Professional Documents

Culture Documents

817058_QMD_1.2

817058_QMD_1.2

Uploaded by

Manela Okic DzidicCopyright:

Available Formats

You might also like

- M 75 90 115 - FourStroke - 2.1LDocument660 pagesM 75 90 115 - FourStroke - 2.1LAlex Diaz79% (19)

- Problem Tree AnalysisDocument3 pagesProblem Tree AnalysisMa Reana Ortega Villareal100% (2)

- Be Boiler Manual PDFDocument206 pagesBe Boiler Manual PDFRavi k Lavu100% (3)

- Gazzola - EDPC 501 - Fall 2016 SyllabusDocument10 pagesGazzola - EDPC 501 - Fall 2016 SyllabusJonathan LimNo ratings yet

- Consumers Are People Too - FrogDocument36 pagesConsumers Are People Too - FrogMalek El BéjiNo ratings yet

- 1 - Merck - Pharma - Rawmaterial - Brochure PDFDocument34 pages1 - Merck - Pharma - Rawmaterial - Brochure PDFTuyền KimNo ratings yet

- Reformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFDocument99 pagesReformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFSanthana Kumar Annamalai100% (1)

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Why Cell Phone Towers Are So Bad For Your Health?Document6 pagesWhy Cell Phone Towers Are So Bad For Your Health?Dr. Sirish100% (1)

- MQD 3.0Document50 pagesMQD 3.0agriloNo ratings yet

- An Overview of Drug Master Files 2167 7689 1000198Document7 pagesAn Overview of Drug Master Files 2167 7689 1000198Shivam VinothNo ratings yet

- Treinamento iFIx32Document60 pagesTreinamento iFIx32guilherme melloNo ratings yet

- 156 VASUDHA PHARMA CHEM LIMITED Company Brochure 20230623113323Document10 pages156 VASUDHA PHARMA CHEM LIMITED Company Brochure 20230623113323deekshithNo ratings yet

- Localized ARIA RTM Clients Customer Release Note 16.1 MR4Document19 pagesLocalized ARIA RTM Clients Customer Release Note 16.1 MR4Gabriela Silva MartinsNo ratings yet

- Monitor PH - C-900 - User Manual 18-1120-06.acDocument40 pagesMonitor PH - C-900 - User Manual 18-1120-06.acCarlos Alberto Ramirez GarciaNo ratings yet

- TDI-Lupranat T80Document2 pagesTDI-Lupranat T80Virender KumarNo ratings yet

- EPA Positive M Atrix Factorization (PM F) 5.0 Fundamentals and User GuideDocument136 pagesEPA Positive M Atrix Factorization (PM F) 5.0 Fundamentals and User GuideJuan David Bastidas SanchezNo ratings yet

- 10.FITOK Company Brochure 160909Document20 pages10.FITOK Company Brochure 160909inglegs75No ratings yet

- Kopra Feb2021Document23 pagesKopra Feb2021sunil.dasarath jadhavNo ratings yet

- Avicel RC 591Document20 pagesAvicel RC 591Hector Chilquillo TorresNo ratings yet

- Plasticizer Presentation March 2010Document58 pagesPlasticizer Presentation March 2010Kaushal KothariNo ratings yet

- Emphaze Hybrid PurifierDocument28 pagesEmphaze Hybrid PurifierjayNo ratings yet

- Dppa Link Afdisd Product Information en-USDocument34 pagesDppa Link Afdisd Product Information en-USPUKKINUN PONGRAKANANONNo ratings yet

- Litdoc18112107 20161015125116Document2 pagesLitdoc18112107 20161015125116Mohammad PouryaqubiNo ratings yet

- IAGTGMPNews IIIDocument2 pagesIAGTGMPNews IIImadhurajusNo ratings yet

- Owner - Manual - 267 277 278 280 287 859 870 877 - Hy25 1380 m1 - Us - 20170627Document44 pagesOwner - Manual - 267 277 278 280 287 859 870 877 - Hy25 1380 m1 - Us - 20170627yaccoubisamiNo ratings yet

- ECA Appropriate GMP For Pharmaceutical ExcipientsDocument4 pagesECA Appropriate GMP For Pharmaceutical Excipientsmailtorubal2573No ratings yet

- FluorezDocument27 pagesFluorezRick RgNo ratings yet

- Parenteral Applications Brochure Br2750en MKDocument8 pagesParenteral Applications Brochure Br2750en MKSagar PopatNo ratings yet

- Marketing Project LaptopDocument26 pagesMarketing Project LaptopJayana ModiNo ratings yet

- Et PN Iso Pump Instruction Manual-OrgDocument60 pagesEt PN Iso Pump Instruction Manual-OrgSd Ver69% (13)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingSameh RadwanNo ratings yet

- TRACERCO Taggant BrochureDocument16 pagesTRACERCO Taggant BrochureKarthick SarathyNo ratings yet

- Reference Product - AssessmentDocument3 pagesReference Product - AssessmentBett KevinNo ratings yet

- MACH LED 120F / 120: Directions For UseDocument25 pagesMACH LED 120F / 120: Directions For UseMoas GabrounNo ratings yet

- Roof TilesDocument14 pagesRoof Tileswrite2prathibaNo ratings yet

- Proteus XR F Generator Service Manual SM 5764770-1EN 4Document540 pagesProteus XR F Generator Service Manual SM 5764770-1EN 4fortroniNo ratings yet

- Lutensol AO 3 Safety SheetDocument5 pagesLutensol AO 3 Safety SheetPiipee AndresNo ratings yet

- Abbott CatalogueDocument8 pagesAbbott CataloguekadirucaNo ratings yet

- ERES WinCC TIA RT-Prof V16 en en-USDocument28 pagesERES WinCC TIA RT-Prof V16 en en-USArsalanAliNo ratings yet

- MediawebserverDocument3 pagesMediawebservertripathi prashantNo ratings yet

- TM-1002 AVEVA Plant (12 Series) Drawing Production (Basic) Rev 5.0Document123 pagesTM-1002 AVEVA Plant (12 Series) Drawing Production (Basic) Rev 5.0SOFTWARE SHARINGNo ratings yet

- BASF 10484 ProCat PDS 190429 120543 Rev.04 2021Document2 pagesBASF 10484 ProCat PDS 190429 120543 Rev.04 2021salsasafira926No ratings yet

- ePMP Release Notes 4.5.6Document6 pagesePMP Release Notes 4.5.6gspolettoNo ratings yet

- Vitamin E-Acetate Care - TI - REV4-1 PDFDocument4 pagesVitamin E-Acetate Care - TI - REV4-1 PDFFatima Ezzohra SafsafaNo ratings yet

- MA0008Document1 pageMA0008Alfonso RivasNo ratings yet

- CalibrationWorld 2013-01 ENGDocument28 pagesCalibrationWorld 2013-01 ENGAfam-Anadu UcheNo ratings yet

- 51 XMT PDocument124 pages51 XMT PSeltromind SrlNo ratings yet

- LTQ Orbitrap XL HardwareDocument124 pagesLTQ Orbitrap XL Hardwarerusspickford100% (1)

- Eres Annex 11 Eu GMP SiemensDocument30 pagesEres Annex 11 Eu GMP SiemenshuykhiemNo ratings yet

- 3.5 T Bolier ManualDocument206 pages3.5 T Bolier Manualchandravadiyaketan150467% (3)

- 0FDA - SMF - The Drug Manufacturers Guide To Site Master Files ExecSeries 1 1 PDFDocument65 pages0FDA - SMF - The Drug Manufacturers Guide To Site Master Files ExecSeries 1 1 PDFDiemTrinhNguyenThienNo ratings yet

- Vrla Handbook: English Industrial BatteriesDocument70 pagesVrla Handbook: English Industrial BatteriesbobyNo ratings yet

- RimalPatel 23 MBA BP AssignmentDocument11 pagesRimalPatel 23 MBA BP AssignmentKillol ShahNo ratings yet

- 00 OpI 20141338Document367 pages00 OpI 20141338kevin nerioNo ratings yet

- Fdocuments - in - Gehc Service Manual Procare b40 b20 Monitor PDFDocument252 pagesFdocuments - in - Gehc Service Manual Procare b40 b20 Monitor PDFkarim100% (1)

- Fcde 0110uk PDFDocument580 pagesFcde 0110uk PDFbtsgr parkerNo ratings yet

- ERES PM-QUALITY V10 enDocument28 pagesERES PM-QUALITY V10 enAbdul KalimNo ratings yet

- Cinryze C4V005AS - COADocument11 pagesCinryze C4V005AS - COASebastian PSNo ratings yet

- TRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFDocument94 pagesTRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFInt PueNo ratings yet

- Guideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardFrom EverandGuideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardNo ratings yet

- Multi-Objective Optimization in Chemical Engineering: Developments and ApplicationsFrom EverandMulti-Objective Optimization in Chemical Engineering: Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderFrom EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderNo ratings yet

- The Examples of Job VacancyDocument2 pagesThe Examples of Job VacancysasNo ratings yet

- The Boston Globe - 10 October 2022Document37 pagesThe Boston Globe - 10 October 2022Lemelin GauthierNo ratings yet

- Practical Research 2: 4Th QuarterDocument4 pagesPractical Research 2: 4Th Quartergamms upNo ratings yet

- Case Study 2Document6 pagesCase Study 2Rahmani MuharimNo ratings yet

- 2 Risk Identification FormDocument6 pages2 Risk Identification FormkamranNo ratings yet

- MSC (N) SyllabusDocument246 pagesMSC (N) SyllabussabeethuNo ratings yet

- Nurs 478 Qip PresentationDocument15 pagesNurs 478 Qip Presentationapi-489650178No ratings yet

- Final 1Document5 pagesFinal 1khansha ComputersNo ratings yet

- Biopharmaceutical LexiconDocument65 pagesBiopharmaceutical Lexiconryu_chile28234No ratings yet

- Epidermophyton (Skin, Nails) : Microsporum, TrichophytonDocument5 pagesEpidermophyton (Skin, Nails) : Microsporum, TrichophytonRoyNo ratings yet

- ArticolsssaDocument11 pagesArticolsssaCosmin GabrielNo ratings yet

- Print Bro BAB 5Document4 pagesPrint Bro BAB 5Gung LisaNo ratings yet

- Interactive Learning Activities Parker CarpenterDocument1 pageInteractive Learning Activities Parker Carpenterapi-360582909No ratings yet

- DCL Report - Hygitech HSDocument2 pagesDCL Report - Hygitech HSFarhan RashidNo ratings yet

- MSDS-POLINTEK L & P Group-DMI INDUSTRIDocument8 pagesMSDS-POLINTEK L & P Group-DMI INDUSTRIYosep SasadaNo ratings yet

- Revision Test 4 - Class 12D1 2021-2022Document7 pagesRevision Test 4 - Class 12D1 2021-2022Tenebrae LuxNo ratings yet

- Jsa - CMC WorkDocument11 pagesJsa - CMC WorkEjazNo ratings yet

- ACLS Precourse Self-AssessmentDocument2 pagesACLS Precourse Self-AssessmentMandela KibiritiNo ratings yet

- CAU FacultyApplications are invited on the prescribed application form for the posts of Assistant Professors on permanent basis in the following subjects in the pay Band ‐ III of Rs. 15600‐39100 with Academic Grade Pay Rs. 6000/‐ plus usual allowances as admissible under the rules of University of Delhi from time to time .Document8 pagesCAU FacultyApplications are invited on the prescribed application form for the posts of Assistant Professors on permanent basis in the following subjects in the pay Band ‐ III of Rs. 15600‐39100 with Academic Grade Pay Rs. 6000/‐ plus usual allowances as admissible under the rules of University of Delhi from time to time .siddulaNo ratings yet

- Examiner Report NEBOSH IGC2 Oct Dec 2015 PDFDocument14 pagesExaminer Report NEBOSH IGC2 Oct Dec 2015 PDFShaik Anwar0% (2)

- Challenges To Effective Drug TherapyDocument5 pagesChallenges To Effective Drug TherapyAlyssaGrandeMontimorNo ratings yet

- MSDS Conant - 1 - 75 - GR-ID-SDS - 02Document16 pagesMSDS Conant - 1 - 75 - GR-ID-SDS - 02purwadiNo ratings yet

- What Is HappinessDocument8 pagesWhat Is HappinessAbdul RashidNo ratings yet

- Willits Accellerated Achilles RehabDocument2 pagesWillits Accellerated Achilles RehabattilabajusNo ratings yet

- Vampire Survivors Jumpchain 1.3Document120 pagesVampire Survivors Jumpchain 1.3ZiggurathNo ratings yet

- Answer Sheet Week 1 Pe 8Document2 pagesAnswer Sheet Week 1 Pe 8Riza LeeNo ratings yet

817058_QMD_1.2

817058_QMD_1.2

Uploaded by

Manela Okic DzidicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

817058_QMD_1.2

817058_QMD_1.2

Uploaded by

Manela Okic DzidicCopyright:

Available Formats

Emprove Quality ®

Management Dossier

Documentation to support risk assessment

817058

Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Not appropriate for regulatory submission as active pharmaceutical

ingredient. The use of this dossier shall be subject to the terms of

use that can be found at Emprove.de

The life science business

of Merck KGaA, Darmstadt,

Germany operates as

MilliporeSigma in the

U.S. and Canada.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Table of Contents

version history report.................................................................................................2

Introduction.................................................................................................................3

Chapter 1: Supply Chain Information........................................................................4

Chapter 2: Statement on Good Distribution Practices............................................6

Chapter 3: Product Quality Self-Assessment.........................................................10

Chapter 4: Site Quality Self Assessment................................................................19

Chapter 5: Supplier Audit Report Summary...........................................................34

Chapter 6: Quality Risk Management Process Summary.....................................36

Chapter 7: Change Management Process Summary.............................................38

Annex.........................................................................................................................40

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 1 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Version History Report

Chapter Name Statement Type New Version Number Old Version Number Replacement Reason

Chapter 1: Supply Chain D_Supply Chain Editorial/Formatting

1.1 1.0

Information Information Change

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 2 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Introduction

The Emprove® dossiers are designed to enable our customers to respond to the regulatory

recommendations/requirements easily, quickly, and adequately. As a result of the Emprove®

qualification processes, we offer the Emprove® Material Qualification Dossier (in line with CTD format).

This dossier is designed to facilitate qualification of material for application in the pharmaceutical

industry. With the Emprove® Quality Management Dossier, we assist in conducting the required risk

assessments. With the Emprove® Operational Excellence Dossier, we provide supporting information

to optimize processes according to the relevant regulations.

Version history

The dossier version number is indicated in the header of every page. Product quality-relevant content

changes result in a full-version increase, for example version 1.0 to 2.0. Editorial or formatting

changes result in a sub-version increase, for example 1.0 to 1.1.

Additionally, the Version History Report provides an overview of components which have been

updated in this version.

Regulatory Framework

Regulatory agencies expect a risk-based approach to managing a drug’s quality throughout its

lifecycle: from early development through commercial manufacturing. These concepts are clearly

articulated in ICH Q8-Q11, for example ICH Q10 chapter 2.7 addresses the responsibility of the drug

product manufacturer to evaluate and qualify purchased materials.

The US Food and Drug Administration Safety and Innovation Act (FDASIA) introduces similar

requirements, with FDASIA Title VII Section 711 indicating the need for oversight and controls to

ensure quality. This includes managing the risk of, and establishing the safety of, raw materials and

materials used in the manufacturing of drugs. European Commission Guideline 2015/C 95/02

describes the requirements for excipient GMP risk assessment in the EU as mandated by Directive

2001/83/EC.

With our Supply Chain Information and Quality Self Assessments we provide transparency on the

manufacturing steps, facilities and quality systems applied to support our customers risk assessment

needs.

European Commission Guideline 2015/C 95/01 describes the requirements for GDP for active

pharmaceutical ingredients in the EU. The principles of this guideline can also be applied to excipients

for which no specific guidelines exist in the EU.

The IPEC Good Distribution Practices Guide for Pharmaceutical Excipients provides guidance on the

application of GDP to steps in the distribution/supply chain.

The risk-based approach on how storage and distribution conditions are defined for our

pharmaceutical starting and raw materials is described in our Statement on Good Distribution Practice.

With the Quality Risk Management Process Summary, we provide an overview of our approach to

identify and adequately assess potential risks related to manufacture and distribution of our products.

This is in line with ICH Guideline Q9 Quality Risk Management and ISO 31000 Risk Management

Principles & Guidelines.

The Change Management Process Summary describes the process of evaluation, implementation and

notification of changes, considering the impact of the change on the product quality in line with the

overall Risk Management Process. The Change Management process allows changes to be managed

in compliance with competent authority requirements.

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 3 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 1: Supply Chain Information

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 4 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 5 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 2: Statement on Good Distribution Practices

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 6 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 7 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 8 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 9 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 3: Product Quality Self-Assessment

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 10 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 11 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 12 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 13 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 14 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 15 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 16 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 17 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 18 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 4: Site Quality Self-Assessment

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 19 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 20 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 21 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 22 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 23 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 24 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 25 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 26 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 27 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 28 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 29 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 30 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 31 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 32 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 33 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 5: Supplier Audit Report Summary

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 34 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 35 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 6: Quality Risk Management Process Summary

In our Life Science (LS) business, Quality Risk Management is an integral part of our manufacturing

and distribution Quality Management System. All functions, responsible for the manufacture and

handling of our product offerings, are effectively and consistently evaluating and controlling identified

risks, governed by an effective Quality Risk Management process. The LS Quality Risk Management

process is aligned with ICH Guideline Q9 Quality Risk Management and ISO 31000 Risk

Management Principles & Guidelines.

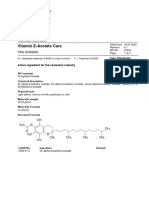

Figure 1: Overview of LS Quality Risk Management process (adopted from ICH Q9):

Quality Risk Management at LS uses process and scientific knowledge for the identification and

evaluation of risk to product quality. The level of effort, formality and documentation of the quality risk

management process is commensurate with the level of risk identified.

A Quality & Regulatory Risk Register is mandatory for all LS manufacturing sites and distribution

centres. This is designed to identify and evaluate, through an annual risk planning cycle based on the

Quality Risk Management process described above, Quality and/or Regulatory risks that have the

potential to impact product quality or the application of our products for our customers.

In addition to the Risk Register, Risk Management, using tools such as FMEA and HACCP, is an

integral part of routine manufacturing and product realization and supply processes and as such is

incorporated into the Change Management, New Product Introduction, Supplier Management, Non-

Conformance / Deviation & CAPA, Out of Specification and Complaint Investigation processes of LS.

For some identified risks, even the best Quality Risk Management practices might not entirely

eliminate all risk. In cases where risks are not fully mitigated, residual risk will be re-assessed and

may be accepted, with appropriate documentation and approval by responsible stakeholders.

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 36 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Actions to mitigate risks are documented and communicated appropriately, for example through

CAPAs, Change Controls and Objectives for the next planning period. These processes and regular

risk reviews are then used as tools to track and trend the effectiveness of these actions.

While we strive to continuously identify and manage any risks associated with the manufacture,

testing, release, and distribution of our product offerings, it is ultimately our customers’ responsibility

to perform their own risk assessment for their individual use or application. Any additional risk

identified during our customers’ use or application of our products should be assessed by the

customer and notified to us as appropriate.

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 37 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Chapter 7: Change Management Process Summary

In our Life Science (LS) business, Change Management is an integral part of our manufacturing and

distribution Quality Management System (QMS). Our LS Change Management process allows

changes to be managed in compliance with competent authority requirements. Internal procedures

and applicable industry guidance provided by organizations such as BioPhorum or IPEC federation,

define the responsibilities for the various roles involved in the Change Management Process.

Our LS Risk Management process ensures that all potential risks are identified and adequately

assessed, mitigated, and managed to closure. The LS Risk Management process helps the Change

Team to define activities that reflect the magnitude of change, where the level of effort and formality of

any the proposed Implementation Action Plan is commensurate with the level of identified risk.

The main phases of our Change Management process are outlined in Figure 1.

Our obligations and processes for Customer Notifications, that may arise from any change

implementation, are also integrated into the overall Change Management Process at LS. Customer

Notification is not a requirement for all Change Controls. The LS Change Management process

includes consideration for changes which should be notified to relevant customers, who have opted-in

to our change notification program for their products, depending on the type of change, the product’s

MQ level as defined by the M-Clarity™ program, the intended application of the product or service

and the potential Quality Agreement between LS and the customer. During the ‘Assess Change’

phase of the Change process, it will be determined by the Change Team and relevant customer

facing functions if Customer Notification is required. As well the need for authority notifications is

determined. Changes impacting Emprove® Dossier content are also reflected in the post-change

updated version of the Dossier.

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 38 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Phase 1: Evaluation

• High level Stakeholder review of

Proposed Change.

• Decision, to progress with change or

not (guided by key stakeholders).

Phase 2: Change Assessment

• Complete detailed Risk Assessment of

the proposed Change (e.g. through a

Process FMEA).

• Identify products, processes, and

customers (internal & external)

impacted by the change.

• Document Quality & Regulatory impact

on product and intended customer

application of the product.

• Develop Implementation action plan

guided by completed risk assessment.

Considerations may include but are

not limited to:

o Product specifications

o Extractables

o Shelf life

o Material evaluation

o Material declarations

• Determination of Customer Notification

Strategy.

Phase 3: Change Approval

• On completion of Risk Assessment

and development of the

Implementation Action plan, the

Change is routed for approval by

relevant Stakeholders, Subject Matter

Experts (SME) and functions.

Phase 4: Implementation

• Execute the Action plan.

• Document results, which may include,

but are not limited to:

o Validation/Qualification as

applicable

▪ IQ / OQ / PQ

▪ Sterilisation

▪ Test Method

Qualification

▪ Software Validation

▪ Cleaning Validation

o Test results

o Trainings

o Procedural updates

• Execute the Customer Notification

Strategy as applicable.

• Inventory Management.

Phase 5: Monitoring

• Incorporate a Post-Implementation

Monitoring plan to monitor consistency

and Quality of the product / process

post change, if applicable.

• Review of completed change details

and change closure.

Figure 1: Overview of LS Change Management Process

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 39 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

Annex

References:

ICH HARMONISED TRIPARTITE GUIDELINE PHARMACEUTICAL DEVELOPMENT Q8

Current version

ICH HARMONISED TRIPARTITE GUIDELINE QUALITY RISK MANAGEMENT Q9

Current version

ICH HARMONISED TRIPARTITE GUIDELINE PHARMACEUTICAL QUALITY SYSTEM Q10

Current version

ICH HARMONISED TRIPARTITE GUIDELINE DEVELOPMENT AND MANUFACTURE OF DRUG

SUBSTANCES Q11

Current version

Code of Federal Regulations, TITLE 21--FOOD AND DRUGS CHAPTER I--FOOD AND DRUG

ADMINISTRATION

DEPARTMENT OF HEALTH AND HUMAN SERVICES, SUBCHAPTER C—DRUGS: General Part

211: Current Good Manufacturing Practice for Finished Pharmaceuticals

Food and Drug Administration Safety and Innovation Act FDASIA Title VII Drug Supply Chain

Provisions

EudraLex

The Rules Governing Medicinal Products in the European Union Volume 4

EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use,

Chapter 1 Pharmaceutical Quality System, Chapter 5 Production

EU Guidelines of 19 March 2015 on the formalized risk assessment for ascertaining the appropriate

good manufacturing practice for excipients of medicinal products for human use (2015/C 95/02)

DIRECTIVE 2001/83/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 6 November 2001 on the Community code relating to medicinal products for human use

EU Guidelines of 19 March 2015 on principles of Good Distribution Practice of active substances for

medicinal products for human use (2015/C 95/01)

IPEC Federation: The IPEC Good Distribution Practices Guide for Pharmaceutical Excipients

Current version

International Organization for Standardization: ISO 31000 Risk Management - Guidelines

Current version

IPEC Federation: The IPEC Significant Change Guide

Current version

Raw Materials: Supplier change notifications: change areas and requirements

BioPhorum Operations Group Ltd and Bio-Process Systems Alliance

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023 Page 40 of 40

and/or its affiliates. All Rights Reserved.

Version: 1.2 Status: Approved

817058 Maleic acid EMPROVE® ESSENTIAL Ph Eur,NF

For additional information,

please visit

Emprove.de

We provide information and advice to our customers on application technologies and regulatory matters to

the best of our knowledge and ability, but without obligation or liability. Existing laws and regulations are to

be observed in all cases by our customers. This also applies in respect to any rights of third parties. Our

information and advice do not relieve our customers of their own responsibility for checking the suitability of

our products for the envisaged purpose.

© 2020 Merck KGaA, Darmstadt, Germany and/or its affiliates. All Rights Reserved. MilliporeSigma, the vibrant M, SAFC

and Emprove are trademarks of Merck KGaA, Darmstadt, Germany or its affiliates. All other trademarks are the property

of their respective owners. Detailed information on trademarks is available via publicly accessible resources.

©2014-2020 Merck KGaA, Darmstadt, Germany Status Date: 04/07/2023

and/or its affiliates. All Rights Reserved.

You might also like

- M 75 90 115 - FourStroke - 2.1LDocument660 pagesM 75 90 115 - FourStroke - 2.1LAlex Diaz79% (19)

- Problem Tree AnalysisDocument3 pagesProblem Tree AnalysisMa Reana Ortega Villareal100% (2)

- Be Boiler Manual PDFDocument206 pagesBe Boiler Manual PDFRavi k Lavu100% (3)

- Gazzola - EDPC 501 - Fall 2016 SyllabusDocument10 pagesGazzola - EDPC 501 - Fall 2016 SyllabusJonathan LimNo ratings yet

- Consumers Are People Too - FrogDocument36 pagesConsumers Are People Too - FrogMalek El BéjiNo ratings yet

- 1 - Merck - Pharma - Rawmaterial - Brochure PDFDocument34 pages1 - Merck - Pharma - Rawmaterial - Brochure PDFTuyền KimNo ratings yet

- Reformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFDocument99 pagesReformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFSanthana Kumar Annamalai100% (1)

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Why Cell Phone Towers Are So Bad For Your Health?Document6 pagesWhy Cell Phone Towers Are So Bad For Your Health?Dr. Sirish100% (1)

- MQD 3.0Document50 pagesMQD 3.0agriloNo ratings yet

- An Overview of Drug Master Files 2167 7689 1000198Document7 pagesAn Overview of Drug Master Files 2167 7689 1000198Shivam VinothNo ratings yet

- Treinamento iFIx32Document60 pagesTreinamento iFIx32guilherme melloNo ratings yet

- 156 VASUDHA PHARMA CHEM LIMITED Company Brochure 20230623113323Document10 pages156 VASUDHA PHARMA CHEM LIMITED Company Brochure 20230623113323deekshithNo ratings yet

- Localized ARIA RTM Clients Customer Release Note 16.1 MR4Document19 pagesLocalized ARIA RTM Clients Customer Release Note 16.1 MR4Gabriela Silva MartinsNo ratings yet

- Monitor PH - C-900 - User Manual 18-1120-06.acDocument40 pagesMonitor PH - C-900 - User Manual 18-1120-06.acCarlos Alberto Ramirez GarciaNo ratings yet

- TDI-Lupranat T80Document2 pagesTDI-Lupranat T80Virender KumarNo ratings yet

- EPA Positive M Atrix Factorization (PM F) 5.0 Fundamentals and User GuideDocument136 pagesEPA Positive M Atrix Factorization (PM F) 5.0 Fundamentals and User GuideJuan David Bastidas SanchezNo ratings yet

- 10.FITOK Company Brochure 160909Document20 pages10.FITOK Company Brochure 160909inglegs75No ratings yet

- Kopra Feb2021Document23 pagesKopra Feb2021sunil.dasarath jadhavNo ratings yet

- Avicel RC 591Document20 pagesAvicel RC 591Hector Chilquillo TorresNo ratings yet

- Plasticizer Presentation March 2010Document58 pagesPlasticizer Presentation March 2010Kaushal KothariNo ratings yet

- Emphaze Hybrid PurifierDocument28 pagesEmphaze Hybrid PurifierjayNo ratings yet

- Dppa Link Afdisd Product Information en-USDocument34 pagesDppa Link Afdisd Product Information en-USPUKKINUN PONGRAKANANONNo ratings yet

- Litdoc18112107 20161015125116Document2 pagesLitdoc18112107 20161015125116Mohammad PouryaqubiNo ratings yet

- IAGTGMPNews IIIDocument2 pagesIAGTGMPNews IIImadhurajusNo ratings yet

- Owner - Manual - 267 277 278 280 287 859 870 877 - Hy25 1380 m1 - Us - 20170627Document44 pagesOwner - Manual - 267 277 278 280 287 859 870 877 - Hy25 1380 m1 - Us - 20170627yaccoubisamiNo ratings yet

- ECA Appropriate GMP For Pharmaceutical ExcipientsDocument4 pagesECA Appropriate GMP For Pharmaceutical Excipientsmailtorubal2573No ratings yet

- FluorezDocument27 pagesFluorezRick RgNo ratings yet

- Parenteral Applications Brochure Br2750en MKDocument8 pagesParenteral Applications Brochure Br2750en MKSagar PopatNo ratings yet

- Marketing Project LaptopDocument26 pagesMarketing Project LaptopJayana ModiNo ratings yet

- Et PN Iso Pump Instruction Manual-OrgDocument60 pagesEt PN Iso Pump Instruction Manual-OrgSd Ver69% (13)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingSameh RadwanNo ratings yet

- TRACERCO Taggant BrochureDocument16 pagesTRACERCO Taggant BrochureKarthick SarathyNo ratings yet

- Reference Product - AssessmentDocument3 pagesReference Product - AssessmentBett KevinNo ratings yet

- MACH LED 120F / 120: Directions For UseDocument25 pagesMACH LED 120F / 120: Directions For UseMoas GabrounNo ratings yet

- Roof TilesDocument14 pagesRoof Tileswrite2prathibaNo ratings yet

- Proteus XR F Generator Service Manual SM 5764770-1EN 4Document540 pagesProteus XR F Generator Service Manual SM 5764770-1EN 4fortroniNo ratings yet

- Lutensol AO 3 Safety SheetDocument5 pagesLutensol AO 3 Safety SheetPiipee AndresNo ratings yet

- Abbott CatalogueDocument8 pagesAbbott CataloguekadirucaNo ratings yet

- ERES WinCC TIA RT-Prof V16 en en-USDocument28 pagesERES WinCC TIA RT-Prof V16 en en-USArsalanAliNo ratings yet

- MediawebserverDocument3 pagesMediawebservertripathi prashantNo ratings yet

- TM-1002 AVEVA Plant (12 Series) Drawing Production (Basic) Rev 5.0Document123 pagesTM-1002 AVEVA Plant (12 Series) Drawing Production (Basic) Rev 5.0SOFTWARE SHARINGNo ratings yet

- BASF 10484 ProCat PDS 190429 120543 Rev.04 2021Document2 pagesBASF 10484 ProCat PDS 190429 120543 Rev.04 2021salsasafira926No ratings yet

- ePMP Release Notes 4.5.6Document6 pagesePMP Release Notes 4.5.6gspolettoNo ratings yet

- Vitamin E-Acetate Care - TI - REV4-1 PDFDocument4 pagesVitamin E-Acetate Care - TI - REV4-1 PDFFatima Ezzohra SafsafaNo ratings yet

- MA0008Document1 pageMA0008Alfonso RivasNo ratings yet

- CalibrationWorld 2013-01 ENGDocument28 pagesCalibrationWorld 2013-01 ENGAfam-Anadu UcheNo ratings yet

- 51 XMT PDocument124 pages51 XMT PSeltromind SrlNo ratings yet

- LTQ Orbitrap XL HardwareDocument124 pagesLTQ Orbitrap XL Hardwarerusspickford100% (1)

- Eres Annex 11 Eu GMP SiemensDocument30 pagesEres Annex 11 Eu GMP SiemenshuykhiemNo ratings yet

- 3.5 T Bolier ManualDocument206 pages3.5 T Bolier Manualchandravadiyaketan150467% (3)

- 0FDA - SMF - The Drug Manufacturers Guide To Site Master Files ExecSeries 1 1 PDFDocument65 pages0FDA - SMF - The Drug Manufacturers Guide To Site Master Files ExecSeries 1 1 PDFDiemTrinhNguyenThienNo ratings yet

- Vrla Handbook: English Industrial BatteriesDocument70 pagesVrla Handbook: English Industrial BatteriesbobyNo ratings yet

- RimalPatel 23 MBA BP AssignmentDocument11 pagesRimalPatel 23 MBA BP AssignmentKillol ShahNo ratings yet

- 00 OpI 20141338Document367 pages00 OpI 20141338kevin nerioNo ratings yet

- Fdocuments - in - Gehc Service Manual Procare b40 b20 Monitor PDFDocument252 pagesFdocuments - in - Gehc Service Manual Procare b40 b20 Monitor PDFkarim100% (1)

- Fcde 0110uk PDFDocument580 pagesFcde 0110uk PDFbtsgr parkerNo ratings yet

- ERES PM-QUALITY V10 enDocument28 pagesERES PM-QUALITY V10 enAbdul KalimNo ratings yet

- Cinryze C4V005AS - COADocument11 pagesCinryze C4V005AS - COASebastian PSNo ratings yet

- TRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFDocument94 pagesTRACE1300 - 1310 - Spare Parts Guide - 5ED NEW PDFInt PueNo ratings yet

- Guideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardFrom EverandGuideline for EN 9100:2018: An Introduction to the European Aerospace and Defence StandardNo ratings yet

- Multi-Objective Optimization in Chemical Engineering: Developments and ApplicationsFrom EverandMulti-Objective Optimization in Chemical Engineering: Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderFrom EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderNo ratings yet

- The Examples of Job VacancyDocument2 pagesThe Examples of Job VacancysasNo ratings yet

- The Boston Globe - 10 October 2022Document37 pagesThe Boston Globe - 10 October 2022Lemelin GauthierNo ratings yet

- Practical Research 2: 4Th QuarterDocument4 pagesPractical Research 2: 4Th Quartergamms upNo ratings yet

- Case Study 2Document6 pagesCase Study 2Rahmani MuharimNo ratings yet

- 2 Risk Identification FormDocument6 pages2 Risk Identification FormkamranNo ratings yet

- MSC (N) SyllabusDocument246 pagesMSC (N) SyllabussabeethuNo ratings yet

- Nurs 478 Qip PresentationDocument15 pagesNurs 478 Qip Presentationapi-489650178No ratings yet

- Final 1Document5 pagesFinal 1khansha ComputersNo ratings yet

- Biopharmaceutical LexiconDocument65 pagesBiopharmaceutical Lexiconryu_chile28234No ratings yet

- Epidermophyton (Skin, Nails) : Microsporum, TrichophytonDocument5 pagesEpidermophyton (Skin, Nails) : Microsporum, TrichophytonRoyNo ratings yet

- ArticolsssaDocument11 pagesArticolsssaCosmin GabrielNo ratings yet

- Print Bro BAB 5Document4 pagesPrint Bro BAB 5Gung LisaNo ratings yet

- Interactive Learning Activities Parker CarpenterDocument1 pageInteractive Learning Activities Parker Carpenterapi-360582909No ratings yet

- DCL Report - Hygitech HSDocument2 pagesDCL Report - Hygitech HSFarhan RashidNo ratings yet

- MSDS-POLINTEK L & P Group-DMI INDUSTRIDocument8 pagesMSDS-POLINTEK L & P Group-DMI INDUSTRIYosep SasadaNo ratings yet

- Revision Test 4 - Class 12D1 2021-2022Document7 pagesRevision Test 4 - Class 12D1 2021-2022Tenebrae LuxNo ratings yet

- Jsa - CMC WorkDocument11 pagesJsa - CMC WorkEjazNo ratings yet

- ACLS Precourse Self-AssessmentDocument2 pagesACLS Precourse Self-AssessmentMandela KibiritiNo ratings yet

- CAU FacultyApplications are invited on the prescribed application form for the posts of Assistant Professors on permanent basis in the following subjects in the pay Band ‐ III of Rs. 15600‐39100 with Academic Grade Pay Rs. 6000/‐ plus usual allowances as admissible under the rules of University of Delhi from time to time .Document8 pagesCAU FacultyApplications are invited on the prescribed application form for the posts of Assistant Professors on permanent basis in the following subjects in the pay Band ‐ III of Rs. 15600‐39100 with Academic Grade Pay Rs. 6000/‐ plus usual allowances as admissible under the rules of University of Delhi from time to time .siddulaNo ratings yet

- Examiner Report NEBOSH IGC2 Oct Dec 2015 PDFDocument14 pagesExaminer Report NEBOSH IGC2 Oct Dec 2015 PDFShaik Anwar0% (2)

- Challenges To Effective Drug TherapyDocument5 pagesChallenges To Effective Drug TherapyAlyssaGrandeMontimorNo ratings yet

- MSDS Conant - 1 - 75 - GR-ID-SDS - 02Document16 pagesMSDS Conant - 1 - 75 - GR-ID-SDS - 02purwadiNo ratings yet

- What Is HappinessDocument8 pagesWhat Is HappinessAbdul RashidNo ratings yet

- Willits Accellerated Achilles RehabDocument2 pagesWillits Accellerated Achilles RehabattilabajusNo ratings yet

- Vampire Survivors Jumpchain 1.3Document120 pagesVampire Survivors Jumpchain 1.3ZiggurathNo ratings yet

- Answer Sheet Week 1 Pe 8Document2 pagesAnswer Sheet Week 1 Pe 8Riza LeeNo ratings yet