Professional Documents

Culture Documents

S-105000-04FRM Safety Equipment Control List

S-105000-04FRM Safety Equipment Control List

Uploaded by

Prashant GauravCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S-105000-04FRM Safety Equipment Control List

S-105000-04FRM Safety Equipment Control List

Uploaded by

Prashant GauravCopyright:

Available Formats

<S-105000-04FRM>

NYK SMS Manual (Rev: 2024-01-01)

Page 1 of 3

SAFETY EQUIPMENT CONTROL LIST (Sample List)

Vessel _______________________________________ Dated .

Flag State COMPANY

Requirement Requirement Manufacture / Remarks (E.g Which requirement / when planned

S.No. Description Expiry / Due Date

Last Service Date etc)

Flag: .

AA LIFE SAVING APPLIANCES

1 Line Throwing Apparatus As per Maker7

2 Rocket Parachute Flares (xx Nos) for Bridge As per Maker7

3 MOB Markers (Port) As per Maker7

4 MOB Markers (Stbd) As per Maker7

5 EPIRB Servicing / Testing (Shore) Annual

6 EPIRB Battery As per Maker7

7 EPIRB HRU As per Maker7

8 SART Battery (xx Nos) As per Maker7

9 GMDSS Walkie-Talkie Spare Batteries (xx Nos) As per Maker7

10 Life Jacket Lights As per Maker7

11 Immersion Suit Light As per Maker7

12 a) Liferaft onboard inspection (S.No: xxxxxxxxxxxxx) ( xx Persons) Annual Applicable for Extended service liferaft only.

b) Liferaft servicing (S.No: xxxxxxxxxxxxx) ( xx Persons) As per Maker8

c) Hydrostatic Release Unit As per Maker7

13 Buoyant Smoke Floats for Lifeboats (xx Nos) As per Maker7

14 Rocket Parachute Flares (xx Nos) for Lifeboats As per Maker7

15 Hand Flares (xx Nos) for Lifeboats As per Maker7

16 Food Rations (xx Packets) for Lifeboats As per Maker7

17 Lifeboat First Aid Kit (xx Nos) As per Maker7

18 Anti Sea Sickness Pills for Lifeboat As per Maker7

19 Self Igniting Lights - Battery Replacement Annual

20 Port Lifeboat Lowering and Manouvering in Water 3 months

21 Stbd. Lifeboat Lowering and Manouvering in Water 3 months

22 Port Lifeboat Falls Renewed 5 years For NYKSM 3 Years

23 Starboard Lifeboat Falls Renewed 5 years For NYKSM 3 Years

24 LifeBoat Onload Release Gear and Launching Appliances (Shore) 1 year

Including dynamic test with proof load of 1.1 times the

25 Testing of LifeBoat and Lifeboat Davit (Shore) 5 years maximum working load of the winch as required by

SOLAS

Inpection and maintenance of life boat, life boat fall, on load release

26 1year Annual test as required by SOLAS

mechanism and life boat davit by competent workshop.

27 Immersion Suit Air pressure Test by competent workshop 2 years/3 years

Rescue Boat Engine Fuel - Gasoline

28 1 year Including Spare charge of Gasoline

(Applicable to RB with outboard Engine)

<S-105000-04FRM>

NYK SMS Manual (Rev: 2024-01-01)

Page 2 of 3

SAFETY EQUIPMENT CONTROL LIST (Sample List)

Vessel _______________________________________ Dated .

Flag State COMPANY

Requirement Requirement Manufacture / Remarks (E.g Which requirement / when planned

S.No. Description Expiry / Due Date

Last Service Date etc)

Flag: .

BB FIRE FIGHTING APPLIANCES

1 a) 9ltrs Foam Extinguisher (lifeboat) (xx nos) - Inspection Annual By ship's staff

b) Inspection by Shore As per Flag

c) Recharge Annual

d) Hydrostatic Pressure Test As per Flag

2 a) 3.5 kg DCP Extinguisher(xx Nos) - Inspection Annual

b) Inspection by Shore As per Flag

c) Recharge 5 years

d) Hydrostatic Pressure Test As per Flag

e) Spare Charges (No & Qty on board) As per Flag List Flag requirement here

3 a) 6.8kg CO2 Extinguisher(xx Nos including xx spares) Annual Inspection by ship's staff

b) Inspection by Shore As per Flag

c) Hydrostatic Pressure Test As per Flag

d) Checking of Contents / Bottle weighment As per Flag

4 a) 135ltr Foam Ext (xx Nos) in Engine Room Annual Inspection by Ship's staff

b) Inspection by Shore As per Flag

c) Recharge As per Maker

d) Hydrostatic Pressure Test As per Flag

5 a) 45 Ltr Foam Ext (xx Nos) in Engine Room Annual Inspection by ship's staff

b) Inspection by Shore As per Flag

c) Recharge Annual

d) Hydrostatic Pressure Test As per Flag

6 a) Portable Foam Applicator (xx Nos) Annual Inspection by ship's staff

b) Inspection by Shore As per Flag

c) Recharge 4 years

7 Foaming Solution As per Maker

8 a) Fixed Fire fighting : CO2 Bottle weighment IS / SS

b) CO2 Bottles - Hydrostatic Pressure Testing 20yrs then 5 yrs

c) Line Blowing and Nozzle Check (By Shore staff) Annual

d) Master and Safety vv Operational Test (By Shore Staff) Annual

e) Control Valve Internal Inspection 5 years

10 Air Quality Test of BA Compressor (Shore workshop) Annual

11 Pressure Testing of Fire Mains (Ship Staff) 6 monthly Upto ~ 6kg / cm2

12 Pressure Testing of Fire Hoses-Acc. (Ship Staff) 6 monthly Upto ~ 6kg / cm2

<S-105000-04FRM>

NYK SMS Manual (Rev: 2024-01-01)

Page 3 of 3

SAFETY EQUIPMENT CONTROL LIST (Sample List)

Vessel _______________________________________ Dated .

Flag State COMPANY

Requirement Requirement Manufacture / Remarks (E.g Which requirement / when planned

S.No. Description Expiry / Due Date

Last Service Date etc)

Flag: .

13 Pressure Testing of Fire Hoses-Deck. (Ship Staff) 6 monthly Upto ~ 6kg / cm2

14 Sprinkler System for Paint Locker (Ship Staff) 3 monthly

15 Emergency Fire Pump Class Annual Survey Annual

16 Air Ventilation shut-off dampers/flaps - Remote Operation Annual

17 a) SCBA bottles - Hydrostatic Pressure Testing (xx Nos) 5 yrs

b) Servicing of SCBA Equipment / Bottles As per Flag

Enter interval as per

CC MISCELLANEOUS ITEMS

your ship type

1 Drinking Water Shore Analysis 6 monthly

2 O2 resuscitators shore servicing As per Maker

3 Emergency Batteries 7.5 or 5 yrs Enter interval as per For LNG Carriers: 7.5 yrs,

(See Remark) Other ships:5yrs

your ship type

4 Emergency Generator

For Tanker and Gas Carriers : 3 Monthly,

1 M*, 3 M or 6 M Other Ships: 6 Monthly

a) Load Test (See Remark) *Vessels having capability of synchronizing Emergency

SB with Main SB: Monthly

b) Fuel Tank Remote Cut Off 3 monthly

c) Replacement of LO 2 years

d) Replacement of Starting Battery 3 years

5 a) FO Emergency shut off valves Operational Test 6 monthly

b) FO Quick Closing Valves test 6 monthly

6 Gas Detector's shore caliberation As per maker

7 O2 Analyser's shore caliberation As per maker

8 Barometer's shore caliberation Annual

9 Alcometer As per SMS Based on ship type and maker's requirement

10 VDR performance checks Annual

Note: 1 This list is a sample list. It is to be utilised for reporting purposes as per S-P-10.50.00, Section 4

Note: 2 The Company should be informed whenever any shore service / supply is getting due within next 3 months

Note: 3 Items included in Column for "Description" may be added or deleted as per actual fittings on vessels

Note: 4 Flag State requirement is to be entered as per applicable flag of the vessel and must be monitored for any changes or amendments

Note: 5 Safety Officer should complete the company requirements. In case of requirement being "As per Maker" the maker's requirement should be indicated in Remarks.

Note: 6 If the requirements of SMS and Flag state are not similar, the stricter (lesser interval) shall be complied with

For JG Flag vessels - In case these items are required to be supplied with HK type approval stamp, please ensure that the requisition is raised at least 6 months before the expiry date. Please indicate clearly that the item

Note: 7

shall be provided with Type approval (HK stamp).

In accordance with IMO MSC.1/Circ.1328,

Note: 8 For JG Flag vessels - Annual.

For other Flag vessel - As per the Maker’s criteria subjected to Flag State approval

You might also like

- 2ND MATE ORAL QUESTIONS - FUNCTION ONE Most Asked QuestionsDocument25 pages2ND MATE ORAL QUESTIONS - FUNCTION ONE Most Asked QuestionsJayesh Solaskar89% (9)

- Red Storm RisingDocument116 pagesRed Storm Risingremow85% (13)

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- Nav 03 - Underkeel and Overhead Clearance FormDocument4 pagesNav 03 - Underkeel and Overhead Clearance FormКонстантин Кулаков100% (1)

- A As Bu Uilt: AS SL Oil Visco Lubri Osity A Catio Addit On List Ive Do T Osing Syste EMDocument2 pagesA As Bu Uilt: AS SL Oil Visco Lubri Osity A Catio Addit On List Ive Do T Osing Syste EMFOMCNo ratings yet

- IPDS Closure Format - PMA ReportDocument2 pagesIPDS Closure Format - PMA Reportmanjeet mishraNo ratings yet

- Job Information: Job No Sheet No RevDocument2 pagesJob Information: Job No Sheet No RevJedidiahClementNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Requerimiento Concreto SemanalDocument11 pagesRequerimiento Concreto SemanalMiguelangel ChávezNo ratings yet

- XXXX Design Calculations: 2019-02-13 RevisionDocument20 pagesXXXX Design Calculations: 2019-02-13 RevisionFernando RealNo ratings yet

- Sod IvarDocument41 pagesSod IvarSacha's ChannelNo ratings yet

- Report Balok Anak StaadDocument4 pagesReport Balok Anak StaadKimberly EdlynNo ratings yet

- Data Sheet Crude Oil Tank Mixer PDFDocument3 pagesData Sheet Crude Oil Tank Mixer PDFsiska bedegul100% (1)

- Repairs and Maintenance: Service ManualDocument81 pagesRepairs and Maintenance: Service Manualkumpulantiga3No ratings yet

- Hoja de Datos de Recipiente BechtelDocument3 pagesHoja de Datos de Recipiente BechtelPedro Luis Choque MamaniNo ratings yet

- Business Planning MAR 16 - MHDocument5 pagesBusiness Planning MAR 16 - MHSunil JoshiNo ratings yet

- Herunefer W 13Document3 pagesHerunefer W 13Islam AtifNo ratings yet

- Check ValvesDocument12 pagesCheck Valveshaniif mkNo ratings yet

- Templates - Feeder SegregationDocument10 pagesTemplates - Feeder SegregationSandeep ChoudharyNo ratings yet

- Maintenance LogDocument5 pagesMaintenance LogAhmed OusamaNo ratings yet

- TBC Fender PDFDocument3 pagesTBC Fender PDFmuhammad amanyNo ratings yet

- Form Penetrant TestDocument5 pagesForm Penetrant TestAgung PrasetyooNo ratings yet

- Visio-VSM AssignmentDocument1 pageVisio-VSM AssignmentKiran IqbalNo ratings yet

- DAEWOO H.N0.2210/1: Water Treatment ProcedureDocument37 pagesDAEWOO H.N0.2210/1: Water Treatment ProcedureDatsun FernandesNo ratings yet

- 8 PPRA FormatDocument2 pages8 PPRA FormatEgo TaleNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1K76UV468B9E5RTDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1K76UV468B9E5RTanon_689770283No ratings yet

- M Ii,/a N/A: R.R.J KGDocument1 pageM Ii,/a N/A: R.R.J KGAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- ND050320 6000202C Transformer Capacity Calculation O 20211102Document5 pagesND050320 6000202C Transformer Capacity Calculation O 20211102Leonid GNo ratings yet

- 26.QA-NPD-26 Sani Moulds-Defrost Arm Ace 16-01Document24 pages26.QA-NPD-26 Sani Moulds-Defrost Arm Ace 16-01delightplasticsNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- 220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Document1 page220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Vibhor ChourasiyaNo ratings yet

- Inventaire Des Equipements de SecuritéDocument1 pageInventaire Des Equipements de SecuritéRoddy LawRazakarisonNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- UncontrolledDocument31 pagesUncontrolledSerajahmad56No ratings yet

- Mechanical Maintenance: Date 7 March 2018Document8 pagesMechanical Maintenance: Date 7 March 2018Mahesh MishraNo ratings yet

- CorteDocument2 pagesCorteRODRIGO FREDDY TICONIPA QUISPENo ratings yet

- Rev.08.8.17.64 NightDocument8 pagesRev.08.8.17.64 NightAnonymous YCeKjTtNo ratings yet

- RPG 7 WikipediaDocument8 pagesRPG 7 WikipediagdudgshsNo ratings yet

- Libro Creating Continuous FlowDocument16 pagesLibro Creating Continuous Flowitza rodriguezNo ratings yet

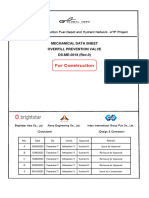

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Document2 pagesDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaNo ratings yet

- Implementation - Plan - MSIL - 18th March PDFDocument21 pagesImplementation - Plan - MSIL - 18th March PDFRavi BhushanNo ratings yet

- Shock and Vibration Summary TestDocument19 pagesShock and Vibration Summary TestMạnh Đức NguyễnNo ratings yet

- Handling Manual CHM-1-2156 - For SPC SpliceDocument4 pagesHandling Manual CHM-1-2156 - For SPC SpliceTrần Long VũNo ratings yet

- Certified Test, Adjust and Balance Report: Balancing DevicesDocument1 pageCertified Test, Adjust and Balance Report: Balancing Devicesahmed younisNo ratings yet

- CT DCT - Maintenance 3808Document6 pagesCT DCT - Maintenance 3808Andrew LiebermannNo ratings yet

- 1 Proposed Utilities Building (Pcwbs-A610) : Short-Circuit AnalysisDocument17 pages1 Proposed Utilities Building (Pcwbs-A610) : Short-Circuit AnalysismuthukumarNo ratings yet

- Store Inventry Report of OCTOBER - 2014Document11 pagesStore Inventry Report of OCTOBER - 2014Anonymous C52AEINo ratings yet

- Requerimiento Concreto Semanal - Almacen Testigos N°6 - 22.11.2019Document11 pagesRequerimiento Concreto Semanal - Almacen Testigos N°6 - 22.11.2019Miguelangel ChávezNo ratings yet

- Worldyards May 2007 NewsletterDocument20 pagesWorldyards May 2007 Newsletternestor mospanNo ratings yet

- 17.11.2020 Day & Night ShiftDocument1 page17.11.2020 Day & Night ShiftLakmal JayashanthaNo ratings yet

- Making Materials Flow Part1Document13 pagesMaking Materials Flow Part1Jhon KenNo ratings yet

- Beam W8X58SSDocument8 pagesBeam W8X58SSyoshdog@gmail.comNo ratings yet

- Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)Document10 pagesCatalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)Jeroan AyamNo ratings yet

- Kartu Riwayat AlatDocument26 pagesKartu Riwayat AlatAwaluddin HanafieNo ratings yet

- Bhaluka Project Capacity With Estimated Costing of All MC & Others For OperationDocument2 pagesBhaluka Project Capacity With Estimated Costing of All MC & Others For OperationHabibur RahmanNo ratings yet

- 3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Document1 page3-Data Sheet For Cpi With CP 34 M3-HR - Rev 1Cristobal CherigoNo ratings yet

- Ficha Tecnica - MHIKE-D404A - enDocument3 pagesFicha Tecnica - MHIKE-D404A - enService GamberiniNo ratings yet

- RIR & SIR - 6 Monthly Safety Inspection - TCMSDocument4 pagesRIR & SIR - 6 Monthly Safety Inspection - TCMSRonny DoankNo ratings yet

- Waterpfoofing ConsumptionDocument2 pagesWaterpfoofing ConsumptionAbhijeet PawarNo ratings yet

- Colume Detile by Etabs 16Document2 pagesColume Detile by Etabs 16hedayatullahNo ratings yet

- Staad Model Report 6dec21Document25 pagesStaad Model Report 6dec21Anwar Issa MatarnehNo ratings yet

- Cycle Time Report WEX018 6020BDocument6 pagesCycle Time Report WEX018 6020BDandung Yunianto123No ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- S-111000-01FRM Standard Muster ListDocument2 pagesS-111000-01FRM Standard Muster ListPrashant GauravNo ratings yet

- S-093003-03CHK Controlled Entry Space PermitDocument1 pageS-093003-03CHK Controlled Entry Space PermitPrashant GauravNo ratings yet

- S-033000-01CHK Self Familiarization and Training - Deck SampleDocument19 pagesS-033000-01CHK Self Familiarization and Training - Deck SamplePrashant GauravNo ratings yet

- S-033000-03CHK Tanker Familiarization ChecklistsDocument10 pagesS-033000-03CHK Tanker Familiarization ChecklistsPrashant GauravNo ratings yet

- International Convention For Safe Containers, 1972: Document HistoryDocument36 pagesInternational Convention For Safe Containers, 1972: Document HistoryPrashant GauravNo ratings yet

- Unit 9 Short Test 1B: GrammarDocument2 pagesUnit 9 Short Test 1B: GrammarTanya KolinkovskaNo ratings yet

- Moral-Dilemmas WritingDocument19 pagesMoral-Dilemmas Writingyeya giraldoNo ratings yet

- Piers and Warf - Military HandbookDocument215 pagesPiers and Warf - Military HandbookPedro CedeñoNo ratings yet

- Brazilian Yellow Maize: F.O.B. Contract For Full CargoDocument4 pagesBrazilian Yellow Maize: F.O.B. Contract For Full CargoLucia Valéria TeixeiraNo ratings yet

- INSG Nandgi July22Document10 pagesINSG Nandgi July22candymaluNo ratings yet

- BalcluthaDocument2 pagesBalcluthaapi-542991204No ratings yet

- LHD 110 DRW 501592 3 Jyn 85Document1 pageLHD 110 DRW 501592 3 Jyn 85Tajana TovarovićNo ratings yet

- IMO GesamtDocument86 pagesIMO GesamtBrillyanNo ratings yet

- Merchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Document11 pagesMerchant Marine Academy 2nd Semester - P. Papaleonidas - 2011-89-99Наталья ЛандикNo ratings yet

- First Voyage Around The WorldDocument6 pagesFirst Voyage Around The WorldMicko Alcala IINo ratings yet

- Simple Paper ModelDocument4 pagesSimple Paper Modelapi-478942743100% (1)

- Types of HousesDocument4 pagesTypes of HousesHdjeh XjshhwNo ratings yet

- Entry Movement Book PDFDocument1 pageEntry Movement Book PDFSupreme starNo ratings yet

- Stability Booklet H-147Document55 pagesStability Booklet H-147Nur SalimNo ratings yet

- Test Bank For Biology The Unity and Diversity of Life 12th EditionDocument34 pagesTest Bank For Biology The Unity and Diversity of Life 12th Editionoscines.filicide.qzie100% (43)

- Unseaworthy and Unsafe ShipDocument6 pagesUnseaworthy and Unsafe ShipcapmanirajNo ratings yet

- Colreg Rule 13, 14 and 15Document3 pagesColreg Rule 13, 14 and 15Miles RecablancaNo ratings yet

- New Excursions and Hotels in Sri LankaDocument25 pagesNew Excursions and Hotels in Sri LankaDon Dilan BuddhikaNo ratings yet

- Boyd Marine: Final ReportDocument27 pagesBoyd Marine: Final ReportDarmansyah0% (1)

- LNG CarrierDocument94 pagesLNG CarrierJEET BANERJEENo ratings yet

- Proposed Circular Shipboard Training Program - 20220917 - 204524Document8 pagesProposed Circular Shipboard Training Program - 20220917 - 204524armanNo ratings yet

- Question One:-Answer The Following QuestionsDocument7 pagesQuestion One:-Answer The Following Questionssabri100% (1)

- Reading PlastikiDocument16 pagesReading PlastikiDaniel C. Hernandez RojasNo ratings yet

- Test Bank For Dental Materials 11th Edition by PowersDocument36 pagesTest Bank For Dental Materials 11th Edition by Powersknappishcherif.a2v4100% (54)

- Lifeboat Equipment ListDocument1 pageLifeboat Equipment Listjosua albertNo ratings yet

- SKB PRDS Rulebook Web 20210219Document12 pagesSKB PRDS Rulebook Web 20210219Paty GSNo ratings yet

- Test Bank For Pediatric Nursing: Caring For Children and Their Families, 3rd Edition, Nicki L. Potts, Barbara L. MandlecoDocument33 pagesTest Bank For Pediatric Nursing: Caring For Children and Their Families, 3rd Edition, Nicki L. Potts, Barbara L. Mandlecoterreity.warfarehsstta100% (15)