Professional Documents

Culture Documents

41-22-001_avk130_en 2206_478776

41-22-001_avk130_en 2206_478776

Uploaded by

Orbit 001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

41-22-001_avk130_en 2206_478776

41-22-001_avk130_en 2206_478776

Uploaded by

Orbit 001Copyright:

Available Formats

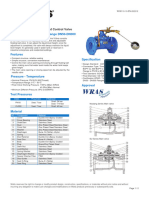

AVK SWING CHECK VALVE, RESILIENT SEATED, PN10/16, 41/22-001

LEVER

BS 5153 short, lever w. weight RH side, EPDM, A4 bolts, 300µm blue EP coating

AVK series 41 swing check valves come with both metal and resilient seats. Installed in pumping applications to prevent back

flow they can be used for drinking water as well as waste water. The disc is connected to the shaft via a flexible bush that

allows disc and valve seat to adjust exactly. All interior parts are stainless steel or coated with drinking water approved epoxy

or EPDM. The series 41 valves are available with either closed bushings or protruding shaft end where a lever with a weight or

a spring can be fitted to mitigate pressure surges.

Product description:

Resilient seat swing check valve to EN 1074 standard. For drinking water and neutral liquids to max. 70°C

Standards:

· Designed according to AS/NZS 2638.2

· Flange drilling to EN1092, PN10/16

Test/Approvals:

· Seat: 1.1 x PN (in bar), Body: 1.5 x PN (in bar). Operation torque test.

Features:

· Resilient seat provides a drop tight closure and due to the light weight it requires a minimum of force to open/close

· Shaft fitted in the bonnet allowing for easy maintenance without removing valve from pipeline

· Shaft material 1.4404 (AISI 316L) stainless steel

· Position indicating lever with an adjustable weight that aids the disc in closing quickly to reduce water hammer

· Hinge of stainless steel for sizes ≤ DN 200; ductile iron coated with drinking water approved epoxy for larger

· Bonnet gasket in a groove between bonnet and body to prevent blow-out

· All seals and coatings with contact to the fluid are approved for drinking water - coating is blue, 300µm fusion bonded

epoxy

· Disc design with a steel or ductile iron insert fully vulcanized with EPDM rubber

· Bosses on each side of the valve seat allow for installation of pressure gauge, by-pass, etc.

Accessories:

Lever and weight/spring, lever protection guard, proximity switch, combi-flanges, flange adaptors.

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

©Fusion Group 2021 yupzon - 10-Feb-2022 10:03

1/3

AVK SWING CHECK VALVE, RESILIENT SEATED, PN10/16, LEVER 41/22-001

BS 5153 short, lever w. weight RH side, EPDM, A4 bolts, 300µm blue EP coating

Component list:

1

1. Bolt Stainless steel A4

15

15. Bushing, closed Brass DZR

2

2. Nut Stainless steel A4

16

16. Tab washer Stainless steel A4

3

3. Washer Stainless steel A4

17

17. Bolt Stainless steel A4

4

4. Bushing Polyamide

18

18. Shaft Stainless steel 316L

5

5. Disc Steel S235JR

19

19. O-ring EPDM rubber

6

6. Body Ductile iron GJS-500-7 (GGG-50)

20

20. O-ring EPDM rubber

7

7. Gasket EPDM rubber

21

21. Bushing, open Brass DZR

8

8. Bolt Stainless steel A4

22

22. O-ring EPDM rubber

9

9. Pin Stainless steel A4

23

23. Lever Ductile iron GJS-500-7 (GGG-50)

10

10. Hinge Stainless steel 316

24

24. Washer Stainless steel A4

11

11. Key Stainless steel A4

25

25. Nut Stainless steel A4

12

12. Bonnet Ductile iron GJS-500-7 (GGG-50)

26

26. Weight Cast iron GJL-250 (GG-25)

13

13. Washer Stainless steel A4

27

27. Screw Stainless steel A4

14

14. Thrust plate Stainless steel

Components may be substituted with equivalent or higher class materials without prior notification.

Item 10: Ductile iron for DN ≥ 250

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

©Fusion Group 2021 yupzon - 10-Feb-2022 10:03

2/3

AVK SWING CHECK VALVE, RESILIENT SEATED, PN10/16, LEVER 41/22-001

BS 5153 short, lever w. weight RH side, EPDM, A4 bolts, 300µm blue EP coating

Reference nos. and dimensions:

Ref. No. DN Flange L H W1 D Dt Dh Ds Number Theoretical

mm drilling mm mm mm mm mm mm mm of bolts weight/kg

41-050-22-0180106 50 PN10/16 203 110 160 165 102 125 19 4 14

41-080-22-0180106 80 PN10/16 241 140 160 200 138 160 19 8 17

41-100-22-0180106 100 PN10/16 292 150 175 220 158 180 19 8 22

41-150-22-0180106 150 PN10/16 356 195 220 285 212 240 23 8 42

41-200-22-0080106 200 PN10 495 230 240 340 268 295 23 8 67

41-200-22-0180106 200 PN16 495 230 240 340 268 295 23 12 67

41-250-22-0080106 250 PN10 622 270 415 406 320 350 23 12 161

41-250-22-0180106 250 PN16 622 270 415 406 320 355 28 12 161

41-300-22-0080106 300 PN10 699 300 415 460 370 400 23 12 238

41-300-22-0180106 300 PN16 699 300 415 460 370 410 28 12 238

Row to make sure table is never blank

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

©Fusion Group 2021 yupzon - 10-Feb-2022 10:03

3/3

You might also like

- Cub Cadet RZT Series Zero Turn Service Repair ManualDocument30 pagesCub Cadet RZT Series Zero Turn Service Repair ManualRoger Miller67% (6)

- Wimax Mac Ieee 802-16Document37 pagesWimax Mac Ieee 802-16Gajendra GanigaNo ratings yet

- CTD200 Series Card Dispenser Start GuideDocument2 pagesCTD200 Series Card Dispenser Start GuideMedicsindex Telepin SlidecaseNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- 851 41 001 - OptDocument3 pages851 41 001 - OptSabikun NaharNo ratings yet

- Gate Valve AvkDocument3 pagesGate Valve AvkIwan SetiawanNo ratings yet

- Avk Air ValveDocument3 pagesAvk Air ValveNaqiudin ZainudinNo ratings yet

- 756-218-002_avk130_en 2207_480568Document3 pages756-218-002_avk130_en 2207_480568Orbit 001No ratings yet

- 756-218-005 - Avk130 - en 2206 - 478848Document3 pages756-218-005 - Avk130 - en 2206 - 478848afryansyahNo ratings yet

- Avk Control Valve, One Way Altitude, Pn10/16 859/2031-001: Reduced Bore, SS 304 Trim, WRAS Rubber, 300 M Blue EPDocument4 pagesAvk Control Valve, One Way Altitude, Pn10/16 859/2031-001: Reduced Bore, SS 304 Trim, WRAS Rubber, 300 M Blue EPindra putraNo ratings yet

- Data Sheet AvkDocument3 pagesData Sheet AvkPDAM Tirta Kandilo Kabupaten PaserNo ratings yet

- Avk Double Eccentric Butterfly Valve, Pn25 756/118-002Document3 pagesAvk Double Eccentric Butterfly Valve, Pn25 756/118-002thehuy015No ratings yet

- Avk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400Document2 pagesAvk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400umair186No ratings yet

- A900 - Control HidraulicoDocument14 pagesA900 - Control HidraulicoAnnie De WildeNo ratings yet

- Avk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Document3 pagesAvk Gate Valve, Flanged, Pn10/16 06/30-0035: EN 558-2 S.14/DIN F4, DN40-600Ali AafaaqNo ratings yet

- 859-001X-001 Avk002ax EniDocument5 pages859-001X-001 Avk002ax Enikimik47No ratings yet

- Os&Y Gate Valves: Product OverviewDocument2 pagesOs&Y Gate Valves: Product Overviewroland09No ratings yet

- Avk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsDocument5 pagesAvk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsleejaemunNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- 02-20-003 Avk031 EnlDocument2 pages02-20-003 Avk031 EnlMohamed ShohadyNo ratings yet

- 756-100-671 - Avk002ax - Eni - 432306 DOUBLE ECCENTRIC FLANGE BUTERFLY VALVE (AVK)Document3 pages756-100-671 - Avk002ax - Eni - 432306 DOUBLE ECCENTRIC FLANGE BUTERFLY VALVE (AVK)arixbonengNo ratings yet

- 24-90-001 - Avk130 - en 2206 - 478650Document2 pages24-90-001 - Avk130 - en 2206 - 478650bre brilianNo ratings yet

- 76-70-005_avkcms_en 2203_431550Document2 pages76-70-005_avkcms_en 2203_431550Orbit 001No ratings yet

- 21-36-002 Avkcms enDocument3 pages21-36-002 Avkcms enbrilian pungkyNo ratings yet

- AVK - Gate Valve OS&Y UL - FM - OutdoorDocument2 pagesAVK - Gate Valve OS&Y UL - FM - OutdoorVINOD PAULNo ratings yet

- 2018 12 18 A200 PN AFC V9 (Pressure Reducing Valve)Document6 pages2018 12 18 A200 PN AFC V9 (Pressure Reducing Valve)dian wahyudiNo ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- 859-000X-001 Avk002ax EniDocument3 pages859-000X-001 Avk002ax EniCosmin NăhupNo ratings yet

- 24-96-001 - Avkcms - en 2208Document2 pages24-96-001 - Avkcms - en 2208Yonish SisoNo ratings yet

- Avk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400Document2 pagesAvk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400brilian pungkyNo ratings yet

- Arv DesignDocument4 pagesArv Designshan07011984No ratings yet

- AVk New 101Document3 pagesAVk New 101shan07011984No ratings yet

- AVK Gate Valve130 - EN 2214Document2 pagesAVK Gate Valve130 - EN 2214Citra masNo ratings yet

- 06-30-036 - Avkcms - en 2234 - 428408Document2 pages06-30-036 - Avkcms - en 2234 - 428408Ilse FerreiraNo ratings yet

- 06-30-029 Avk002ax EniDocument2 pages06-30-029 Avk002ax EniFiroz HussainNo ratings yet

- Alpine 2021-01-20 Gbgx Pn v1 Rsv Bevel GbDocument3 pagesAlpine 2021-01-20 Gbgx Pn v1 Rsv Bevel GbafryansyahNo ratings yet

- AVK Gate Valve With Polyethylene Pipe EndDocument3 pagesAVK Gate Valve With Polyethylene Pipe Endklatheesh72No ratings yet

- AFC Gate ValveDocument4 pagesAFC Gate ValveAnnie De WildeNo ratings yet

- Avk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved RubberDocument2 pagesAvk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved Rubberkhai ruleNo ratings yet

- ES Model W-M115-3Document2 pagesES Model W-M115-3moekimo3No ratings yet

- FP 700 EngineeringDocument8 pagesFP 700 EngineeringCarlos Alberto VargasNo ratings yet

- Sanyata SAFEAir Large Linear Pneumatic 1.1Document4 pagesSanyata SAFEAir Large Linear Pneumatic 1.1HariHaran RajendranNo ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- 15-67-003 Avkcms en 427788Document2 pages15-67-003 Avkcms en 427788bre brilianNo ratings yet

- 84-90-001 Avk002ax Eni 432447Document3 pages84-90-001 Avk002ax Eni 432447Gotica ManagementNo ratings yet

- Series 64 Screwed End Ball ValvesDocument2 pagesSeries 64 Screwed End Ball ValvesProcess Controls & Services100% (1)

- Type C: Hopper Shape Knife Gate ValveDocument13 pagesType C: Hopper Shape Knife Gate ValveAbdur Rohman Al BaabNo ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- 84-92-001 Avkcms enDocument3 pages84-92-001 Avkcms enShpresim KuchiNo ratings yet

- Avk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRDocument2 pagesAvk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRbrilian pungkyNo ratings yet

- Brochure Pressure Reducing Valve RYUKODocument7 pagesBrochure Pressure Reducing Valve RYUKOPandyNo ratings yet

- Van bươm điều khiển Khi nen AUTOMA ACMDocument1 pageVan bươm điều khiển Khi nen AUTOMA ACMAutoma Viet NamNo ratings yet

- 84-45-003 Avk002ax Eni 432444Document3 pages84-45-003 Avk002ax Eni 432444Gotica ManagementNo ratings yet

- ProValve Knife Gate ValveDocument12 pagesProValve Knife Gate ValveHarry HonchoNo ratings yet

- Avk Flanged Gate Valve, Os&Y, Ul/Fm Approved, 250 Psi 145/56-001Document2 pagesAvk Flanged Gate Valve, Os&Y, Ul/Fm Approved, 250 Psi 145/56-001Ray MartinNo ratings yet

- 76-71-006 Avkcms enDocument2 pages76-71-006 Avkcms enbre brilianNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Van Cong Ty Chim Ydk Apt2Document2 pagesVan Cong Ty Chim Ydk Apt2Le NghiNo ratings yet

- Model: Heavy Duty Knife Gate ValveDocument10 pagesModel: Heavy Duty Knife Gate ValveOscar ZavaletaNo ratings yet

- Model: Heavy Duty Knife Gate ValveDocument10 pagesModel: Heavy Duty Knife Gate Valveviki851No ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- Da en 01Document400 pagesDa en 01Batboy BatkoNo ratings yet

- 7.3 Series N Parallel 2013Document14 pages7.3 Series N Parallel 2013fillyana01No ratings yet

- ACN: Water (80:20% V/V)Document1 pageACN: Water (80:20% V/V)madhubaddapuriNo ratings yet

- Method Statement - Installation of Sewerage Piles in Live LineDocument9 pagesMethod Statement - Installation of Sewerage Piles in Live LineaceNo ratings yet

- Frequency KorotkoffDocument5 pagesFrequency KorotkoffKenneth Palma CarmonaNo ratings yet

- Rishi Agarwal CVDocument2 pagesRishi Agarwal CVSourav PandaNo ratings yet

- OsiSense XCC - XCC1514TS11XDocument6 pagesOsiSense XCC - XCC1514TS11X'Suazo StreetboyNo ratings yet

- Intellectual Property Topic 3 Slides PresentationDocument8 pagesIntellectual Property Topic 3 Slides PresentationSyahirah ArifNo ratings yet

- Induction MotorDocument20 pagesInduction MotorMahêshwär Rêððý BobbaNo ratings yet

- Collapse of The World Trade CentreDocument15 pagesCollapse of The World Trade CentrePiyush KumarNo ratings yet

- Poster RT 01Document1 pagePoster RT 01RuiFPTNo ratings yet

- Ametek 0Document19 pagesAmetek 0senthilrsenthilNo ratings yet

- Workshop 5 Stiffened Plate Subjected To Pressure LoadDocument29 pagesWorkshop 5 Stiffened Plate Subjected To Pressure LoadsmendozaNo ratings yet

- Optimal Control PDFDocument91 pagesOptimal Control PDFAshutosh AnandNo ratings yet

- System Sensor MDL3R Data SheetDocument2 pagesSystem Sensor MDL3R Data SheetJMAC SupplyNo ratings yet

- ALCAD L - M - H Ranges: Nickel Cadmium BatteriesDocument2 pagesALCAD L - M - H Ranges: Nickel Cadmium BatteriesAngel Quijano Armengol100% (1)

- Structural Steel ErectionDocument8 pagesStructural Steel Erectionbratishkaity100% (1)

- Pradeep Jha June-2019Document13 pagesPradeep Jha June-2019mkpNo ratings yet

- Interface Qos: Security LevelDocument6 pagesInterface Qos: Security Levelmafasa_2005No ratings yet

- Op Amp McqsDocument5 pagesOp Amp McqsMuhammad TousiqNo ratings yet

- Unigraphics General Interview QuestionsDocument5 pagesUnigraphics General Interview QuestionsmanulalsNo ratings yet

- 50-Applicable Codes and StandardsDocument48 pages50-Applicable Codes and StandardsmohsenNo ratings yet

- Reflection PaperDocument1 pageReflection PaperHarold LandichoNo ratings yet

- 8000231-Metric and Inch (Sae) FastenersDocument11 pages8000231-Metric and Inch (Sae) FastenersFrancisco DiazNo ratings yet

- URAL 2017 - Owners - Manual - EnglishDocument86 pagesURAL 2017 - Owners - Manual - EnglishPerformNo ratings yet

- How Offset Printing WorksDocument2 pagesHow Offset Printing Workspavan4samudralaNo ratings yet

- General Shear Failure Local Shear Failure: Net Ulimate Bearing Capacity of Shallow FoundationDocument2 pagesGeneral Shear Failure Local Shear Failure: Net Ulimate Bearing Capacity of Shallow Foundationaditya gair100% (1)