Professional Documents

Culture Documents

KPC F QAC 001_Inspection and Test Plan

KPC F QAC 001_Inspection and Test Plan

Uploaded by

marckeCopyright:

Available Formats

You might also like

- Erection Method Statement Royal Comision (Hollow Core)Document17 pagesErection Method Statement Royal Comision (Hollow Core)marcke0% (1)

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Method Statement For CuttingDocument5 pagesMethod Statement For Cuttingmarcke0% (1)

- DM's Guild - The Elemental Spellbook (5e) PDFDocument24 pagesDM's Guild - The Elemental Spellbook (5e) PDFbalim01100% (1)

- Quality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")Document3 pagesQuality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")sriram.5230No ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of Tanksosers100% (1)

- Itp Atwts PDFDocument3 pagesItp Atwts PDFrahmath nawazNo ratings yet

- Safety Valve Qap 270622Document2 pagesSafety Valve Qap 270622Pavul RajNo ratings yet

- Qap Amtp-Cp-Qc 01 Dlfbe Tco r6Document10 pagesQap Amtp-Cp-Qc 01 Dlfbe Tco r6Бауыржан ЖусуповNo ratings yet

- ETHIO Infra Engineering Private Limited Company: Summary of Test ResultsDocument1 pageETHIO Infra Engineering Private Limited Company: Summary of Test ResultsSolomon MehariNo ratings yet

- Indicative QAP For Submersible PumpDocument3 pagesIndicative QAP For Submersible PumpAnuj Pandey100% (2)

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Client:-Project: - Consultant: - Contaractor: - Name of PanelDocument1 pageClient:-Project: - Consultant: - Contaractor: - Name of PanelChaturbhai HadiyalNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- Common Quality Assurance PlanDocument3 pagesCommon Quality Assurance PlanQASWA ENGINEERING IMRANNo ratings yet

- 350 Acetic AcidDocument1 page350 Acetic Acidinderverma1975No ratings yet

- Asme Sec Ix AWS API ASME B 31.8Document25 pagesAsme Sec Ix AWS API ASME B 31.8smdriyazbashaNo ratings yet

- QCP & Report Rev 03Document30 pagesQCP & Report Rev 03Heri FebriyantoNo ratings yet

- LOI - Fuel Cooler Assy (72 FC 47 0000-A)Document2 pagesLOI - Fuel Cooler Assy (72 FC 47 0000-A)Prabhakaran CHNQualityNo ratings yet

- ITP Aluminum DCM Rev 00Document1 pageITP Aluminum DCM Rev 00maheshpanditNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Shuqaiq Phase-3 Water Transmission SystemDocument5 pagesShuqaiq Phase-3 Water Transmission Systemrahmath nawazNo ratings yet

- Gtes LT HSRP QapDocument5 pagesGtes LT HSRP Qapshashank shahNo ratings yet

- Quality Assurance Standard Quality Plan Column and Ceiling GirderDocument9 pagesQuality Assurance Standard Quality Plan Column and Ceiling Girdertalk2dilpreetNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- TC 0.80 1000 CoilDocument1 pageTC 0.80 1000 Coilvikram jainNo ratings yet

- Quality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Document9 pagesQuality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Sachin KumarNo ratings yet

- Mix Design ComplainceDocument7 pagesMix Design Complainceraja qammar100% (2)

- Inspection and Test PlanDocument3 pagesInspection and Test Planrahmath nawazNo ratings yet

- Itp RJM PDFDocument3 pagesItp RJM PDFrahmath nawazNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Inspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded JointsDocument5 pagesInspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded Jointsrahmath nawazNo ratings yet

- 4.1. Flow Proses Mur M12 A192 2HDocument2 pages4.1. Flow Proses Mur M12 A192 2Hcahayabp. isoNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- CPS-1 Typical Collector Pipe SystemDocument2 pagesCPS-1 Typical Collector Pipe SystemLyra De MesaNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Standard Quality Plan: Conforming To Code: Is 8183Document4 pagesStandard Quality Plan: Conforming To Code: Is 8183jagan100% (1)

- Board Line: - 022 66595154: As Per Iso 2341Document1 pageBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALINo ratings yet

- JJ3223124887Document1 pageJJ3223124887पवन द्विवेदीNo ratings yet

- MPS DraftDocument7 pagesMPS DraftAngga ErlanggaNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- MET - 13 - IGC Practice B - R00 PDFDocument5 pagesMET - 13 - IGC Practice B - R00 PDFkaushal sagarNo ratings yet

- BTG 11.12.22-11.18.22 T-1 PDFDocument1 pageBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- Qap Gate ValveDocument1 pageQap Gate ValveAjit PatilNo ratings yet

- General Arrangement Drawing For 2Nd Stage Desalter Recycle Wash Water Pumps A98-G-0104 A/B & A98-G-0204 A/B NMR: "7902-601.1, 7902-602.1"Document2 pagesGeneral Arrangement Drawing For 2Nd Stage Desalter Recycle Wash Water Pumps A98-G-0104 A/B & A98-G-0204 A/B NMR: "7902-601.1, 7902-602.1"SENTHILNo ratings yet

- CV of BDocument6 pagesCV of BSyed Mohamed Gani GaniNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- RP 18 MPT 001 TCR AlupcoDocument3 pagesRP 18 MPT 001 TCR AlupcoRonel John Rodriguez CustodioNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- M-ANM-3K1DPE-CCFE-EDR-000004 11Document1 pageM-ANM-3K1DPE-CCFE-EDR-000004 11marckeNo ratings yet

- M-ANM-3A1DPW-CC00-MAR-000019-ADocument74 pagesM-ANM-3A1DPW-CC00-MAR-000019-AmarckeNo ratings yet

- Safety Engineer shareef cv (2)Document3 pagesSafety Engineer shareef cv (2)marckeNo ratings yet

- che balane gateDocument2 pagesche balane gatemarckeNo ratings yet

- NC Attachment for CracksDocument7 pagesNC Attachment for CracksmarckeNo ratings yet

- kristine cuDocument22 pageskristine cumarckeNo ratings yet

- AbrasionDocument3 pagesAbrasionmarckeNo ratings yet

- SDP_Casting AreaDocument1 pageSDP_Casting AreamarckeNo ratings yet

- rc comments reportDocument24 pagesrc comments reportmarckeNo ratings yet

- KPC-F-QAC-018_Weekly Quality ReportDocument2 pagesKPC-F-QAC-018_Weekly Quality ReportmarckeNo ratings yet

- Hotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1Document2 pagesHotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1marckeNo ratings yet

- KPC-F-QAC-002_Inspection and Usage Log for Steel ReinforcementDocument1 pageKPC-F-QAC-002_Inspection and Usage Log for Steel ReinforcementmarckeNo ratings yet

- Moisture ContentDocument1 pageMoisture ContentmarckeNo ratings yet

- Report On Cement For Precast ConcreteDocument4 pagesReport On Cement For Precast ConcretemarckeNo ratings yet

- CPD Certificate - 10Document1 pageCPD Certificate - 10marckeNo ratings yet

- Reynaldo Mamacos BPO SupervisorDocument3 pagesReynaldo Mamacos BPO SupervisormarckeNo ratings yet

- Travel Request Form: Personal InformationDocument2 pagesTravel Request Form: Personal InformationmarckeNo ratings yet

- MS For Grouting ApplicationDocument20 pagesMS For Grouting ApplicationmarckeNo ratings yet

- Relationship Between Density and Moisture ContentDocument2 pagesRelationship Between Density and Moisture ContentivanNo ratings yet

- Hierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeDocument17 pagesHierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeSyed Anas HussaniNo ratings yet

- Comprehensive 2025 Leaflet (5) - CompressedDocument18 pagesComprehensive 2025 Leaflet (5) - CompressedHALOLLOLNo ratings yet

- Aslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product SheetDocument1 pageAslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product Sheet192113No ratings yet

- 955.04 Nitrogeno en FertilizantesDocument1 page955.04 Nitrogeno en Fertilizanteslizeth rico quinteroNo ratings yet

- Specs Muscenone® Firmenich 962191 (Muscenone Delta)Document1 pageSpecs Muscenone® Firmenich 962191 (Muscenone Delta)路人甲No ratings yet

- 03 Neutralization Reactions Worksheet KeyDocument2 pages03 Neutralization Reactions Worksheet KeySokahaNo ratings yet

- Visual Guide To OPCW Science and TechnologyDocument25 pagesVisual Guide To OPCW Science and TechnologyWacel HamaniNo ratings yet

- CSEC Chemistry January 2020 P2 Q3Document3 pagesCSEC Chemistry January 2020 P2 Q3Alphx XZNo ratings yet

- L. M. Chart: Products & SolutionDocument2 pagesL. M. Chart: Products & SolutionPrice Action Trading SurajNo ratings yet

- MIXED PLASTIC RECYCLING PLANT STUW - HT - CHE - 2020 - Carducci - NunzioDocument52 pagesMIXED PLASTIC RECYCLING PLANT STUW - HT - CHE - 2020 - Carducci - NunzioDHSanjNo ratings yet

- Sonu RESUME-2Document3 pagesSonu RESUME-2Sagar ThakreNo ratings yet

- E 05-03-2022 Power Interruption Schedule FullDocument22 pagesE 05-03-2022 Power Interruption Schedule FullAda Derana100% (2)

- Acid - Base Chemistry - ShortDocument27 pagesAcid - Base Chemistry - ShortSachin PatilNo ratings yet

- SCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfDocument12 pagesSCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfRetep ArenNo ratings yet

- HTLP-80 Application ProcedureDocument9 pagesHTLP-80 Application ProceduremaheshNo ratings yet

- Astm E415-21Document3 pagesAstm E415-21Guilherme ChagasNo ratings yet

- Heterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDocument40 pagesHeterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDidula ThrimannaNo ratings yet

- Measuring Rancidity in Fats and OilsDocument6 pagesMeasuring Rancidity in Fats and OilsFrankPapa100% (1)

- Fat and Protein MetabolismDocument2 pagesFat and Protein MetabolismMark Zedrix MediarioNo ratings yet

- Byk - P 4102 - TDS - 1643511993Document2 pagesByk - P 4102 - TDS - 1643511993swapon kumar shillNo ratings yet

- LESSON 4-Solidification of Metals and AlloysDocument19 pagesLESSON 4-Solidification of Metals and Alloysmichael-education KNo ratings yet

- Quiz 3Document8 pagesQuiz 3Imee DichosoNo ratings yet

- Chem7a BSN-1-J Module2 Group5 DapulaseDocument4 pagesChem7a BSN-1-J Module2 Group5 DapulaseKiana JezalynNo ratings yet

- Fiitjee Phase Test 1 JEE MAIN CM BatchesDocument20 pagesFiitjee Phase Test 1 JEE MAIN CM BatchesHeath Ledger100% (2)

- Bresle Salt Test GuidingDocument5 pagesBresle Salt Test GuidinglambtranNo ratings yet

- Formal Chemistry Lab ReportsDocument4 pagesFormal Chemistry Lab ReportsAram IbrahimNo ratings yet

- Rheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsDocument9 pagesRheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsRatri HiusenaNo ratings yet

- Organic Module1Document3 pagesOrganic Module1John mark ObiadoNo ratings yet

KPC F QAC 001_Inspection and Test Plan

KPC F QAC 001_Inspection and Test Plan

Uploaded by

marckeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KPC F QAC 001_Inspection and Test Plan

KPC F QAC 001_Inspection and Test Plan

Uploaded by

marckeCopyright:

Available Formats

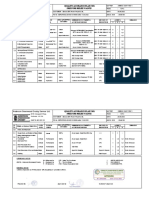

PREPARED BY : MR

INSPECTION AND TEST PLAN VERIFIED BY : GM

CONCRETE RAW MATERIAL & CONCRETE

INTEGRATED MANAGEMENT SYSTEM

PAGE NO. : 1 0F 2

FREQUENCY OF QUALITY CONTROL OPERATIONS

FREQUENCY

TEST METHOD /

EACH EACH AGE DAYS ACCEPTANCE VERIFYING QC HANDBOOK

ITEM / DESCRIPTION SPECIFICATION DAILY WEEKLY MONTH 3 - MONTH 6 - MONTH ANNUAL RANDOM EACH BED RESPONSIBILTY

SHPMNT. CAST ACTUAL CRITERIA DOCUMENTS REF.

REFERENCE

CEMENT

WATER

OPC TYPE 1 ASTM C150 • MTC-ASTM C150 N/A MTC 2.2.1

TDS • = 2000 ppm KPC KPC-F-B&M-001 2.2.4

pH VALUE

ASTM C1602 /

• = 6.5 - 8.5 KPC KPC-F-B&M-001 2.2.4

•

C1602M-0M6

OTHER AS REQ'D. IL* IL RESULT 2.2.4

ADMIXTURE

WATER REDUCERS,

RETARDERS, ACCELERATORS,

HIGH-RANGE WATER

REDUCERS

ASTM C494 • N/A MTC 2.2.5

AIR ENTRAINMENT ASTM C260 • MTC-ASTM C494

N/A MTC 2.2.5

COLORING ASTM C979 • N/A MTC 2.2.5

CORROSION INHIBITORS

REINFORCEMENT

ASTM G109 • N/A MTC 2.2.5

PRESTRESS STRANDS ASTM A416 • MTC-ASTM A416 N/A MTC 6.3

DEFORMED BARS ASTM A615 • MTC-ASTM A615 N/A MTC 2.3.1

BAR MATS & WELDED WIRE

FABRIC

ASTM A184, A185,

A497 • MTC-ASTM A184,

A185, A497

N/A MTC 2.3.3

FINE AGGREGATE

SIEVE ANALYSIS ASTM C136 • -- KPC KPC-F-B&M-002 2.2.2

MATL. FINER THAN 0.75

MICRON

ASTM C117 • = ≤ 2% KPC KPC-F-B&M-002 2.2.2

WATER ABSORPTION ASTM C127-128 • -- IL IL RESULT 5.5.2

CLAY LUMPS & FRIABLE

PARTICLES

ASTM C142 • = ≤ 1% IL IL RESULT 2.2.2

CHLORIDE CONTENT BS 1377-812 • = ≤ 0.6% IL IL RESULT 2.2.2

SULPHATE CONTENT

COARSE AGGREGATE

BS 1377-812 • = ≤ 0.4% IL IL RESULT 2.2.2

SIEVE ANALYSIS ASTM C136 • -- KPC KPC-F-B&M-003 2.1.3

WATER ABSORPTION ASTM C127-128 • -- IL IL RESULT 5.2.2

CLAY LUMPS & FRIABLE

PARTICLES

ASTM C142 • = ≤ 2% IL IL RESULT 2.2.3

LOS ANGELES ABRASION

FRESH CONCRETE TESTING

ASTM C131 • 40% MAX. IL IL RESULT 2.1.3

SLUMP ASTM C143 EVERY 1 TEST SAMPLE OF CONCRETE -- KPC KPC-F-QAC-005 5.3.2

CONCRETE TEMP.

ASTM C172 / ACI

305R-306R • 32°C (MAX.) KPC KPC-F-QAC-006 5.3.3

HOLLOW CORE SLABS = 1 TEST SAMPLE (4 CUBES) / DAY / DESIGN MIX / BED

OTHER PRESTRESSED UNITS = 1 TEST SAMPLE (4 CUBES) / DAY / DESIGN MIX / BED

SAMPLING OF CONCRETE WP & OTHER SKELETON UNITS : 1 TEST SAMPLE = 4 CUBES

BS 1881:PART 108 AS PER PROCEDURE KPC KPC-F-QAC-005 5.3.1a

(CUBES) IF 5m2 AND LESS PER DAY = 2 TEST SAMPLE / WEEK / DESIGN MIX

IF 5m2 - 50m2 PER DAY = 1 TEST SAMPLE / DAY / DESIGN MIX

IF MORE THAN 50m2 PER DAY = 2 TEST SAMPLES / DAY / DESIGN MIX

* IL - INDEPENDENT LABORATORY

** IF CLIENT SPECIFIED THE ITP, THE MORE STRINGENT REQUIREMENT WILL BE FOLLOWED. IMS FORM

NO.

: KPC-F-QAC-001.0

AL KIFAH PRECAST COMPANY INTEGRATED MANAGEMENT SYSTEM . QA/QC DEPARTMENT

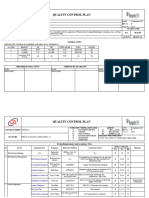

PREPARED BY : MR

INSPECTION AND TEST PLAN VERIFIED BY : GM

CONCRETE AND OPERATIONAL INSPECTIONS

INTEGRATED MANAGEMENT SYSTEM

PAGE NO. : 2 OF 2

FREQUENCY OF QUALITY CONTROL OPERATIONS

FREQUENCY

TEST METHOD / EACH

EACH AGE DAYS ACCEPTANCE VERIFYING QC HANDBOOK

ITEM / DESCRIPTION SPECIFICATION CAST / DAILY WEEKLY MONTH 3 - MONTH 6 - MONTH ANNUAL RANDOM EACH BED RESPONSIBILTY

SHPMNT. ACTUAL CRITERIA DOCUMENTS REF.

REFERENCE UNIT

HOLLOW CORE SLABS = 1 TEST SAMPLE (4 CYLINDERS) / DAY / DESIGN MIX / BED

OTHER PRESTRESSED UNITS = 1 TEST SAMPLE (4 CYLINDERS) / DAY / DESIGN MIX / BED

SAMPLING OF CONCRETE WP & OTHER SKELETON UNITS : 1 TEST SAMPLE = 4 CYLINDERS

ASTM C172 AS PER PROCEDURE KPC KPC-F-QAC-005 5.3.1b

(CYLINDER) IF 5m2 AND LESS PER DAY = 2 TEST SAMPLE / WEEK / DESIGN MIX

IF 5m2 - 50m2 PER DAY = 1 TEST SAMPLE / DAY / DESIGN MIX

IF MORE THAN 50m2 PER DAY = 2 TEST SAMPLES / DAY / DESIGN MIX

IF 1 TEST SAMPLE = 4 CUBES/CYLINDER (HOLLOW CORE SLABS)

1 CUBE = 3 DAYS COMPRESSIVE STRENGTH AS PER KPC DESIGN

CONCRETE SPECIMEN TESTING KPC KPC KPC-F-QAC-005 5.3.6

2 CUBES = 28 DAYS COMPRESSIVE STRENGTH REQUIREMENTS

1 CUBE = DEMOULDING STRENGTH

HARDENED CONCRETE TESTING

3/7/28 DAYS

SAMPLES)

(CUBE

BS 1881: PART 116 • AS PER KPC DESIGN

KPC KPC-F-QAC-006 5.3.6

•

REQUIREMENTS

3/7/28 DAYS

ASTM C31 KPC KPC-F-QAC-006 5.3.6

(CYLINDER SAMPLES)*

CONCRETE CHARACTERISTIC STRENGTH

TEST REPORT KPC • KPC KPC

STATISTICAL

ANALYSIS

1.1.3

PRE-POUR INSPECTION

KPC;

KPC-F-D&D-004 /

MOULDS KPC DOCUMENT MIN. 20% OF TOTAL MOULDS KPC DESIGN TOLERANCES 4.3.1 4.3.2

KPC-F-WAC-009/010

AS PER FORM

KPC-F-D&D-004 /

REINFORCEMENT POSITION KPC DOCUMENT MIN. 20% OF TOTAL MOULDS KPC DESIGN KPC 4.3.3

KPC-F-WAC-009/010

KPC-F-D&D-004 /

MISC. EMBEDDED ITEMS KPC DOUCMENT MIN. 20% OF TOTAL MOULDS KPC DESIGN KPC 4.3.4

KPC-F-WAC-009/010

CASTING PROPER

HIGH AMBIENT TEMPERATURE, HIGH CONCRETE TEMPERATURE, LOW RELATIVE HUMIDITY, WIND, SOLAR ACI; CONC. TEMP =

HOT WEATHER PRECAUTION ACI 305R KPC KPC-F-QAC-006 4.4.6

RADIATION (CONCRETE TEMP = 32°C MAX) 32°C (MAX.)

AVG. DAILY TEMP = 5°C OR LESS OR AIR TEMP = 10°C FOR MORE THAN 1/2 OF ANY 24-HR PERIOD FOR 3 CONSECUTIVE

ACI; CONC. TEMP =

COLD WEATHER PRECAUTION ACI 306R DAYS (CONCRETE TEMP = 7°C MIN) KPC KPC-F-QAC-006 4.4.7

7°C (MIN.)

POST-POUR INSPECTION

CURING BY HEAT & MOISTURE ASTM C403 • AS PER PROCEDURE KPC

KPC-F-QAC-

011/012/013

4.5.3

MOISTURE CURING KPC • 3 DAYS MIN. KPC

KPC-F-QAC-

011/012/013

4.5.2

POST-POUR INSPECTION,

STORAGE & MARKING

VARIOUS

STANDARDS • QUALITY

HANDBOOK

KPC

KPC-F-QAC-

011/012/013

4.7 / 4.8

* - ACTUAL CYLINDER TEST IF REQUIRED BY CUSTOMER OR CUBE TEST RESULT MAY BE CONVERTED TO CYLINDER BY: CYLINDER TEST RESULT

(Mpa) = CUBE TEST RESULT (Mpa) X 0.85

** - IF NOT SPECIFIED IN KPC DRAWINGS ACI 318 WILL BE FOLLOWED

IMS FORM

NO.

: KPC-F-QAC-001.0

AL KIFAH PRECAST COMPANY INTEGRATED MANAGEMENT SYSTEM . QA/QC DEPARTMENT

You might also like

- Erection Method Statement Royal Comision (Hollow Core)Document17 pagesErection Method Statement Royal Comision (Hollow Core)marcke0% (1)

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- Method Statement For CuttingDocument5 pagesMethod Statement For Cuttingmarcke0% (1)

- DM's Guild - The Elemental Spellbook (5e) PDFDocument24 pagesDM's Guild - The Elemental Spellbook (5e) PDFbalim01100% (1)

- Quality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")Document3 pagesQuality Assurance Plan For MV Switchgear (Type - Unigear/Leangear Cubicle With " Vd4/Vind - Breaker")sriram.5230No ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of Tanksosers100% (1)

- Itp Atwts PDFDocument3 pagesItp Atwts PDFrahmath nawazNo ratings yet

- Safety Valve Qap 270622Document2 pagesSafety Valve Qap 270622Pavul RajNo ratings yet

- Qap Amtp-Cp-Qc 01 Dlfbe Tco r6Document10 pagesQap Amtp-Cp-Qc 01 Dlfbe Tco r6Бауыржан ЖусуповNo ratings yet

- ETHIO Infra Engineering Private Limited Company: Summary of Test ResultsDocument1 pageETHIO Infra Engineering Private Limited Company: Summary of Test ResultsSolomon MehariNo ratings yet

- Indicative QAP For Submersible PumpDocument3 pagesIndicative QAP For Submersible PumpAnuj Pandey100% (2)

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Client:-Project: - Consultant: - Contaractor: - Name of PanelDocument1 pageClient:-Project: - Consultant: - Contaractor: - Name of PanelChaturbhai HadiyalNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- Common Quality Assurance PlanDocument3 pagesCommon Quality Assurance PlanQASWA ENGINEERING IMRANNo ratings yet

- 350 Acetic AcidDocument1 page350 Acetic Acidinderverma1975No ratings yet

- Asme Sec Ix AWS API ASME B 31.8Document25 pagesAsme Sec Ix AWS API ASME B 31.8smdriyazbashaNo ratings yet

- QCP & Report Rev 03Document30 pagesQCP & Report Rev 03Heri FebriyantoNo ratings yet

- LOI - Fuel Cooler Assy (72 FC 47 0000-A)Document2 pagesLOI - Fuel Cooler Assy (72 FC 47 0000-A)Prabhakaran CHNQualityNo ratings yet

- ITP Aluminum DCM Rev 00Document1 pageITP Aluminum DCM Rev 00maheshpanditNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Shuqaiq Phase-3 Water Transmission SystemDocument5 pagesShuqaiq Phase-3 Water Transmission Systemrahmath nawazNo ratings yet

- Gtes LT HSRP QapDocument5 pagesGtes LT HSRP Qapshashank shahNo ratings yet

- Quality Assurance Standard Quality Plan Column and Ceiling GirderDocument9 pagesQuality Assurance Standard Quality Plan Column and Ceiling Girdertalk2dilpreetNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- TC 0.80 1000 CoilDocument1 pageTC 0.80 1000 Coilvikram jainNo ratings yet

- Quality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Document9 pagesQuality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Sachin KumarNo ratings yet

- Mix Design ComplainceDocument7 pagesMix Design Complainceraja qammar100% (2)

- Inspection and Test PlanDocument3 pagesInspection and Test Planrahmath nawazNo ratings yet

- Itp RJM PDFDocument3 pagesItp RJM PDFrahmath nawazNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Inspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded JointsDocument5 pagesInspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded Jointsrahmath nawazNo ratings yet

- 4.1. Flow Proses Mur M12 A192 2HDocument2 pages4.1. Flow Proses Mur M12 A192 2Hcahayabp. isoNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- CPS-1 Typical Collector Pipe SystemDocument2 pagesCPS-1 Typical Collector Pipe SystemLyra De MesaNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Standard Quality Plan: Conforming To Code: Is 8183Document4 pagesStandard Quality Plan: Conforming To Code: Is 8183jagan100% (1)

- Board Line: - 022 66595154: As Per Iso 2341Document1 pageBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALINo ratings yet

- JJ3223124887Document1 pageJJ3223124887पवन द्विवेदीNo ratings yet

- MPS DraftDocument7 pagesMPS DraftAngga ErlanggaNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- MET - 13 - IGC Practice B - R00 PDFDocument5 pagesMET - 13 - IGC Practice B - R00 PDFkaushal sagarNo ratings yet

- BTG 11.12.22-11.18.22 T-1 PDFDocument1 pageBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- Qap Gate ValveDocument1 pageQap Gate ValveAjit PatilNo ratings yet

- General Arrangement Drawing For 2Nd Stage Desalter Recycle Wash Water Pumps A98-G-0104 A/B & A98-G-0204 A/B NMR: "7902-601.1, 7902-602.1"Document2 pagesGeneral Arrangement Drawing For 2Nd Stage Desalter Recycle Wash Water Pumps A98-G-0104 A/B & A98-G-0204 A/B NMR: "7902-601.1, 7902-602.1"SENTHILNo ratings yet

- CV of BDocument6 pagesCV of BSyed Mohamed Gani GaniNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- RP 18 MPT 001 TCR AlupcoDocument3 pagesRP 18 MPT 001 TCR AlupcoRonel John Rodriguez CustodioNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- M-ANM-3K1DPE-CCFE-EDR-000004 11Document1 pageM-ANM-3K1DPE-CCFE-EDR-000004 11marckeNo ratings yet

- M-ANM-3A1DPW-CC00-MAR-000019-ADocument74 pagesM-ANM-3A1DPW-CC00-MAR-000019-AmarckeNo ratings yet

- Safety Engineer shareef cv (2)Document3 pagesSafety Engineer shareef cv (2)marckeNo ratings yet

- che balane gateDocument2 pagesche balane gatemarckeNo ratings yet

- NC Attachment for CracksDocument7 pagesNC Attachment for CracksmarckeNo ratings yet

- kristine cuDocument22 pageskristine cumarckeNo ratings yet

- AbrasionDocument3 pagesAbrasionmarckeNo ratings yet

- SDP_Casting AreaDocument1 pageSDP_Casting AreamarckeNo ratings yet

- rc comments reportDocument24 pagesrc comments reportmarckeNo ratings yet

- KPC-F-QAC-018_Weekly Quality ReportDocument2 pagesKPC-F-QAC-018_Weekly Quality ReportmarckeNo ratings yet

- Hotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1Document2 pagesHotel Reservation Request Form: Personal Information Travelling Hotel Guest # 1marckeNo ratings yet

- KPC-F-QAC-002_Inspection and Usage Log for Steel ReinforcementDocument1 pageKPC-F-QAC-002_Inspection and Usage Log for Steel ReinforcementmarckeNo ratings yet

- Moisture ContentDocument1 pageMoisture ContentmarckeNo ratings yet

- Report On Cement For Precast ConcreteDocument4 pagesReport On Cement For Precast ConcretemarckeNo ratings yet

- CPD Certificate - 10Document1 pageCPD Certificate - 10marckeNo ratings yet

- Reynaldo Mamacos BPO SupervisorDocument3 pagesReynaldo Mamacos BPO SupervisormarckeNo ratings yet

- Travel Request Form: Personal InformationDocument2 pagesTravel Request Form: Personal InformationmarckeNo ratings yet

- MS For Grouting ApplicationDocument20 pagesMS For Grouting ApplicationmarckeNo ratings yet

- Relationship Between Density and Moisture ContentDocument2 pagesRelationship Between Density and Moisture ContentivanNo ratings yet

- Hierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeDocument17 pagesHierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeSyed Anas HussaniNo ratings yet

- Comprehensive 2025 Leaflet (5) - CompressedDocument18 pagesComprehensive 2025 Leaflet (5) - CompressedHALOLLOLNo ratings yet

- Aslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product SheetDocument1 pageAslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product Sheet192113No ratings yet

- 955.04 Nitrogeno en FertilizantesDocument1 page955.04 Nitrogeno en Fertilizanteslizeth rico quinteroNo ratings yet

- Specs Muscenone® Firmenich 962191 (Muscenone Delta)Document1 pageSpecs Muscenone® Firmenich 962191 (Muscenone Delta)路人甲No ratings yet

- 03 Neutralization Reactions Worksheet KeyDocument2 pages03 Neutralization Reactions Worksheet KeySokahaNo ratings yet

- Visual Guide To OPCW Science and TechnologyDocument25 pagesVisual Guide To OPCW Science and TechnologyWacel HamaniNo ratings yet

- CSEC Chemistry January 2020 P2 Q3Document3 pagesCSEC Chemistry January 2020 P2 Q3Alphx XZNo ratings yet

- L. M. Chart: Products & SolutionDocument2 pagesL. M. Chart: Products & SolutionPrice Action Trading SurajNo ratings yet

- MIXED PLASTIC RECYCLING PLANT STUW - HT - CHE - 2020 - Carducci - NunzioDocument52 pagesMIXED PLASTIC RECYCLING PLANT STUW - HT - CHE - 2020 - Carducci - NunzioDHSanjNo ratings yet

- Sonu RESUME-2Document3 pagesSonu RESUME-2Sagar ThakreNo ratings yet

- E 05-03-2022 Power Interruption Schedule FullDocument22 pagesE 05-03-2022 Power Interruption Schedule FullAda Derana100% (2)

- Acid - Base Chemistry - ShortDocument27 pagesAcid - Base Chemistry - ShortSachin PatilNo ratings yet

- SCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfDocument12 pagesSCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfRetep ArenNo ratings yet

- HTLP-80 Application ProcedureDocument9 pagesHTLP-80 Application ProceduremaheshNo ratings yet

- Astm E415-21Document3 pagesAstm E415-21Guilherme ChagasNo ratings yet

- Heterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDocument40 pagesHeterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDidula ThrimannaNo ratings yet

- Measuring Rancidity in Fats and OilsDocument6 pagesMeasuring Rancidity in Fats and OilsFrankPapa100% (1)

- Fat and Protein MetabolismDocument2 pagesFat and Protein MetabolismMark Zedrix MediarioNo ratings yet

- Byk - P 4102 - TDS - 1643511993Document2 pagesByk - P 4102 - TDS - 1643511993swapon kumar shillNo ratings yet

- LESSON 4-Solidification of Metals and AlloysDocument19 pagesLESSON 4-Solidification of Metals and Alloysmichael-education KNo ratings yet

- Quiz 3Document8 pagesQuiz 3Imee DichosoNo ratings yet

- Chem7a BSN-1-J Module2 Group5 DapulaseDocument4 pagesChem7a BSN-1-J Module2 Group5 DapulaseKiana JezalynNo ratings yet

- Fiitjee Phase Test 1 JEE MAIN CM BatchesDocument20 pagesFiitjee Phase Test 1 JEE MAIN CM BatchesHeath Ledger100% (2)

- Bresle Salt Test GuidingDocument5 pagesBresle Salt Test GuidinglambtranNo ratings yet

- Formal Chemistry Lab ReportsDocument4 pagesFormal Chemistry Lab ReportsAram IbrahimNo ratings yet

- Rheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsDocument9 pagesRheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsRatri HiusenaNo ratings yet

- Organic Module1Document3 pagesOrganic Module1John mark ObiadoNo ratings yet