 pagesD6477Luana PalmaNo ratings yet

- Kelani Cu CablesDocument12 pagesKelani Cu CablesHansika Rajapaksha0% (1)

- BOQ Sample of Electrical DesignDocument2 pagesBOQ Sample of Electrical DesignAshik Rahman RifatNo ratings yet

- Designs For Brazil of Lightning Resistant OPGWDocument7 pagesDesigns For Brazil of Lightning Resistant OPGWJjjjpf100% (1)

- XLPE Insulated Power Cable - Garylion CableDocument60 pagesXLPE Insulated Power Cable - Garylion CableemmanskiNo ratings yet

- 132/76 KV XLPE Cable: Single-Core XLPE High Voltage Cable With Aluminium Laminated SheathDocument1 page132/76 KV XLPE Cable: Single-Core XLPE High Voltage Cable With Aluminium Laminated SheathBilal JavaidNo ratings yet

- NBR 14136 Plugs and Socket Outlets in BrazilDocument7 pagesNBR 14136 Plugs and Socket Outlets in BrazilCLOUD ALIGLOBALNo ratings yet

- 2017 NEC Code CH 2 Article 215 225 3Document20 pages2017 NEC Code CH 2 Article 215 225 3Roy Ferdy MassoloNo ratings yet

- Single Core & Multicore Flexible CablesDocument12 pagesSingle Core & Multicore Flexible Cablesdh24992499No ratings yet

- QCS-2010 Section 21 Part 10 Wiring Accessories and General PowerDocument8 pagesQCS-2010 Section 21 Part 10 Wiring Accessories and General Powerbryanpastor106No ratings yet

- Ancilliaryautopakcatvp PDFDocument56 pagesAncilliaryautopakcatvp PDFDaniel DumitruNo ratings yet

- R12 T07B24 Ifmi XX XX SDW El 10010Document1 pageR12 T07B24 Ifmi XX XX SDW El 10010Abrar DigitalNo ratings yet

- Lifting StandardsDocument17 pagesLifting Standardsanantharamakrishnan kNo ratings yet

- Rod Breakdown MachineDocument2 pagesRod Breakdown MachineMuhammad Nur CahyadiNo ratings yet

- OHMPRO CABLE GLANDS - LUGS CATALOG - BMPDocument36 pagesOHMPRO CABLE GLANDS - LUGS CATALOG - BMPVijai PrasathNo ratings yet

- Final Exam: Summer 2020: Please Write Your Answer in This GoogleDocument12 pagesFinal Exam: Summer 2020: Please Write Your Answer in This GoogleAjouwad Khandoker ÆdibNo ratings yet

- Tutorial, TB 531, B1-30 Cable System Electrical Characteristics PDFDocument27 pagesTutorial, TB 531, B1-30 Cable System Electrical Characteristics PDFgovindarulNo ratings yet

- Chapters 6 ExercisesDocument11 pagesChapters 6 ExercisesbibinbibinNo ratings yet

- Raychem Tubing Products: Selection GuideDocument12 pagesRaychem Tubing Products: Selection GuidetdjapyNo ratings yet

- Splicing Instructions For Flemish Eye TerminationsDocument9 pagesSplicing Instructions For Flemish Eye TerminationsGodfred Quarm0% (1)

- Research Proposal Samsom OwinoDocument15 pagesResearch Proposal Samsom OwinoDaniel Edward OmondiNo ratings yet

- Grounding and Its TypesDocument48 pagesGrounding and Its TypesAqeel � JZ Batch 22No ratings yet

- Proxxon Micromot New Products 2024Document6 pagesProxxon Micromot New Products 2024Vlad RoșoiNo ratings yet

- House Wiring Emf PDFDocument18 pagesHouse Wiring Emf PDFAbraham JyothimonNo ratings yet

- CPV Operating Manual 2011 95722Document28 pagesCPV Operating Manual 2011 95722Ana Goreti Sousa TorresNo ratings yet

- C-L-X Okoseal-N P-Os: Product DataDocument2 pagesC-L-X Okoseal-N P-Os: Product DatacubarturNo ratings yet

- Molylube Open Gear & Rope LubricantDocument2 pagesMolylube Open Gear & Rope LubricantdhowardjNo ratings yet

- Conductor and SuperconductorDocument12 pagesConductor and Superconductorankesh_ghoghariNo ratings yet

- Kata LogDocument54 pagesKata LogCatur EriyantoNo ratings yet