Professional Documents

Culture Documents

UNP jis UP

UNP jis UP

Uploaded by

Mochammad Arif Budi SetiawanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UNP jis UP

UNP jis UP

Uploaded by

Mochammad Arif Budi SetiawanCopyright:

Available Formats

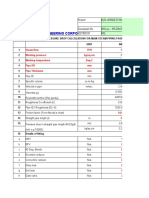

PT BOMA BISMA INDRA Form :

PROJECT MANAGEMENT & SERVICE DIVISION

JL. KHM. Mansyur 229 Surabaya 60162

PAGE : OF

INSPECTION RECORD OF UNP/CHANNELS U

CUSTOMER : PT BIMA PALMA NUGRAHA BBI JOB No. : 10.002.2

USER : PT BIMA PALMA NUGRAHA P.O/B.Q/ SPPB No. :

PROJECT NAME : CPO Mill Cap 30 T FFB/H Extandable to 60 T FFB/H Project LPB No. :

STAGE OF INSPECTION : RAW MATERIAL RECEIVING DATE OF INSPECTION :

RECORD No. : SUPPLIER :

UNIT SIZE : mm / Inch. MEASUREMENT INSTRUMENT : Caliper / Roll metre / Micrometre

IDENTIFICATION ITEM DIMENSION TOL. REMARKS

No. SPEC. ACTUAL SPECIFICATION:

H 125 ± 2.0 UNP.125x65xx6x8 L = 6 Mtr

B1 65 ± 2.0 Matrl. : SS 400 JIS G 3101

B2 65 ± 2.0

t1 6 ± 1.0

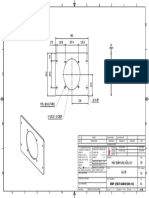

t2 8 ± 1.0 t2 t2 B1

B1

L 6000 +40 , -0

L

T 0 <1

t1 T T

H 125 ± 2.0

B1 65 ± 2.0 H

B2 65 ± 2.0

t1 6 ± 1.0

t2 8 ± 1.0 reference: dimensional tolerance JIS G 3192

L 6000 +40 , -0 T T

T 0 <1 VISUAL CHECK

RESULT OF INSPECTION, STRAIGTNESS :

SURFACE CONDITION :

EXAMINER, QC MANAGER, QC WITNESSED/REVIEWED BY, REMARKS

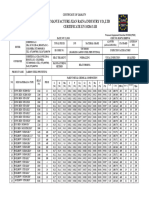

REFERENCE OF DIMENSION TOLERANCES

STANDARD USED : JIS G 3101 (Rolled steels for general structure)

JIS G 3192 (Shape, Dimension, Weight and Tolerance for Hot Rolled steel Bar and Bar-in-Coil)

material : SS 400

shapes and dimensional tolerances of angels, I sections, channels, bulb flats and T sections

Dimension Tolerance Remarks

Leg length Under 50 ± 1.5

(B) 50 or over to and excl. 100 ± 2.0

100 or over to and excl. 200 ± 3.0

200 or over ± 4.0

Depth (H) under 100 ± 1.5

100 or over to and excl. 200 ± 2.0

200 or over to and excl. 400 ± 3.0

400 or over ± 4.0

Thickness For leg length (B for T Under 6.3 ± 0.6

(t1,t2) section) or under 130 in 6.3 or over to and excl. 10 ± 0.7 t2 t2 B1

B1

depth 10 or over to and excl.16 ± 0.8

L

16 or over ± 1.0

t1

For leg length A (B for T Under 6.3 ± 0.7

section) or 130 or oven in 6.3 or over to and excl. 10 ± 0.8 H

depth 10 or over to and excl.16 ± 1.0

16 or over to and excl. 25 ± 1.2

25 or over ± 1.5

Length 7 m or under +40 , -0

Over 7 m Add 5mm to the plus side tolerance given

in the above column for every 1m incre-

ase in lengths or its fraction.

Out of square (T) I section 2.5% or under of width B

Section excluding I and T 2.5% or under of width of flange B (or leg T T

sections length)

Bend I and T sections 0.2% or under of length

Sections excluding I and T 0.3% or under of length

sections T T

T T

Form :

PAGE : OF

INSPECTION RECORD RECEIVING MATERIAL

CUSTOMER : BBI JOB No. :

USER : P.O/B.Q/ SPPB No. :

PROJECT NAME : LPB No. :

STAGE OF INSPECTION : RAW MATERIAL DATE OF INSPECTION :

RECORD No. : SUPPLIER :

UNIT SIZE : mm / Inch. MEASUREMENT INSTRUMENT : Caliper / Roll metre / Micrometre

IDENTIFICATION ITEM DIMENSION TOL. REMARKS

No. SPEC. ACTUAL SPECIFICATION:

H UNP

B1 Matrl. : SS 400

B2

t1

t2 t2 t2 B1

B1

L

L

T

t1 T T

H

B1 H

B2

t1

t2 reference: dimensional tolerance JIS G 3192

L T T

T VISUAL CHECK

RESULT OF INSPECTION, STRAIGTNESS :

SURFACE CONDITION :

PREPARED BY CHECKED BY APPROVED BY REVIEWED / WITNESSED BY REMARK

You might also like

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 pageJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- Test Certificate: (AS PER EN 10204 TYPE 3.1)Document2 pagesTest Certificate: (AS PER EN 10204 TYPE 3.1)quality100% (1)

- Yarn ManufacturerersDocument31 pagesYarn ManufacturerersMarufNo ratings yet

- Admiralty Manual of Navigation (2003 Edition) PDFDocument131 pagesAdmiralty Manual of Navigation (2003 Edition) PDFMuak K100% (2)

- SeminarDocument10 pagesSeminarSridharNo ratings yet

- CBR TEST Sta 0+160 - 0+260Document1 pageCBR TEST Sta 0+160 - 0+260Dede NurcahyadiNo ratings yet

- Av02 2228en Ds HLMP Cx1a 2013 05 22-1827913Document13 pagesAv02 2228en Ds HLMP Cx1a 2013 05 22-1827913Daniel PradoNo ratings yet

- A500 Spec SheetDocument2 pagesA500 Spec SheetMikku KattaNo ratings yet

- A500 Spec PDFDocument2 pagesA500 Spec PDFUgur SenNo ratings yet

- Sole Plate-628 R.STDDocument18 pagesSole Plate-628 R.STDVenkatakumarreddy kudumalaNo ratings yet

- 1 1720BL15B0050-1519232 PDFDocument5 pages1 1720BL15B0050-1519232 PDFrakeeNo ratings yet

- Aluminum Electrolytic Capacitors/ M Radial Lead Type: FeaturesDocument5 pagesAluminum Electrolytic Capacitors/ M Radial Lead Type: FeaturesnonameNo ratings yet

- Time Study of Gate Valve Body 24X150 1setupDocument4 pagesTime Study of Gate Valve Body 24X150 1setupdada kolekarNo ratings yet

- 67 HCMDocument17 pages67 HCMKundan MahasethNo ratings yet

- Technical Fiche Profile H65 Rev 13Document2 pagesTechnical Fiche Profile H65 Rev 13Satendra ThakurNo ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- BETE WTX-metricDocument2 pagesBETE WTX-metricAlfian JunaidiNo ratings yet

- HLCA0530SD Series - A03 2020.11.12Document6 pagesHLCA0530SD Series - A03 2020.11.12ttNo ratings yet

- QAR-QD#407-7 Hollow Printing RollsDocument2 pagesQAR-QD#407-7 Hollow Printing RollsIrwanto ManafNo ratings yet

- Specifications of Raw Materials: Technical Fiche Profile H 65Document3 pagesSpecifications of Raw Materials: Technical Fiche Profile H 65RigoRuizNo ratings yet

- Design: NB: Size Lists Give "On Line" Tolerances For Rod ApplicationsDocument2 pagesDesign: NB: Size Lists Give "On Line" Tolerances For Rod ApplicationsNal FivefivetwooneNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- Dim 893 Dimensional..Document2 pagesDim 893 Dimensional..Inesperado InespNo ratings yet

- Technical Details: Piston SealsDocument2 pagesTechnical Details: Piston SealsRPINILLA (EICO S.A.)No ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- Data Sheet Multilayer Chip Inductor: CL SeriesDocument6 pagesData Sheet Multilayer Chip Inductor: CL SeriesOussama MessaoudiNo ratings yet

- Features/Benefits Typical ApplicationsDocument1 pageFeatures/Benefits Typical ApplicationsGo DaveNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- T 60 DiffsimulatorDocument5 pagesT 60 DiffsimulatorHector Raul VerizuetaNo ratings yet

- Cip0530-Lr 575534Document8 pagesCip0530-Lr 575534Oussama MessaoudiNo ratings yet

- 2-Port Slip-In Cartridge Valve Pressure Function, Poppet Type Cone A (1:1) Type L-CEE Sizes 16 Up To 63Document2 pages2-Port Slip-In Cartridge Valve Pressure Function, Poppet Type Cone A (1:1) Type L-CEE Sizes 16 Up To 63Mauricio Ariel H. OrellanaNo ratings yet

- Drum - Vertical Wire Mesh Mist EliminatorDocument8 pagesDrum - Vertical Wire Mesh Mist EliminatorAnonymous oVRvsdWzfBNo ratings yet

- 113 80 330 FD 202 - Rev1 19Document1 page113 80 330 FD 202 - Rev1 19Maria Eduarda AndradeNo ratings yet

- Reinforcement CalculationDocument8 pagesReinforcement Calculationer.praveenraj30No ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- Acceptance CriteriaDocument3 pagesAcceptance Criteriapoongodisk100% (1)

- S1 PruebaDocument10 pagesS1 PruebaDither Francisco GutierrezNo ratings yet

- A3 Mybmrchuc: VDP-1507-G004-D01-01Document1 pageA3 Mybmrchuc: VDP-1507-G004-D01-01tênchỉđểgọiNo ratings yet

- 113 80 330 FD 202 - Rev1 17Document1 page113 80 330 FD 202 - Rev1 17Maria Eduarda AndradeNo ratings yet

- Certificado Calidad CodosDocument1 pageCertificado Calidad CodosAndresFelipeCorreaNo ratings yet

- GB Trelljet681Document1 pageGB Trelljet681magnavacchi serviceNo ratings yet

- Performance CheckDocument61 pagesPerformance CheckOscar LosadaNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Spring CatlagueDocument32 pagesSpring CatlagueDhinesh DftNo ratings yet

- UHT UHT: Damage Assessment ReportDocument2 pagesUHT UHT: Damage Assessment ReportstkmNo ratings yet

- Dar 1120 001Document2 pagesDar 1120 001stkmNo ratings yet

- CBH-22-296 DIN 931 HB HT M10 X 70 SELF 8.8Document2 pagesCBH-22-296 DIN 931 HB HT M10 X 70 SELF 8.8qualityNo ratings yet

- Bete WTXDocument2 pagesBete WTXPraditia DanisNo ratings yet

- NF08-20Document7 pagesNF08-20Juan R.No ratings yet

- SKH Process Report1Document8 pagesSKH Process Report1Mohan KumarNo ratings yet

- Ventilador Interno PowerFlex 753 Frame 4 e 5 Nidec Ta225DC M34313-16Document3 pagesVentilador Interno PowerFlex 753 Frame 4 e 5 Nidec Ta225DC M34313-16Rogerio Pereira de PaulaNo ratings yet

- 65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)Document8 pages65A10184-09-0905-01-008 Rev.2 (FLow Meter Sizing Cal)chhandak beraNo ratings yet

- 10.1 Data-Sheet-CapacitorDocument10 pages10.1 Data-Sheet-CapacitorMarco OlivaresNo ratings yet

- Elastomeric Bearings: 6 (1) Design Load On BearingsDocument8 pagesElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexNo ratings yet

- Epc Pip Cal 0002Document3 pagesEpc Pip Cal 0002mb.pipingNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- WB 40 LC Data SheetDocument8 pagesWB 40 LC Data SheetsandeepkhandarNo ratings yet

- CBH-22-294 DIN 603 CB M6 X 32 BTZP 4.6Document1 pageCBH-22-294 DIN 603 CB M6 X 32 BTZP 4.6qualityNo ratings yet

- Spectrophotometer UseDocument4 pagesSpectrophotometer UseEsperanza Fernández MuñozNo ratings yet

- GMW8 2019 03 (Hot Dip Zinc Coating Sheet Steel)Document8 pagesGMW8 2019 03 (Hot Dip Zinc Coating Sheet Steel)dpfloresNo ratings yet

- Eastman Copolyester Eastar GN 001Document2 pagesEastman Copolyester Eastar GN 001Josephine NgNo ratings yet

- Occlusal Vertical Dimension Treatment Planning Decisions and Management ConsiderationsDocument16 pagesOcclusal Vertical Dimension Treatment Planning Decisions and Management ConsiderationsHector Flores Soto100% (4)

- My Happy Marriage Volume 03 LNDocument252 pagesMy Happy Marriage Volume 03 LNnailsnailsgoodinbed100% (2)

- Sis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024Document1 pageSis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024GOWRIJEYASHANKAR S KNo ratings yet

- Apollo Experience Report Environmental Acceptance TestingDocument61 pagesApollo Experience Report Environmental Acceptance TestingBob AndrepontNo ratings yet

- Muscular Tissues: Skeletal MusclesDocument3 pagesMuscular Tissues: Skeletal Musclesalimsaadun alimsaadunNo ratings yet

- Clay & Shale Industries in OntarioDocument193 pagesClay & Shale Industries in OntarioJohn JohnsonNo ratings yet

- 1.4 Fourier Transform Technique: 1 1 X 1 1 X X XDocument11 pages1.4 Fourier Transform Technique: 1 1 X 1 1 X X XanaNo ratings yet

- Application of UV Spectrophotometric Method For Estimation of Iron in Tablet Dosage FormDocument2 pagesApplication of UV Spectrophotometric Method For Estimation of Iron in Tablet Dosage Formahmed ismailNo ratings yet

- Indian Institute of Technology, Kharagpur:: X"' P (3 X N (O, ?Document2 pagesIndian Institute of Technology, Kharagpur:: X"' P (3 X N (O, ?brahma2deen2chaudharNo ratings yet

- Equine Facilitated TherapyDocument100 pagesEquine Facilitated TherapyBasil Donovan Fletcher100% (1)

- Heart Sounds: Presented by Group 2A & 3ADocument13 pagesHeart Sounds: Presented by Group 2A & 3AMeow Catto100% (1)

- TAC640 Service ManualDocument15 pagesTAC640 Service ManualCARMAIN100% (1)

- NCR 7403 Uzivatelska PriruckaDocument149 pagesNCR 7403 Uzivatelska Priruckadukindonutz123No ratings yet

- Manuscript For Lab 8 (Enzymes)Document11 pagesManuscript For Lab 8 (Enzymes)NURSYAHIRAH MOHD NAZIRNo ratings yet

- Wild Magic Extended ListDocument6 pagesWild Magic Extended ListbeepboopbotNo ratings yet

- Control Charts in SAP QM: Step by StepDocument10 pagesControl Charts in SAP QM: Step by StepPiyush BoseNo ratings yet

- Murray Thomson Thesis HandbookDocument257 pagesMurray Thomson Thesis HandbookSherif Mohamed KhattabNo ratings yet

- Yaesu Fc757at Instruction ManualDocument28 pagesYaesu Fc757at Instruction ManualAudio TecnologiaNo ratings yet

- Eat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Document2 pagesEat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Miruna MocleașăNo ratings yet

- SnowblowerDocument28 pagesSnowblowerJim KrebsNo ratings yet

- The Welding Journal 1958 7Document150 pagesThe Welding Journal 1958 7AlexeyNo ratings yet

- Cradles of Early ScienceDocument6 pagesCradles of Early ScienceMelody Balingasa NapireNo ratings yet

- BIJDENDIJK Offerlist Conventional 27.06.2022Document2 pagesBIJDENDIJK Offerlist Conventional 27.06.2022Stow CoffeeNo ratings yet