Professional Documents

Culture Documents

3631_71

3631_71

Uploaded by

gl.automacaoCopyright:

Available Formats

You might also like

- John Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFDocument31 pagesJohn Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFEquipment Manuals0% (2)

- Service Manual - 13-15-20-23EKOZD - 11-13-16.5-17.5-19.5-20EFKOZD PDFDocument280 pagesService Manual - 13-15-20-23EKOZD - 11-13-16.5-17.5-19.5-20EFKOZD PDFxxxxxxxxxxxxxxxxxxx100% (6)

- Schilling Robotics Conan 7P Manipulator System: Position-Controlled, 3 KM Submersible 24 VDC Base ModuleDocument218 pagesSchilling Robotics Conan 7P Manipulator System: Position-Controlled, 3 KM Submersible 24 VDC Base ModuleDiegus PalchettiNo ratings yet

- Fire Training Manual - SOLASDocument23 pagesFire Training Manual - SOLASHashem Gam100% (6)

- BS en 00615-2009 PDFDocument36 pagesBS en 00615-2009 PDFBorislav Vulić50% (2)

- Rigmaster Manual 8204Document122 pagesRigmaster Manual 8204Rodrigo MirandaNo ratings yet

- K601888 Brake System B250-B300 For Geared Machines W163-W200-W250Document45 pagesK601888 Brake System B250-B300 For Geared Machines W163-W200-W250Yasmin Quintela100% (1)

- Information & Operations Manual For Bavaria Cruiser 37Document37 pagesInformation & Operations Manual For Bavaria Cruiser 37RDNo ratings yet

- R-102 Manual PDFDocument141 pagesR-102 Manual PDFphibet83% (6)

- Manual d150 10aDocument215 pagesManual d150 10aJORGE CAICEDO100% (1)

- Manual D150-10a PDFDocument215 pagesManual D150-10a PDFJORGE CAICEDO100% (2)

- Tp6442 Eng Bg9kDocument284 pagesTp6442 Eng Bg9kGenildo SilvaNo ratings yet

- Manual Conan 199-0306 PDFDocument272 pagesManual Conan 199-0306 PDFGileno100% (1)

- Im Fpo-Gen2Document22 pagesIm Fpo-Gen2hassanqr89No ratings yet

- Sampson ControlerDocument52 pagesSampson Controlerpetar.petrov.111964No ratings yet

- 1 - Operating InstructionsDocument172 pages1 - Operating InstructionsAlkiviadis NtanisNo ratings yet

- TP6861 - 33-125EFOZDJ Operation ManualDocument120 pagesTP6861 - 33-125EFOZDJ Operation ManualthainarimeNo ratings yet

- Kohler 33-125efozdj Operation ManualDocument120 pagesKohler 33-125efozdj Operation ManualYiannis MikelisNo ratings yet

- tp6392 PDFDocument56 pagestp6392 PDFEgberto Pino GuerreroNo ratings yet

- Cond 3110: Conductivity MeterDocument41 pagesCond 3110: Conductivity Meterpurezone1979No ratings yet

- SM9400 Operating InstructionsDocument37 pagesSM9400 Operating InstructionsEdwardNo ratings yet

- tp5986 Eng GZRWDocument72 pagestp5986 Eng GZRWgeorge dimitroulisNo ratings yet

- COSIMAT N Plus EDocument40 pagesCOSIMAT N Plus EDmitry Selyugin0% (1)

- 20 2250kW Operation ManualDocument64 pages20 2250kW Operation Manualangel aguilarNo ratings yet

- Repeater Compass: Type 133 - 560 NG001 To NG010Document48 pagesRepeater Compass: Type 133 - 560 NG001 To NG010Rong PencileNo ratings yet

- Service: Commercial Generator SetsDocument76 pagesService: Commercial Generator SetsEgberto Pino GuerreroNo ratings yet

- Cosimat N+ PDFDocument38 pagesCosimat N+ PDFmass72No ratings yet

- Tp6127 - MPAC 1000 Controller & Service ManualDocument172 pagesTp6127 - MPAC 1000 Controller & Service ManualMP DieselNo ratings yet

- Manual Titan4 AtualizadoDocument332 pagesManual Titan4 AtualizadoCRISTIANO COUTINHONo ratings yet

- 55EOZCJ-200EOZCJ Service ManualDocument344 pages55EOZCJ-200EOZCJ Service Manualmichael.dwyer.documentsNo ratings yet

- Instruction Book HiLight V4W WUX 9829 4075 00 ENDocument40 pagesInstruction Book HiLight V4W WUX 9829 4075 00 ENArielNo ratings yet

- Precision & Flexibility by Dencohappel: Officecool - LecuDocument36 pagesPrecision & Flexibility by Dencohappel: Officecool - Lecuportocala12No ratings yet

- Ud7000 Parte 1 V19Document56 pagesUd7000 Parte 1 V19LaurentEuniceNo ratings yet

- Scan Coin SC303 and SC313 Coin Counter Service Manual Part 1Document57 pagesScan Coin SC303 and SC313 Coin Counter Service Manual Part 1Raul HuaytallaNo ratings yet

- AC160 1 83154b Part1 - enDocument884 pagesAC160 1 83154b Part1 - enSandoval Ramos Eddy100% (1)

- WTW Cond 3110 PDFDocument42 pagesWTW Cond 3110 PDFiqfalNo ratings yet

- Rover 24Document226 pagesRover 24Agus mulyadiNo ratings yet

- Mounting Instructions: Digital Torque TransducerDocument140 pagesMounting Instructions: Digital Torque TransducerAna RuganiNo ratings yet

- Conwell EveryManHisOwnUniversityDocument80 pagesConwell EveryManHisOwnUniversityJoseph AdikwuNo ratings yet

- ST1.3 Series: Product ManualDocument46 pagesST1.3 Series: Product ManualPampu1No ratings yet

- tp6109 Kohler Tarjeta PDFDocument68 pagestp6109 Kohler Tarjeta PDFGabino Ubilio Murillo100% (1)

- DEC 550 Controller OperationDocument168 pagesDEC 550 Controller OperationTom LeonardNo ratings yet

- 40 150 PDFDocument68 pages40 150 PDFChap Boon GohNo ratings yet

- SAMURAI - Manual en 3.0 NewDocument148 pagesSAMURAI - Manual en 3.0 NewRenzo ArangoNo ratings yet

- 150EFOZDJ Service ManualDocument304 pages150EFOZDJ Service Manualelectricidad.acasiNo ratings yet

- Balança Santariuos PDFDocument283 pagesBalança Santariuos PDFCélio LeãoNo ratings yet

- Ud7000 Parte 2 V19Document134 pagesUd7000 Parte 2 V19LaurentEuniceNo ratings yet

- Alcatel-Lucent GSM: 9125 Compact TC DescriptionDocument80 pagesAlcatel-Lucent GSM: 9125 Compact TC DescriptionAM MOTO OMCRNo ratings yet

- Service Manual 11 Au 35EFKOZD tp6953 PDFDocument360 pagesService Manual 11 Au 35EFKOZD tp6953 PDFNicolas TisnéNo ratings yet

- Operation Instruction D2840 (2) LE301Document92 pagesOperation Instruction D2840 (2) LE301Konstantin Potmenskiy100% (1)

- Operation: Residential/Commercial Generator SetsDocument72 pagesOperation: Residential/Commercial Generator SetsAnonymous mLLhWgE8LTNo ratings yet

- CP TD1 User ManualDocument70 pagesCP TD1 User ManualSna BerNo ratings yet

- Operation: Residential/Commercial Generator SetsDocument76 pagesOperation: Residential/Commercial Generator SetsАлексей Семикин100% (1)

- Service: Marine Generator SetsDocument116 pagesService: Marine Generator SetsWilly Alexander RamirezNo ratings yet

- ManualDocument73 pagesManualKusma SwandaruNo ratings yet

- Saftronics Cv10 ManualDocument121 pagesSaftronics Cv10 ManualAndres Elias Carrillo ManriqueNo ratings yet

- Digital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupDocument100 pagesDigital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupPaul RidgeNo ratings yet

- Maintenance ManualDocument148 pagesMaintenance Manualgabrieljeg371No ratings yet

- Operation Manual: Rice Lake TCDocument42 pagesOperation Manual: Rice Lake TCSebastian AyalaNo ratings yet

- TP 5750Document80 pagesTP 5750Roberto Sanchez ZapataNo ratings yet

- WebastoserviceDocument72 pagesWebastoserviceanasrl2006No ratings yet

- Osmo 23GDocument111 pagesOsmo 23Gluis bazanNo ratings yet

- ChecklistDocument26 pagesChecklistmajdirossross100% (1)

- Chapter 2 Part 3Document14 pagesChapter 2 Part 3Abdul Halim AsmungiNo ratings yet

- Fire Fighting in Commercial Buildings, Application Guide - GrundfosDocument56 pagesFire Fighting in Commercial Buildings, Application Guide - GrundfosercolinoNo ratings yet

- Mreq Vs Preq Vs Po Vs Grns - With Item DescDocument105 pagesMreq Vs Preq Vs Po Vs Grns - With Item DescAjas AjuNo ratings yet

- NIT Rourkela-Safety EngineeringDocument23 pagesNIT Rourkela-Safety Engineeringshahnawaz ahmedNo ratings yet

- CatalogDocument130 pagesCatalogAmit KumarNo ratings yet

- R20 - Potassium Chromate IndicatorDocument4 pagesR20 - Potassium Chromate IndicatorLaboratorium PT MASNo ratings yet

- Tebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Document4 pagesTebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Ahmed MohamedNo ratings yet

- How To Safely Lift & CarryDocument7 pagesHow To Safely Lift & Carrychris0% (1)

- Halon Extinguishing Agents: Safety & Health ConcernsDocument4 pagesHalon Extinguishing Agents: Safety & Health ConcernskbonairNo ratings yet

- Safety ManualDocument17 pagesSafety ManualArpita Biswas100% (1)

- Battle Damage Assessment and Repair (BDAR) Procedures 63H34F05 / Version MOSC 01 Oct 2004 Administrative DataDocument35 pagesBattle Damage Assessment and Repair (BDAR) Procedures 63H34F05 / Version MOSC 01 Oct 2004 Administrative DataLo Shun FatNo ratings yet

- Chapter 38 NS1030 Sue Study GuideDocument19 pagesChapter 38 NS1030 Sue Study GuideLuke Rachel WurzNo ratings yet

- Emergency Management Plan SampleDocument60 pagesEmergency Management Plan SampleartscraftsNo ratings yet

- Master'S Handing Over Note: Contacts and PicDocument16 pagesMaster'S Handing Over Note: Contacts and PicVishal KumarNo ratings yet

- Filter MideaDocument22 pagesFilter MideaMahibul HasanNo ratings yet

- Fire Emergency Preparedness SeminarDocument65 pagesFire Emergency Preparedness SeminarTAURUS EMS100% (1)

- Fire Extinguisher Checklist CDocument3 pagesFire Extinguisher Checklist CTristano EffendiNo ratings yet

- 025 MSDS Terracide LO11Document7 pages025 MSDS Terracide LO11Andreas PradanaNo ratings yet

- Titus Lithium Battery: Safety Data SheetDocument5 pagesTitus Lithium Battery: Safety Data SheetKittikun Ap UnitechNo ratings yet

- Test Your Fire Extinguisher KnowledgeDocument4 pagesTest Your Fire Extinguisher KnowledgeMANOUJ GOELNo ratings yet

- Fire Protection SystemDocument84 pagesFire Protection Systemmohd farhan ariff zaitonNo ratings yet

- ChemistryDocument47 pagesChemistryJai MurugeshNo ratings yet

- Fire - Extinguishers - Table PDFDocument2 pagesFire - Extinguishers - Table PDFSardar Puneet Singh BhatiaNo ratings yet

3631_71

3631_71

Uploaded by

gl.automacaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3631_71

3631_71

Uploaded by

gl.automacaoCopyright:

Available Formats

Operating Instructions

Counter Stacker CB-16 3631

Machine Number

Article Number of Operating Instructions 3631.8300B71

Counter Stacker CB-16 Table of contents

Page

Introduction

Set-Up of Operating Manual . . . . . . . . . . . . . . . . 1.10.1

General . . . . . . . . . . . . . . . . . . . . . 1.10.1

Short Description . . . . . . . . . . . . . . . . . . . 1.20.1

Authorized use . . . . . . . . . . . . . . . . . . . . 1.20.1

General Safety Guidelines . . . . . . . . . . . . . . . . . 1.30.1

Electrical Connections . . . . . . . . . . . . . . . . . . 1.30.2

Additional Safety Guidelines . . . . . . . . . . . . . . . . 1.30.3

Special Guidelines . . . . . . . . . . . . . . . . . . . 1.30.6

Danger- and Notification Symbols . . . . . . . . . . . . . . . 1.30.7

Mushroom Stop Buttons . . . . . . . . . . . . . . . . . 1.30.9

Decommissioning, Storage . . . . . . . . . . . . . . . . 1.30.11

Disposal . . . . . . . . . . . . . . . . . . . . . 1.30.11

Maintenance . . . . . . . . . . . . . . . . . . . . . 1.40.1

General . . . . . . . . . . . . . . . . . . . . . 1.40.1

Maintenance Plan . . . . . . . . . . . . . . . . . . . 1.40.2

Technical Data

Technical Data . . . . . . . . . . . . . . . . . . . . 2.10.1

Disposition . . . . . . . . . . . . . . . . . . . . . 2.10.1

Production speed . . . . . . . . . . . . . . . . . . . 2.10.3

Belt Speeds . . . . . . . . . . . . . . . . . . . . 2.10.4

Electrical consumption . . . . . . . . . . . . . . . . . . 2.10.4

Ambient conditions . . . . . . . . . . . . . . . . . . 2.10.4

Air supply . . . . . . . . . . . . . . . . . . . . . 2.10.5

Noise level . . . . . . . . . . . . . . . . . . . . . 2.10.6

Floor requirements . . . . . . . . . . . . . . . . . . 2.10.6

Alignment . . . . . . . . . . . . . . . . . . . . . 2.20.1

Alignment and connection . . . . . . . . . . . . . . . . . 2.20.1

Control

Control- and Operating Unit . . . . . . . . . . . . . . . . 3.10.1

Control- and Operating Unit . . . . . . . . . . . . . . . . 3.10.1

Start-Up . . . . . . . . . . . . . . . . . . . . . 3.10.2

Size setting . . . . . . . . . . . . . . . . . . . . 3.10.3

Basit Settings

Mechanical Basic Settings . . . . . . . . . . . . . . . . . 4.10.1

Turntable . . . . . . . . . . . . . . . . . . . . . 4.10.1

Pusher . . . . . . . . . . . . . . . . . . . . . . 4.10.2

Reed Switch for End Position . . . . . . . . . . . . . . . . 4.10.3

12.2001 3631.8300B71 Operating Instructions 0.00.1

Table of contents

Small size equipment

Control . . . . . . . . . . . . . . . . . . . . . . 5.10.1

Technical Data . . . . . . . . . . . . . . . . . . . 5.10.1

Maintenance

Maintenance work . . . . . . . . . . . . . . . . . . . 6.10.1

Handwheels . . . . . . . . . . . . . . . . . . . . 6.10.1

Maintenance unit . . . . . . . . . . . . . . . . . . . 6.10.1

Lubrication

Manual lubrication . . . . . . . . . . . . . . . . . . . 7.10.1

Oil Compensating Glass . . . . . . . . . . . . . . . . . 7.10.1

Repair instructions

Change of belts . . . . . . . . . . . . . . . . . . . 8.10.1

General instructions . . . . . . . . . . . . . . . . . . 8.10.1

0.00.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Set-Up of Operating Manual

Introduction

General

The operating manual contains several chapters. A table of contents gives an overview on the topics covered in

the different chapters.

If a large chapter is covered in one chapter, it is subdivided and the individual partial descriptions have different

version numbers. The table of contents preceding the chapter gives an overview of the partial descriptions of the

chapter.

In addition to the operating manual a spare parts catalog with parts listing is supplied. Please refer to this spare

parts catalog for any spare parts orders.

Page Organization

The page header shows the title of the chapter, the machine name and the machine number. The footer lists the

edition date, the register number, the version number and the page number. (Illustrated pages do not show the

machine name and machine number.)

####

Version title # #### # Version title

Edition Date M. name and chapter title

Chapter No.

Type of document

Version No.

Article number

and language #.#.# #### #### #.# #.# #### #### #.#.# Page No.

12.2001 3631.8300B71 Operating Instructions 1.10.1

Counter Stacker CB-16 Short Description

Introduction

Authorized use

The Counter Stacker CB-16 is used to stack adhesive bound book blocks, brochures, magazines, pocket books,

catalogs, etc.

The stacks can be selected compensated or non-compensated, based on products and finishing.

If needed deliveries for manual removal or in-line finishing are available.

The Counter Stacker CB-16 is equipped with transport rollers and plug-in connections for universal use.

Identification of Work Stations

Main work stations are in the area of the start-stop keys, on the Commander and on the cover feeder.

For size changes, maintenance, upkeep and for cleaning the safety guards can be tilted open. Work stations are

around the Counter Stacker CB-16.

12.2001 3631.3800B71 Operating Instructions 1.20.1

Counter Stacker CB-16 General Safety Guidelines

Introduction

Transport of Machine Elements

The machine parts are supplied in boxes, crates and/or on pallets. The transports are marked with the locations

for chains (symbol), cut-outs for carrying belts or free area for the forks of the fork lift. The packing is marked

with numbers, which on the packing list will have references as to size, weight and content.

The transport should always be supervised by a Müller Martini service engineer!

Please refer to the respective system layout for detailed weight and transport information!

Set-Up of Machine Elements

Make sure that crane, fork lift or other equipment used to lift the machine have the necessary capacity and are in

perfect operating condition.

Never run or stand below the machine, when it is lifted off the floor.

The machine parts should only be lifted so far that any objects in the way can be bypassed.

Set-up only by a Müller Martini service engineer. The manufacturer will decline any and all

liability if the customer installs the machine himself.

Location / Levelling

The Counter Stacker CB-16 should be set up on a level solid floor.Floor levelness, space requirements and

customer supply lines are shown on the layout. Floor loads are listed in the technical data. For maintenance

approx. 1 m / 3.3 ft space must be kept free around the Counter Stacker CB-16.

12.2001 3631.8300B71 Operating Instructions 1.30.1

General Safety Guidelines

Electrical Connections

The electrical connections are made by trained electricians according to the electrical schematic supplied. The

necessary requirements are listed in the technical data and on the layout. All electrical lines and units must be

installed according to all national and local codes and regulations.

Check direction of rotation of all motors!

Cleaning

The Counter Stacker CB-16 is sprayed with a rust preventative for transport. If cleaning fluids are used, follow all

manufacturer’s instructions (ventilate room, danger of explosion, do not smoke, etc.).

Use a proper cleaner for the plexiglass covers. Do not use any thinners.

1.30.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 General Safety Guidelines

Introduction

All persons working on and with MÜLLER MARTINI machines are required to read and understand the chapters

relating to their work and follow all instructions and notices contained in them. This applies particularly to the

chapter "Safety Guidelines", which is binding for all persons and tasks!

- The machine should only be operated by trained personnel! It should not be operated by unauthorized person-

nel!

- Prior to any start-up of the machine make sure that no persons or objects are in the machine’s danger radius!

- Retighten all screws loosened for cleaning or an adjustment according to the instructions!

- Do not remove, change, or deactivate any safety devices!

- Co2- or dry chemical fire extinguishers should be mounted in easily accessible areas on both sides of the per-

fect binding system!

- Follow all national and local safety guidelines as well as additional operator’s instructions (safety glasses, ear

plugs, etc.)!

Additional Safety Guidelines

Electrical System

Switches, housings and control cabinets can only be opened by authorized trained personnel, after the main

switch on the main control cabinet has been locked out/tagged out! For any work on the power supply the

complete energy supply to the system must be disconnected and locked out/tagged out.

Please note that electrical circuits that run separately, are insulated individually and are color-coded are to be

considered energized. This concerns primarily supply lines to the main switch!

Attach warning sign on main switch.

Cleaning

- During all cleaning and settings always press one of the stop buttons!

- Keep all ignitable solvents away from sparks, flames and other combustible sources!

12.2001 3631.8300B71 Operating Instructions 1.30.3

General Safety Guidelines

Maintenance

- The owner of the perfect binding system is required to operate it only in perfect and undamaged condition.

Maintenance and set-up are described in the operating manual.

During maintenance pay special attention to the following:

- The perfect binding system can only be serviced by authorized personnel.

- All maintenance- and inspections should only be made with the machine switched off (main switch on "0") and

the EMERGENCY STOP button pressed.

- When working on machine parts that are controlled pneumatically, machine elements may move during con-

nection or disconnection of the air supply!

- The machine environment must be kept clean. Any oil spills are to be removed immediately.

- Only original spare parts must be used. Muller Martini will decline any and all liability if these guidelines are not

followed.

- If safety devices were disabled or after electrical work, all safety devices should be tested for correct function

prior to start-up of the machine!

- All gauges and keys used for settings should be removed prior to restarting the machine!

- Gas pressure springs are used on several guards. If the pressure in these gas pressure springs decreases,

they must be exchanged!

Technical State of the Art

The Counter Stacker CB-16 corresponds to present state of the art technology and all current valid safety

regulations. A model of this perfect binding system was tested by the Association for Print- and Paper

Processing and certified with the GS or BG label.

Despite the above safety risks may still exist, especially if the perfect binding system is operated improperly or by

unauthorized personnel.

1.30.4 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 General Safety Guidelines

Introduction

Other Safety Risks

Any use of technical products is connected with danger. Dangers that could not be eliminated either by design or

protective devices are other dangers.

The safety notices in this operating manual were determined by an analysis of other dangers and point out these

possible safety risks.

Obligatory Notification and Authorization after Modifications

It is not permitted to make technical changes such as add-ons or modifications on the Counter Stacker CB-16

without the written authorization of MÜLLER MARTINI.

This applies also to installation or removal of third-party control-, infeed- and transfer systems, if they affect the

Counter Stacker CB-16.

Authorized Use

The Counter Stacker CB-16 serves solely for counting and stacking of books, catalogs and magazines.

Limitations in use and identification data are in the chapter "Technical Data".

All instructions and guidelines in the operating manual should be followed!

Unauthorized Use

Any use other than in the area originally intended and corresponding to the technical data is considered

unauthorized. Any subsequent damages due to unauthorized use will not be covered by any warranty or liability.

Non-Compliance of Safety Guidelines

- MÜLLER MARTINI will not be liable for any damages resulting from disregard of the instructions and notices in

the operating manual. This applies especially to:

- Damage resulting from improper operation or use.

- Damage due to disregard of safety-related instructions in the operating manual or warning signs on the

machine.

- Damage due to incomplete or lacking maintenance.

12.2001 3631.8300B71 Operating Instructions 1.30.5

General Safety Guidelines

Special Guidelines

Applicable Area

All information, instructions and safety-related notices in this operating manual apply solely to the Counter

Stacker CB-16

Availability of Operating Manual

One copy of the operating manual must be available with the machine for the operating personnel at all times.

Emergency Exit

The owner of the Counter Stacker CB-16 must make sure that in case of emergencies an exit conforming to all

local regulations is available for the personnel. It is especially important that there be no doors opening against

the emergency exit and that no objects are blocking the path.

Nameplate

The nameplates contain information on the machine type, the machine number and the year of manufacture.

Type Year of Manufacture

Mach. No.

Made in Switzerland

1.30.6 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 General Safety Guidelines

Introduction

Danger- and Notification Symbols

This operating manual makes use of some notification symbols to point out other safety- and important technical

requirements:

Information on dangers that may lead to death, severe injuries, irreversible psychological

harm or considerable machine damage.

Information on dangers which may lead to serious injuries, psychological harm or machine

damage.

Danger of electrical shock.

Information pointing out technical or efficiency requirements. Non-compliance may lead to

faults, inefficiency and possibly production losses.

Warning - danger of pinch points. When the machine is running there is danger that body

limbs, hair or objects may be caught in moving belts, or other rotating parts - danger of

injury.

We recommend to put up the following sign in the area of the perfect binder:

Noise! Wear Ear Protection.

Fire

All fires can be extinguished with a CO2 or dry chemical fire extinguisher.

12.2001 3631.8300B71 Operating Instructions 1.30.7

General Safety Guidelines

Main Switch

(A) Main switch

Fig. 1

Signal lamp

(B) Signal lamp

Fig. 2

1.30.8 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 General Safety Guidelines

Introduction

Mushroom Stop Buttons

If the Counter Stacker CB-16 is operated as a part of a total system, the

entire system usually has several stop circuits that are independent of

each other.

The Counter Stacker CB-16 is stopped only with the Counter Stacker

CB-16 EMERGENCY STOP buttons. Depending on the operating status

upstream and downstream system elements continue to run.

The owner of the system is responsible that the operating personnel is

trained regularly on the function of the stop circuits.

(A) EMERGENCY STOP on the right side

Fig. 3

(B) EMERGENCY STOP on the left side

Fig. 4

12.2001 3631.8300B71 Operating Instructions 1.30.9

General Safety Guidelines

Safety guards

All safety guards are completely locked, with the exception of the doors to be opened.

All doors and safety guards are electrically interlocked. If a door or guard are opened during production or in set-

up mode, the Counter Stacker CB-16 will stop immediately.

Front safety guards

Front safety guards (A/B) are electrically interlocked.

A

A B

Fig. 5

Top safety guards

Top safety guard (C) is electrically interlocked.

C

Fig. 6

1.30.10 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 General Safety Guidelines

Introduction

Decommissioning, Storage

Introduction

This chapter describes the necessary functions that must be carried out by the operator if the Counter Stacker

CB-16 is to be stored for a time period of 6 months or longer.

Decommissioning

The Counter Stacker CB-16 can only be decommissioned by a service technician or properly trained personnel.

If the customer decommissions the Counter Stacker CB-16 we will decline any and all warranty and liability.

Storage

The system and all its components should be protected with a plastic sheet from dust, moisture, etc.

Ambient conditions:

Temperature: Min./Max. 10/40 °C / 50°F - 104°F.

Humidity: Min./Max. 40/70%

Disposal

The owner or operator will dispose of the Counter Stacker CB-16 .

Sort and separate all materials according to groups (iron, aluminum, plastic, electronic parts, glue, oil, etc) and

bring to the respective recycling stations.

Please follow all relevant local and national laws and guidelines for disposal of the Counter

Stacker CB-16 .

12.2001 3631.8300B71 Operating Instructions 1.30.11

Counter Stacker CB-16 Maintenance

Introduction

General

Regular maintenance and inspections are very important, because they prevent unnecessary breakdowns and

increase operating safety.

Maintenance includes cleaning, control and lubrication. Detailed maintenance instructions are contained in the

chapters of the respective stations.

- The Counter Stacker CB-16 must be maintained by authorized personnel only.

- For safety reasons all maintenance- and inspections should be carried out with the

machine locked out / tagged out.

- Prior to any work press the EMERGENCY STOP button.

- Turn main switch into position "0".

- Reinstall all safety guards immediately after maintenance has been completed.

- Dispose of used oil according to all national and regional laws and guidelines.

12.2001 3631.8300B71 Operating Instructions 1.40.1

Maintenance

Maintenance Plan

After 8–12 Hours

- Clean photocells and reflectors. (Do not use solvent-based cleaners.)

- Remove paper shreds and dust.

- Check oil level of the pneumatic maintenance unit and if necessary, refill oil.

After 40–60 Hours

- Clean entire system. (Do not blow dirt into bearings and guide parts.)

- Clean and check transport belts, if necessary, replace.

After 160–200 Operating Hours

- Remove and blow out cotton filter on control cabinet.

- Check function of all safety- and stop switches. (Turn on the Counter Stacker CB-16, and by opening safety

guards check if the respective safety elements are activated and the Counter Stacker CB-16 stops.).

- Check gear oil level.

- Check for loose screws.

- Check lubrication lines for leaks.

The manufacturer will decline any and all liability for any damage due to lacking or incorrect

maintenance.

1.40.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Technical Data

Technical Data

Disposition

Infeed Height hE Stack Height 300mm Stack Height 240mm

800 L = 2166 L = 2208

850 L = 2190 L = 2228

890 L = 2208 L = 2242

Dimensions without frame stack height 300 mm (11-7/8"), with frame stack height 240 mm (9-1/2").

Load plan

Weights:

1 belt delivery 1050 kg / 2310 lb 2 belt deliveries 1145 kg / 2520 lb

12.2001 3631.8300B71 Operating Instructions 2.10.1

Technical Data

Sizes

CB16/300 CB16/240

Belt Delivery Roller Belt Delivery Roller

Delivery Delivery

right (X) in direction right (X) right (X) in direction right (X)

and/or left of travel (Z) and/or left and/or left of travel (Z) and/or left

(Y) (Y) (Y) (Y)

min. 140 (120*) 140 140 (100*) 140

A

max. 450 340 450 450 340 450

min. 100 140 (100*) 100 100 (70*) 140 (100*) 100

B

max 340 340

min. 3 3

C

max. 70 70

* Additional conditions for small size (optional)

- The centering rollers in the delivery with speed reduction can only be aligned to a book width B = 100 mm.

Stack height H = 300 (11-7/8")

- Scales and counter displays for A and B must be set 25 mm larger. Stack height H = 240 (9-1/2")

- The maximum speed is 6000 copies/h

- All digital displays for size adjustments plus 50 mm (2") (except book thickness).

Sizes with spine length A less than 120 mm (4-3/4") cannot be tuned any more.

2.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Technical Data

Technical Data

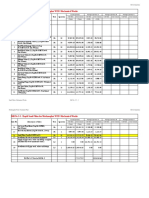

Production speed

Ejector cycle time in seconds

(lift pusher+ ejector ahead

+ ejector back)

standard stacking

over stacking

max. book thickness (mm)

production speed (c/h)

individual copies

key bundles

loose signature production

number of books in lower pusher

= Stack height 240mm = Stack height 300mm

Example A (H = 240mm): Example B (H = 300mm):

Book thickness = 23mm Book thickness = 26mm

Number of book in lower pusher = 4 Number of book in lower pusher = 5

Production speed at a cycle time Production speed at a cycle time

of 1.3s = 11’000 Ex./h of 1.5s = 12’000 Ex./h

12.2001 3631.8300B71 Operating Instructions 2.10.3

Technical Data

Belt Speeds

Belt Speed 50 Hz 60 Hz

Infeed min. 0.21 m/s 0.25 m/s

max 2.1 m/s 2.5 m/s

Belt delivery min. 0.2 m/s 0.24 m/s

(with speed reduction)

max 1.03 m/s 1.23 m/s

Electrical consumption

Drive 50 Hz 60 Hz

Infeed Multiple voltage range motor 1.1 kW 1.1 kW

Delivery Variable speed drive for belt 0.25 kW 0.25 kW

delivery with speed reduction

Please refer to the system layout plan for nominal current, voltage and fuse.

Ambient conditions

Temperature range 10° to 40° Celsius / 50° to 104° Fahrenheit

Humidity range 40% to 70%

2.10.4 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Technical Data

Technical Data

Air supply

Position of connecting clutch (A)

A

Fig. 1

Air requirements

Pressure Volume Inner hose diameter

6 bar 50 Nm3/h 14 mm

Please refer to the system layout plan for air requirements as well as the location of the

required connections.

12.2001 3631.8300B71 Operating Instructions 2.10.5

Technical Data

Noise level

The sound pressure level measured according to DIN 45635 Part 27 is max. 85 dB (A)

Floor requirements

Floor load

See page 2.10.1

Floor levelness

The permissible floor level deviation is + 5 mm (3/16") across 10 m (33 ft) length

2.10.6 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Alignment

Technical Data

Alignment and connection

- Align Counter Stacker CB-16 on site and secure with

B lift-off spindle (A)

- Establish the pneumatic connection (B) (6 bar / 87 psi)

and the electrical connections (C) and (D)

Fig. 1

- The lower outlet (D) is used as power supply line, the

upper outlet (C) as control connection.

Fig. 2

- Set the infeed transport belt to the height of the

upstream machine.

- Align center infeed transport belt to center of upstream

machine.

Fig. 3

12.2001 3631.8300B71 Operating Instructions 2.20.1

Counter Stacker CB-16 Control- and Operating Unit

Control

Control- and Operating Unit

A B C D E

(A) Main Switch

(B) Start-Key - Acknowledge fault

- Start Counter Stacker CB-16

(C) Stop-Key - Timed machine stop

(D) Display - Display

(E) Keyboard - Only keys with a lit LED are activated.

- A blinking LED shows a certain status

12.2001 3631.8300B71 Operating Instructions 3.10.1

Control- and Operating Unit

Start-Up

- Set the speed of the infeed belt with the handwheel (A).

Fig. 1

- If necessary, adjust the pusher speed (B). (see basic set-

tings) B

Fig. 2

C Adjust the speed of the belt delivery also with the

handwheel (C).

Fig. 3

3.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Control- and Operating Unit

Control

Size setting

Use the handwheels for a size adjustment according to the mechanical digital display, after the locking

mechanism has been loosened.

Book thickness

Book width Spine length

Infeed

(A) Book guide (infeed belt extension)

(B) Upper belt (oblique part)

A

Fig. 4

12.2001 3631.8300B71 Operating Instructions 3.10.3

Control- and Operating Unit

Intermediate Stacking

(A) Upper belt (horizontal part)

(B) Book thickness

(C) Spine length

A

B C

Fig. 5

Delivery

(D) Centering rolls

Fig. 6

3.10.4 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Control- and Operating Unit

Control

Side stops / Turntable

The side stops (spine length) are set according to the

B C scale (A).

A Turn knurled nut (B), After loosening the clamp levers

(C).

Add 1-5 mm (5/128" - 3/16") play for each page.

Fig. 7

The side stops (spine length) can be set according to the

scale (D).

After loosening the clamp levers (E) they are pushed to the

required position.

Add 1-5 mm (5/128" - 3/16") play for each page. E

The setting described above refers to the delivery in running

direction. With a delivery to the side "book width" is set

according to the scale (D) and "spine length" to the scale

(A).

D

Fig. 8

12.2001 3631.8300B71 Operating Instructions 3.10.5

Control- and Operating Unit

Production dependent settings

Processing aids

In order to stiffen thin products the running signature (A)

can be bent depending on requirement.

A

Fig. 9

In addition blow air (B) can be used to prevent the covers

from rising up. B

Fig. 10

3.10.6 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Control- and Operating Unit

Control

Special sizes

Size Larger Than 340 mm in Direction of Book Travel

For size length larger than 340 mm in direction of book travel the book stack cannot be

turned.

From spine length 410 mm on the foam rubber rollers can no longer be tightly aligned.

(Collision with open hopper flaps).

Changeover to Size Larger Than 340 mm in Direction of Book Travel

For the changeover to size larger than 340 mm in

direction of book travel execute the following steps:

A - Loosen star knob (A).

- Use handwheel (B) to move to size 340 mm according

B to scale (C).

C - Tighten star knob (A).

- Remove the threaded pin with point (fig. 12 A).

- Now the upper bin can be brought to the required size

with a book.

- Use clamp lever (fig. 13 B) to lock the stop.

Fig. 11

12.2001 3631.8300B71 Operating Instructions 3.10.7

Control- and Operating Unit

Changeover to "Normal" Size

During the changeover the handwheel (fig. 11 B) must be clamped with the star knob (fig.

11 A).

For changeover to "normal" size execute the following

steps:

- Loosen the stop with the clamp lever (B).

- Return the upper bin into its original position.

- Turn in threaded pin with point (A). (Caution: the

A threaded pin must fit exactly into the tap)

- You can now loosen the star knob (fig. 11 A).

Size setting is "normal" again.

Fig. 12

Fig. 13

3.10.8 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Mechanical Basic Settings

Basit Settings

Turntable

C - The exact positioning of the cylinder head is

determined when the distance (A) = 16.5mm (5/8")

B stimmt. It can be adjusted after loosening the lock nut

and turning the head (B) accordingly.

- Adjust the oil damper with throttle screw (C) so the

turning time is 590 - 720 ms. (The turning time shows

in the clear text display "TURNTABLE CYLINDER

EXTENDED / RETRACTED").

Fig. 1

The proximity switches (D) of the end stops must be

positioned with their front surface 0.2 - 0.5 mm (1/128" - D E

1/64") behind the stop surface (E).

Fig. 2

The play between the turntable and the support is set for

0.1 - 0.2 mm (0.004" - 1/128") (F).

F

Fig. 3

12.2001 3631.8300B71 Operating Instructions 4.10.1

Mechanical Basic Settings

Pusher

- Move pusher (A) into the displayed end position (piston

A extended). In this position the distance (C) (between

side guard - outer edge) and pusher holder must be 30

mm (1-3/16"). Adjustment on joint (B).

- Start counter stacker operation.

B C

Fig. 4

- Carefully turn screws of the end layer dampening (D) until

the pusher moves smoothly into the end layer.

D

Fig. 5

- Use throttle valve (E) to adjust the pusher time to 0.47 -

0.52 ms (the pusher time appears in the clear text

display "PUSHER CYLINDER EXTENDED /

RETRACTED").

E

Fig. 6

4.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Mechanical Basic Settings

Basit Settings

Reed Switch for End Position

Sketch

- (A) Ejector

A D - (B) Pusher up/down

- The reed switch (C) for "pusher up" is installed in the

highest possible position.

- Usually the dimensions listed in Fig. 7 are applicable.

C

cable

Fig. 7

Pusher

- The switching point of the reed switches not in the center. E

Therefore, the shorter dimension (E) must always be

installed against the cylinder ends.

- The switching of the reed switches can be observed on

the LED’s in the control cabinet.

Fig. 8

03.2002 3631.8300B71 Operating Instructions 4.10.3

Mechanical Basic Settings

Ejector

- Front reed switch

Fig. 9

- Rear reed switch

Fig. 10

4.10.4 3631.8300B71 Operating Instructions 03.2002

Counter Stacker CB-16 Control

Small size equipment

Technical Data

Sizes

Smallest sizes 100 x 70 mm

Conditions (Requirements)

The small size equipment can only be used for a stack height H = 240 mm (9-1/2") with left and/or right delivery

The max. speed is 6000 cop/hr

Set all digital displays for size adjustments - size plus 50 mm (2") (except book thickness)

The centering rollers in the delivery with speed reduction can only be aligned up to a book width B = 100 mm (4")

Sizes with spine length A less than 120 mm (4-11/16") cannot be turned anymore

Control

Special program for small sizes

Set the shred inhibit on the board in the control cabinet to position 4 (plug position 03)

If plastic inserts are installed in the stack bin you must enter "bin side plates installed" into the control.

12.2001 3631.8300B71 Operating Instructions 5.10.1

Control

Infeed

Mount infeed guides (A) and (B)

A B

Fig. 1

Intermediate stack

Install the intermediate stack guides (C) and (D)

C

D

Fig. 2

Mount the plastic inserts (E) and (F)

E F

Fig. 3

5.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Control

Small size equipment

Turntable

A B C D Mount the inserts (A/B/C/D) to the turntable side stops

Fig. 4

12.2001 3631.8300B71 Operating Instructions 5.10.3

Counter Stacker CB-16 Maintenance work

Maintenance

Handwheels

The handwheels can be disassembled after removing the

cover (A) by pressing it with a screwdriver.

A

Fig. 1

Maintenance unit

For detailed instructions refer to page 20.92.01/02

Air Pressure Adjustment Valves

- The adjustment is made on adjustment spindle (B), the

pressure setting can be read on the gauge.

- The compressed air is 6 bar / 87 psi

Fig. 2

12.2001 3631.8300B71 Operating Instructions 6.10.1

Maintenance work

Oil Mister

- The setting is made on adjustment screw (A) (slotted

A screw).

- The setting should be approx. 1 drop of oil per minute

Fig. 3

6.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Manual lubrication

Lubrication

Oil Compensating Glass

Refill oil

- Turn off the machine by pressing the mushroom stop but- B

ton.

- Remove cap screw (B).

- Refill oil No.11 untill the oil level reaches the mark.

Mount cap screw.

Fig. 1

12.2001 3631.8300B71 Operating Instructions 7.10.1

Manual lubrication

Gear Oil Change

- A gear oil change should be made after 5’000 operating hours.

- 0.3 Liter / Mobilgear 629 CLP 150

A (A) Cap screw

(B) Oil drain screw

(C) Oil sight glass

C

Fig. 2

7.10.2 3631.8300B71 Operating Instructions 12.2001

Counter Stacker CB-16 Manual lubrication

Lubrication

Roller chains

Lubricate roller chain (A) semi-annually with grease

no.13

A

Fig. 3

Lubricate roller chain (B) semi-annually with grease no. 13. B

Fig. 4

Cylinder

Lightly oil all extended pistons on all cylinders with pneumatic oil No.4.

12.2001 3631.8300B71 Operating Instructions 7.10.3

Counter Stacker CB-16 Change of belts

Repair instructions

General instructions

- Cover tapered ends with adhesive tape.

- Insert belt as shown in sheme.

- Coat one tapered surface evenly with Fixol glue and expose to air for 1/2 minute. (Close glue container tightly.

Durability after opening approx. 6 months.)

- Position the dry side and the one covered with glue exatly in the center of the preheated heating press surface

even and straight on top of each other.

- Close press and press at maximum pressure at 100° C (212° F) for 10 minutes.

Delivery

1 2

1 Type Habasit F-1 3630.1315.4 50/1.2x989mm

2 Type Habasit F-1 3630.1314.4 100/1.2x857mm

12.2001 3631.8300B71 Operating Instructions 8.10.1

Change of belts

Position of transport belts

1 Type Habasit F-1 3630.1151.4 25/1.2x1010mm

2 Type Habasit F-1 3631.1161.4 40/1.2x4548mm

3 Type Habasit F-1 3631.1160.4 40/1.2x4236mm

4 Type Habasit F-1 3631.1233.4 40/1.2x1880mm

8.10.2 3631.8300B71 Operating Instructions 12.2001

You might also like

- John Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFDocument31 pagesJohn Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFEquipment Manuals0% (2)

- Service Manual - 13-15-20-23EKOZD - 11-13-16.5-17.5-19.5-20EFKOZD PDFDocument280 pagesService Manual - 13-15-20-23EKOZD - 11-13-16.5-17.5-19.5-20EFKOZD PDFxxxxxxxxxxxxxxxxxxx100% (6)

- Schilling Robotics Conan 7P Manipulator System: Position-Controlled, 3 KM Submersible 24 VDC Base ModuleDocument218 pagesSchilling Robotics Conan 7P Manipulator System: Position-Controlled, 3 KM Submersible 24 VDC Base ModuleDiegus PalchettiNo ratings yet

- Fire Training Manual - SOLASDocument23 pagesFire Training Manual - SOLASHashem Gam100% (6)

- BS en 00615-2009 PDFDocument36 pagesBS en 00615-2009 PDFBorislav Vulić50% (2)

- Rigmaster Manual 8204Document122 pagesRigmaster Manual 8204Rodrigo MirandaNo ratings yet

- K601888 Brake System B250-B300 For Geared Machines W163-W200-W250Document45 pagesK601888 Brake System B250-B300 For Geared Machines W163-W200-W250Yasmin Quintela100% (1)

- Information & Operations Manual For Bavaria Cruiser 37Document37 pagesInformation & Operations Manual For Bavaria Cruiser 37RDNo ratings yet

- R-102 Manual PDFDocument141 pagesR-102 Manual PDFphibet83% (6)

- Manual d150 10aDocument215 pagesManual d150 10aJORGE CAICEDO100% (1)

- Manual D150-10a PDFDocument215 pagesManual D150-10a PDFJORGE CAICEDO100% (2)

- Tp6442 Eng Bg9kDocument284 pagesTp6442 Eng Bg9kGenildo SilvaNo ratings yet

- Manual Conan 199-0306 PDFDocument272 pagesManual Conan 199-0306 PDFGileno100% (1)

- Im Fpo-Gen2Document22 pagesIm Fpo-Gen2hassanqr89No ratings yet

- Sampson ControlerDocument52 pagesSampson Controlerpetar.petrov.111964No ratings yet

- 1 - Operating InstructionsDocument172 pages1 - Operating InstructionsAlkiviadis NtanisNo ratings yet

- TP6861 - 33-125EFOZDJ Operation ManualDocument120 pagesTP6861 - 33-125EFOZDJ Operation ManualthainarimeNo ratings yet

- Kohler 33-125efozdj Operation ManualDocument120 pagesKohler 33-125efozdj Operation ManualYiannis MikelisNo ratings yet

- tp6392 PDFDocument56 pagestp6392 PDFEgberto Pino GuerreroNo ratings yet

- Cond 3110: Conductivity MeterDocument41 pagesCond 3110: Conductivity Meterpurezone1979No ratings yet

- SM9400 Operating InstructionsDocument37 pagesSM9400 Operating InstructionsEdwardNo ratings yet

- tp5986 Eng GZRWDocument72 pagestp5986 Eng GZRWgeorge dimitroulisNo ratings yet

- COSIMAT N Plus EDocument40 pagesCOSIMAT N Plus EDmitry Selyugin0% (1)

- 20 2250kW Operation ManualDocument64 pages20 2250kW Operation Manualangel aguilarNo ratings yet

- Repeater Compass: Type 133 - 560 NG001 To NG010Document48 pagesRepeater Compass: Type 133 - 560 NG001 To NG010Rong PencileNo ratings yet

- Service: Commercial Generator SetsDocument76 pagesService: Commercial Generator SetsEgberto Pino GuerreroNo ratings yet

- Cosimat N+ PDFDocument38 pagesCosimat N+ PDFmass72No ratings yet

- Tp6127 - MPAC 1000 Controller & Service ManualDocument172 pagesTp6127 - MPAC 1000 Controller & Service ManualMP DieselNo ratings yet

- Manual Titan4 AtualizadoDocument332 pagesManual Titan4 AtualizadoCRISTIANO COUTINHONo ratings yet

- 55EOZCJ-200EOZCJ Service ManualDocument344 pages55EOZCJ-200EOZCJ Service Manualmichael.dwyer.documentsNo ratings yet

- Instruction Book HiLight V4W WUX 9829 4075 00 ENDocument40 pagesInstruction Book HiLight V4W WUX 9829 4075 00 ENArielNo ratings yet

- Precision & Flexibility by Dencohappel: Officecool - LecuDocument36 pagesPrecision & Flexibility by Dencohappel: Officecool - Lecuportocala12No ratings yet

- Ud7000 Parte 1 V19Document56 pagesUd7000 Parte 1 V19LaurentEuniceNo ratings yet

- Scan Coin SC303 and SC313 Coin Counter Service Manual Part 1Document57 pagesScan Coin SC303 and SC313 Coin Counter Service Manual Part 1Raul HuaytallaNo ratings yet

- AC160 1 83154b Part1 - enDocument884 pagesAC160 1 83154b Part1 - enSandoval Ramos Eddy100% (1)

- WTW Cond 3110 PDFDocument42 pagesWTW Cond 3110 PDFiqfalNo ratings yet

- Rover 24Document226 pagesRover 24Agus mulyadiNo ratings yet

- Mounting Instructions: Digital Torque TransducerDocument140 pagesMounting Instructions: Digital Torque TransducerAna RuganiNo ratings yet

- Conwell EveryManHisOwnUniversityDocument80 pagesConwell EveryManHisOwnUniversityJoseph AdikwuNo ratings yet

- ST1.3 Series: Product ManualDocument46 pagesST1.3 Series: Product ManualPampu1No ratings yet

- tp6109 Kohler Tarjeta PDFDocument68 pagestp6109 Kohler Tarjeta PDFGabino Ubilio Murillo100% (1)

- DEC 550 Controller OperationDocument168 pagesDEC 550 Controller OperationTom LeonardNo ratings yet

- 40 150 PDFDocument68 pages40 150 PDFChap Boon GohNo ratings yet

- SAMURAI - Manual en 3.0 NewDocument148 pagesSAMURAI - Manual en 3.0 NewRenzo ArangoNo ratings yet

- 150EFOZDJ Service ManualDocument304 pages150EFOZDJ Service Manualelectricidad.acasiNo ratings yet

- Balança Santariuos PDFDocument283 pagesBalança Santariuos PDFCélio LeãoNo ratings yet

- Ud7000 Parte 2 V19Document134 pagesUd7000 Parte 2 V19LaurentEuniceNo ratings yet

- Alcatel-Lucent GSM: 9125 Compact TC DescriptionDocument80 pagesAlcatel-Lucent GSM: 9125 Compact TC DescriptionAM MOTO OMCRNo ratings yet

- Service Manual 11 Au 35EFKOZD tp6953 PDFDocument360 pagesService Manual 11 Au 35EFKOZD tp6953 PDFNicolas TisnéNo ratings yet

- Operation Instruction D2840 (2) LE301Document92 pagesOperation Instruction D2840 (2) LE301Konstantin Potmenskiy100% (1)

- Operation: Residential/Commercial Generator SetsDocument72 pagesOperation: Residential/Commercial Generator SetsAnonymous mLLhWgE8LTNo ratings yet

- CP TD1 User ManualDocument70 pagesCP TD1 User ManualSna BerNo ratings yet

- Operation: Residential/Commercial Generator SetsDocument76 pagesOperation: Residential/Commercial Generator SetsАлексей Семикин100% (1)

- Service: Marine Generator SetsDocument116 pagesService: Marine Generator SetsWilly Alexander RamirezNo ratings yet

- ManualDocument73 pagesManualKusma SwandaruNo ratings yet

- Saftronics Cv10 ManualDocument121 pagesSaftronics Cv10 ManualAndres Elias Carrillo ManriqueNo ratings yet

- Digital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupDocument100 pagesDigital Servo Amplifier Servo Star 601... 620: Assembly, Installation, SetupPaul RidgeNo ratings yet

- Maintenance ManualDocument148 pagesMaintenance Manualgabrieljeg371No ratings yet

- Operation Manual: Rice Lake TCDocument42 pagesOperation Manual: Rice Lake TCSebastian AyalaNo ratings yet

- TP 5750Document80 pagesTP 5750Roberto Sanchez ZapataNo ratings yet

- WebastoserviceDocument72 pagesWebastoserviceanasrl2006No ratings yet

- Osmo 23GDocument111 pagesOsmo 23Gluis bazanNo ratings yet

- ChecklistDocument26 pagesChecklistmajdirossross100% (1)

- Chapter 2 Part 3Document14 pagesChapter 2 Part 3Abdul Halim AsmungiNo ratings yet

- Fire Fighting in Commercial Buildings, Application Guide - GrundfosDocument56 pagesFire Fighting in Commercial Buildings, Application Guide - GrundfosercolinoNo ratings yet

- Mreq Vs Preq Vs Po Vs Grns - With Item DescDocument105 pagesMreq Vs Preq Vs Po Vs Grns - With Item DescAjas AjuNo ratings yet

- NIT Rourkela-Safety EngineeringDocument23 pagesNIT Rourkela-Safety Engineeringshahnawaz ahmedNo ratings yet

- CatalogDocument130 pagesCatalogAmit KumarNo ratings yet

- R20 - Potassium Chromate IndicatorDocument4 pagesR20 - Potassium Chromate IndicatorLaboratorium PT MASNo ratings yet

- Tebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Document4 pagesTebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Ahmed MohamedNo ratings yet

- How To Safely Lift & CarryDocument7 pagesHow To Safely Lift & Carrychris0% (1)

- Halon Extinguishing Agents: Safety & Health ConcernsDocument4 pagesHalon Extinguishing Agents: Safety & Health ConcernskbonairNo ratings yet

- Safety ManualDocument17 pagesSafety ManualArpita Biswas100% (1)

- Battle Damage Assessment and Repair (BDAR) Procedures 63H34F05 / Version MOSC 01 Oct 2004 Administrative DataDocument35 pagesBattle Damage Assessment and Repair (BDAR) Procedures 63H34F05 / Version MOSC 01 Oct 2004 Administrative DataLo Shun FatNo ratings yet

- Chapter 38 NS1030 Sue Study GuideDocument19 pagesChapter 38 NS1030 Sue Study GuideLuke Rachel WurzNo ratings yet

- Emergency Management Plan SampleDocument60 pagesEmergency Management Plan SampleartscraftsNo ratings yet

- Master'S Handing Over Note: Contacts and PicDocument16 pagesMaster'S Handing Over Note: Contacts and PicVishal KumarNo ratings yet

- Filter MideaDocument22 pagesFilter MideaMahibul HasanNo ratings yet

- Fire Emergency Preparedness SeminarDocument65 pagesFire Emergency Preparedness SeminarTAURUS EMS100% (1)

- Fire Extinguisher Checklist CDocument3 pagesFire Extinguisher Checklist CTristano EffendiNo ratings yet

- 025 MSDS Terracide LO11Document7 pages025 MSDS Terracide LO11Andreas PradanaNo ratings yet

- Titus Lithium Battery: Safety Data SheetDocument5 pagesTitus Lithium Battery: Safety Data SheetKittikun Ap UnitechNo ratings yet

- Test Your Fire Extinguisher KnowledgeDocument4 pagesTest Your Fire Extinguisher KnowledgeMANOUJ GOELNo ratings yet

- Fire Protection SystemDocument84 pagesFire Protection Systemmohd farhan ariff zaitonNo ratings yet

- ChemistryDocument47 pagesChemistryJai MurugeshNo ratings yet

- Fire - Extinguishers - Table PDFDocument2 pagesFire - Extinguishers - Table PDFSardar Puneet Singh BhatiaNo ratings yet